Скачать

Washer/Extractor

AC Adjustable Frequency

Drive Information

For Allen-Bradley Model Numbers:

160

1305

1336

PowerFlex 40

PowerFlex 400

Part No. F232120R6

January 2010

Supplement

FAULT

READY

U071M

U072M

U073M

U074M

TMB1396C

PHM1396C

U071M

U074M

U072M

U073M

Washer/Extractor

PHM1396C

U071M

U074M

U072M

U073M

AC Adjustable Frequency

Drive Information

For Allen-Bradley Model Numbers:

160

1305

1336

PowerFlex 40

PowerFlex 400

Part No. F232120R6

January 2010

Supplement

Table of

Content s

General Information………………………………………………………………… 3

Nameplate Location…………………………………………………………………… 4

General Inspection…………………………………………………………………….. 5

Storage…………………………………………………………………………………….. 5

PowerFlex 40 and 400 Drive Control Logic………………………………. 6

Installation/Wiring…………………………………………………………………….. 6

Input Power Conditioning………………………………………………………. 6

Electrical Interference……………………………………………………………. 7

Terminal Block Access………………………………………………………….. 8

Power Terminal Block Description …………………………………………. 9

Control Terminal Blocks Description and Control Logic……………. 10

AC Drive Diagnostics/Parameter Viewing……………………………………. 28

PowerFlex Integrated Keypad…………………………………………………. 28

Fault Display and Troubleshooting Information ……………………………. 32

Allen-Bradley Drive Fault Codes ……………………………………………. 33

Troubleshooting Suggestions………………………………………………….. 35

Allen-Bradley 160-Series AC Drives…………………………………………. 36

Installation/Wiring…………………………………………………………………….. 36

Input Power Conditioning………………………………………………………. 36

Electrical Interference……………………………………………………………. 37

Terminal Block Access………………………………………………………….. 39

Power Terminal Block Description …………………………………………. 40

Control Terminal Blocks Description and Control Logic……………. 41

160 Series Drive Control Logic Chart……………………………………… 42

AC Drive Diagnostics/Parameter Viewing……………………………………. 51

160 Program Keypad Module (PKM or Parameter Unit)……………. 51

CopyCat Keypad…………………………………………………………………… 54

Fault Display and Troubleshooting Information ……………………………. 58

Fault Code Identification ……………………………………………………….. 58

Allen-Bradley Drive Fault Codes ……………………………………………. 59

Troubleshooting Suggestions………………………………………………….. 61

Allen-Bradley 1305-Series AC Drives……………………………………….. 62

Installation/Wiring…………………………………………………………………….. 62

Input Power Conditioning………………………………………………………. 62

Electrical Interference……………………………………………………………. 63

Terminal Block Access………………………………………………………….. 64

Power Terminal Block Description …………………………………………. 65

Control Terminal Blocks Description and Control Logic……………. 65

AC Drive Diagnostics/Parameter Viewing……………………………………. 73

Human Interface Module (HIM or Parameter Unit)…………………… 73

HIM Structure Chart – Series A 3.00, Series B 1.01

or Later Versions…………………………………………………………………….. 75

HIM Structure Chart – Earlier Versions……………………………………….. 76

Fault Display and Troubleshooting Information ……………………………. 80

Fault Code Identification ……………………………………………………….. 80

Allen-Bradley Drive Fault Codes ……………………………………………. 81

Troubleshooting Suggestions………………………………………………….. 83

© Copyright 2010, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232120

© Copyright 2006, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Supplement

Allen-Bradley 1336-Series AC Drives……………………………………….. 84

Installation/Wiring…………………………………………………………………….. 84

Input Power Conditioning………………………………………………………. 84

Electrical Interference……………………………………………………………. 85

Terminal Block Access………………………………………………………….. 86

Power Terminal Block Description …………………………………………. 87

Control Terminal Blocks Description and Control Logic……………. 88

AC Drive Diagnostics/Parameter Viewing……………………………………. 98

Human Interface Module (HIM or Parameter Unit)…………………… 98

HIM Structure Chart – Series A 3.00, Series B 1.01

or Later Versions…………………………………………………………………. 100

HIM Structure Chart – Earlier Versions…………………………………… 101

Fault Display and Troubleshooting Information ……………………………. 105

Fault Code Identification……………………………………………………………. 105

Allen-Bradley Drive Fault Codes ……………………………………………. 107

Troubleshooting Suggestions………………………………………………….. 109

2

© Published by permission of the copyright owner – DO NOT COPY or TRANSMIT

F232120

General Information

CAUTION

Only personnel familiar with the drive and

associated machinery should plan or

implement the installation, start-up, and

subsequent maintenance of the system.

Failure to comply may result in personal

injury and/or equipment damage.

W659

• This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static

control precautions are required when installing,

testing, or servicing this assembly. Component

damage may result if ESD control procedures are

not followed.

• An incorrectly applied or installed drive can

result in component damage or a reduction in

product life. Wiring or appl ication errors, such as

incorrect or inadequate AC supply or excessive

ambient temperatures, may result in malfunction

of the system.

• This drive contains power storage devices that

retain their charge for a time after the removal of

main power. Extreme caution should be used

when working in and around the drive. It is

recommended that main disconnect power to the

drive remain off for three minutes prior to

approaching connections.

General Information

W a rnings specific to a particular subject will appear in

the manual with the discussion of that subject.

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

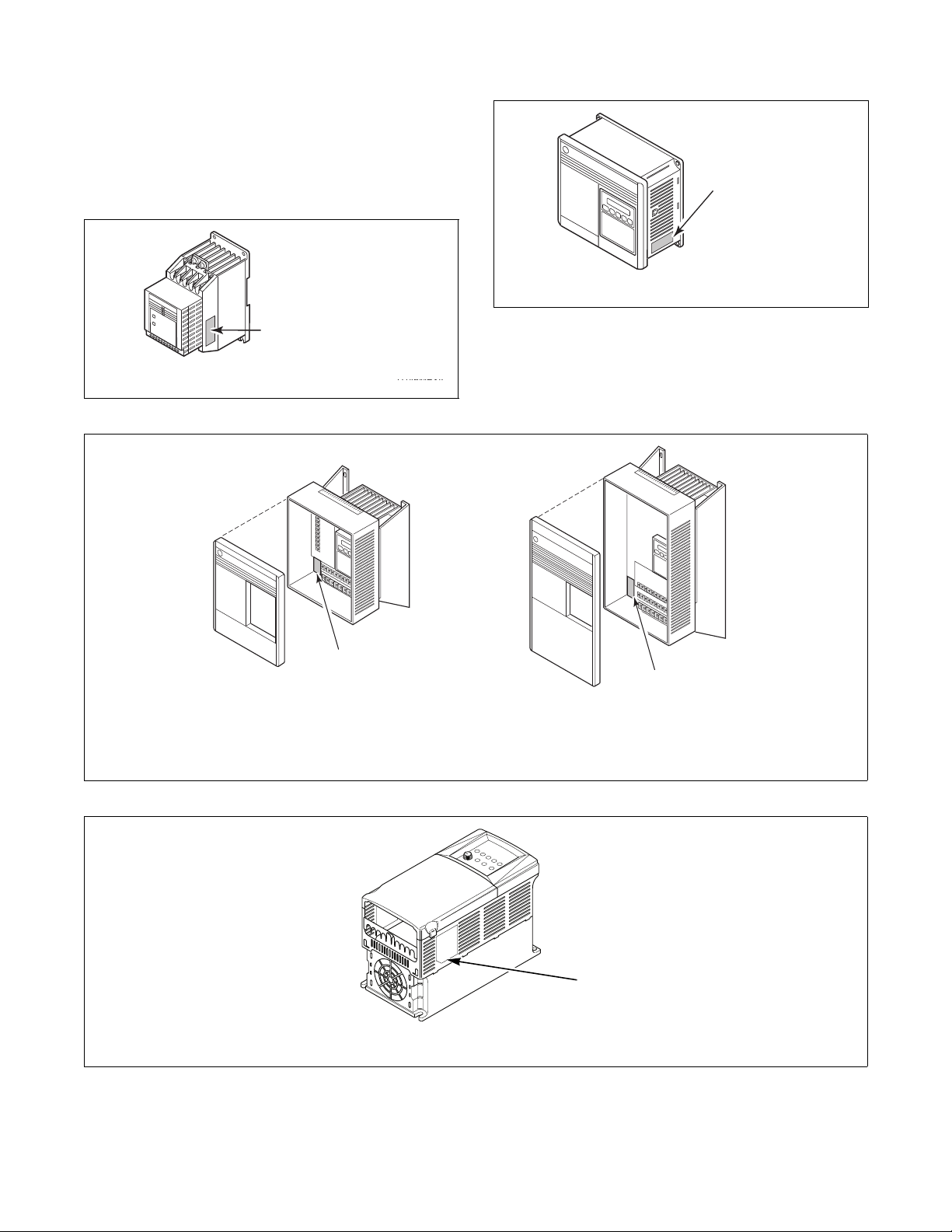

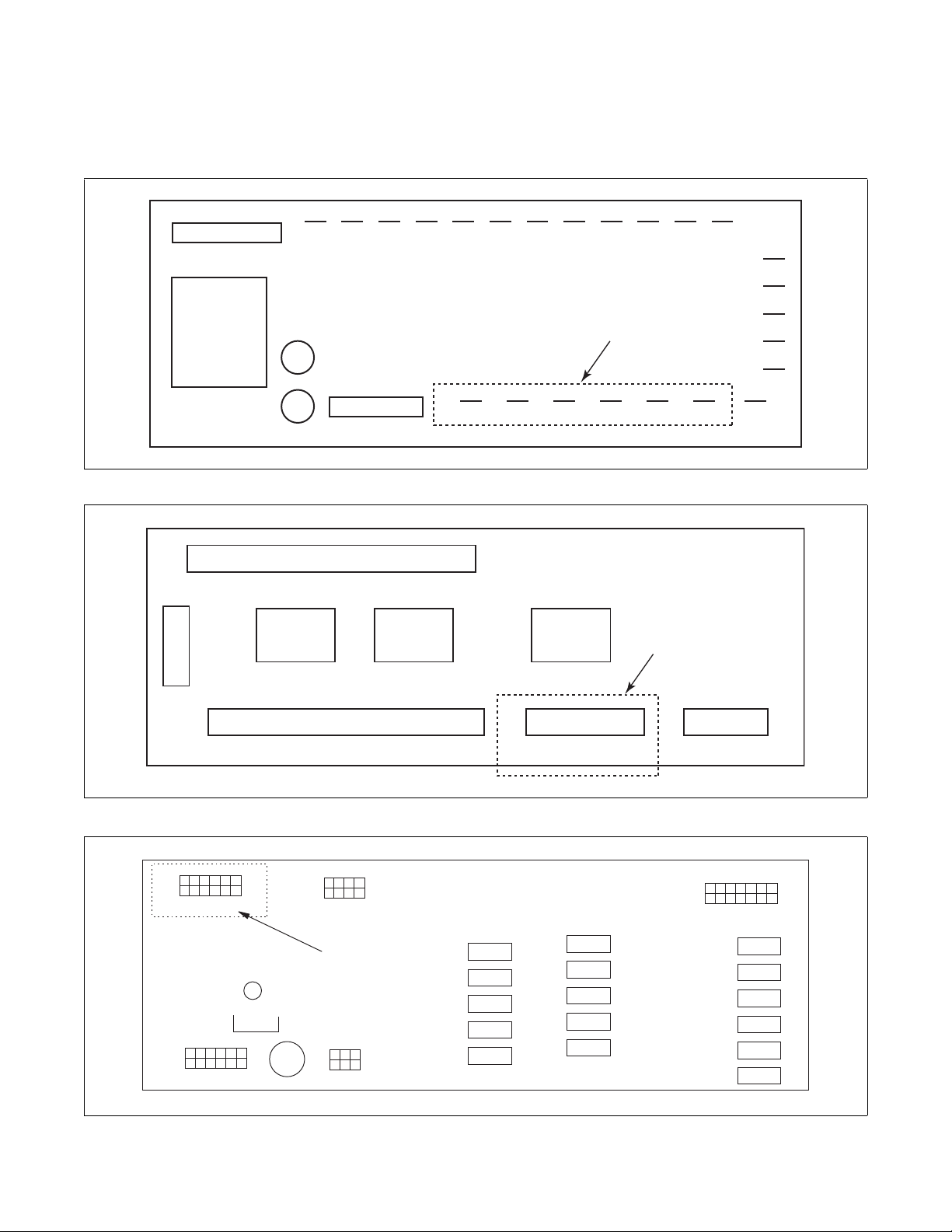

General Information

FAULT

READY

Nameplate Located on

Exterior of Enclosure

U147ME3A

Nameplate Located

on Bottom Portion of

Chassis Behind Cover

Nameplate Located

on Mounting Plate of

Main Control Board

FRAMES A1, A2, A3, A4

FRAMES B-G

1336 PLUS NAMEPLATE LOCATION

Nameplate Located on

Exterior of Enclosure.

POWERFLEX NAMEPLATE LOCA TION

Nameplate Location

Pertinent drive information used in obtaining

information on drive operation or replacement is

located on the nameplate shown in Figures 1

through 4.

U146ME3A

Figure 1

Nameplate Located on

Exterior of Enclosure

U072ME3

U072ME3A

Figure 2

4

Figure 3

TMB1396C

Figure 4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

U147ME3A

PHM1396C

F232120

General Information

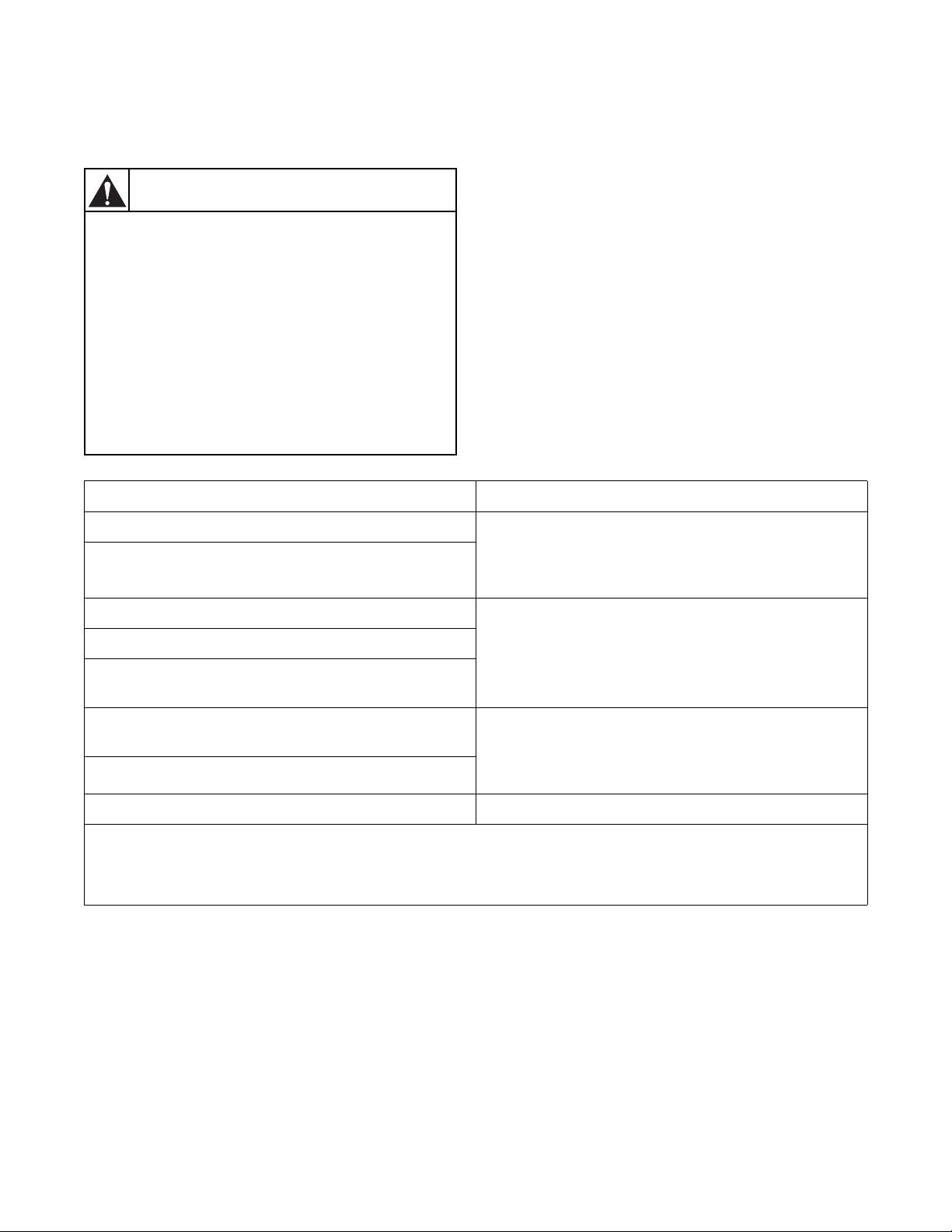

General Inspection

Upon delivery, verify the item’s nameplate catalog

number against the purchase order.

Before the installation and start-up of the drive, a

general inspection of the mechanical integrity (i.e.,

loose parts, wires, connections, etc.) should be made.

Storage

The drive should remain in its shipping container prior

to installation. If the equipment is not to be used for a

period of time, it must be stored according to the

following instructions in order to maintain warranty

coverage:

• Store in a clean, dry location.

• Store within an ambient temperature range of -40

to 70 degrees C.

• Store within a relative humidity range of 0 to 95

percent.

• Do not store equipment where it could be

exposed to a corrosive atmosphere.

• Do not store equipment in a construction area.

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

PowerFlex 40 and 400 Drive Control Logic

An incorrectly installed system can result in

component damage or reduction in product

life. The most common causes are:

1. Wiring AC line to drive output or control

terminals.

2. EXTERNAL voltage application to control

terminals.

3. Incorrect or inadequate AC supply.

Contact factory for assistance with

application or wiring.

W660

CAUTION

PowerFlex 40 and 400 Drive Control Logic

Installation/Wiring

Input Power Condition Corrective Action

Low Line impedance (less than 1% line reactance)

Greater than 120 kVA supply transformer

Input Power Conditioning

The drive is suitable for direct connection to input

power within the rated voltage of the drive. Listed in

Table 1

cause component damage or reduction in product life.

If any of the conditions exist, as described in Table 1,

install one of the devices listed under the heading

Corrective Action on the line side of the drive.

IMPORTANT: Only one device per branch circuit

is required. It should be mounted closest to the

branch and sized to handle the total current of the

branch circuit.

• Install Line Reactor

• or Isolation Transformer

• or Bus Inductor – 5.5 & 11kW (7.5 & 15 HP) drives

are certain input power conditions which may

only

Line has power factor correction capacitors

Line has frequent power interruptions

Line has intermittent noise spikes in excess of 6000V

(lightning)

Phase to ground voltage exceeds 125% of normal line to line

voltage

Ungrounded distribution system

240V open delta configuration (stinger leg)

(1)

For drives applied on an open delta with a middle phase grounded neutral system, the phase opposite the phase that is tapped in the

middle to the neutral or earth is referred to as the “stinger leg,” “high leg,” “red leg,” etc. This leg should be identified throughout the

system with red or orange tape on the wire at each connection point. The stinger leg should be connected to the center Phase B on the

reactor.

(1)

• Install Line Reactor

• or Isolation Transformer

• Remove MOV jumper to ground.

• or Install Isolation Transformer with grounded

secondary

if necessary

• Install Line Reactor

Table 1

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232120

PowerFlex 40 and 400 Drive Control Logic

CAUTION

ELECTRIC SHOCK HAZARD! Service and

maintenance to be performed only by an

authorized technician. Disconnect power

before opening any access panels.

W661

Electrical Interference

EMI

Careful attention must be given to the arrangement of

power and ground connections to the drive to avoid

interference with nearby sensitive equipment. Be sure

to replace all ground connections to their appropriate

locations.

RFI

Drives can be installed with an RFI filter, which

controls high-frequency conducted emissions into the

main supply lines.

Where it is essential that very low emission levels

must be achieved or if conformity with standards is

required, the optional RFI filter may be present.

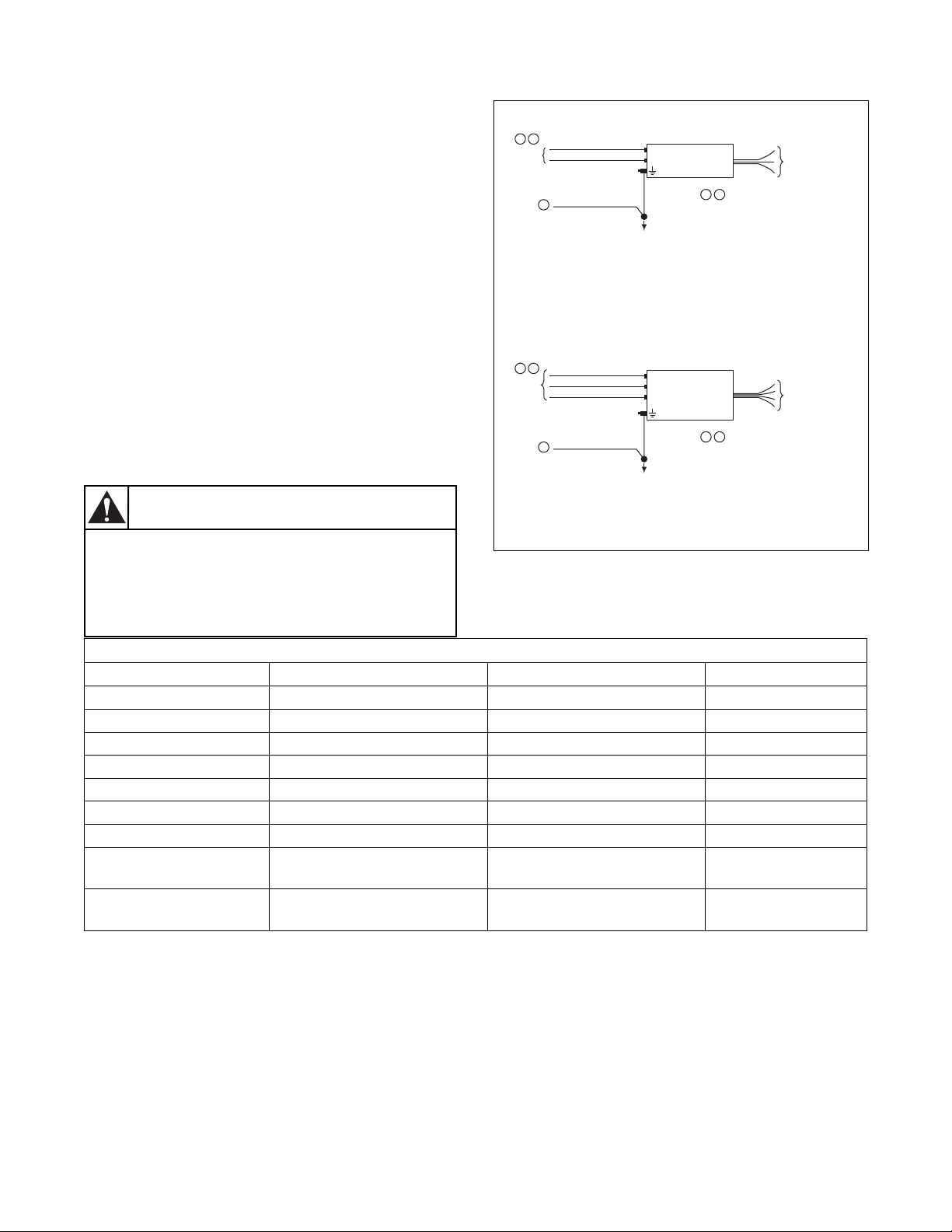

Figure 5 displays an electrical schematic for various

RFI configurations. Table 2 shows associated RFI

filter part numbers.

1 2

INPUT

POWER

1 2

INPUT

POWER

PROVEN EARTH GROUND

3

PROVEN EARTH GROUND

3

SINGLE PHASE MACHINES

ALLEN-BRADLEY

L1

RFI

L2

WASHING

MACHINE

GROUNDING

TERMINAL

LINE

FILTER

LOAD

2

3

TO AC DRIVE UNIT Ð

GREEN-YELLOW WIRE MUST CONNECT TO

AC DRIVE GROUND TERMINAL.

BLACK WIRES WILL CONNECT TO AC DRIVE

INPUT TERMINALS «R», «S» & «T».

BLACK WIRES ARE NOT LABELED AND THEIR

RESPECTIVE TERMINATION IN AC DRIVE IS

NOT OF IMPORTANCE.

THREE PHASE MACHINES

L1

ALLEN-BRADLEY

L2

RFI

LINE

L3

WASHING

MACHINE

GROUNDING

TERMINAL

FILTER

LOAD

2

3

TO AC DRIVE UNIT Ð

GREEN-YELLOW WIRE MUST CONNECT TO

AC DRIVE GROUND TERMINAL.

BLACK WIRES WILL CONNECT TO AC DRIVE

INPUT TERMINALS «R», «S» & «T».

BLACK WIRES ARE NOT LABELED AND THEIR

RESPECTIVE TERMINATION IN AC DRIVE IS

NOT OF IMPORTANCE.

Figure 5

U166ME3

U166ME3A

RFI Filter Part Number Information

Drive P/N Drive Catalog Machine Voltage Filter P/N

F8044301 and F8168603 22B-B017N104xx 200-240V 50-60Hz 3 phase F8053901

F8044401 and F8168604 22B-D010N104xx 380-480V 50-60Hz 3 phase F8053902

F8044701 and F8168601 22B-B012N104xx 200-240V 50-60 Hz 3 Phase F8053901

F8044901 and F8168602 22B-D6P0N104xx 380-480V 50-60 Hz 3 Phase F8053902

C002501 and F8168701 22B-B024N104xx 200-240V 50-60 Hz 3 Phase F8054001

C002502 and F8168702 22B-D012N104xx 380-480V 50-60 Hz 3 Phase F8054002

C002507 and F8168705 22B-D024N104xx 380-480V 50-60 Hz 3 Phase C002569

C002502, F200309300

22B-B033N104Axx 200-240V 50-60Hz 3 phase F8054001

and F8168703

C002506, F200309400

22B-D017N104Axx 380-480V 50-60Hz 3 phase F8054002

and F8168704

Table 2

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

PowerFlex 40 and 400 Drive Control Logic

WARNING

To reduce risk of electric shock, severe

injury or death, allow machine power to

remain off for three minutes minimum prior

to working in and around AC drive. Proceed

with caution.

W662

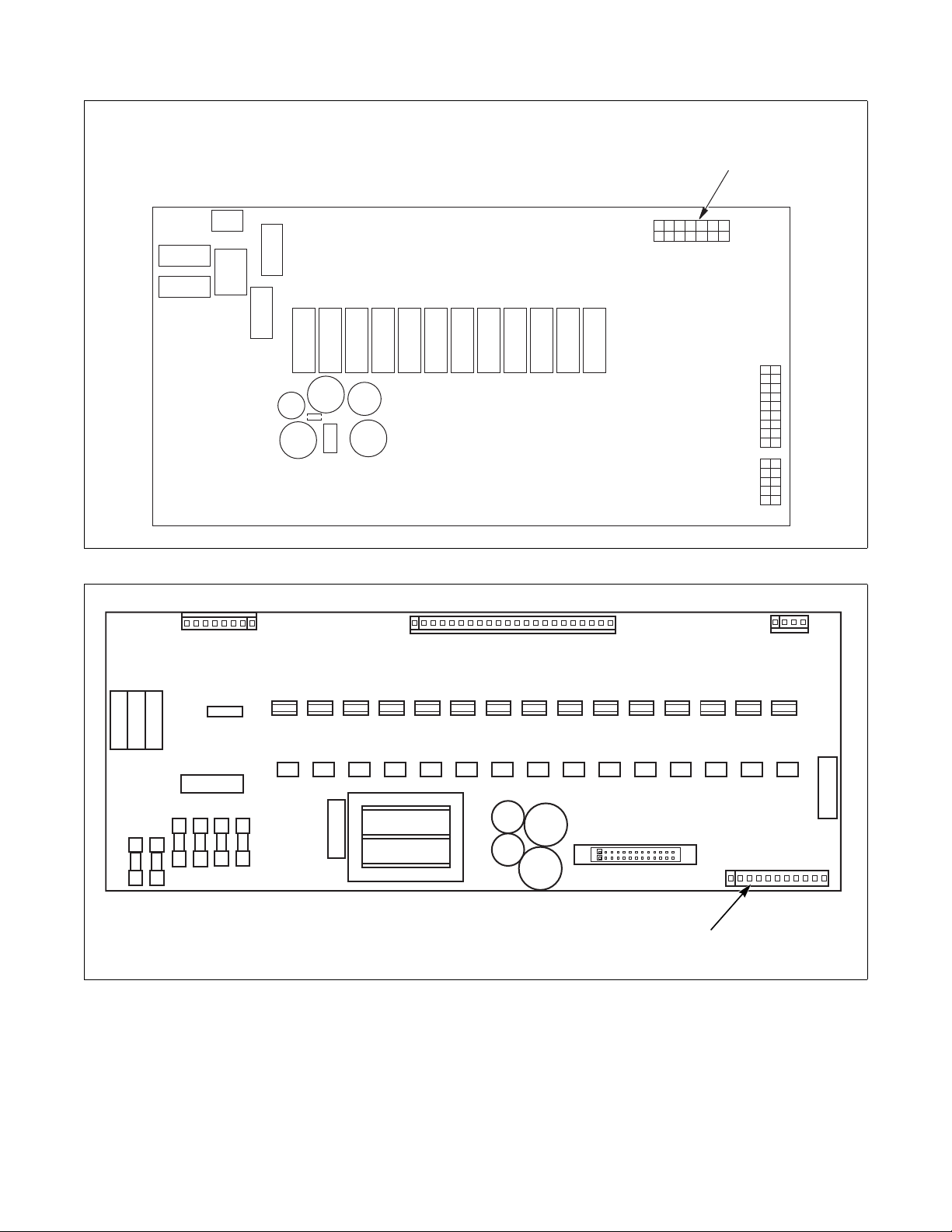

POWER TERMINAL BLOCK (TYPICAL)

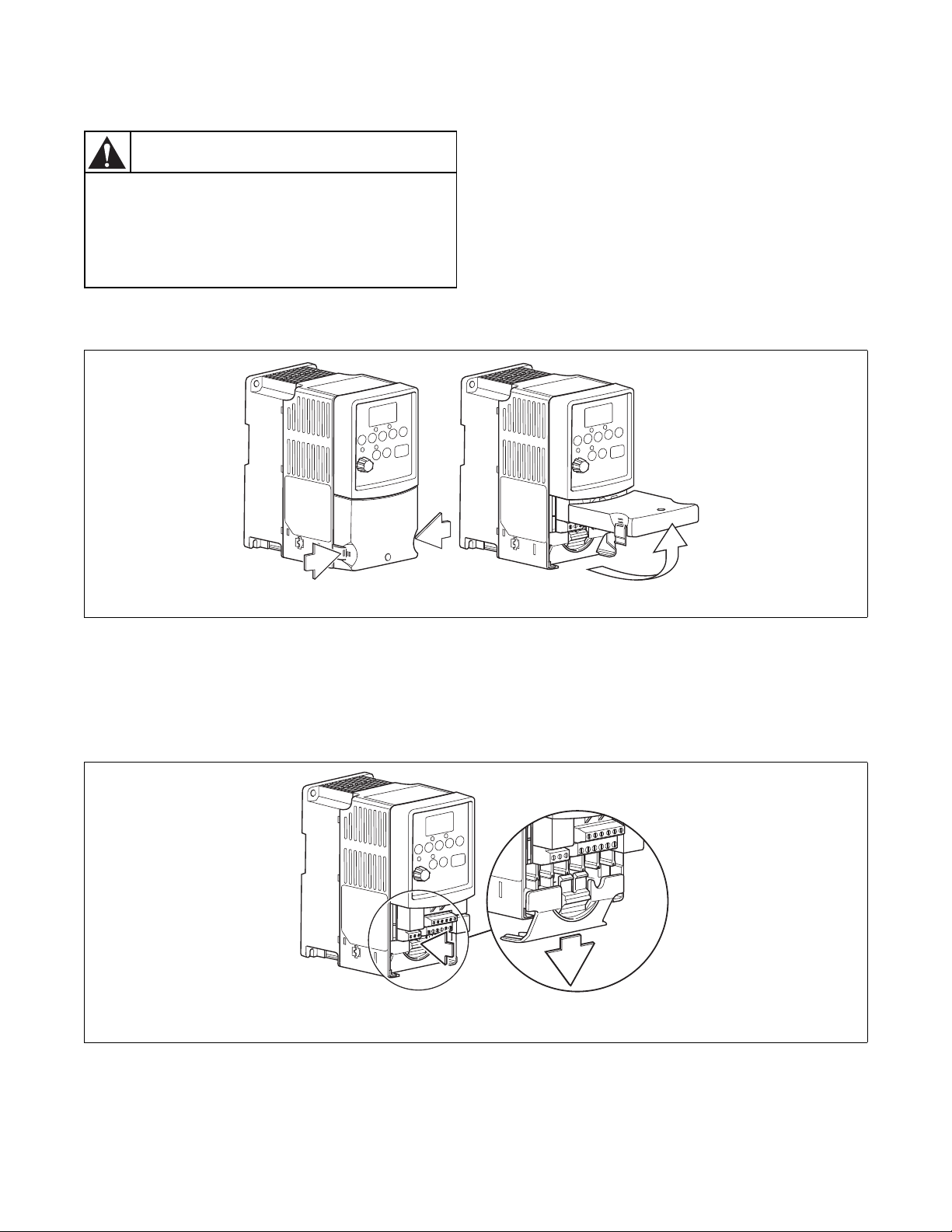

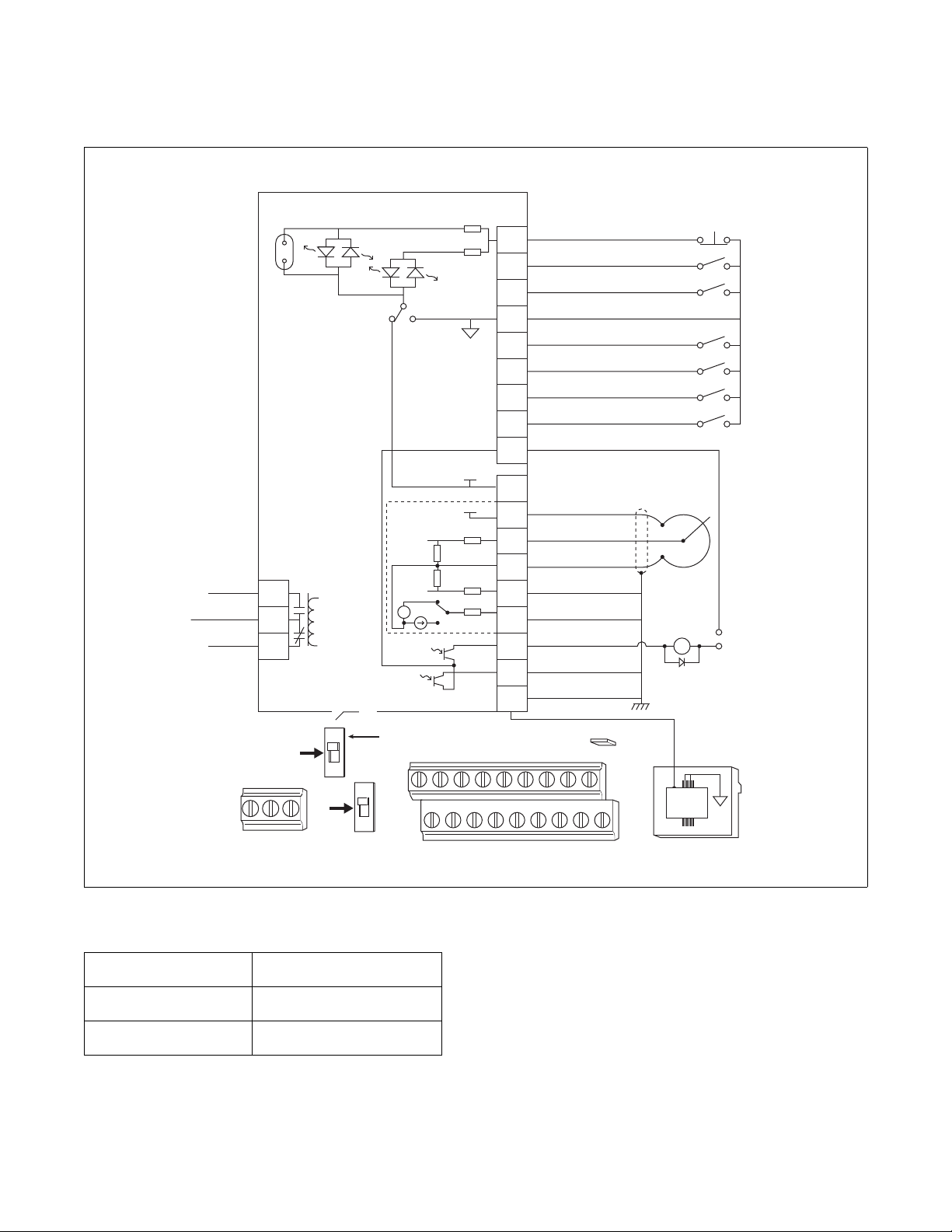

Terminal Block Access

The following information illustrates the terminal

block designations for each of the drive models.

Opening the Cover

1. Press and hold in the tabs on each side of the

cover. Refer to Figure 6.

2. Pull the cover out and up to release.

Power Terminal Block

The drive utilizes a finger guard over the power wiring

terminals. To remove:

1. Press in and hold the locking tab.

PHM636N

Figure 6

2. Slide finger guard down and out. Refer to

Figure 7.

3. Replace the finger guard when wiring is

complete.

PHM637N

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 7

F232120

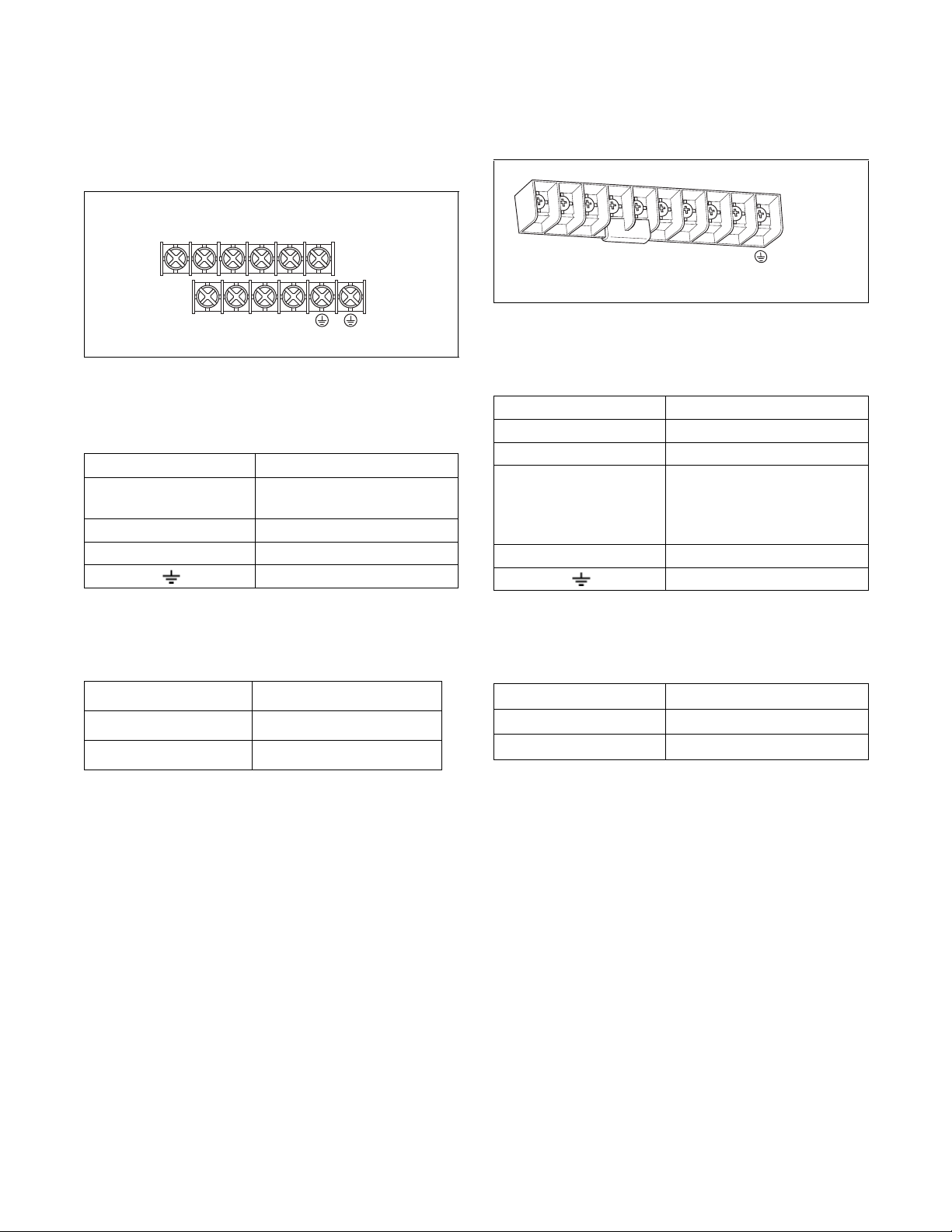

PowerFlex 40 and 400 Drive Control Logic

R/L 1

B Frame

S/L 2 T/L 3 U/T 1 V/T 2 W/T 3

DC- DC+ BR+ BR-

R/L 1

S/L 2

T/L 3

P 1

P 2

DC-

U/T 1

V/T 2

W/T 3

Frame D

Power Terminal Block Description

PowerFlex 40

Input and Output Power Terminals (TB1)

Figure 8

PowerFlex 40

Power Block Terminal (TB1)

Terminal Description

R/L1, S/L2, T/L3 Singl e-phase or

3-phase Power Input

U/T1, V/T2, W/T3 3-phase Motor Output

DC-1, DC+, -DC DC Bus Connection

Ground Connection (PE)

Table 3

PowerFlex 40

PHM741N

PowerFlex 400

Input and Output Power Terminals (TB1)

PHM742N

Figure 9

PowerFlex 400

PowerFlex Power Block Terminal (TBI)

Terminal Description

R/L1, S/L2, T/L3 3-phase Power Input

U/T1, V/T2, W/T3 3-phase Motor Output

P1, P3 DC Bus inductor connection

jumper or Bus inductor must

be present for drive to powerup.

P2, DC- DC Bus Connection

Ground Connection (PE)

Table 5

PowerFlex 400

Power Terminal Block

Torque

Max Wire Size

Min Wire Size

Table 4

1.7-2.2 N-m (16-19 lb-in)

2

5.3 mm

1.3 mm

(10 AWG)

2

(16 AWG)

Power Terminal Block

Torque

Max Wire Size

Min Wire Size

Table 6

5.1N-m (45 lb-in)

33.6 mm

8.4 mm

2

(2 AWG)

2

(8 AWG)

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

PowerFlex 40 and 400 Drive Control Logic

WARNING

To reduce risk of electric shock, severe

injury or death, allow machine power to

remain off for three minutes minimum prior

to working in and around AC drive. Proceed

with caution.

W662

CAUTION

Never permanently jumper the AC drive

balance output terminals or short the wires

in these terminals together. This will

override the balance detection routine and

cause the wash cycle to abort, potentially

causing machine damage or personal injury

in the process.

W671

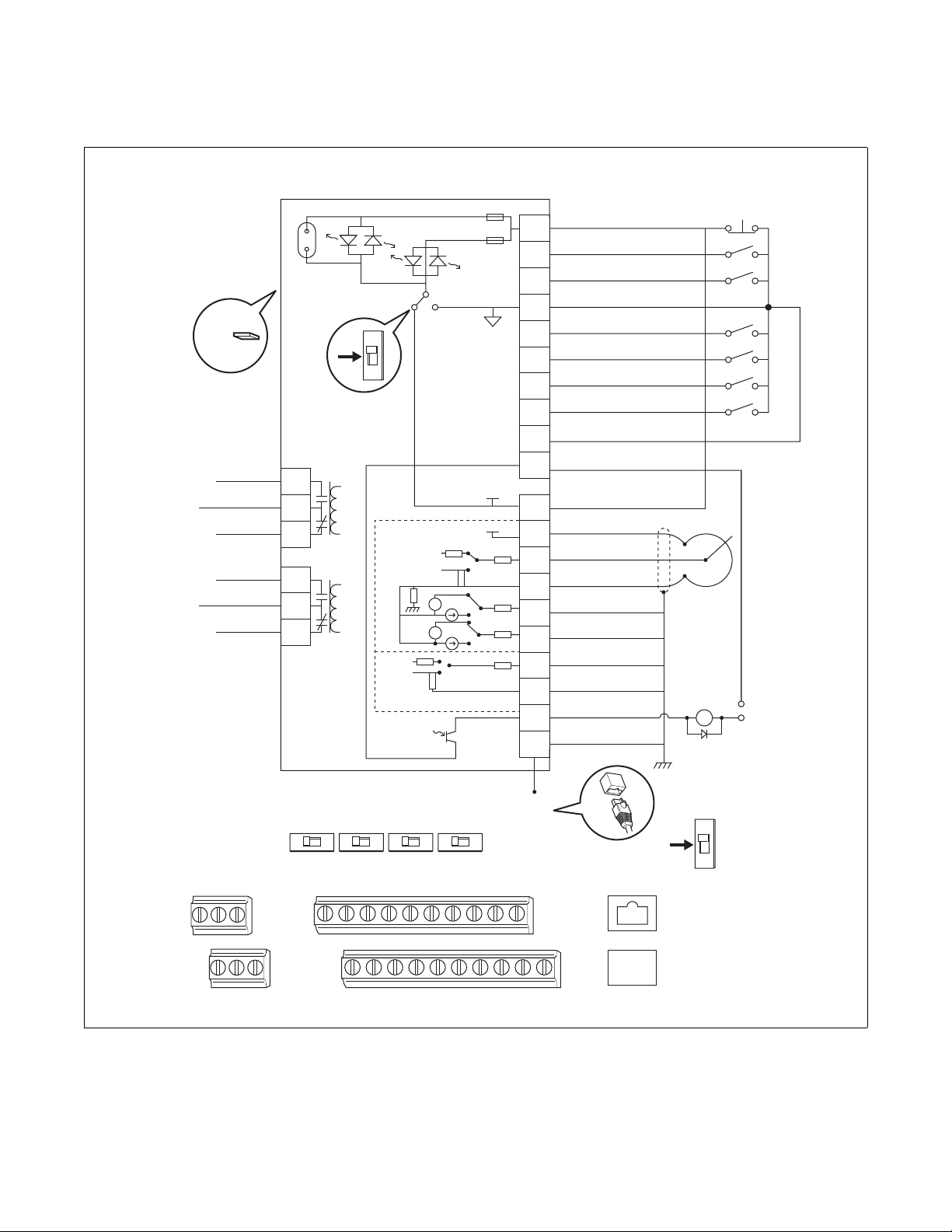

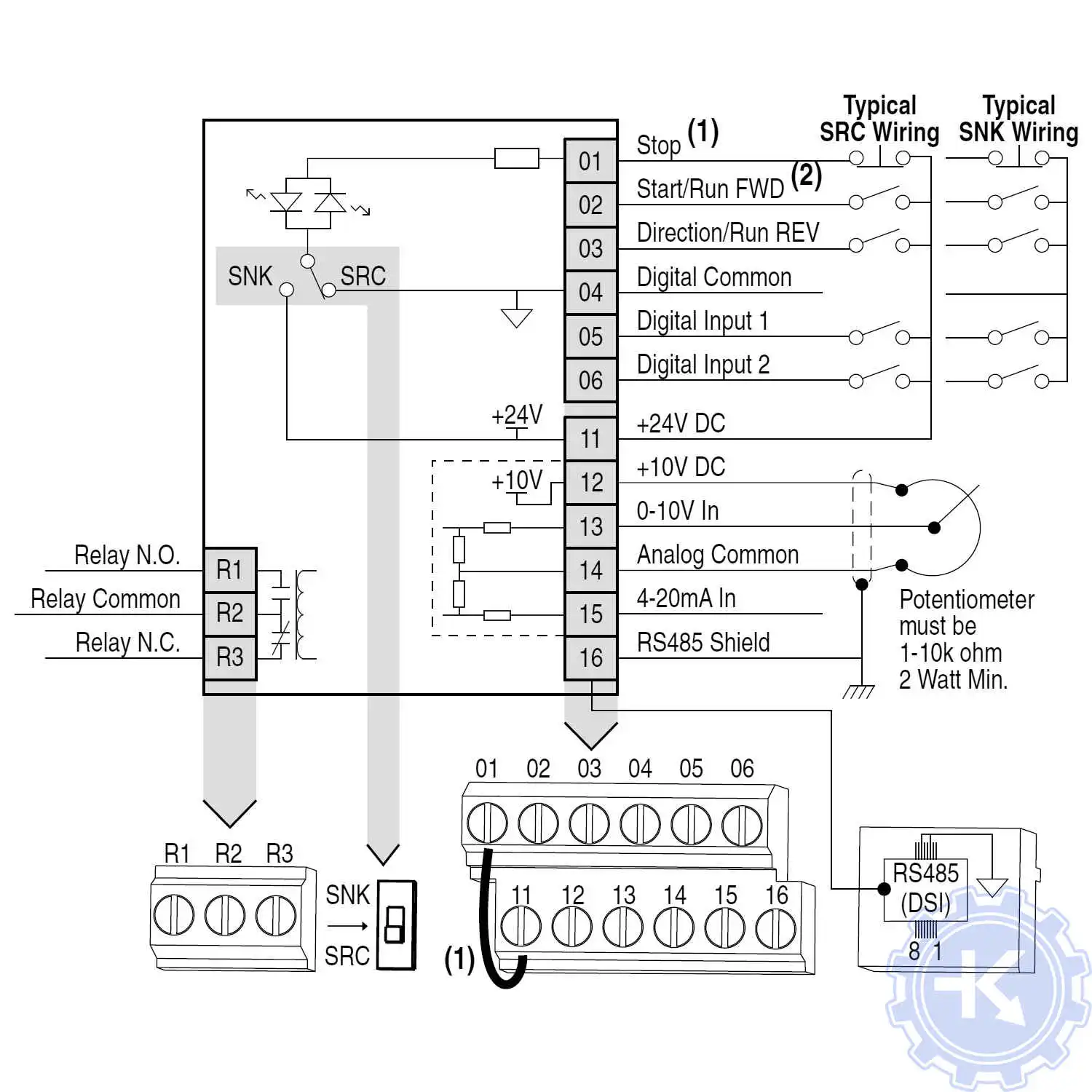

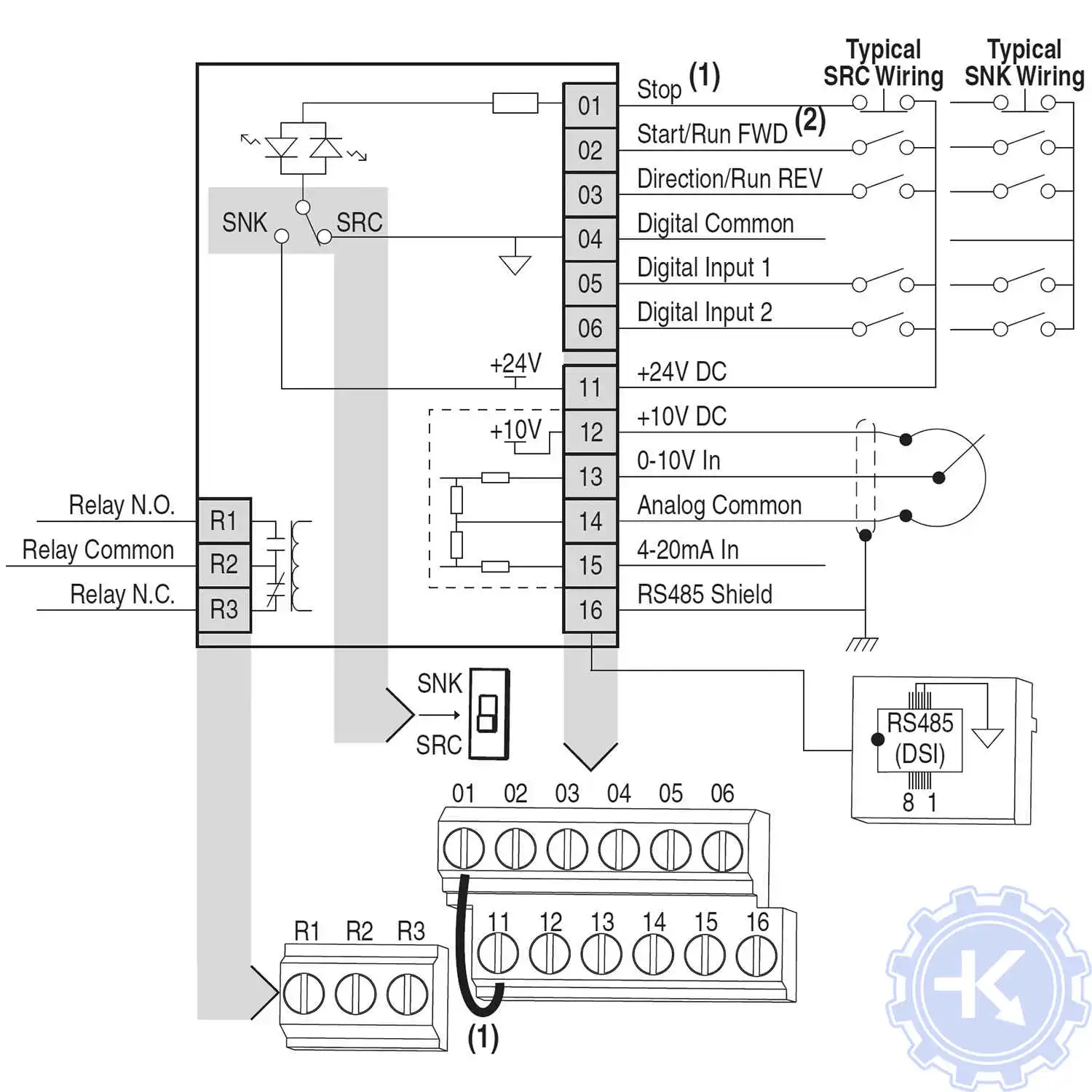

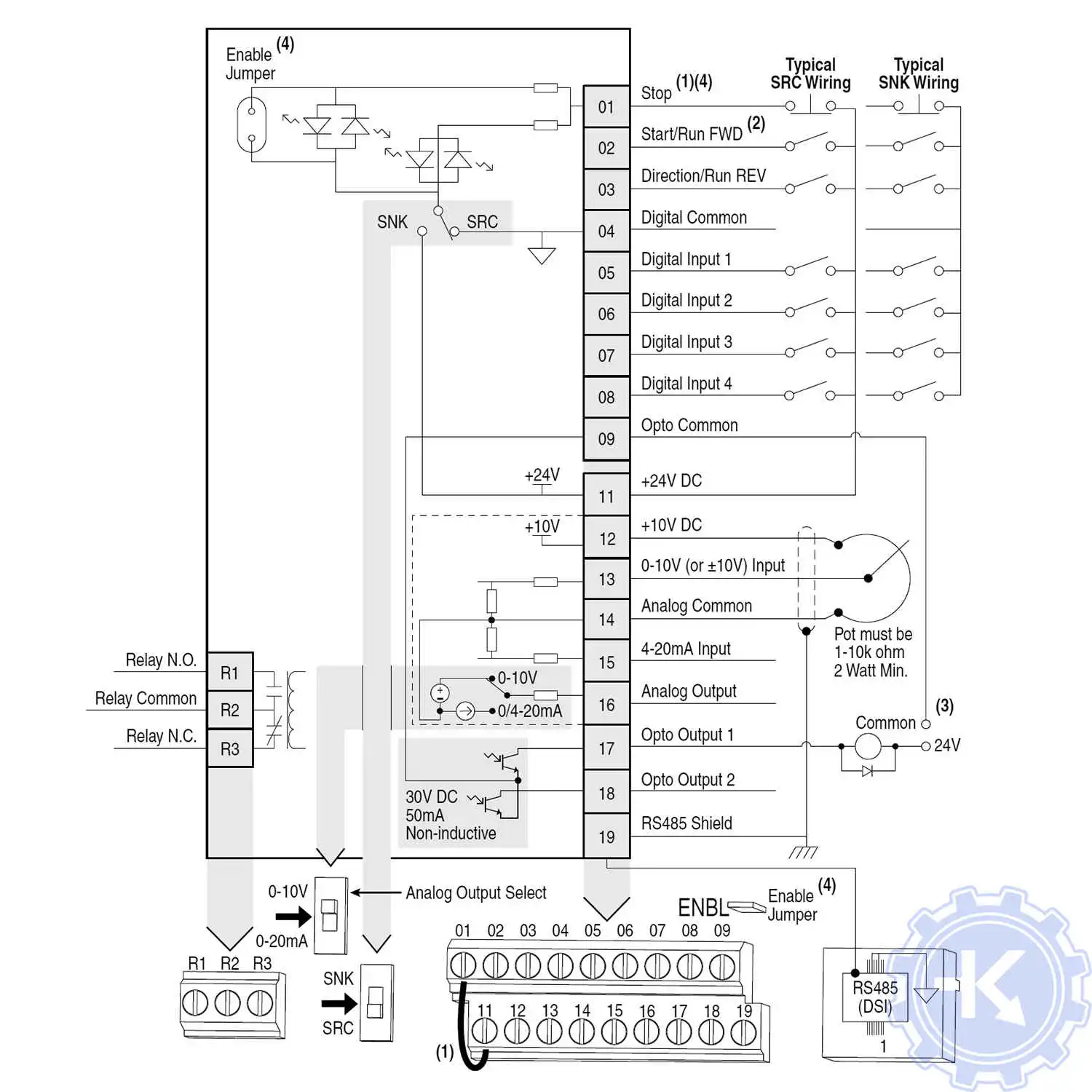

Control Terminal Blocks Description and

Control Logic

NOTE: Do not connect AC drive digital common,

analog common, or common terminals to chassis

ground.

Input Mode Parameter

The control terminal functions are determined in part

by the “Start Source” parameter #36. Changing this

parameter affects the function of some terminals.

Speed Selection

Motor speeds on digitally-controlled AC drives are

controlled by solid state or mechanical switch closure

inputs to Digital In 1, Digital In 2, and Digital In 3

terminals. Similarly, motor rotation direction is

controlled by inputs to Start/Run FWD and Direction/

Run REV terminals. Refer to Figure 10.

An inactive control input terminal (H) will measure

approximately 24v DC while an active control input

terminal (L) will measure less than 1v DC. When a

control input (i.e., Digital In 1, 2, 3, 4, Fwd, Rev, or

Stop) is connected to a common terminal (terminal 4),

the voltage on the control input terminal is reduced to

near zero and the input is activated.

Balance Output

The AC drive balance output signal is transmitted to

the machine controller by the operation of an on-board

normally open relay or transistor. Refer to Figure 10.

The AC drive will analyze the wash load distribution

during certain drain steps and communicate the

severity of load imbalance to the machine controller.

The machine controller then determines if the load is

suitably distributed for the programmed spin speed.

The severity of load imbalance is communicated

digitally by the on-board relay or transistor using a

series of pulses or continuous open or closed state.

Stop/Enable Input

The Stop Input function is machine dependent. The

input is typically used to disable the drive either when

the frame vibration safety limit switch has been

tripped or when the loading door has been opened.

Refer to the applicable machine electrical schematic

for details on the connection of this input. When the

Stop Input signal is interrupted, the control input

signals must be removed and reapplied to restart the

motor operation.

Tables 8 – 14 designate the speed and rotation

direction based on inputs to the control terminals. The

AC drive’ s input status parameters display of 1 s and 0s

at various machine actions can be viewed while

monitoring parameter #13 and/or #14. When the

control input terminal voltage is high (inactive) the

status display will read “0” (logic 0). When the control

input terminal voltage is low (active) the status will

read “1” (logic 1).

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232120

PowerFlex 40 and 400 Drive Control Logic

Sink/Source Switch

The PowerFlex series of drives include a DIP Switch

that will allow the drive input signals to be wired as

“sink” or “source”. This switch should be set to the

sink mode on all Alliance Laundry equipment made at

the time of this publication. Setting this switch in the

source mode will cause the drive to not operate and be

mistaken as a failed drive.

0-10V/0-20m A Switch

The PowerFlex series of drives include a DIP switch

that will allow the drive analog input signals to be

wired as a 0-10V/0-20 mA switch.This switch should

be set to the 0-10V mode on all Alliance Laundry

Equipment made at the time of this publication.

Setting this switch in the 0-20 mA mode may cause

the drive to not operate and be mistaken as a failed

drive.

Fault Code Display

Refer to Fault Display and Troubleshooting

Information.

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

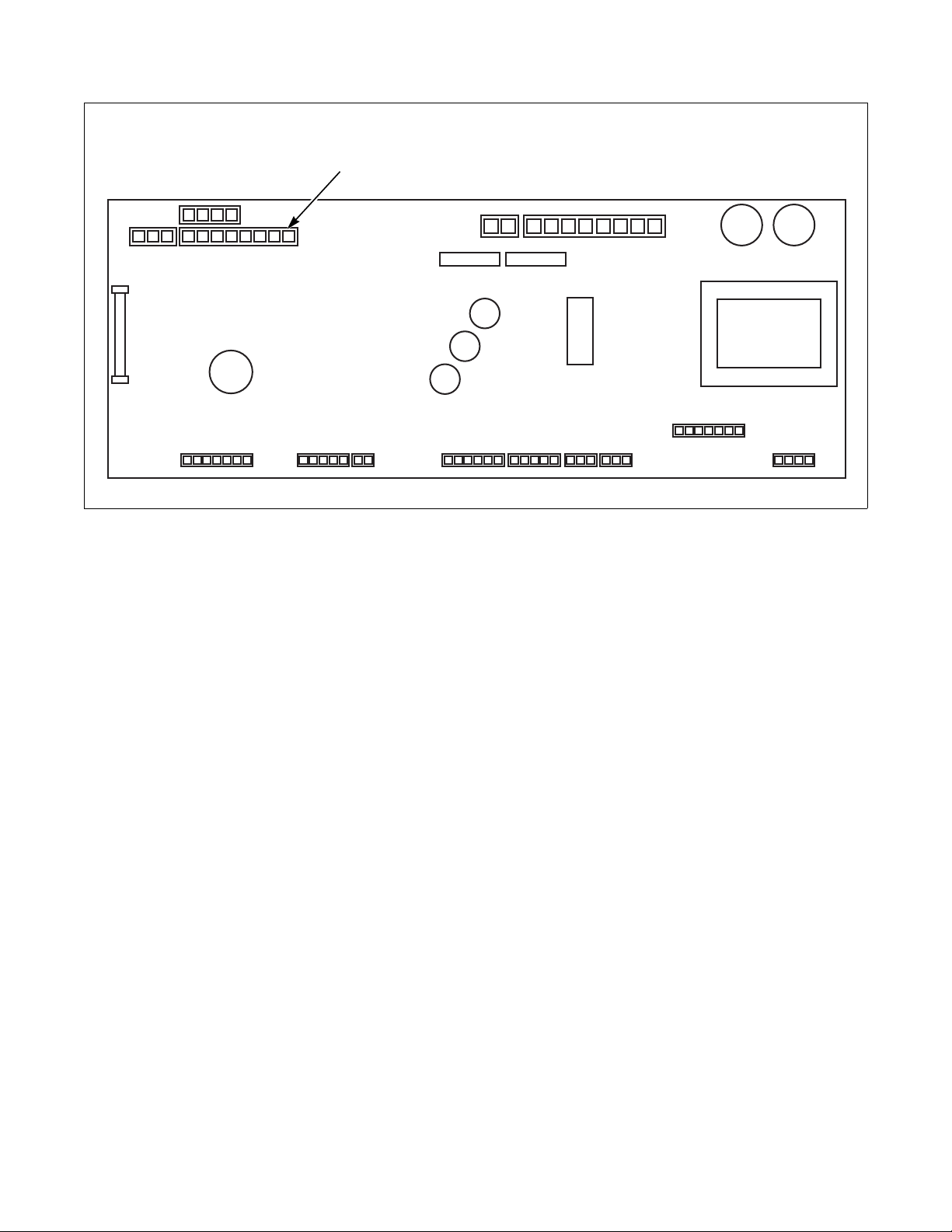

PowerFlex 40 and 400 Drive Control Logic

+

—

18

17

16

15

14

13

12

11

19

19

09

18

08

17

07

16

06

15

05

14

04

13

03

12

02

11

01

R3

R3

ENBL

RS485 Shield

Opto Output 2

Bal Output

Analog Output

4-20mA Input

Analog Common

0-10V ( or ± 10V) Input

+ 10V DC

+ 24V DC

Bal Common

Digital Input 4

Digital Input 3

Digital Input 2

Digital Input 1

Digital Common

REV

FWD

Stop

SNK SRC

+10V

+24V

0-10V

0/4-20mA

30V DC

50mA

Non-inductive

Relay N.O.

Relay Common

Relay N.C.

Pot must be

1-10k ohm

1 Watt Min.

Common

24V

Enable

Jumper

Control Wiring Block Diagram

Enable

Jumper

RS485

(DSI)

0-10V Analog Output Select

0-20mA

SNK

SRC

R2R1

R2

R1

08

07

06

05

04

03

02

01

09

Typical

SNK Wiring

PowerFlex 40 Control Terminal Block

Designations

Control Input/Output Terminal Block

Max Wire Size

Min Wire Size

Torque

0.5-0.8 N-m (4.4-7.0 lb-in)

1.3 mm

0.13 mm

Table 7

2

(16 AWG)

2

(26 AWG)

Figure 10

PHM780N

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232120

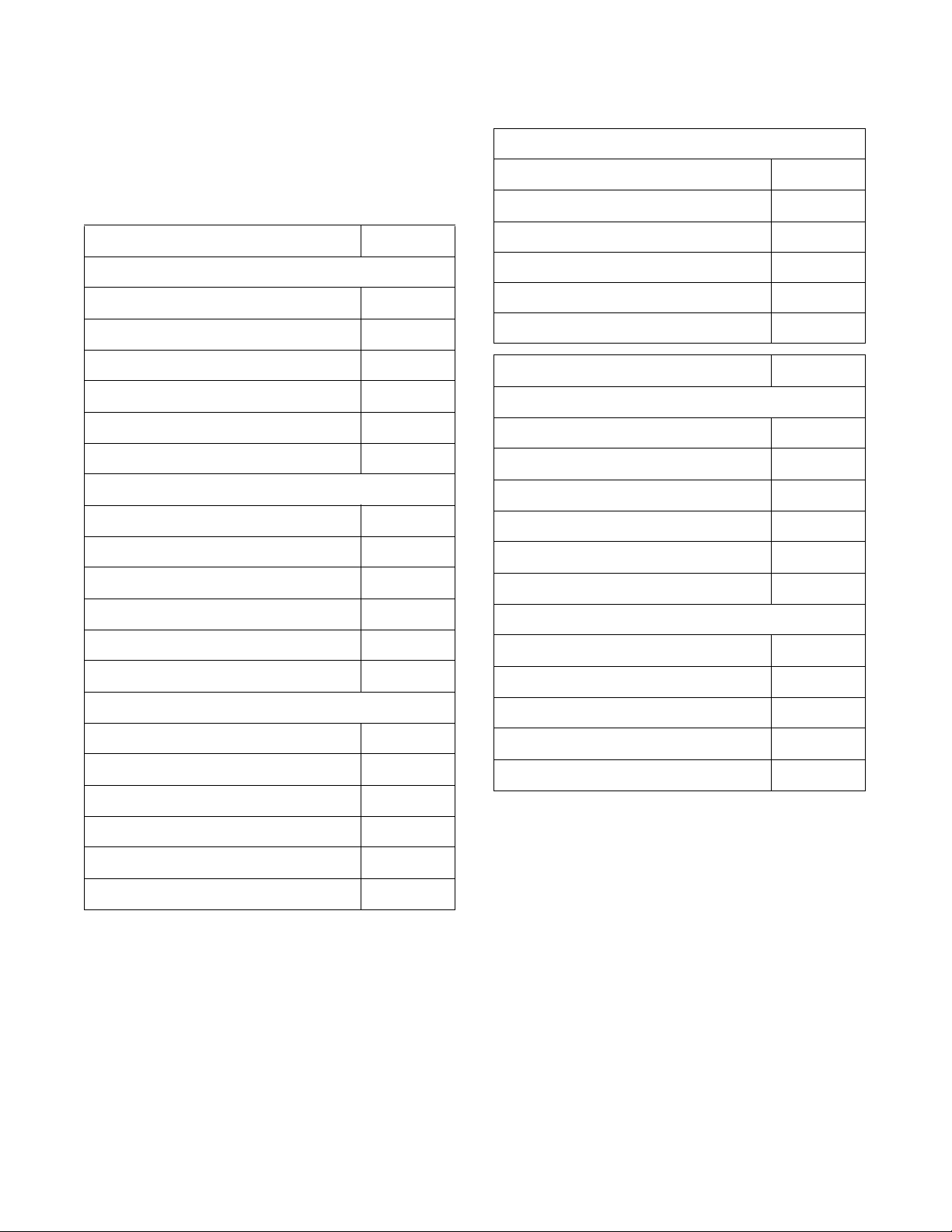

PHM781N

+

—

+

—

0-10V

0-10V

Isolated

18

17

16

15

14

13

12

11

19

20

10090706 080504030201

20191716 181514131211

R6

R3

Opto Output

AS485 Shield

Analog Common 2

Analog Input 2 (AI2)

Analog Output 2 (AO2)

Analog Output 1(AO1)

Analog Common 1

Analog Input 1 (AI1)

+ 10V DC Source

+ 24V DC Source

Opto Common

Digital Common

Digital Input 4

Digital Input 3

Digital Input 2

Digital Input 1

Digital Common

Direction/Run REV

Start/Run FWD

Stop /

Function Loss

1 of 7 Digital Input Circuits

SNK SRC

+10V

0-10V

0-20mA

+24V

0-20mA

30V DC

50mA

Non-inductive

A01

10V 20mA

A02

10V 20mA

AI1

10V 20mA

AI1

RS485

(DSI)

RS485

RS485

10V 20mA

#2 Relay N.O.

#2 Relay Common

#2 Relay N.C.

Pot must be

1-10k ohm

2 Watt Min.

Common

24V

Enable

Jumper

Earth Referenced

Frames D & E

ENBL

Control Wiring Block Diagram

SNK

SRC

R2R1

R6R5R4

R5

R4

R3

#1 Relay N.O.

#1 Relay Common

#1 Relay N.C.

R2

R1

08

07

06

05

04

03

02

01

09

10

Typical

SNK Wiring

SNK

SRC

PowerFlex 400 Control Terminal Block

Designations

PowerFlex 40 and 400 Drive Control Logic

PHM781N

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 11

13

PowerFlex 40 and 400 Drive Control Logic

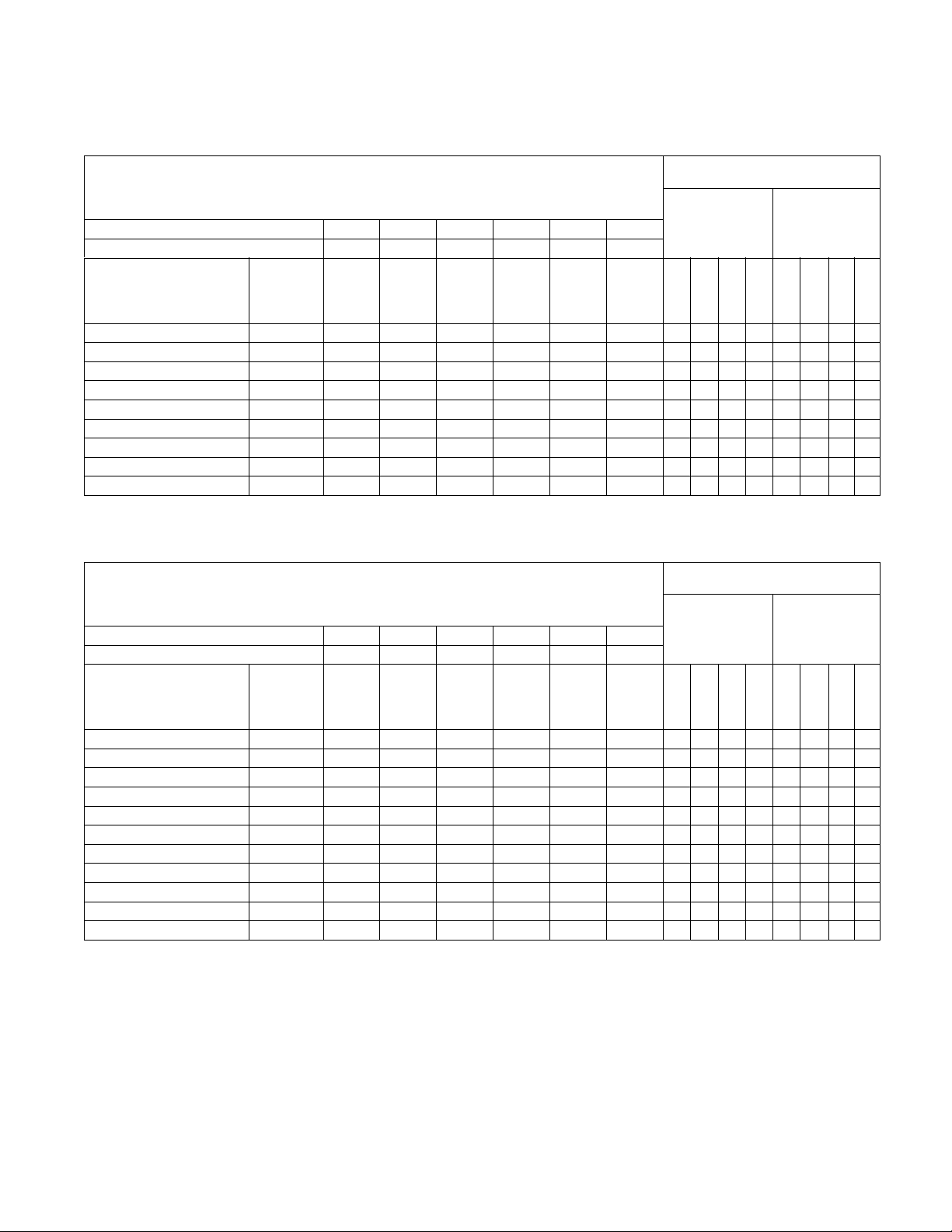

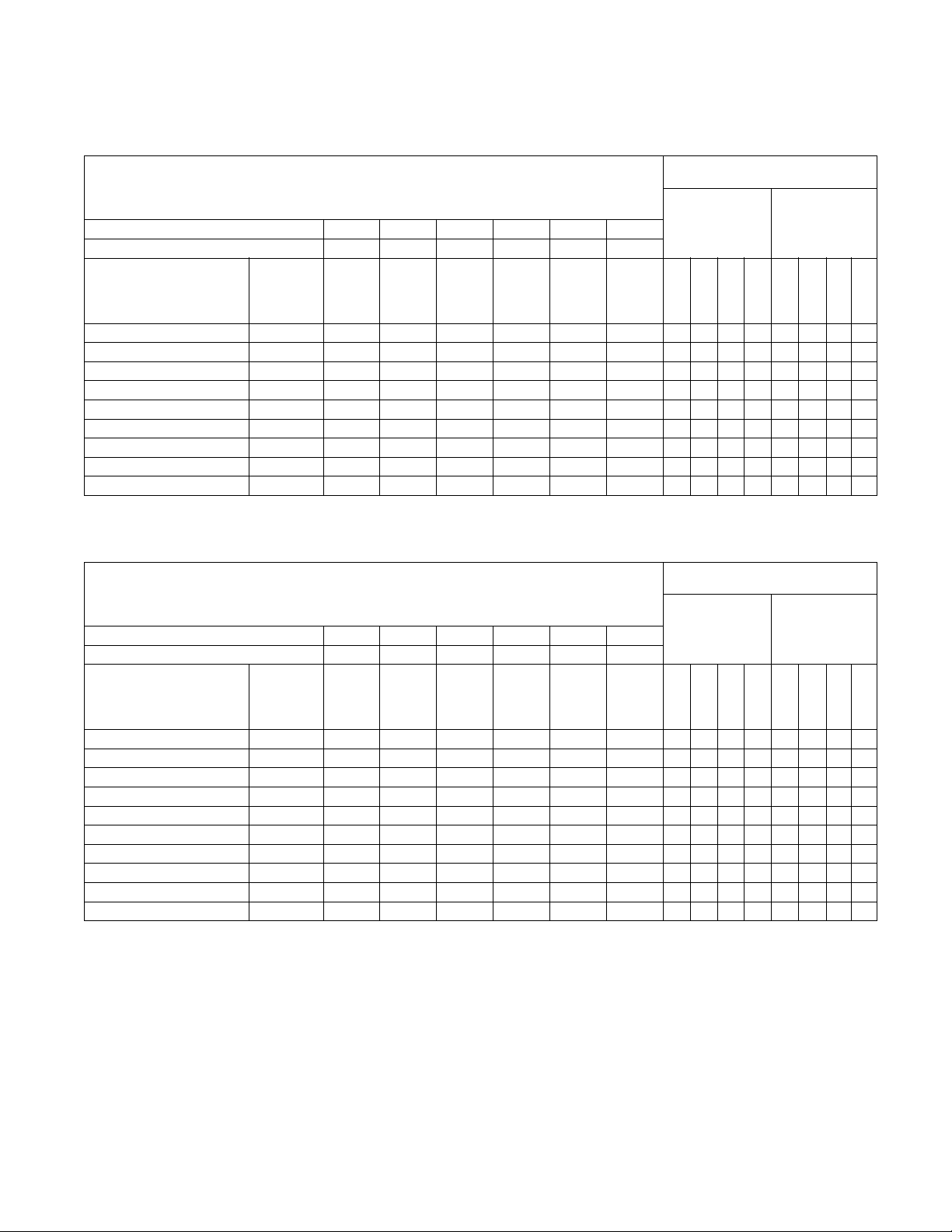

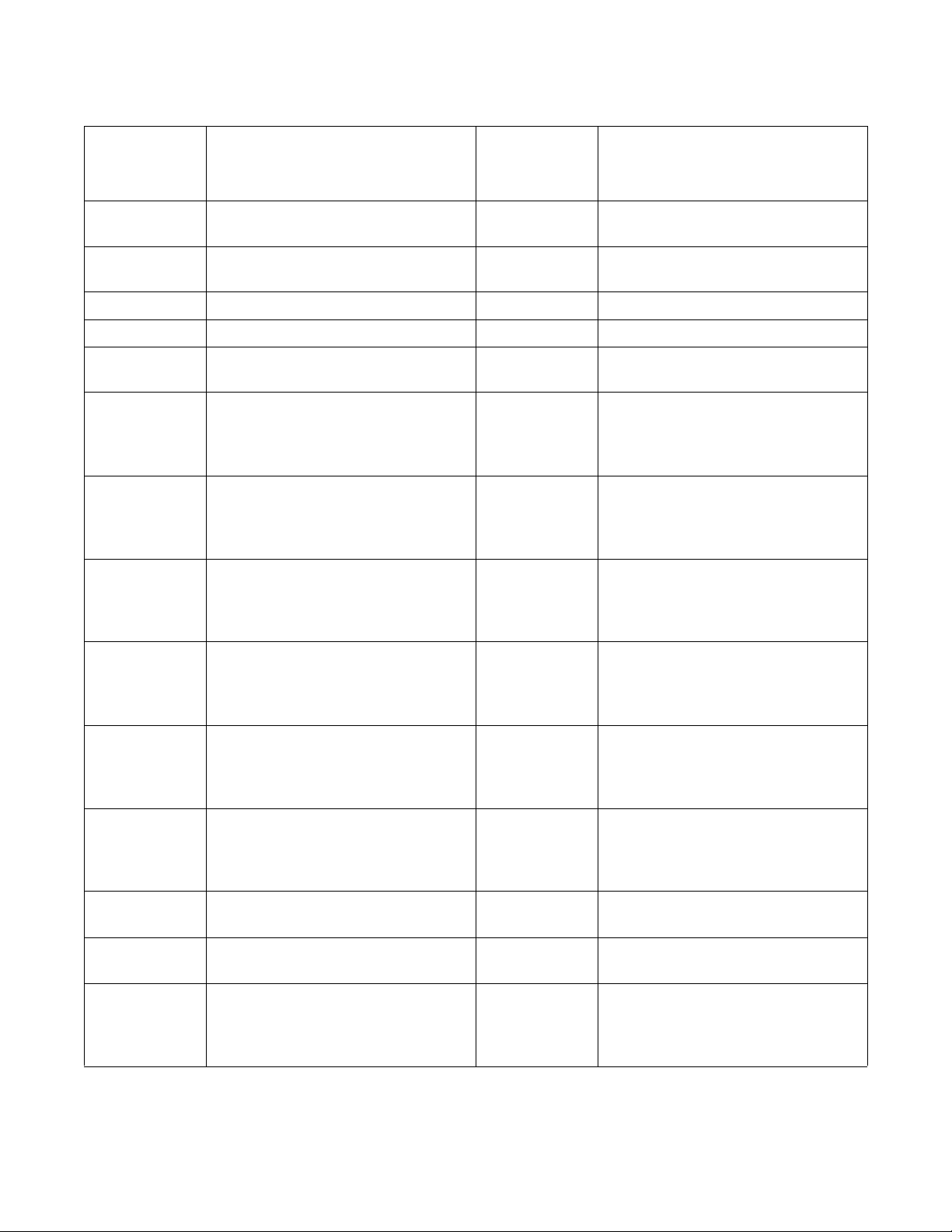

PowerFlex 40 Drive Control Logic Chart

Cabinet Hardmount

“A” control, “B” control, “V” Control and EDC/Netmaster Control

H – Signal Voltage High (approximately 24V DC)

L – Signal Voltage Low (less than 1V DC)

DC Volt Meter Red Probe Terminal Location

DC Volt Meter Black Probe Terminal Location

Digital

In 3

Digital

In 2

07 06 05 01 03 02

04 04 04 04 04 04

Digital

In 1

Stop Rev Fwd

0 = No signal received

1 = Signal received

Digital Input

Status – Parameter

d014

Control Input

Status – Parameter

d013

Action

Idle

1/2 Wash Speed Forward

1/2 Wash Speed Reverse

Wash Speed Forward

Wash Speed Reverse

Distribution Speed

Spin 1

Spin 2

Spin 3

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Cabinet Hardmount

Galaxy control, Quantum control and UniMac Software Control

H – Signal Voltage High (approximately 24V DC)

L – Signal Voltage Low (less than 1V DC)

DC Volt Meter Red Probe Terminal Location

DC Volt Meter Black Probe Terminal Location

Action

Idle

Reduced Wash speed (ccw)

Reduced Wash Speed (cw)

Wash Speed (ccw)

Wash S peed (cw)

Distribution Speed 1 (ccw)

Extract Speed 1 (ccw)

Extract Speed 2 (ccw)

Extract Speed 3 (ccw)

Extract Speed 4 (ccw)

Extract Speed 5 (ccw)

Frequency

Preset

Parameter #

N/A H H H L/H H H 000000/100

71 H H L L H L *10010101

71 H H L L L H 00010110

72 HLHL HL*10100101

72 H L H L L H 00100110

74 LHHL HL*11000101

73 H L L L H L *10110101

76 LLHL HL*11100101

75 L H L L H L *11010101

Frequency

Preset

Parameter #

N/A H H H L/ H H H 000000/100

70 H H H L L H 00000110

70 H H H L H L 00000101

72 H L H L L H 00100110

72 H L H L H L 00100101

71 H H L L L H 00010110

76 L L H L L H 01100110

75 L H L L L H 01010110

73 H L L L L H 00110110

77 L L L L L H 01110110

74 L H H L L H 01000110

Terminal

(SW3)

Digital

Terminal

(SW3)

Terminal

#07

In 3

07 06 05 01 03 02

04 04 04 04 04 04

#07

(SW2)

Digital

Terminal

(SW2)

#06

In 2

#06

Terminal

#05

(SW1)

Digital

In 1

Terminal

#05

(SW1)

Terminal

(Stop)

Stop Rev Fwd

Terminal

(Stop)

#01

#01

Terminal

#03

(STR)

Terminal

#03

(STR)

Terminal

#02

(STF)

Terminal

#02

(STF)

(SW3)

Digital In 3

*Digital In 4

Status – Parameter

*Digital In 4

Digital In 2

0 = No signal received

1 = Signal received

Digital Input

d014

Digital In 3

Digital In 2

Table 8

(SW2)

(SW1)

DB Trans

Digital In 1

Control Input

Status – Parameter

DB Trans

Digital In 1

On

On

Stop

d013

Stop

Rev (STR)

Fwd (STF)

Rev

Fwd

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232120

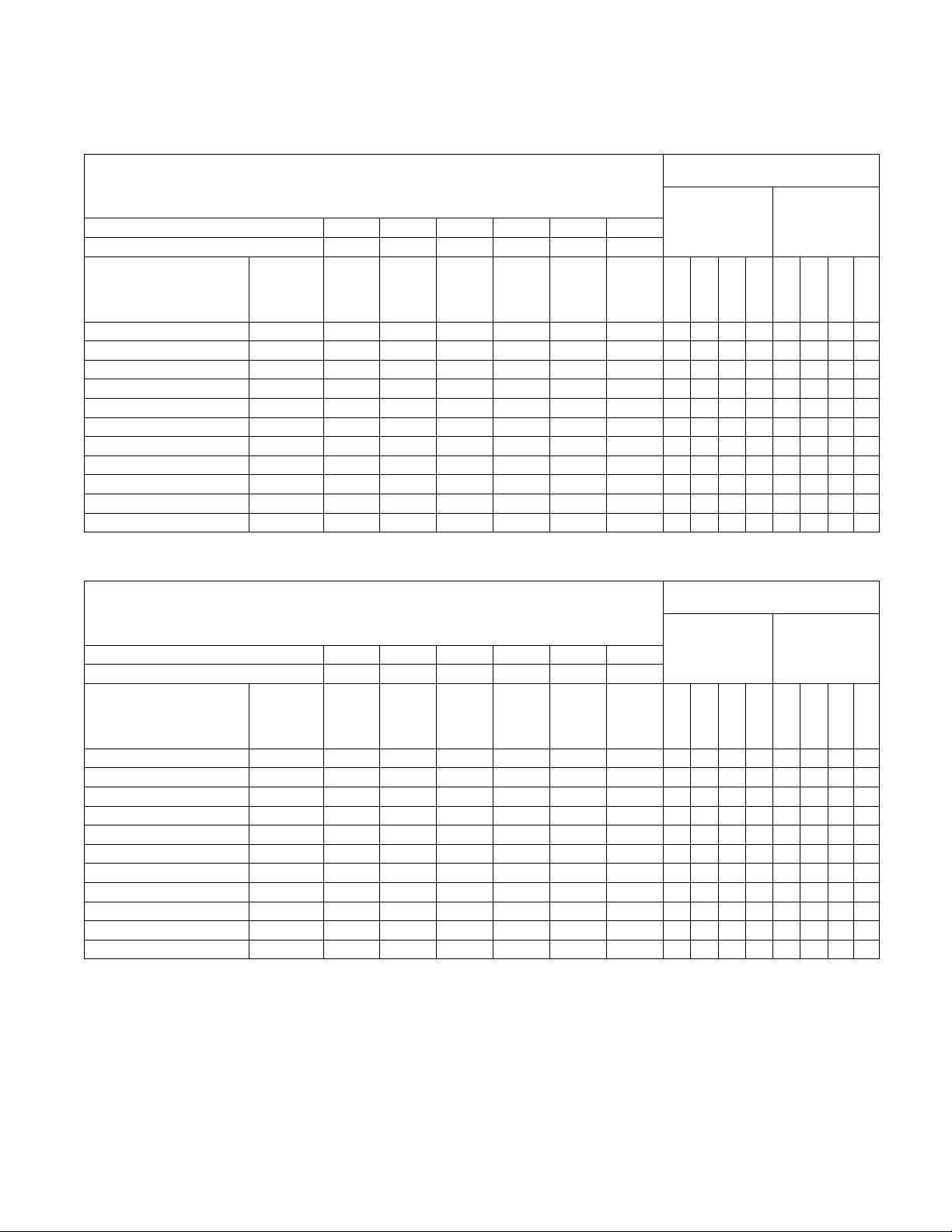

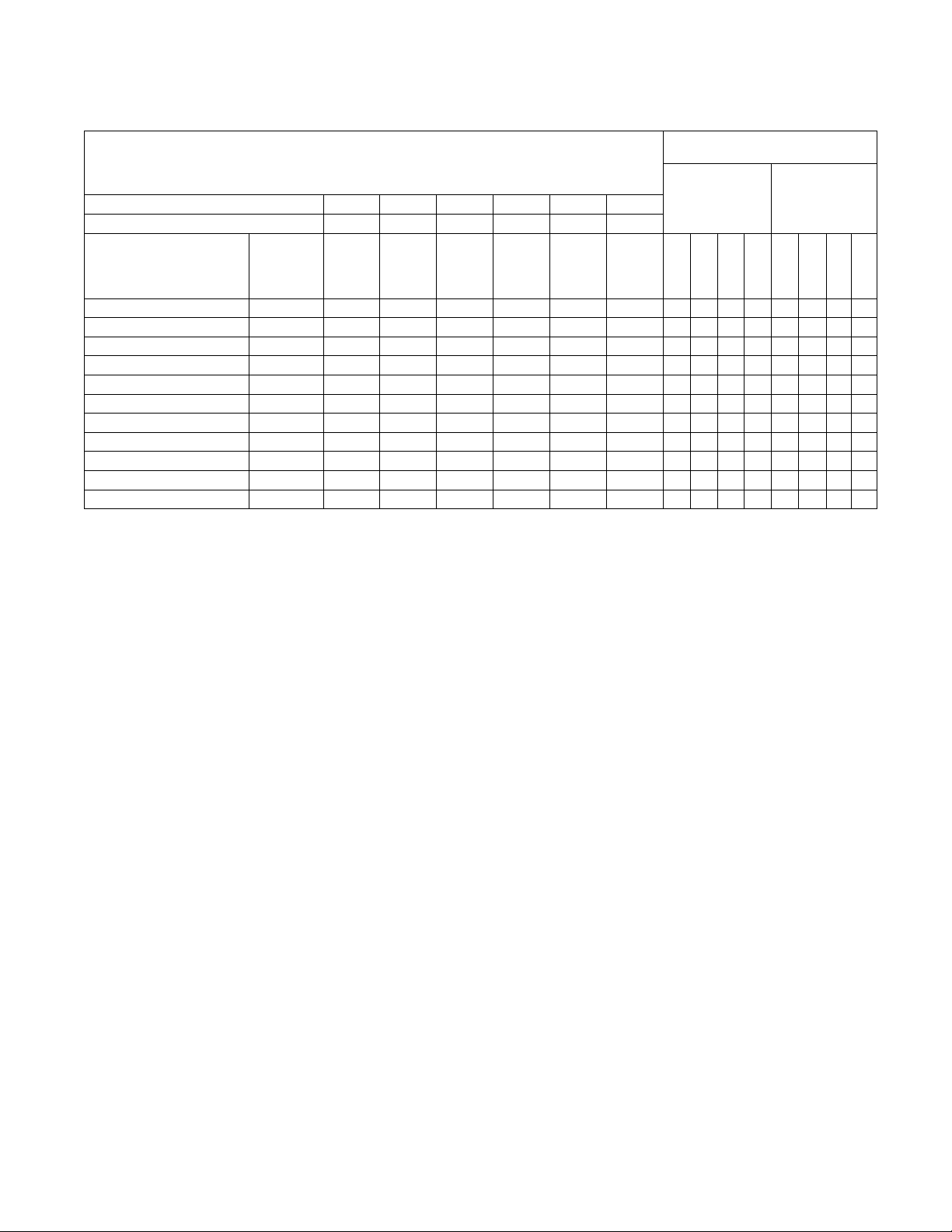

PowerFlex 40 Drive Control Logic Chart

Pocket Hardmount — 35 lb through 125 lb Capacity

UniLinc control and M30 control

H – Signal Voltage High (approximately 24V DC)

L – Signal Voltage Low (less than 1V DC)

DC Volt Meter Red Probe Terminal Location

DC Volt Meter Black Probe Terminal Location

Digital

In 3

Digital

In 2

07 06 05 01 03 02

04 04 04 04 04 04

Digital

In 1

PowerFlex 40 and 400 Drive Control Logic

Stop Rev Fwd

0 = No signal received

1 = Signal received

Digital Input

Status – Parameter

d014

Control Input

Status – Parameter

d013

Action

Idle

Reduced Wash Speed (cw)

Reduced Wash Speed (ccw)

Wash S peed (cw)

Wash Speed (ccw)

Distribution Speed (cw)

Extract Speed 1 (ccw)

Extract Speed 2 (ccw)

Extract Speed 3 (ccw)

Extract Speed 4 (ccw)

Extract Speed 5 (ccw)

Pocket Hardmount — 150 Capacity

Terminator control Control

H – Signal Voltage High (approximately 24V DC)

L – Signal Voltage Low (less than 1V DC)

DC Volt Meter Red Probe Terminal Location

DC Volt Meter Black Probe Terminal Location

Action

Idle

Reduced Wash speed (ccw)

Reduced Wash Speed (cw)

Wash Speed (ccw)

Wash S peed (cw)

Distribution Speed (ccw)

Very Low Extract (ccw)

Low Extract (ccw)

Medium Extract (ccw)

High Extract (ccw)

Very High Extract (ccw)

Frequency

Preset

Parameter #

N/A H H H L/ H H H 000000/100

70 H H H L H L 00000101

70 H H H L L H 00000110

72 H L H L H L 00100101

72 H L H L L H 00100110

71 H H L L H L 00010101

76 L L H L H L 01100101

75 L H L L H L 01010101

73 H L L L H L 00110101

77 L L L L H L 01110101

74 L H H L H L 01000101

Frequency

Preset

Parameter #

N/A H H H L/H H H 000000/100

70 H H H L L H 00000110

70 H H H L H L 00000101

72 H L H L L H 00100110

72 H L H L H L 00100101

71 H H L L L H 00010110

76 L L H L L H 01100110

75 L H L L L H 01010110

73 H L L L L H 00110110

77 L L L L L H 01110110

74 L H H L L H 01000110

Terminal

Digital

Terminal

Terminal

#07

In 3

#07

Digital

07 06 05 01 03 02

04 04 04 04 04 04

Terminal

#06

In 2

#06

Terminal

#05

Digital

In 1

Terminal

#05

Terminal

Stop Rev Fwd

Terminal

#01

#01

Terminal

#03

Terminal

#03

Table 9

Terminal

#02

Terminal

#02

Digital In 4

Digital In 3

Digital In 2

0 = No signal received

1 = Signal received

Digital Input

Status – Parameter

d014

Digital In 4

Digital In 3

Digital In 2

On

Stop

DB Trans

Digital In 1

Control Input

Status – Parameter

d013

On

Stop

DB Trans

Digital In 1

Rev

Rev

Fwd

Fwd

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

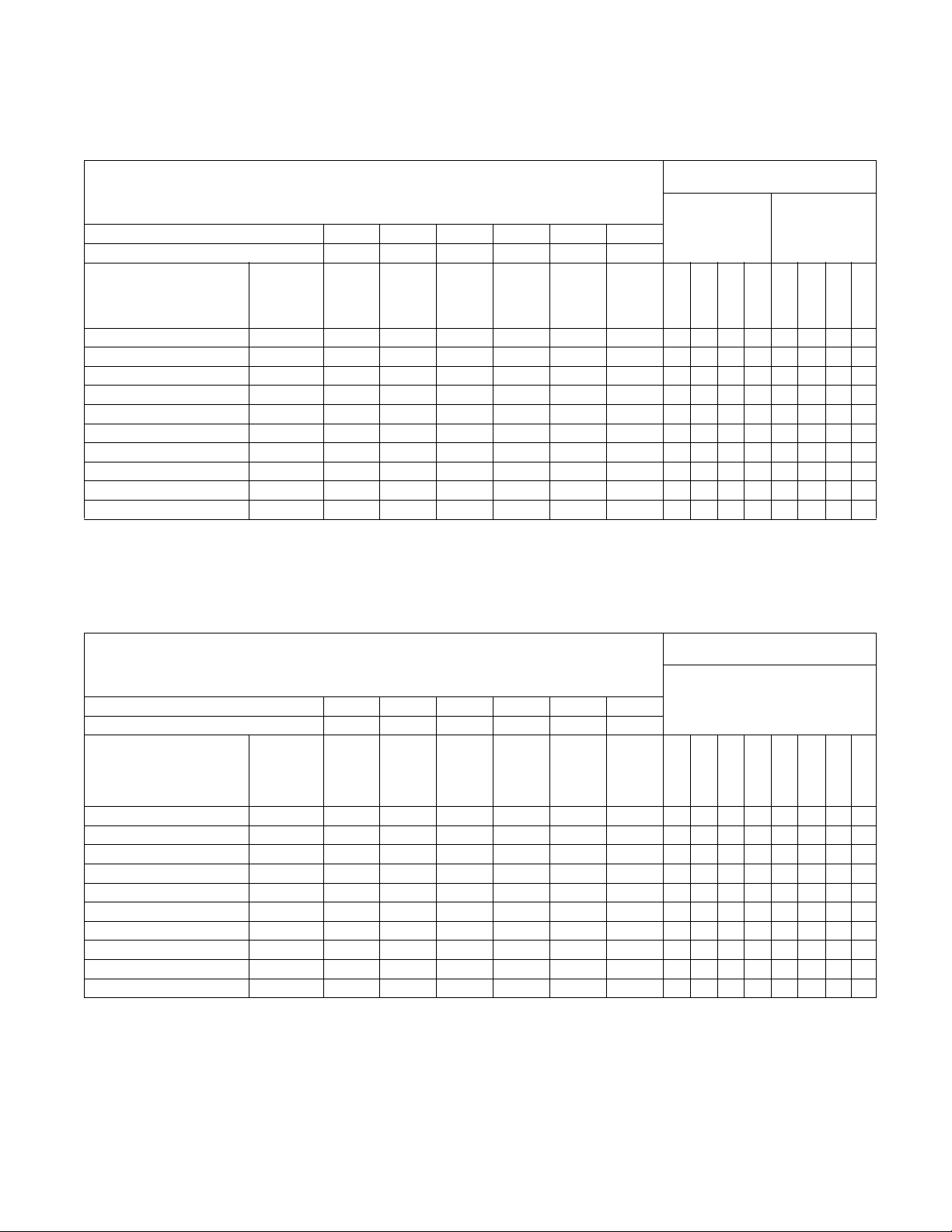

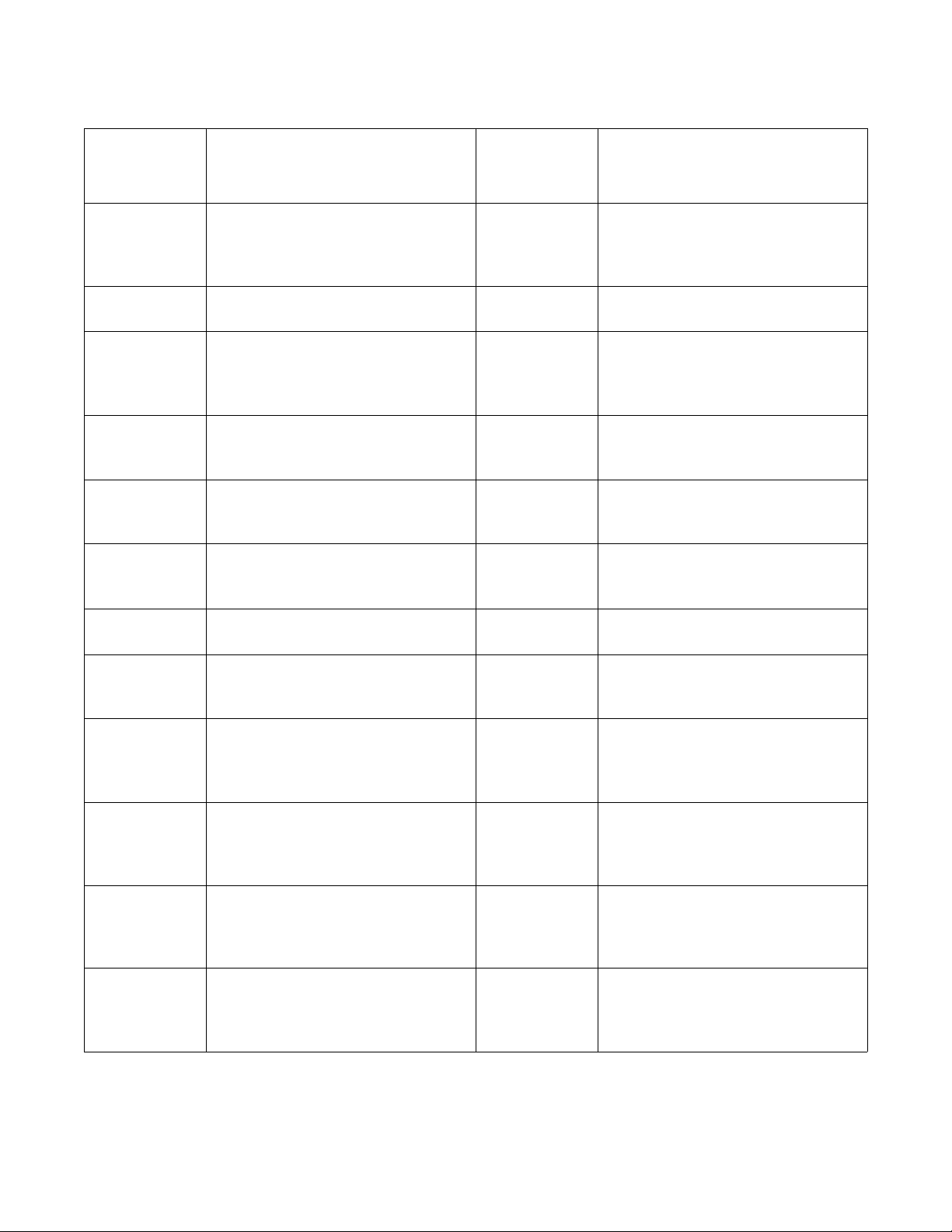

PowerFlex 40 and 400 Drive Control Logic

PowerFlex 40 Drive Control Logic Chart

Pocket Hardmount

“V” control and “A” control — Designs 7 and 8

H – Signal Voltage High (approximately 24V DC)

L – Signal Voltage Low (less than 1V DC)

DC Volt Meter Red Probe Terminal Location

DC Volt Meter Black Probe Terminal Location

Digital

In 3

Digital

In 2

07 06 05 01 03 02

04 04 04 04 04 04

Digital

In 1

Stop Rev Fwd

0 = No signal received

1 = Signal received

Digital Input

Status – Parameter

d014

Control Input

Status – Parameter

d013

Action

Idle

1/2 Wash Speed Forward

1/2 Wash Speed Reverse

Wash Speed Forward

Wash Speed Reverse

Distribution Speed

Spin 1 Extract

Spin 2 Extract

Spin 3 Extract

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Pocket Hardmount

WE-6 control — Design 5 and Earlier

H – Signal Voltage High (approximately 24V DC)

L – Signal Voltage Low (less than 1V DC)

DC Volt Meter Red Probe Terminal Location

DC Volt Meter Black Probe Terminal Location

Action

Idle

1/2 Wash Speed Forward

1/2 Wash Speed Reverse

Wash Speed Forward

Wash Speed Reverse

Distribution Speed

Medium Extract/Spray Rinse

High 1 Extract

High 2 Extract

High 3 Extract

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Frequency

Preset

Parameter #

N/A H H H L/H H H 000000/100

71 H H L L H L *10010101

71 H H L L L H 00010110

72 HLHL HL*10100101

72 H L H L L Ha 00100110

74 LHHL HL*11000101

73 H L L L H L *10110101

76 LLHL HL*11100101

75 L H L L H L *11010101

Frequency

Preset

Parameter #

N/A H H H L/H H H 000000/100

74 L H L L H H *11000101

74 L H H L L H 01000110

72 H L H L H H *10100101

72 H L H L L H 00100110

71 H H L L H L *10010101

76 L L H L H H *11100101

75 LHHLHL*11010101

73 H L L L H L *10110101

77 L L L L H L *11110101

Terminal

(SW3)

Digital

Terminal

(SW3)

Terminal

#07

In 3

07 06 05 01 03 02

04 04 04 04 04 04

#07

(SW2)

Digital

Terminal

(SW2)

#06

In 2

#06

Terminal

#05

(SW1)

Digital

In 1

Terminal

#05

(SW1)

Terminal

(Stop)

Stop Rev Fwd

Terminal

(Stop)

#01

#01

Terminal

#03

(STR)

Terminal

#03

(STR)

Terminal

#02

(STF)

Terminal

#02

(STF)

(SW3)

Digital In 3

*Digital In 4

Status – Parameter

*Digital In 4

Digital In 2

0 = No signal received

1 = Signal received

Digital Input

d014

(SW3)

Digital In 3

Digital In 2

Table 10

(SW2)

(SW2)

On

(SW1)

DB Trans

Digital In 1

Control Input

Status – Parameter

On

(SW1)

DB Trans

Digital In 1

Stop

d013

Stop

Rev (STR)

Fwd (STF)

Rev (STR)

Fwd (STF)

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232120

Pocket Hardmount

WE-6 control — Design 6, 7 and 8

H – Signal Voltage High (approximately 24V DC)

L – Signal Voltage Low (less than 1V DC)

DC Volt Meter Red Probe Terminal Location

DC Volt Meter Black Probe Terminal Location

PowerFlex 40 and 400 Drive Control Logic

Digital

In 3

Digital

In 2

07 06 05 01 03 02

04 04 04 04 04 04

Digital

In 1

Stop Rev Fwd

0 = No signal received

1 = Signal received

Digital Input

Status – Parameter

d014

Control Input

Status – Parameter

d013

Action

Idle

1/2 Wash Speed Forward

1/2 Wash Speed Reverse

Wash Speed Forward

Wash Speed Reverse

Distribution Speed

Medium Extract/Spray Rinse

Extract Speed 1

Extract Speed 2

Extract Speed 3 (default)

Extract Speed 3 (maximum)

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Frequency

Preset

Parameter #

N/A H H H L/H H H 000000/100

70 HHHL HL*10000101

70 H H H L L H 00000110

72 HLHL HL*10100101

72 H L H L L H 00100110

71 H H L L H L *10010101

76 LLHLHL*11100101

75 L H L L H L *11010101

73 H L L L H L *10110101

77 L L L L H L *11110101

74 LLHLHL*11000101

Terminal

#07

(SW3)

Terminal

#06

(SW2)

Terminal

#05

(SW1)

Terminal

#01

(Stop)

Terminal

#03

(STR)

Terminal

#02

(STF)

(SW3)

Digital In 3

*Digital In 4

Digital In 2

Table 11

On

(SW2)

Digital In 1

Stop

(SW1)

DB Tran s

Rev (STR)

Fwd (STF)

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

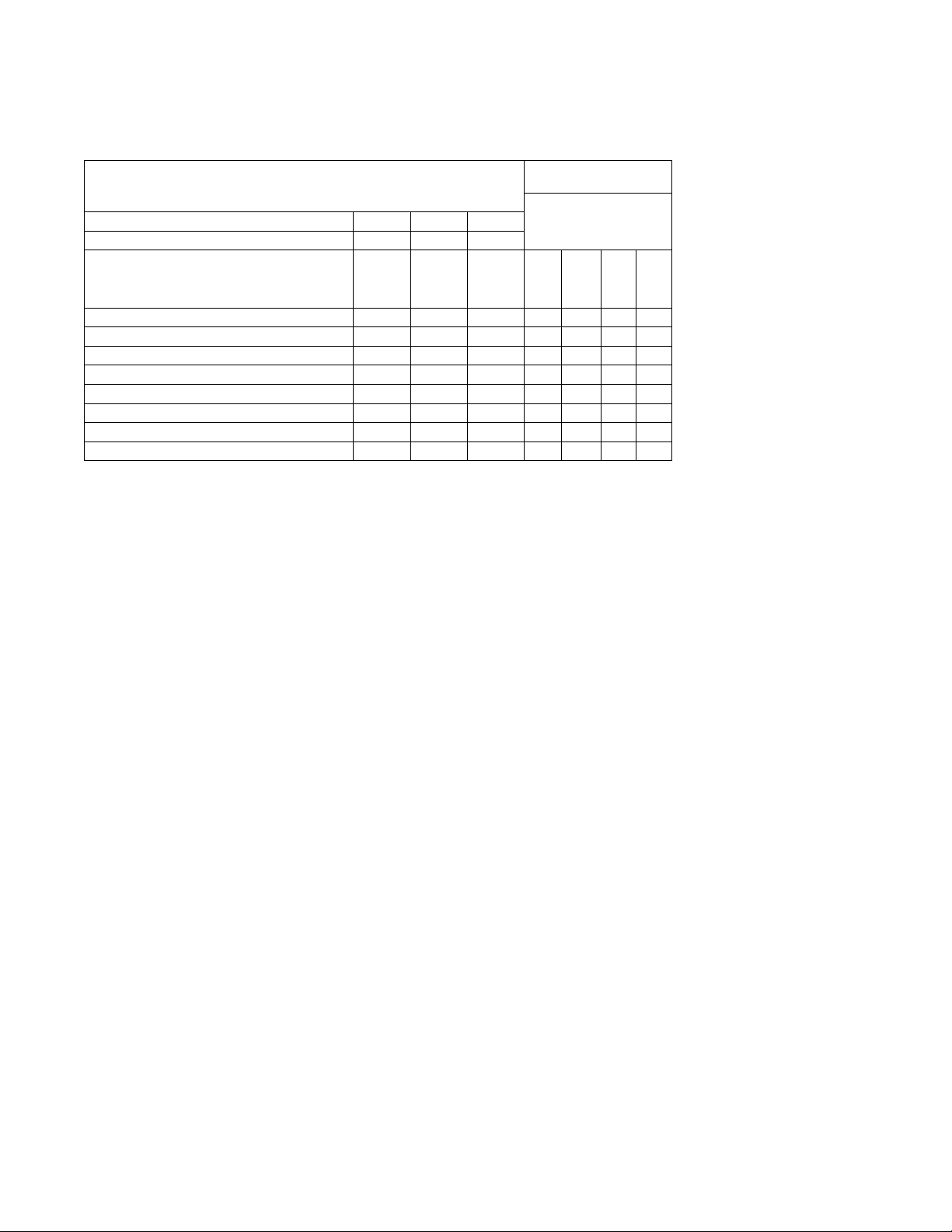

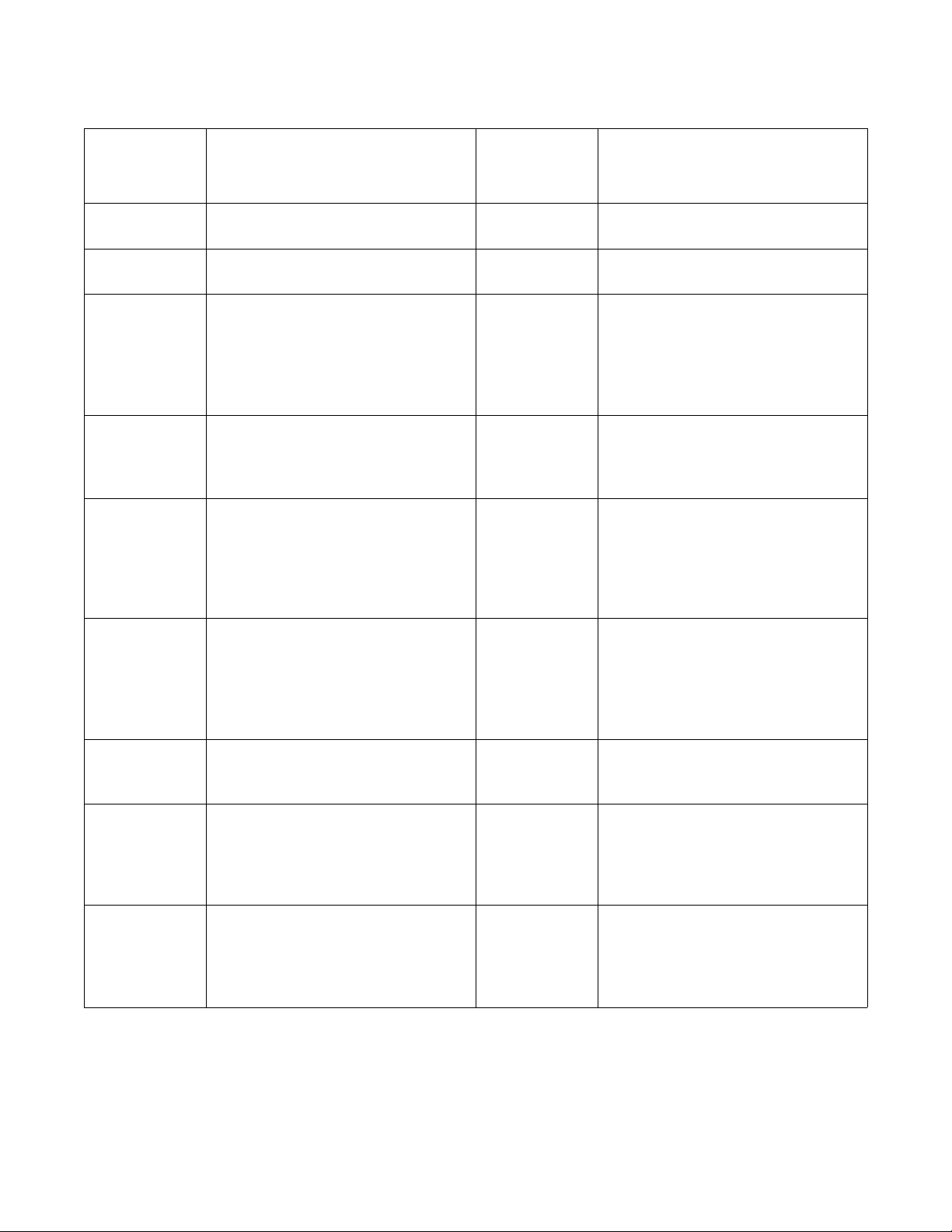

PowerFlex 40 and 400 Drive Control Logic

PowerFlex 40 Drive Control Logic Chart

Cabinet Freestanding

WE-6 control

H – Signal Voltage High (approximately 24V DC)

L – Signal Voltage Low (less than 1V DC)

DC Volt Meter Red Probe Terminal Location

DC Volt Meter Black Probe Terminal Location

Digital

In 3

Digital

In 2

07 06 05 01 03 02

04 04 04 04 04 04

Digital

In 1

Stop Rev Fwd

0 = No signal received

1 = Signal received

Digital Input

Status – Parameter

d014

Control Input

Status – Parameter

d013

Action

Idle

1/2 Wash Speed Forward

1/2 Wash Speed Reverse

Wash Speed Forward

Wash Speed Reverse

Distribution Speed

Medium Extract

High 1 Extract

High 2 Extract

High 3 Extract

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Frequency

Preset

Parameter #

N/A H H H L/H H H 0 0 0 0 0 0/1 0 0

74 LHHL HL*11000101

74 L H H L L H 01000110

72 HLHL HL*10100101

72 H L H L L H 00100110

71 H H L L H L *10010101

76 LLHLHL*11100101

75 L H L L H L *11010101

73 H L L L H L *10110101

77 L L L L H L *11110101

Terminal

#07

(SW3)

Terminal

#06

(SW2)

Terminal

#05

(SW1)

Terminal

#01

(Stop)

Terminal

#03

(STR)

Terminal

#02

(STF)

(SW3)

Digital In 3

*Digital In 4

Table 12

PowerFlex 400 Drive Control Logic Chart

Cabinet Freestanding (250 Model Only)

WE-6 control

H – Signal Voltage High (greater than 10V DC)

L – Signal Voltage Low (less than 1V DC)

DC Volt Meter Red Probe Terminal Location

DC Volt Meter Black Probe Terminal Location

Digital

In 3

Digital

In 2

07 06 05 02 01 03

04 04 04 04 04 04

Digital

In 1

Fwd Stop Rev

0 = No signal received

1 = Signal received

Control Input Status – Parameter d302

Digital In 2

(SW2)

Digital In 1

(SW1)

DB Trans

On

Stop

Rev (STR)

Fwd (STF)

Action

Idle

1/2 Wash Speed Forward

1/2 Wash Speed Reverse

Wash Speed Forward

Wash Speed Reverse

Distribution Speed

Medium Extract

High 1 Extract

High 2 Extract

High 3 Extract

*If digital in 4 is wired to the Forward Input terminal #02, this input will be a “1” whenever the drive receives a forward command. Disregard otherwise.

Frequency

Preset

Parameter #

N/A H H H H L or H H 000000/100

355 L H H L L H 0 *1 1 0 0 1 0 1

355 L H H H L L 00100110

145 H L H L L H 0 *1 0 1 0 1 0 1

145 H L H H L L 00010110

144 H H L L L H 0 *1 0 0 1 1 0 1

357 L L H L L H 0 *1 1 1 0 1 0 1

356 L H L L L H 0 *1 1 0 1 1 0 1

146 H L L L L H 0 *1 0 1 1 1 0 1

358 L L L L L H 0 *1 1 1 1 1 0 1

Terminal

#07

(SW3)

Terminal

#06

(SW2)

Terminal

#05

(SW1)

Terminal

#02

(STF)

Terminal

#01

(Stop)

Terminal

#03

(STR)

Not Used

*Digital In 4

Table 13

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

(SW3)

Digital In 3

Digital In 2

Stop

(SW2)

(SW1)

Rev (STR)

Digital In 1

Fwd (STF)

F232120

PowerFlex 40 Drive Control Logic Chart

Pocket Hardmount — IPH, IP and CP Models

PS40 control

H – Signal Voltage High (approximately 24V DC)

L – Signal Voltage Low (less than 1V DC)

Stop Rev Fwd

DC Volt Meter Red Probe Terminal Location

DC Volt Meter Black Probe Terminal Location

01 03 02

04 04 04

PowerFlex 40 and 400 Drive Control Logic

0 = No signal received

1 = Signal received

Control Input Status –

Parameter d013

Action

Idle

Wash Speed Forward

Wash Speed Reverse

Distribution Speed

Low Spin Speed

Medium Spin Speed

High Spin Speed

SmartSpin

NOTE: IPH models use analog signals to control speed — refer to parameter d002 (command f req.) and d020 (analog input %)

to verify speed input signal.

Terminal

Terminal

#01

LHH0100

L H L 0 1 0 1

L L H 0 1 1 0

L H L 0 1 0 1

LHL0101

LHL0101

LHL0101

LLL0111

#03

Terminal

#02

DB Trans

On

Rev

Stop

Table 14

Fwd

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

PowerFlex 40 and 400 Drive Control Logic

COM

X — fmr

RL RM RH STR STF

P/N F370314

V-Computer Output Board

Drive Control

Connections

J8

J2A

30 31 32 33 34 35

J7A

J3B J1

Ribbon

Terminals 1 thru 16

Terminals 17 thru 29

Drive Control

Connections

P/N F370577

WE-6 Output Board

1

7

6

12

H2

H4

H1

H3

H5

Drive

Control

Connections

P/N: 370433 EDC Output Board

Computer Output Boards

Connections identified on these figures set speed and

direction of the drive.

U135ME3A

Figure 12

Figure 13

20

Figure 14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

U136ME3A

U148ME3A

F232120

PowerFlex 40 and 400 Drive Control Logic

P/N: F8108001 UniLinc Output Board

Drive

Harness

Connection

H13

16 9

81

UNILINC, QUANTUM, GALAXY AND UNIMAC SOFTWARE OUTPUT BOARD

A AND B-CONTROL OUTPUT BOARD

Drive Harness

Connection J11

Figure 15

Figure 16

PHM738N

PHM776N

PHM776N

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

PowerFlex 40 and 400 Drive Control Logic

PS40 CONTROL OUTPUT BOARD

Drive Harness

Connection J11

PHM777N

Figure 17

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232120

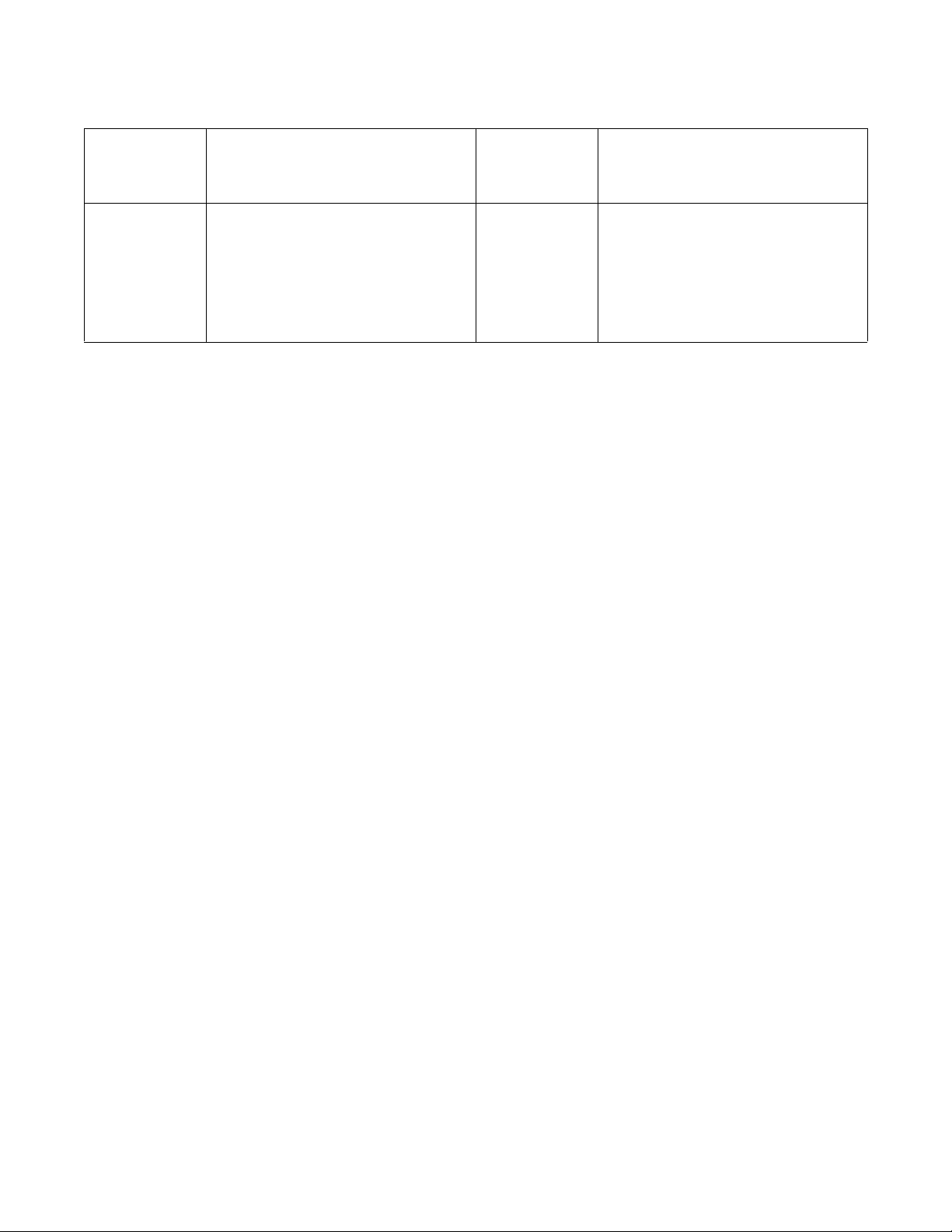

PowerFlex 40 and 400 Drive Control Logic

Control Wire

During troubleshooting, if the wire path between the

control board and the drive is uncertain, refer to

Table 15 for wire connection numbers.

Control Wire Connection Reference Table.

Output Board Terminal

V-Control F370314, F8206501 and F370447-6, etc.

STF

STR

RH

RM

RL

COM

WE-6 Interface Board P/N: F370577, F0370446-xx

J2A-30

J2A-31

J2A-32

J2A-33

J2A-34

J2A-35

EDC – Output Board P/N: F370433

H2-7

H2-8

H2-9

H2-10

02

03

07

06

05

04

04

06

02

07

05

03

07

06

05

04

Table 15 (continued)

UniLinc Control– Output Board F8108001

H13-2

H13-3

H13-4

H13-5

H13-6

H13-7

Output Board Terminal

A and B-Control P/N: F0370448xx

J11-1-8/STF

J11-1-7/STR

J11-1-6/RH

J11-1-5/RM

J11-1-4/RL

J11-1-3/COM

PS40 Main Board P/N: C000281

C12 OV, R-, L-

C12 0-10v

C12 R+

C12 L+

Jumper

Table 15

01, 04, 14

04

07

06

05

03

02

02

03

07

06

03

04

13

02

03

N/A

F232120

H2-11

H2-12

Table 15 (continued)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

03

02

23

PowerFlex 40 and 400 Drive Control Logic

PowerFlex Drive Parameters

PowerFlex 40

Parameter

Group and

Number

PowerFlex 400 Parameter Group

and Number

Parameter

Description

Function

d001 b001 Output

Frequency

d002 b002 Command

Frequency

Displays instantaneous output frequency

(in Hz).

Displays command output frequency (in

Hz).

d003 b003 Output Current Displays output current (in Amps).

d004 b004 Output Voltage Displays output voltage (in VAC).

d005 b005 DC Bus Voltage Displays DC Bus capacitor voltage (in

VDC).

d006 b006 Drive Status Read from left to right, the four bits

indicate the drive’s condition

(decelerating, accelerating, forward and

running). “0” = false and “1” = true

d007 d307 Fault 1 Code Memory location for the most recent

fault. Refer to Table 20 for a list of most

fault codes. Repetitive faults are stored

only once.

d008 d308 Fault 2 Code Memory location for the 2nd most recent

fault. Refer to Table 20 for a list of most

fault codes. Repetitive faults are stored

only once.

d009 d309 Fault 3 Code Memory location for the 3rd most recent

fault. Refer to Table 20 for a list of most

fault codes. Repetitive faults are stored

only once.

d010 b008 Process Display Not applicable to Alliance Laundry

Systems’ equipment. Refer to the

manual supplied with the PowerFlex

drive for detailed information.

d012 d301 Control Source Read from left to right, the digits

indicate the active source of the Speed

Reference (P038) and Start Source

(P036) command.

d013 d302 Control Input

Status

d014 d302 Digital Input

Status

d015 d303 Communication

Status

Refer to Table 8 throug h Table 14 for

Control Status Input diagnostics.

Refer to Table 8 throug h Table 14 for

Digital Input Status diagnostics.

Not applicable to Alliance Laundry

Systems’ equipment. Refer to the manual

supplied with the PowerFlex drive for

detailed information.

Table 16 (co nt i nu ed )

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232120

PowerFlex 40

Parameter

Group and

Number

Table 16 (co nt i nu ed )

PowerFlex 400 Parameter Group

and Number

PowerFlex 40 and 400 Drive Control Logic

Parameter

Description

Function

d016 d320 Control

Firmware

Version

Displays the AC drive’s firmware

version. For PowerFlex 40 drives, this

will be 70.xx, 80.xx or 90.xx. For

PowerFlex 400 drives, this will be 14.01.

d017 d321 Drive Type Displays the numeric code of the drive’s

rating (e.g., 4508 = 5hp 200V drive)

d018 b012 Elapsed Run

Time

Displays the accumulated time the drive

has output power. The display is in 10-

hour increments (e.g., a display of 1

represents a value of 10 hours).

d019 d319 Testpoint Data Displays a hexadecimal value of the

“T estpoint Selection” in parameter

A102.

d020 d305 Analog In

(0-10V)

Displays the value (in percentage) of the

voltage at terminal 13(e.g.,

100.0%=10V)

d021 d306 Analog In

(4-20mA)

Displays the value (in percentage) of the

current at terminal 15 (e.g., 0.0%=4mA;

100.0%=20mA)

d022 b010 Output Power Displays the kilowatts present at

terminals U, V and W (in kW).

d023 d318 Output Power

Factor

Displays the angle in electrical degrees

between the motor voltage and the motor

current.

d024 b014 Drive

Temperature

Displays the present operating

temperature (in Celsius) of the drive’s

internal power devices. Refer to Fault

008 in Ta ble 20.

d025 N/A Counter Status Not applicable to Alliance Laundry

Systems’ equipment. Refer to the manual

supplied with the PowerFlex drive for

detailed information.

d026 N/A Timer Status Not applicable to Alliance Laundry

Systems’ equipment. Refer to the manual

supplied with the PowerFlex drive for

detailed information.

d028 N/A Step Logic

Status

Not applicable to Alliance Laundry

Systems’ equipment. Refer to the manual

supplied with the PowerFlex drive for

detailed information.

Table 16 (co nt i nu ed )

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

PowerFlex 40 and 400 Drive Control Logic

Table 16 (co nt i nu ed )

PowerFlex 40

Parameter

Group and

PowerFlex 400 Parameter Group

and Number

Parameter

Description

Function

Number

d029 b013 T orque Current Displays the present value of the motor’s

torque current (in Amps).

d030 N/A OL Level Displays the real-time m oto r overload

progression (100% = F007 Fault).

P041 P041 Reset to Defaults NOTE: This will reset the drive’s

parameters back to the factory-default

values, requiring the AC drive to be re-

programmed. This will not reset A193.

(0 = Not Active; 1 = Reset — Induces

Fault F048).

A101 A198 Parameter Lock Allows parameter modification.

0 = Parameters Unlocked

1= Parameters Locked

See also parameters A192 and A193.

A152 N/A Limited

Frequency

Displays the maximum allowable

frequency (in Hz) based on DC Bus

voltage. The drive output frequency may

be limited due to low input voltage

conditions to alleviate potential motor

stalling.

A164 R261 Balance State Displays the balance detection algorithm

progression (See A187 and A188). (0 =

Algorithm not active; 1 = programmed

pause time; 2 = programmed sample

time; 3 = programmed filter time; 4 =

result obtained)

A187 N/A SmartSpin

Frequency

Displays the commanded SmartSpin

frequency (in Hz) as determined from

Balance Result A188.

A188 R285 Balance Result Displays the numeric value indicating

severity of load imbalance. A balance

result value will be displayed only when

A164 = 4, otherwise the display will be

0.

A192 N/A Parameter

CRC-16

Displays the numeric code culminating

from the value of all of the parameters.

This is intended as a quick reference and

is used to validate the parameter settings

for a specific application.

26

Table 16 (co nt i nu ed )

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232120

PowerFlex 40 and 400 Drive Control Logic

Table 16 (co nt i nu ed )

PowerFlex 40

Parameter

Group and

PowerFlex 400 Parameter Group

and Number

Parameter

Description

Function

Number

A193 N/A Counter This counter will increment each time

parameter A192 changes. This is

intended as a quick reference to show if

any parameter has been changed after

factory programming, even if a

parameter was changed and then

restored to the ALS-specified value.

NOTE: The above parameters and descriptions are based on firmware version 90.06 and may differ or be missing

from earlier versions of PowerFlex drive firmware. Refer to parameter d016 for the firmware’s version.

NOTE: All PowerFlex drives used in Alliance Laundry Systems’ equipment are custom-developed with unique

features and parameters. Parameter information provided within the Allen-Bradley PowerFlex series AC drive

manual will differ and may not be relevant.

Table 16

F232120

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

PowerFlex 40 and 400 Drive Control Logic

RUN

FWD

REV

VOLTS

PROGRAM

AMPS

HERTZ

FAULT

POWERFLEX LED DISPLAYS

7

1

4

3

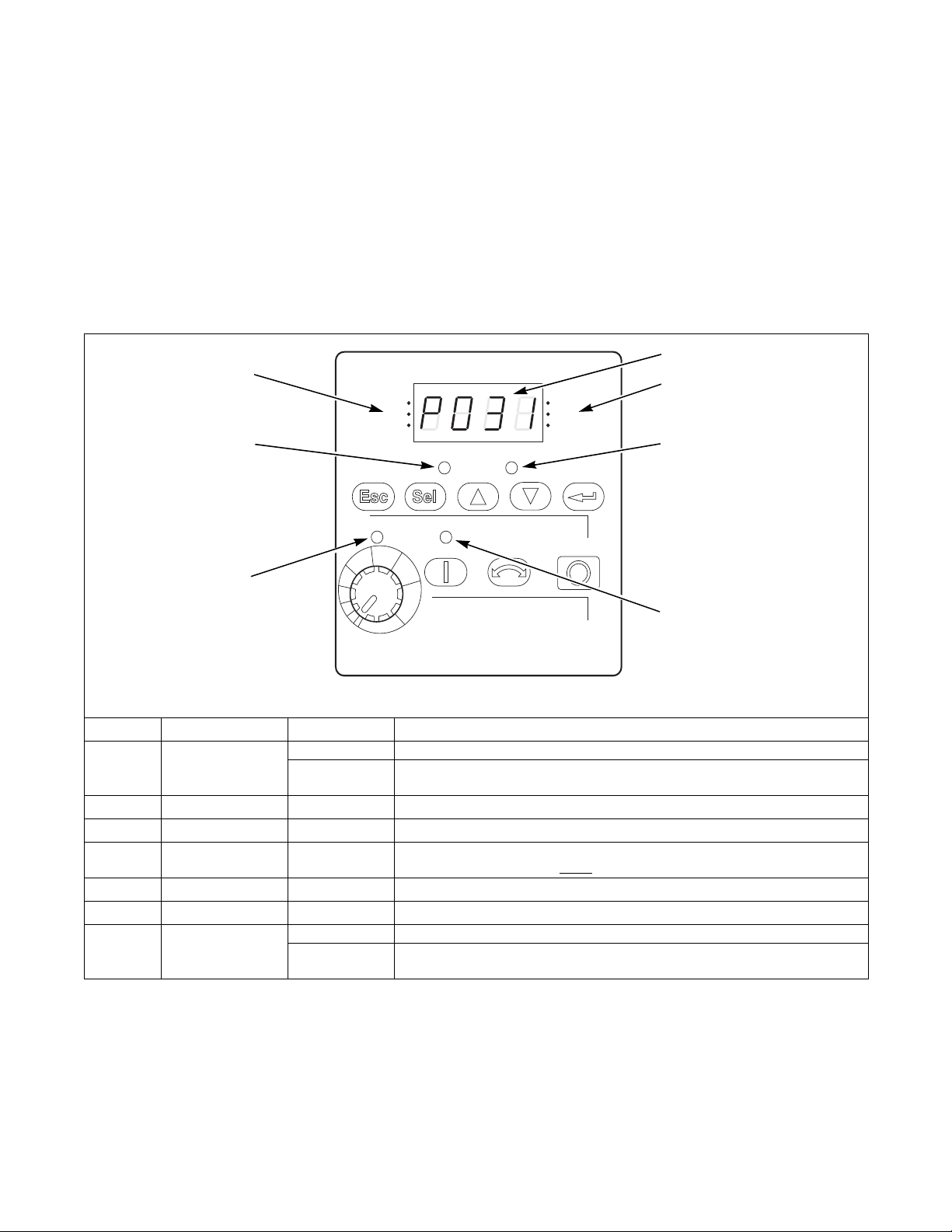

6

2

AC Drive Diagnostics/Parameter

Viewing

PowerFlex Integrated Keypad

The PowerFlex series AC drives have an integral

keypad that can be used for viewing and editing

parameter values. No external parameter unit is

required, however an external hand-held parameter

unit is available (22-HIM-A3) that can provide a userfriendly method of viewing and editing parameter

values in hard-to-access locations.

Integral Keypad

The integral keypad displays several main menu group

selections such as “d”, “P”, and “A” as described

below. Within the Display Group is a fault storage

buffer that stores the last three AC drive fault codes.

Refer to the Fault Display and Troubleshooting

Information Section for more information.

Number LED LED State Description

Display Steady Red Indicates parameter number, parameter value, or fault code.

Flashing Red Single digit flashing indicates that digit can be edited. All digits flashing

indicates a fault condition. See t a b le below.

active unless disabled by A095

Steady Red Indicates drive is running and commanded motor direction.

Flashing Red Drive has been commanded to change direction. Indicates actual motor

direction while decelerating to zero.

1

2

3

4

5

6

7

Displayed Units Steady Red Indicates the units of the parameter value being displayed.

Fault Status Flashing Red Indicates drive is faulted.

Start Key Status Steady Green Indicates Start key on Integral Keypad is active. The Reverse key is also

Pot Status Steady Green Indicates potentiometer on Integral Keypad is active.

Program Status Steady Red Indicates parameter value can be changed.

Run/Direction

Status

Figure 18

PHM640N

(Reverse Disable).

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232120

Loading…

Ремонт частотного преобразователя Rockwell Automation Allen Bradley Powerflex в Веди

|

|

Ремонт частотного преобразователя Rockwell Automation Allen Bradley Powerflex известного американского производителя промышленной электроники, впрочем, как и ремонт частотников выпущенными под другими брендами имеет ряд особенностей в силу своего конструктива. Частотные преобразователи, точнее их начинка делятся на две части:

- Аппаратная часть,

- Программная часть.

Приводы данного производителя не являются исключением из правил, именно поэтому ремонт частотного преобразователя Allen Bradley имеет точно такой же ряд особенностей, как и у других преобразователей.

Диагностировать ту или иную неисправность помогают коды ошибок частотного преобразователя, которые отображаются на небольшом дисплее, расположенном на лицевой панели частотника.

Ремонт частотных преобразователей Rockwell Automation Allen Bradley Powerflex, впрочем, как и любых других частотников выпущенных под другими брендами всегда начинается с аппаратной части, после успешного ремонта аппаратной части наступает очередь программной.

Настройка частотного преобразователя Allen Bradley прописана в инструкции завода производителя, для каждой серии частотных преобразователей настройка будет индивидуальной, так как каждая линейка преобразователей решает свои собственные задачи, этим обусловливается широкая номенклатура данного промышленного оборудования. Но все же есть определенная последовательность настройки привода, которая относится ко всем частотным преобразователям, любого бренда.

Программирование, настройка частотного преобразователя Allen Bradley

Программирование частотных преобразователей Rockwell Automation Allen Bradley Powerflex (настройка) происходит в рамках установленных производителем правил, существует общий алгоритм по настройке (программированию частотных преобразователей), который относится ко всем производителям данного промышленного оборудования. Ниже представлена пошаговая инструкция по настройке частотных преобразователей Allen Bradley и подобного промышленного оборудования других брендов.

- Выбор режима управления приводом (управление по показанию датчиков, дистанционное управление, дистанционное управление).

- В случае использования отдельного (выносного) монитора, настраивается вывод на него технической информации.

- Далее определяем конфигурацию подключения серводвигателя. На данной стадии задаются такие параметры как- возможность применения обратной связи либо без ее применения, а в память блока заносятся данные по: величине крутящего момента, мощности потребителей, номинальное значения частоты, напряжение, ток и скорости вращения ротора.

- Программируется минимально допустимая величина напряжения и частоты, а также время ускорения ротора от ноля до номинального значения.

- И в завершении, в программу управления частотным преобразователем Allen Bradley вносятся функциональные данные со значениями отдельных клемм и особенностями сигналов. Отмечаются действия оборудования, выполняющиеся автоматически при отсутствии информации поступающей в оперативном режиме с датчика.

В некоторых преобразователях частоты существует пункт наличия/отсутствия фильтра в цепи питания двигателя. Этот пункт отвечает за подключение различных видов нагрузок, в том случае, когда возможно выбрать нормальное или инверсное изменение частоты при повышении уровня сигнала обратной связи.

Ошибки частотного преобразователя Allen Bradley

В процессе работы выходит из строя даже самое надежное промышленное оборудование. Частотники в наше время, нашли широкое применение абсолютно во всех сферах промышленности, управляя как мини моторами в оргтехнике, так и гигантскими двигателями в горнодобывающей промышленности.

Для простоты общения со столь сложной электроникой все частотные преобразователи оснащены небольшими дисплеями с помощью которых выводятся информационные сообщения с кодами ошибок, расшифровав которые можно сразу же узнать причину ее возникновения. Если учесть распространенность данной промышленной электроники, то появляется острая нужда в расшифровке кодов ошибок частотных преобразователей. В этой статье мы рассмотрим одного из самых известных производителей промышленной электроники имеющему уважение во всем мире, Rockwell Automation Allen Bradley и серию частотных преобразователей Powerflex 520.

Существует несколько видов ошибок, некоторые из них можно устранить автоматически, а некоторые возможно исправить только, обратившись в специализированный сервисный центр. В руководстве пользователя прописаны все коды ошибок частотного преобразователя Rockwell Automation Allen Bradley Powerflex 520 и их расшифровка.

Коды ошибок частотного преобразователя Allen Bradley Powerflex 520

Ошибка – это условие, останавливающее преобразователь. Существует два типа аварий.

| Тип | Ошибка | Описание |

|---|---|---|

| 1 | С автоматическим сбросом/запуском | Если произошла ошибка этого типа, а для параметра A541 [Auto Rstrt Tries] установлено значение больше «0», запускается настраиваемый пользователем таймер A542 [Auto Rstrt Delay]. Когда таймер достигает нуля, преобразователь предпринимает попытку автоматического сброса ошибки. И в том случае, если условия, вызвавшего ошибку, больше не существует, произойдёт сброс ошибки и преобразователь снова будет запущен. |

| 2 | Несбрасываемая | Этот тип ошибки может потребовать ремонта преобразователя или двигателя, он может быть вызван неправильным подключением кабелей или допущенными в программе ошибками. Для сброса ошибки необходимо устранить её причину. |

| Поз. | Ошибка | Тип | Описание |

|---|---|---|---|

| F000 | Нет ошибки | — | Ошибка отсутствует. |

| F002 | Дополнительный вход | 1 | Вход внешнего отключения (вспом.). |

| F003 | Потеря питания | 2 | В однофазном режиме обнаружена чрезмерная нагрузка. |

| F004 | Пониженное напряжение | 1 | Напряжение шины постоянного тока упало ниже минимального значения. |

| F005 | Перенапряжение | 1 | Напряжение на шине постоянного тока превышает максимальное значение. |

| F006 | Двигатель заблокирован | 1 | Преобразователь не подходит для разгона или торможения двигателя. |

| F007 | Перегрузка двигателя | 1 | Сработал встроенный электронный ограничитель нагрузки. |

| F008 | Перегрев радиатора | 1 | Температура радиатора/модуля питания вышла за пределы допуска. |

| F009 | Перегрев контр.узла | 1 | Температура модуля управления превышает заданное значение. |

| F012 | Превышение аппаратного тока | 2 | Выходной ток преобразователя превысил допустимый предел. |

| F013 | Ошибка заземления | 2 | Обнаружено замыкание на землю одной или нескольких выходных клемм преобразователя. |

| F015(1) | Потеря нагрузки | 2 | Выходной ток крутящего момента ниже значения, установленного параметром A490 [Load Loss Level], в течение времени, превышающего установленное параметром A491 [Load Loss Time]. |

| F021 | Обрыв фазы вывода | 1 | Обрыв фазы вывода (если включена). Настраивается при помощи A557 [Out Phas Loss En]. |

| F029 | Обрыв аналог. ввода | 1 | Для аналогового входа задано сообщение об ошибке в случае пропадания сигнала. Пропал сигнал. Настраивается при помощи t094 [Anlg In V Loss] или t097 [Anlg In mA Loss]. |

| F033 | Попытки авт. перезапуска | 2 | Предпринятые преобразователем попытки сброса ошибки и продолжения работы оканчивались неудачей столько раз, сколько было задано в параметре A541 [Auto Rstrt Tries]. |

| F038 F039 F040 |

Фаза U на землю Фаза V на землю Фаза W на землю |

2 | Ошибка замыкания фазы на землю была обнаружена между преобразователем и двигателем в этой фазе. |

| F041 F042 F043 |

Короткое замыкание фаз U и V Короткое замыкание фаз U и W Короткое замыкание фаз V и W |

2 | Между двумя данными клеммами обнаружено превышение по току. |

| F048 | Запись в параметры значений по умолчанию | 1 | Преобразователь подал команду записи в ЭППЗУ значений по умолчанию. |

| F059(1) | Откр.безопасн. | 1 | Отключены оба защитных входа (Safety 1, Safety 2). Настраивается при помощи t105 [Safety Open En]. |

| F063 | Превышение по току | 1 | Запрограммированное значение A486, A488 [Shear Pinx Level] превышено на период, превышающий время, заданное в A487, A489 [Shear Pin x Time]. |

| F064 | Перегрузка преобразователя | 2 | Превышена допустимая перегрузка преобразователя. |

| F070 | Блок питания | 2 | Обнаружена ошибка питания преобразователя. |

| F071 | Потеря сети DSI | 2 | Управление по Modbus или каналу связи DSI прервано. |

| F072 | Потеря сети Opt | 2 | Управление по удалённой сети платы выбора подключений прервано. |

| F073(1) | Потеря сети EN | 2 | Управление через встроенный адаптер EtherNet/IP прервано. |

| F080 | Ошибка автоподстройки | 2 | Произошла ошибка функции автонастройки или работа функции отменена пользователем. |

| F081 | Потеря DSI Comm | 2 | Связь между преобразователем и ведущим устройством Modbus или DSI прервана. |

| F082 | Потеря Opt Comm | 2 | Связь между преобразователем и сетевой платой выбора подключений прервана. |

| F083(1) | Потеря EN Comm | 2 | Внутренняя связь между преобразователем и встроенным адаптером EtherNet/IP прервана. |

| F091(1) | Потеря энкодера | 2 | Необходим дифференциальный энкодер. Отсутствует сигнал в одном из двух каналов энкодера. |

| F094 | Потеря функции | 2 | Вход «Замораживание-запуск» (потеря функции) не активен, вход к программируемой клемме открыт. |

| F100 | Ошибка контрольной суммы параметра | 2 | Энергонезависимая память параметров преобразователя повреждена. |

| F101 | Внешняя память | 2 | Внешняя энергонезависимая память повреждена. |

| F105 | Ошибка соед. контр. узла | 2 | Модуль управления отсоединён во время включения преобразователя. |

| F106 | Несовместим. контр. уз. – блок пит. | 2 | Модуль управления не может распознать модуль питания. |

| F107 | Замен. контр. уз. – блок пит. | 2 | Модуль управления установлен на модуль питания с отличающейся номинальной мощностью. |

| F109 | Несоотв. контр. уз. – блок пит. | 2 | Модуль управления установлен на модуль питания с отличающейся номинальной мощностью. |

| F110 | Мембранная клавиатура | 2 | Ошибка/отсоединение мембранной клавиатуры. |

| F111(1) | Защитное оборудование | 2 | Аппаратная ошибка включения защитного оборудования. Один из защитных входов не включён. |

| F114 | Сбой микропроц. | 2 | Сбой микропроцессора |

| F122 | Ошибка платы ввода-вывода | 2 | Обнаружен сбой в секции ввода- вывода и управления преобразователя. |

| F125 | Требуется обновление флеш-памяти | 2 | Встроенное ПО в преобразователе повреждено, не согласовано или несовместимо с аппаратурой. |

| F126 | NonRecoverablErr | 2 | Была обнаружена неустранимая ошибка встроенного ПО или аппаратуры. Преобразователь был автоматически остановлен и выполнен сброс. |

| F127 | DSIFlashUpdatReq | 2 | Была обнаружена существенная проблема со встроенным ПО, и преобразователь работает с использованием резервного встроенного ПО, которое поддерживает только связь DSI. |

(1) Эта ошибка неприменима к преобразователям PowerFlex 523.

Частотный преобразователь Allen Bradley инструкция на русском, скачать

Все настройки частотных преобразователей Rockwell Automation Allen Bradley Powerflex приведены в технической документации ниже в удобном формате (PDF) который можно скачать на свой компьютер, распечатать или просто открыть на нашем сайте.

Промышленный частотный преобразователь Allen Bradley инструкции, скачать русскоязычные и англоязычные версии в формате PDF.

|

Частотный преобразователь Allen Bradley PowerFlex 4 инструкция |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 4M инструкция |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 40 инструкция |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 40P инструкция |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 70 инструкция |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 400 инструкция |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 520 инструкция на руссокм |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 520 технические характеристики на русском |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 700AFE инструкция на русском |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 700L инструкция |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 700 инструкция на русском |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 750 инструкция на русском |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex 750 инструкция по монтажу на русском |

Скачать PDF |

|

Частотный преобразователь Allen Bradley PowerFlex-750 инструкция по программированию на русском |

Скачать PDF |

Схемы подключения частотных преобразователей Allen Bradley

Схемы подключений частотных преобразователей Allen Bradley могут отличатся друг от друга даже если эти преобразователи относятся ко одной линейке. Схема подключения преобразователя зависит от потребляемой частотным преобразователем нагрузки или питающей сети к которой подключается частотник 200V – 380V, а также от оборудования с которым предполагается работа данного частотника.

Ниже приведены схемы подключения частотного преобразователя Allen Bradley.

|

Схема подключения частотного преобразователя Allen Bradley PowerFlex-4 |

Схема подключения частотного преобразователя Allen Bradley PowerFlex-4M |

|

|

|

Схема подключения частотного преобразователя Allen Bradley PowerFlex-40 |

|

|

Ремонт частотных преобразователей Allen Bradley в сервисном центре

Сервисный центр «Кернел» производит ремонт частотных преобразователей Rockwell Automation Allen Bradley Powerflex в Веди с 2002 года. За время существования компании наши сотрудники накопили колоссальный опыт в ремонте преобразователей частоты такого известного производителя как Ален Бредли. Ремонт подобного промышленного оборудования ответственное и сложное занятие, требующие максимальной отдачи, профессионализма и максимально полной материальной базе.

Специалисты нашего сервисного центра максимальное внимание уделяют качеству исполнения ремонта, программирования и настройке промышленных преобразователей частоты, не зависимо от производителя данного промышленного оборудования. Именно поэтому мы смело даем гарантию на ремонт частотных преобразователей Rockwell Automation Allen Bradley Powerflex и запасные части замененные в процессе ремонта шесть месяцев.

Ремонт частотных преобразователей Allen Bradley в Веди производится исключительно с использованием оригинальных запасных частей, на компонентном уровне с применением высокотехнологичного оборудования, квалифицированным персоналом с инженерным образованием.

Мы ремонтируем все линейки частотных преобразователей Allen Bradley в том числе:

| Серия ПЧ | Типы частотных преобразователей Rockwell Automation Allen Bradley Powerflex |

|---|---|

| PowerFlex 755 | 20G11GD2P1JA0NNNNN; 20G11GD3P4JA0NNNNN; 20G11GD5P0JA0NNNNN; 20G11GD8P0JA0NNNNN; 20G11GD011JA0NNNNN; 20G11GD014JA0NNNNN; 20G11GD022JA0NNNNN; 20G11GD027JA0NNNNN; 20G11GD034JA0NNNNN; 20G11GD040JA0NNNNN; 20G11GD052JA0NNNNN; 20G11GD065JA0NNNNN; 20G11GD077JA0NNNNN; 20G1AJD430JN0NNNNN; 20G1AJD485JN0NNNNN; 20G1AJD545JN0NNNNN; 20G1AJD617JN0NNNNN; 20G1AJD710JN0NNNNN; 20G1AJD740JN0NNNNN; 20G11JD800JN0NNNNN; 20G11JD960JN0NNNNN; 20G11JD1K0JN0NNNNN; 20G11JD1K2JN0NNNNN; 20G11JD1K3JN0NNNNN; 20G11JD1K4JN0NNNNN; 20G11JD1K5JN0NNNNN; 20G11JD2K0JN0NNNNN; 20G11RB2P2JA0NNNNN; 20G11RB4P2JA0NNNNN; 20G11RB6P8JA0NNNNN; 20G11RB9P6JA0NNNNN; 20G11RB015JA0NNNNN; 20G11NB2P2JA0NNNNN; 20G11NB4P2JA0NNNNN; 20G11NB6P8JA0NNNNN; 20G11NB9P6JA0NNNNN; 20G11NB015JA0NNNNN; 20G11NB022JA0NNNNN; 20G11NB028JA0NNNNN; 20G11NB042JA0NNNNN; 20G11NB054JA0NNNNN; 20G11NB070JA0NNNNN; 20G11NB080JA0NNNNN |

| PowerFlex 753 | 20F11RB2P2JA0NNNNN; 20F11RB4P2JA0NNNNN; 20F11RB6P8JA0NNNNN; 20F11RB9P6JA0NNNNN; 20F11RB015JA0NNNNN; 20F11NB2P2JA0NNNNN; 20F11NB4P2JA0NNNNN; 20F11NB6P8JA0NNNNN; 20F11NB9P6JA0NNNNN; 20F11NB015JA0NNNNN; 20F11NB022JA0NNNNN; 20F11NB028JA0NNNNN; 20F11NB042JA0NNNNN; 20F11NB054JA0NNNNN; 20F11NB070JA0NNNNN; 20F11NB080JA0NNNNN; 20F11GB2P2JA0NNNNN; 20F11GB4P2JA0NNNNN; 20F11GB6P8JA0NNNNN; 20F11GB9P6JA0NNNNN; 20F11GB015JA0NNNNN; 20F11GB022JA0NNNNN; 20F11GB028JA0NNNNN; 20F11GB042JA0NNNNN; 20F11GB054JA0NNNNN; 20F11GB070JA0NNNNN; 20F11FB2P2JA0NNNNN; 20F11FB4P2JA0NNNNN; 20F11FB6P8JA0NNNNN; 20F11FB9P6JA0NNNNN; 20F11FB015JA0NNNNN; 20F11FB022JA0NNNNN; 20F11FB028JA0NNNNN; 20F11FB042JA0NNNNN; 20F11FB054JA0NNNNN; 20F11FB070JA0NNNNN; 20F11FB080JA0NNNNN |

| PowerFlex 755TL PowerFlex 755TR PowerFlex 755TM |

20G1xxC302xNxNNNNN-Cx-Px; 20G1xxC367xNxNNNNN-Cx-Px; 20G1xxC460xNxNNNNN-Cx-Px; 20G1xxC540xNxNNNNN-Cx-Px; 20G1xxC585xNxNNNNN-Cx-Px; 20G1xxC650xNxNNNNN-Cx-Px; 20G1xxC750xNxNNNNN-Cx-Px; 20G1xxC770xNxNNNNN-Cx-Px; 20G1xxC920xNxNNNNN-Cx-Px; 20G1xxC1K0xNxNNNNN-Cx-Px; 20G1xxC1K1xNxNNNNN-Cx-Px; 20G1xxD302xNxNNNNN-Cx-Px; 20G1xxD505xNxNNNNN-Cx-Px; 20G1xxD710xNxNNNNN-Cx-Px; 20G1xxD960xNxNNNNN-Cx-Px; 20G1xxD1K3xNxNNNNN-Cx-Px; 20G1xxD1K6xNxNNNNN-Cx-Px; 20G1xxD2K6xNxNNNNN-Cx-Px; 20G1xxD3K4xNxNNNNN-Cx-Px; 20G1xxE242xNxNNNNN-Cx-Px; 20G1xxE295xNxNNNNN-Cx-Px; 20G1xxE435xNxNNNNN-Cx-Px; 20G1xxE690xNxNNNNN-Cx-Px; 20G1xxE980xNxNNNNN-Cx-Px; 20G1xxE1K2xNxNNNNN-Cx-Px; 20G1xxE2K4xNxNNNNN-Cx-Px; 20G1xxF215xNxNNNNN-Cx-Px; 20G1xxF330xNxNNNNN-Cx-Px; 20G1xxF415xNxNNNNN-Cx-Px; 20G1xxF650xNxNNNNN-Cx-Px; 20G1xxF920xNxNNNNN-Cx-Px; 20G1xxF1K4xNxNNNNN-Cx-Px; 20G1xxF1K8xNxNNNNN-Cx-Px; 20G1xxF2K3xNxNNNNN-Cx-Px; |

| PowerFlex 70 | 20AB2P2A0AYNNNC0; 20AB2P2A0AYNANC0; 20AB4P2A0AYNNNC0; 20AB4P2A0AYNANC0; 20AB6P8A0AYNNNC0; 20AB6P8A0AYNANC0; 20AB9P6A0AYNNNC0; 20AB9P6A0AYNANC0; 20AB015A0AYNANC0; 20AB022A0AYNANC0; 20AB028A0AYNANC0; 20AB042A0AYNANC0; 20AB054A0AYNANC0; 20AB070A0AYNANC0; 20AC1P3A0AYNNNC0; 20AC1P3A0AYNANC0; 20AC2P1A0AYNNNC0; 20AC2P1A0AYNANC0; 20AC3P5A0AYNNNC0; 20AC3P5A0AYNANC0; 20AC5P0A0AYNNNC0; 20AC5P0A0AYNANC0; 20AC8P7A0AYNNNC0; 20AC8P7A0AYNANC0; 20AC011A0AYNANC0; 20AC015A0AYNANC0; 20AC043A0AYNANC0; 20AE0P9A0AYNNNC0; 20AE3P9A0AYNNNC0; 20AE011A0AYNNNC0; 20AE022A0AYNNNC0; 20AE041A0AYNANC0; 20AB2P2C3AYNNNC0; 20AB022C3AYNANC0; 20AB070C3AYNANC0; 20AC2P1C3AYNNNC0; 20AD2P1C3AYNANC0; 20AD011C3AYNANC0; 20AC037C3AYNANC0; 20AD052C3AYNANC0; 20AC072C3AYNANC0 |

| PowerFlex 523 | 25A-V1P6N104; 25A-V2P5N104; 25A-V4P8N104; 25A-V6P0N104; 25A-A1P6N104; 25A-A1P6N114; 25A-A2P5N104; 25A-A2P5N114; 25A-A4P8N104; 25A-A4P8N114; 25A-A8P0N104; 25A-A8P0N114; 25A-A011N104; 25A-A011N114; 25A-B1P6N104; 25A-B2P5N104; 25A-B5P0N104; 25A-B8P0N104; 25A-B011N104; 25A-B017N104; 25A-B024N104; 25A-B032N104; 25A-B048N104; 25A-B062N104; 25A-D1P4N104; 25A-D2P3N114; 25A-D4P0N104; 25A-D6P0N114; 25A-D010N104; 25A-D013N114; 25A-D017N104; 25A-D024N114; 25A-D030N104; 25A-D037N114; 25A-E0P9N104; 25A-E1P7N104; 25A-E3P0N104; 25A-E4P2N104; 25A-E6P6N104; 25A-E9P9N104; 25A-E012N104; 25A-E019N104; 25A-E022N104; 25A-E027N104; 25A-E032N104 |

| PowerFlex 525 | 25B-V2P5N104; 25B-V4P8N104; 25B-V6P0N104; 25B-A2P5N104; 25B-A2P5N114; 25B-A4P8N104; 25B-A4P8N114; 25B-A8P0N104; 25B-A8P0N114; 25B-A011N104; 25B-A011N114; 25B-B2P5N104; 25B-B5P0N104; 25B-B8P0N104; 25B-B011N104; 25B-B017N104; 25B-B024N104; 25B-B032N104; 25B-B048N104; 25B-B062N104; 25B-D1P4N104; 25B-D2P3N114; 25B-D4P0N104; 25B-D6P0N114; 25B-D010N104; 25B-D013N114; 25B-D017N104; 25B-D024N114; 25B-D030N104; 25B-D037N114; 25B-E0P9N104; 25B-E1P7N104; 25B-E3P0N104; 25B-E4P2N104; 25B-E6P6N104; 25B-E9P9N104; 25B-E012N104; 25B-E022N104; 25B-E032N104 |

| PowerFlex 527 | 25C-V2P5N104; 25C-V4P8N104; 25C-V6P0N104; 25C-A2P5N104; 25C-A4P8N104; 25C-A8P0N104; 25C-A011N104; 25C-A2P5N114; 25C-A4P8N114; 25C-A8P0N114; 25C-A011N114; 25C-B2P5N104; 25C-B5P0N104; 25C-B8P0N104; 25C-B011N104; 25C-B017N104; 25C-B024N104; 25C-B032N104; 25C-B048N104; 25C-B062N104; 25C-D1P4N104; 25C-D2P3N104; 25C-D4P0N104; 25C-D6P0N104; 25C-D010N104; 25C-D013N104; 25C-D017N104; 25C-D024N104; 25C-D030N104; 25C-D1P4N114; 25C-D2P3N114; 25C-D4P0N114; 25C-D6P0N114; 25C-D010N114; 25C-D013N114; 25C-D017N114; 25C-D024N114; 25C-D030N114; 25C-D037N114; 25C-D043N114; 25C-E0P9N104; 25C-E1P7N104; 25C-E3P0N104; 25C-E4P2N104; 25C-E6P6N104; 25C-E9P9N104; 25C-E012N104; 25C-E019N104; 25C-E022N104; 25C-E027N104; 25C-E032N104 |

| PowerFlex 4M | 22F-V1P6N103; 22F-V2P5N103; 22F-V4P5N103; 22F-V6P0N103; 22F-A1P6N103; 22F-A1P6N113; 22F-A2P5N103; 22F-A2P5N113; 22F-A4P2N103; 22F-A4P2N113; 22F-A8P0N103; 22F-A8P0N113; 22F-A011N103; 22F-A011N113; 22F-B1P6N103; 22F-B2P5N103; 22F-B4P2N103; 22F-B8P0N103; 22F-B012N103; 22F-B017N103; 22F-B025N104; 22F-B033N104; 22F-D1P5N103; 22F-D1P5N113; 22F-D2P5N103; 22F-D2P5N113; 22F-D4P2N103; 22F-D4P2N113; 22F-D6P0N103; 22F-D6P0N113; 22F-D8P7N103; 22F-D8P7N113; 22F-D013N104; 22F-D013N114; 22F-D018N104; 22F-D018N114; 22F-D024N104; 22F-D024N114 |

| PowerFlex 400 | 22C-B012N103; 22C-B012F103; 22C-B017N103; 22C-B017F103; 22C-B024N103; 22C-B024F103; 22C-B033N103; 22C-B033F103; 22C-B049A103; 22C-B065A103; 22C-B075A103; 22C-B090A103; 22C-B120A103; 22C-B145A103; 22C-D6P0N103; 22C-D6P0F103; 22C-D010N103; 22C-D010F103; 22C-D012N103; 22C-D012F103; 22C-D017N103; 22C-D017F103; 22C-D022N103; 22C-D022F103; 22C-D030N103; 22C-D030F103; 22C-D038A103; 22C-D045A103; 22C-D060A103; 22C-D072A103; 22C-D088A103; 22C-D105A103; 22C-D142A103; 22C-D170A103; 22C-D208A103; 22C-D260A103; 22C-D310A103; 22C-D370A103; 22C-D460A103 |

| PowerFlex 4 | 22A-V1P5N104; 22A-V2P3N104; 22A-V4P5N104; 22A-V6P0N104; 22A-A1P4N103; 22A-A2P1N103; 22A-A3P6N103; 22A-A6P8N103; 22A-A9P6N103; 22A-A1P4N113; 22A-A2P1N113; 22A-A3P6N113; 22A-A6P8N113; 22A-A9P6N113; 22A-A1P5N114; 22A-A2P3N114; 22A-A4P5N114; 22A-A8P0N114; 22A-A1P5N104; 22A-A2P3N104; 22A-A4P5N104; 22A-A8P0N104; 22A-B1P5N104; 22A-B2P3N104; 22A-B4P5N104; 22A-B8P0N104; 22A-B012N104; 22A-B017N104; 22A-D1P4N104; 22A-D2P3N104; 22A-D4P0N104; 22A-D6P0N104; 22A-D8P7N104; 22B-A2P3N114 |

| PowerFlex 40 | 22B-V2P3N104; 22B-V5P0N104; 22B-V6P0N104; 22B-A5P0N114; 22B-A8P0N114; 22B-A012N114; 22B-A2P3N104; 22B-A5P0N104; 22B-A8P0N104; 22B-A012N104; 22B-B2P3N104; 22B-B5P0N104; 22B-B8P0N104; 22B-B012N104; 22B-B017N104; 22B-B024N104; 22B-B033N104; 22B-D1P4N104; 22B-D2P3N104; 22B-D4P0N104; 22B-D6P0N104; 22B-D010N104; 22B-D012N104; 22B-D017N104; 22B-D024N104; 22B-E1P7N104; 22B-E3P0N104; 22B-E4P2N104; 22B-E6P6N104; 22B-E9P9N104; 22B-E012N104; 22B-E019N104 |