HLP-NV Series

HLP-NV Series

I. Introduction 2

1. Checks upon Deliver y 3

2. Nameplate Desc ription of HLP-NV Series I nvert er 3

II. Safety Pre cautions 5

1. Before the Power-up 5

2. Dur ing the Power-up 6

3. Duri ng the Operat ion 6

4. Afte r the Power-off 7

III. Standards and Specicat ions 8

1. Particular Specications 8

2. General Specications 9

IV. Storage and Instal lation 11

1. Storage 11

2. Inst allat ion Site and Environment 11

3. Insta llation and Direction 11

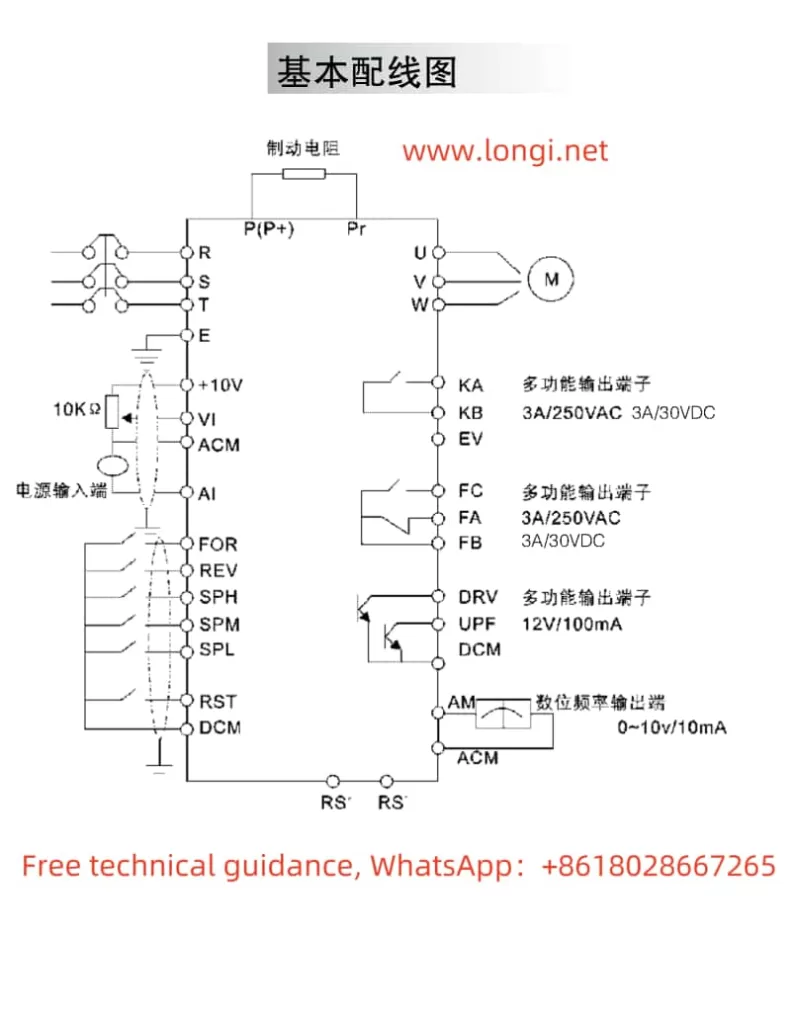

V. Wiring 12

1. Main Circuit Wiring Schematic Diagram 12

2. Description of Terminal Block 13

3. Basic Connection Diagram 15

4. Switches 15

5. Precaut ions on Wiring 16

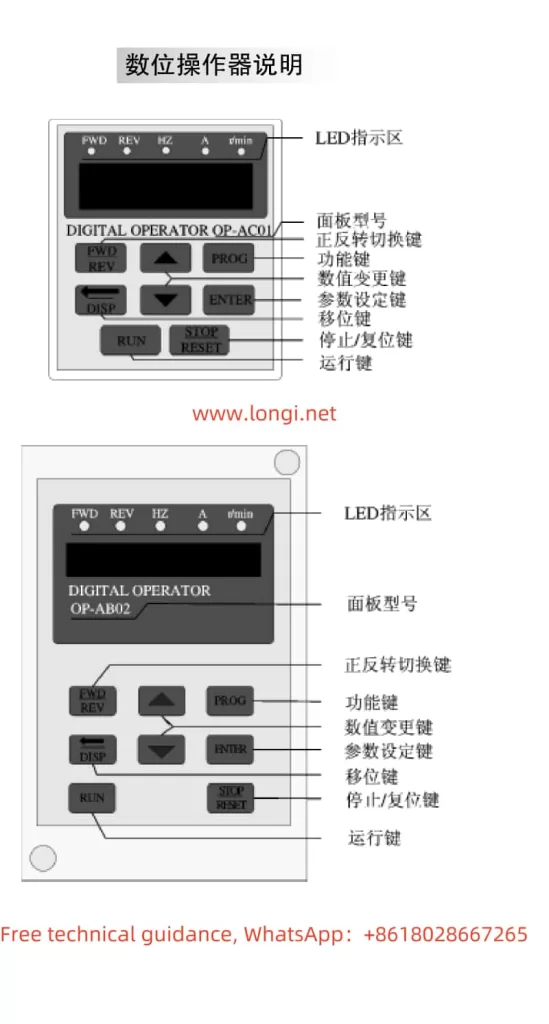

VI. Instruc tion of the LCP Digital Operator 19

1. Description of the LCP Digital Operator 19

2. Programming with LCP 19

VII. Parameter Overv iew 25

VIII. Parameter Descriptions 37

IX. Ma intena nce, Fault I nformat ion and Trouble shooting 90

1. Precautions about Inspection and Maint enance 90

2. Periodical In spection and Ma inten ance items 90

3. Fault Indication and Troubleshooting 91

3. Fault code descript ion and Analysis 92

HLP-NV Series

HLP-NV Series

IX. Appendices 96

Append ix 1: Mounti ng Dime nsions of HOLI P NV inverters 96

Append ix 2: Mount ing Dimensions of LCP Digit al oper ator 98

Append ix 3. Braking Resistor Disposition 98

Append ix 4. Simple Example of Appl iaction 99

Append ix 5:User’s feedback 106

HLP-NV Series

HLP-NV Series

I. Introduction

Than k you for purchas ing and using the gen eral- purp ose inver te r of

HLP-NV series of mu lti-functions and high performance.

Please read caref ully the operation m anual before putt ing the i nvert er to

use so as to correctly install and operate t he inverter, give f ull play to its

functions and ensure the safety. Please keep the operation manual handy

for future reference, maintenance, inspe ction and repai r.

Due to th e invert er of a k ind of ele ct rica l and elect ronic pr od uc t it

must be in sta lled, tested and adjust ed with parameters by specia lized

engineeri ng persons of motor s.

The ma rk s of

remind you of the s afet y and prevention caut ions d uring the handling,

inst allat ion, runn ing and inspection. Please follow t hese instructions to

make su re the safe use of the inver ter. In case of any doubt please contact

our local agent for consult ation. Our professional persons are w illing and

ready to serve you.

The manual is subject to change without notice.

Danger

Caution

and ot her sy mb ols in the ma nu al

Danger

Caution

indicates wrong use may k ill or injure people.

in di ca te s wro ng us e may damage the in ve rte r or

mechan ical system.

Danger

● Be sure to tur n off the input power supply before wiring.

● Do not touch any internal electrical circu it or component when the

charging lamp is sti ll on af ter t he AC power supply is disconnected,

which means the inver ter still has high voltage inside and it is very

dangerous.

● Do not check components and sig nals on the circuit boards dur ing

the operation.

● Do not dissemble or modify any internal con nect ing cord, wiring or

compone nt of the inverter by yourself.

● Be sure to make correct ground con nection of the earth terminal of

the inverter.

● Never remodel it or excha nge control boa rds and compon ent s by

yourself. It may expose you to an electrical shock or explosion, etc.

HLP-NV Series

— 1 —

HLP-NV Series

● Mo t or ov er lo ad prote cti on is inc lu ded in the defau lt set tin gs.

Parameter C01.90 Motor thermal protection is set to value ET R trip.

● Do not ma ke any vol ta ge-withstand ing test with any co mpone nt

ins ide the inverter. These sem i-cond uct or parts are subj ect to th e

damage of high voltage.

● Ne ve r connect th e AC m ain ci rc ui t powe r supply to th e out put

terminals U.V W of the inver ter.

● The main electric circuit boards of CMOS and IC of the inverter are

subject to the ef fect and d amage of st atic electricity. Don’t touch the

main ci rcuit boards.

● Installation, t esting and maintenance must be perfor med by qu alied

professional personnel.

● The inverter should be discarded as industrial waste. It is forbidden

to bur n it.

1. Checks upon Delivery

Th e inver ter has bee n str ictl y and well pa ck ed befo re ex-wo rk . In

co ns id er atio n of var io us fa ctor s d u rin g the tra nsp or tat io n spe ci al

attention should be paid to the followi ng points before the assembly and

installation. If there is anything abnor mal please notify the dealer or the

relevant people of our company.

● Check if the i nver ter has got any damage or defor mat ion during t he

transpor tation and handling.

● Check if the re is one piece of HLP-N V ser ies inverter and one copy of

the instruction manual ava ilable when unpacking it.

● Check the inform atio n on the n ameplate to see if the spe cif icat ions

meet your order (Operating voltage and KVA value).

● Check i f there is somethi ng wrong with the i nne r par ts, wir ing and

circuit board.

● Check if each te rm inal is tightly locked an d if there is a ny foreign

article inside the inver ter.

● Check if t he operator buttons are all rig ht.

● Check if t he option al components you ordered are conta ined.

● Check if t here is a ce rti cate of qu alication and a warr anty card.

Caution

— 2 —

HLP-NV Series

HLP-NV Series

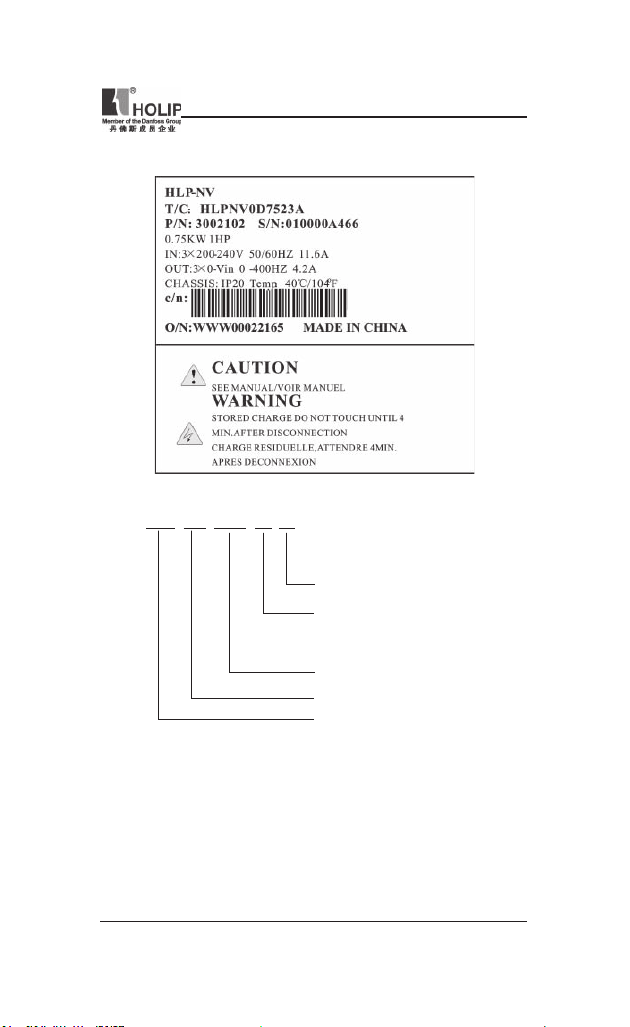

2. Nameplate Description of HLP-NV Series Inverter

Model HLP N V 0D75 23 A

Software Version: A

Voltage Rating: 21:1-Phase AC 220V

23:3-Phase AC 220V

43:3-Phase AC 380V

Inverter Capacity:0 D 75 mean s 0.75KW

Serial No: NV mean s NV ser ies

Trade Mark: HOLIP

HLP-NV Series

— 3 —

HLP-NV Series

II. Safety Precautions

1. Before the Power-up

● Check to be sure t hat the voltage of the main circuit AC power supply

matches the input voltage of the i nverter.

● The symbol

correct ground con nection of the earth terminals of the motor and the

inverter for safety.

● No conta ctor should be inst alled betwee n the power supply and the

inverter to be used for star ting or stopping of the i nvert er. Otherwise

it will affect the serv ice life of the inverter.

● R(L), S,T( N) ter mi nals are powe r input ter minal s, never mixed

with U.V.W t erm inals. Be sure that the wiri ng of the main circuit is

cor rec t. Other wise it will cau se damage s of the inve rt er when the

power is appl ied to it.

● The terminal of

to li ne zero. Otherw ise it will easily cause the prote ction or er rors of

the inverter.

, repr esents grou nd te rmi na ls . Be su re to ma ke

Danger

must be grou nded separately and never connect ed

Caution

● Do not ca rr y t he front cover of the inver ter directly when handling.

It should be hand led with the base to prevent the fall-off of the f ront

cover and avoid the dr opp ing of the inve rt er, which may pos sibly

cause the injur ies to pe ople and the damages to the i nvert er.

● Mount the i nver ter on a met al or other nonc ombustible mater ial to

avoid the risk of re.

● Insta ll the inverter in a safe loc ation, avoid ing hig h tempe rat ure,

direct sunlight, hu mid ai r or water.

● Kee p the inv erte r fro m th e re a ch of chi ldr e n or pe r so ns not

concer ned.

● The in ve r te r can only be use d at the pla ce s acc redit ed by our

com pa ny. Any unau th or iz ed work ing envi ronment may have th e

risks of re, gas explosion, ele ctric shock and other incidents.

● Install a he at sink or other cooling device when inst alling more than

one inverter in the same enclosure so that t he temperature in side t he

enclosu re be kept below 40℃ to avoid overheat or the risk of re.

Caution

— 4 —

HLP-NV Series

HLP-NV Series

● Be su re to tu r n of f t h e po we r s up ply bef o re d i sse mbl i n g or

assembl ing the operation key panel a nd xing the front cover to avoid

bad cont act causing faults or non- display of the oper ator.

● Do not in stall the inverter in a space with explosive gas to avoid the

risk of explosion.

● If the i nvert er is used at or above 1000m above seal level, the cooli ng

efciency will be worse, so please run it by de-rating.

● Do not install any c ontactor and other comp onents of cap acit or or

var istor on the o utp ut side of the inverter. Other wise it will cau se

malfunctions and damages of components of the inverter.

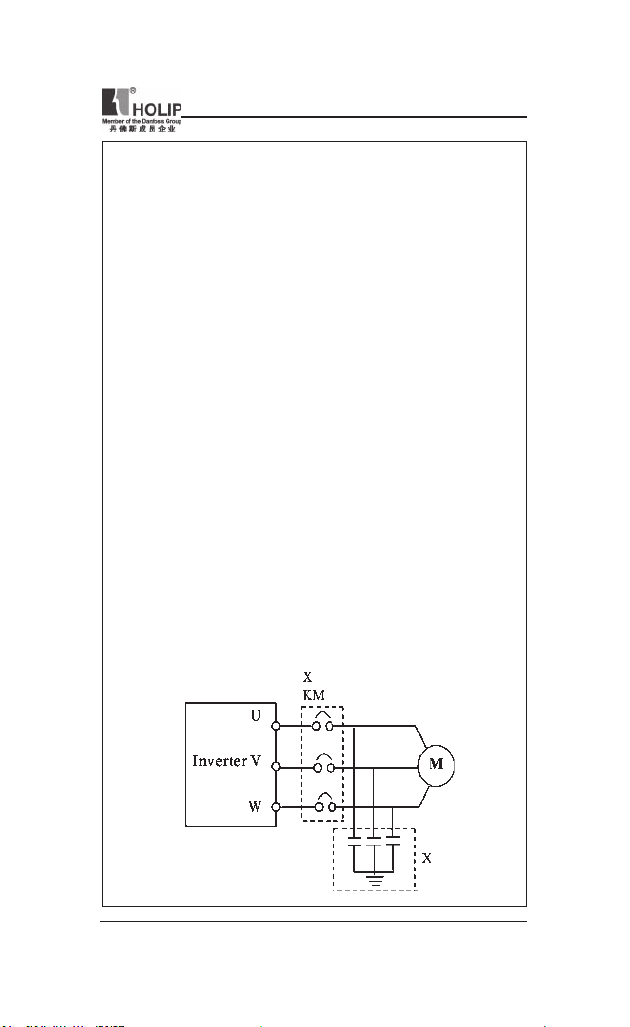

● Do not ins tall any switch co mp on en t like ai r cir cu it brea ke r or

cont actor at t he output of the i nverter. If any of such components

mu st be ins t al led beca use of t he req uir e me nts of pro ces s and

others, it must be ensu red that the inverte r has no out put when the

swit ch acts. In addit ion, it is forbidden to install any c apacitor for

improvement of power factor or any varist or agai nst thunder at t he

output. Othe rwise it will cause malfunctions, tr ipping protection a nd

damages of components of the inverter. Please remove them as shown

in the below diagr am.

● It wi ll affect the service life of the inverter if a contact is connected

to the front end of input of the inver ter t o cont rol its starts and st ops.

Generally it is re qu ir ed to cont rol it thr ou gh Con trol term inal s.

Special attention should be p aid t o its use in the case of frequent

star ts and stops.

● Pleas e use an indep ende nt powe r supply for the i nver ter. D o avoid

using the common power supply with an electrical welder and other

equipme nt wi th st ro ng di st urbance. Ot herwise it wi ll ca us e the

protection or even d amage of t he inver ter.

HLP-NV Series

— 5 —

HLP-NV Series

2. During the Power-up

● Do not plug the conne ctors of the inve rter du ri ng the power up to

avoid any surge i nto the main control board due to pluggi ng, which

might cause the damage of the inverter.

● Always have the protective cove r in place before the power up to

avoid electrical shock injur y.

Danger

3. During the Operation

● Never c onnect or discon nect the motor set while the inverter is in

run ning. O ther wise it will cause over-current trip and even bur n up

the mai n circu it of the inverter.

● Never rem ove th e fr ont cover of the inverter w hile the inve rt er is

powered up to avoid any inju ry of electric shock.

● Do not come close to the machine when the fault resta rt fu nction is

use d to avoid any thing unexp ect ed. The m otor may automa tic ally

resta rt af ter its stop.

● The f unction of STOP Swit ch is on ly valid af ter set ti ng, which is

different with the use of emergent stop switch. Please pay attention to

it when usi ng it.

Danger

● Do not touch the heat sink, braking resistor, or other heat elements.

Caution

These can become very hot.

● Be sure that the motor and m achine is withi n the applicable spe ed

ranges before sta rting operat ion because the inver ter is quite easy to

run f rom lower speed to higher sp eed.

● Do not check the sign al s on ci rcuit bo ar ds wh ile the inve rt er is

run ning to avoid danger.

● Be caref ul when changing the inver ter settings. The inverter has been

adju sted and set before ex-work . Do not a djust it wanton ly. Please

make proper adjustments according to the requ ired f unct ions.

● Do consider the vib ration, noise an d the speed limi t of the motor

bearings and the mechanical devices whe n the inverter is ru nni ng at

or above the f requency of 50Hz.

— 6 —

HLP-NV Series

HLP-NV Series

4. After the Power-off

● Touching t he electrical parts may be fatal — even afte r the equipment

ha s been disco nn ec ted f rom mains. Also ma ke su re th at ot he r

voltage input s have been disconnected, (li nkage of DC intermediate

circuit).

● Be aware that there may be high volt age on the DC lin k even when

the LEDs a re tu rned of f.

● Before touching any potentially live parts of the VLT Micro, wait at

least as follows:

200 — 240 V, 0.4 – 1.5 kW: wait at lea st 4 minutes.

380 — 480 V,0.75 – 2.2 kW: wait at least 4 minutes.

Shor ter time is allowed only if indicated on the nameplate for t he

specic unit.

HLP-NV Series

— 7 —

HLP-NV Series

III. Standards and Specications

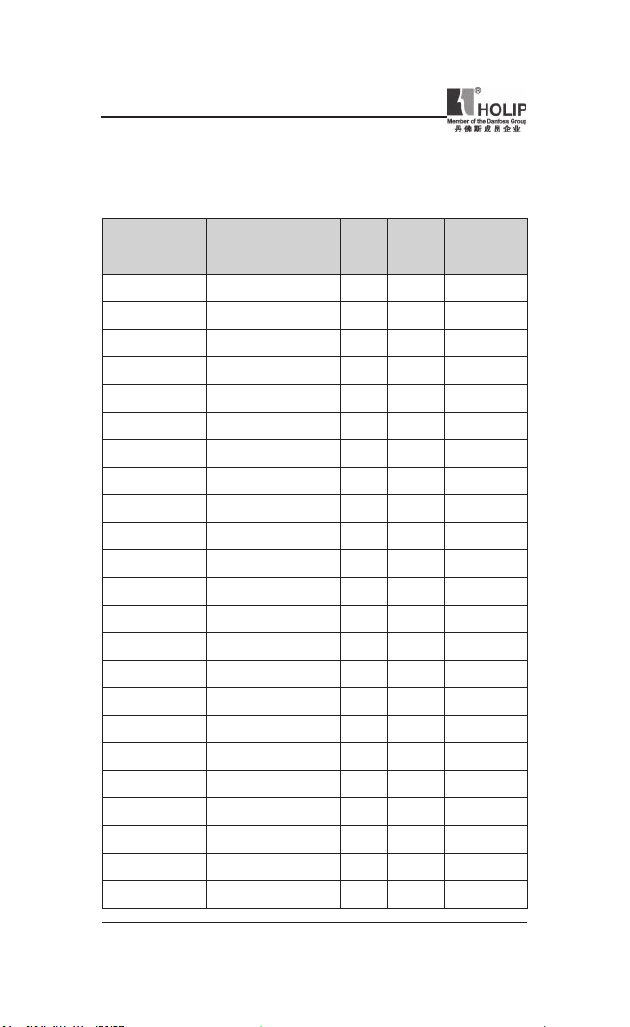

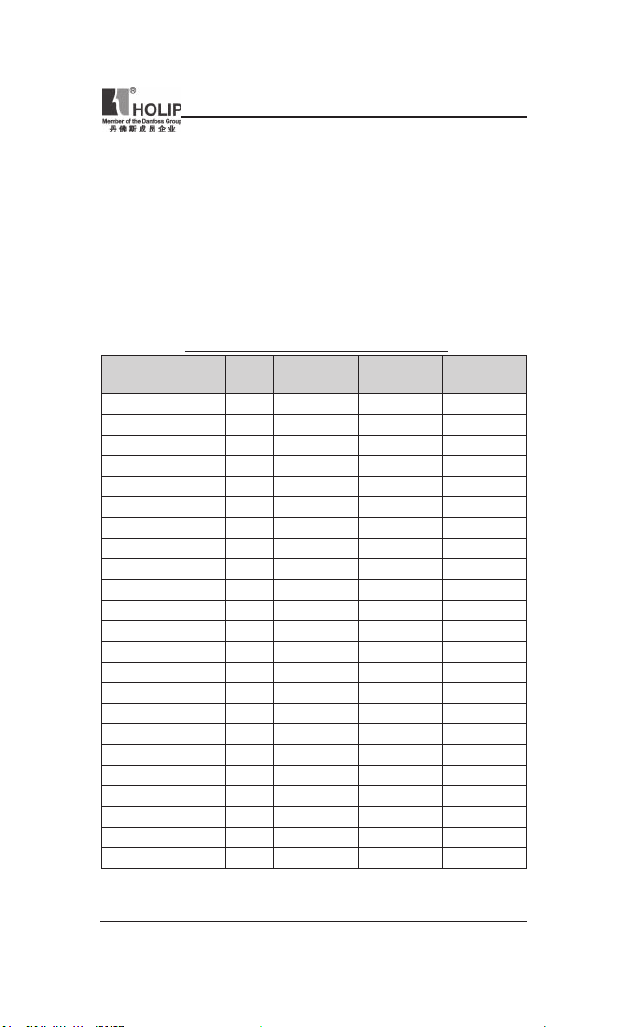

1. Particular Specications

Outp ut

Model Input Voltag e

HLPN V0D1821A 1×200-240V 50/60H z 0.18 1.2 0.18

HLPN V0D3721A 1×200-240V 50/6 0Hz 0.37 2.2 0.37

HLPN V0D7521A 1×200-240V 50/60 Hz 0.75 4.2 0.75

HLPN V01D521A 1×200-240V 50/60Hz 1.5 6.8 1.5

HLPN V02D221A 1×200-24 0V 50/60Hz 2.2 9.6 2.2

HLPN V0D2523A 3×200-240V 50/60Hz 0.25 1.5 0.25

HLPN V0D3723A 3×200-24 0V 50/60Hz 0.37 2.2 0.37

HLPN V0D7523A 3×200-24 0V 50/60Hz 0.75 4.2 0.75

HLPN V01D523A 3×200-240V 50 /60Hz 1.5 6.8 1.5

HLPN V02D223A 3×200 -240V 50/60Hz 2.2 9.6 2.2

HLPN V03D723A 3×200-24 0V 50/60Hz 3.7 15.2 3.7

HLPN V0D3743A 3×380-480V 50/60Hz 0. 37 1.2 0.37

HLPN V0D7543A 3×380-48 0V 50/60Hz 0.75 2.2 0.75

HLPN V01D543A 3×380-480V 50/60Hz 1.5 3.7 1.5

HLPN V02D243A 3×380- 480V 50/60Hz 2.2 5.3 2.2

HLPN V03D043A 3×380- 480V 50/60Hz 3.0 7.2 3.0

HLPN V04D043A 3×380- 480V 50/60H z 4.0 9.0 4.0

HLPN V05D543A 3×380-480V 50/60Hz 5.5 12 5.5

HLPN V07D543A 3×380- 480V 50/60Hz 7.5 15.5 7.5

HLPN V001143A 3×380-48 0V 50/60Hz 11 23.0 11

HLPN V001543A 3×380 -480V 50/60Hz 15 31.0 15

HLPN V18D543A 3×380-480V 50 /60Hz 18.5 37.0 18.5

HLPN V002243A 3×380-480V 50/60 Hz 22 43.0 22

Power

(KW)

Cur rent

(A)

Suitable

Motor

(KW)

— 8 —

HLP-NV Series

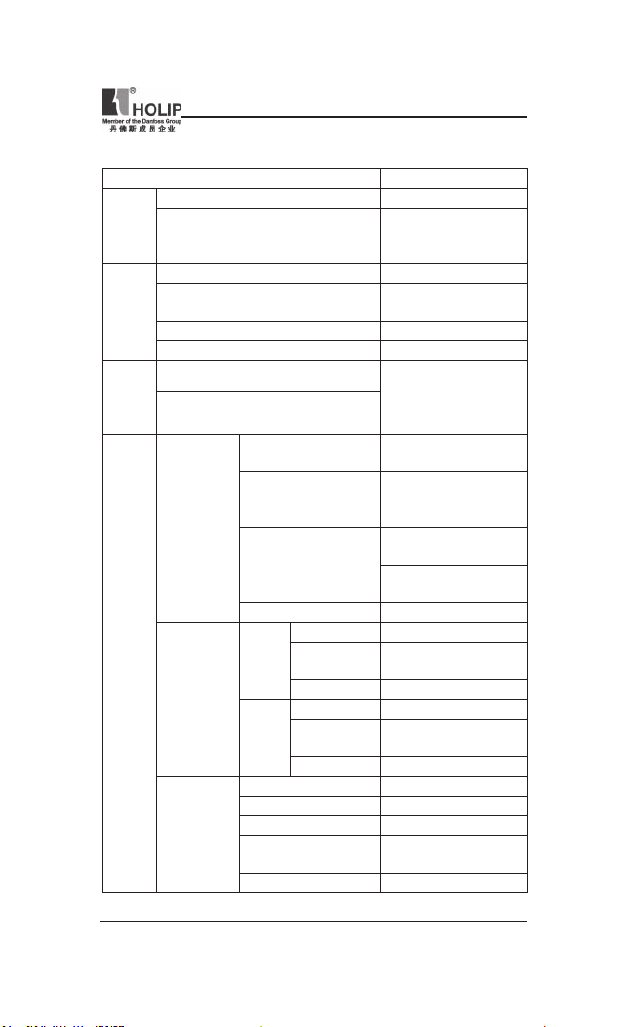

2. General Specications

Inverter Ser ies H LP-NV

Frequency 48~62HZ

Power

supply

Supply Voltage

Output voltage 0~100% of supply volt age

Output frequency

Motor

output

Over load 150% of rated cu rrent

Acc/De c time 0.05~3600s

Runn ing control

Control

Frequency sett ing

Number

Progr ammable

digital inputs

Control

terminals

Anology

inputs

Anology

output s

Voltage level

Logic Voltage level

Input resistance 4KΩ

Number 1;ter minal nos.: VI N

Voltage

Voltage level

Input resistance 10KΩ

Number 2; ter minal nos.: VI N,AIN

Cur rent

Cur rent ra nge

Input resistance 200 Ω

Number 1;Te rmi nal nos.: AO

Output Cur rent ra nge 0/4-20mA

Max.Load 500 Ω

Accuracy

Resolution 8bit

380~480V±10% for 380V

single/three phase

200~240V±10% for 220V

0-200H Z(V VC+),

0-400HZ(V/F)

LCP operate;

Multi input ter minals;

RS 485 ser ial

commu nication

5, term inal nos.: RUN

F/R,RST,JOG,EMS

0~24V DC (“PN P” OR

“NPN ”) ; Maximum

input: 28V DC

PNP: “0”<5VDC;

“1”>10VDC;

NPN: “0” >19VDC;

“1” <14VDC

0-10V DC ;

Maximum input 20V DC

0/4-20mA(scaleable);

Maximum input: 30mA

Max.er ror:0.5% of full

scale

HLP-NV Series

;

,

HLP-NV Series

— 9 —

HLP-NV Series

24V DC

RS 485

Control

terminals

Realy out pus

10V DC output

Enclosure IP20

Ambient temper ature -10℃~50

Max.relative hum idity 5%-95%

Surroundings

Vibration test 1.0g

Max.altitude above sea level

Electronic the rmal motor prot ection against overload.

Temperature monitoring of the heatsink ensures that the fre quency

converter tr ips if the temperatu re reaches 95 °C ± 5°C. An overload

temperatu re can not be reset until the temperature of t he heatsink

is below 70 °C ± 5°C (Guideline — these temperatures may vary for

different power si zes, enclosures etc.).

The frequency converter is protected against short-circuits on motor

terminals U, V, W.

The frequency converter is protected against ear th faults on motor

Protection

terminals U, V, W.

Functions

Monitor ing of the inter mediate circuit voltage ensures that t he

frequency conve rter trips if the intermediate circuit voltage is too low

or too hig h.

If a motor phase is missing, the frequency converter may tr ip.

If mains fault occurs, the frequency converter will ramp down to stop

and issues a war ning.

If a mains phase is missing, the frequency conver ter trips or issues a

warn ing (dependingon the load).

Terminal number EV

Max.load 200m A

Terminal number

Ground for RS485 COM

Terminal number

Resistive load

Max

load

Inductive load

Terminal number +10V

Output voltage 10.5±0.5V

Max.load 25mA

RS+(TX+,RX+),

RS- (T X-,RX-)

1,FA-FB(make),

FA-FC(break)

250V AC 2A

30V DC 2A

250V AC 0.2A

24V DC 0.1A

1000m

3000m(derati ng)

℃

— 10 —

HLP-NV Series

HLP-NV Series

IV. Storage and Installation

1. Storage

The invert er mu st be kept in its or iginal package box before in stallation.

Pay at tention to the followings when keeping it in storage if the inver ter

is not used for the time being:

● It must be stored in a d ry pla ce without rubbish or dust.

● The suitable temperat ure for storage is between -20℃ and +65℃.

● The relative humidity required is 0-95% without condensation.

● There is no corrosive gas or l iquid in t he storage ambience.

● It’s better to lay the inverter on a rack and keep it in a proper package.

● It is better not to store the inverter for long time. Long t ime storage of

the inver ter wil l lead to the deterioration of electrolytic capacity. If it

needs to b e stored for a long ti me make sure t o power it up one time

withi n a year and t he power-up ti me should be at least above ve hours.

When powered up t he voltage must be increased slowly with a voltage

regulator to the rated volt age value.

2. Installation Site and Environment

The inverter should be instal led at the following location:

● Ambient temper ature -5℃ to 40℃ with good ventilation.

● No water d rop and low moisture.

● Free from direct sunshine, h igh temperat ure and heavy dust fall.

● Free from corrosive gas or liquid.

● Less dust, oil gas and metallic pa rticles

● Free from vibration and easy for ser vice and inspection.

● Free from the interference of elect romag netic noise.

Attention : The ambient condit ions of the invert er will aff ec t its

service life.

3. Installation and Direction

● Th er e mu st be en ou g h sp ace lef t ar ound the inv er te r for eas y

maintenance and cooling.

● The inverter must b e installed vertically wit h the smooth ventilation

HLP-NV Series

— 11 —

HLP-NV Series

for effect ive cooling.

● If t here is a ny instabi lity when installi ng t he inverter, please put a at

board u nder the invert er bottom base and inst all it again. If the inverter

is installe d on a loose surfa ce, st ress may cause damage of part s in the

main ci rcuit so as to damage the inverter.

● The inverter should be in stalled on non-combustible mater ials, such as

iron plat e.

● If sever al inver ters are inst alled , up per an d lower, toget her in one

cabine t, pleas e add heat dissipation pla tes and lea ve enoug h space

between the inverters.

— 12 —

HLP-NV Series

V. Wiring

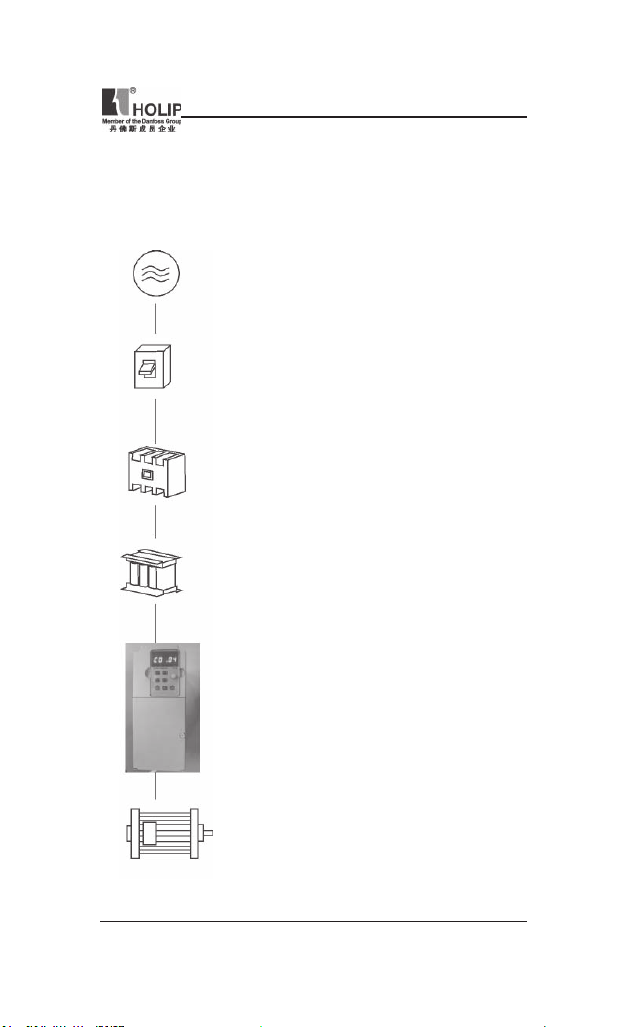

1. Main Circuit Wiring Schematic Diagram

Power supply:

● Verif y that the i nver te r’s r ate d volta ge coi ncid es

with AC p ower supply voltage to avoid a damage

of the inver ter.

No fuse breaker:

● Refer to the related list.

Ground fault circuit interrupter:

● Use one of anti-high harmonic.

Electromagnetic cont actor:

● Note: Do not use the electromagnetic contactor as

the on/off button of power supply for t he inver ter.

AC reactor:

● It is re commended to in st al l an AC reactor for

power factor improvement if the input capacit y is

more tha n 1000KVA.

Inverter:

● Be sur e to make correct c onnections of the main

ci rcu it wire s an d con t ro l sig nal wire s of the

inverter.

● Be s ure to make corre ct sett ing of para meters for

the inverter.

HLP-NV Series

HLP-NV Series

— 13 —

HLP-NV Series

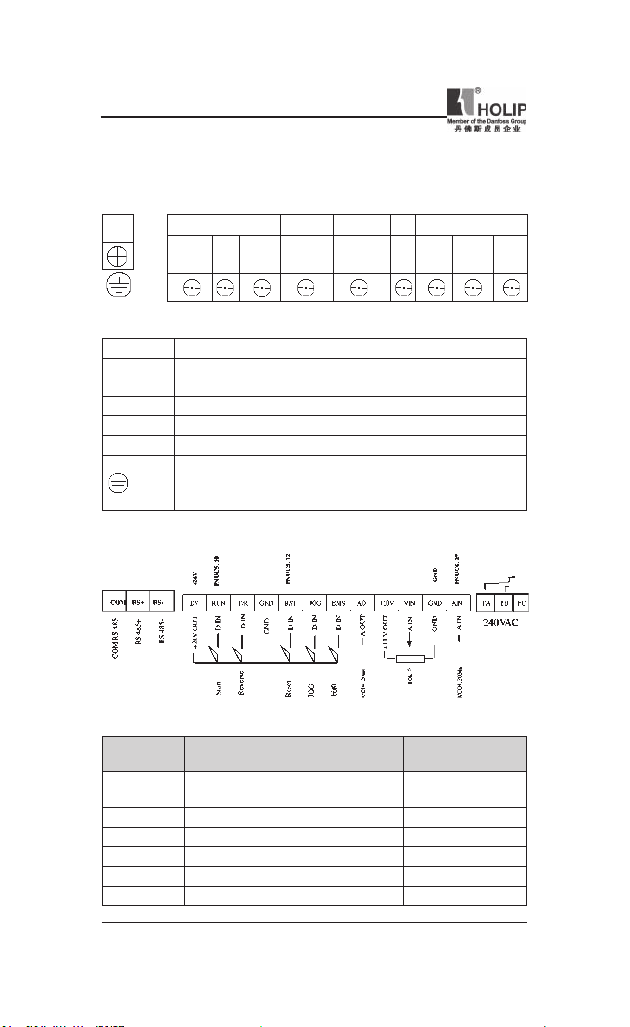

2. Description of Terminal Block

1)Arr angeme nt of Main ci rcuit Term inals

POWER MOTOR

R

L)

(

Function Description of Main circuit Terminals

Symbol Function Description

R S T

U.V.W Out put ter minal of the inve rter

+UDC BR Conne ctor for br aki ng resistor (optional).

-UDC Connector for DC reactor

2) Arra ngement of Control Circuit Terminals

In pu t ter min al of AC li ne power. (220V class:for bot h

single/three phase, si ngle phase connected to L and N)

Grou nd ter minal: the third method of g rounding for 220V

and special grou nding for 380 V of Electrical Engineering

Regulations.

T

S

-UDC +UDC BR U V W

(N)

Function Description of Control Ci rcuit Terminals

Symbol Function Descr iption

EV

RUN Multi- Dig ital Input Start

F/R Multi- Dig ital Input Reverse

GND Digital Ground (for 24V power)

RST Multi- Dig ital Input Reset

JOG Multi- Dig ital Input Jog

— 14 —

Common Terminal of Digital and

Control Signals ( +24V Power)

HLP-NV Series

Default setting

setting

HLP-NV Series

Symbol Function Descr iption

EMS Multi- Digital Input Bit0

AO Multi- Analog Output 0/4-20m A

+10V Power Supply for Analog Setti ng +10V

VIN Multi- A nalog input Voltage

GND Analog Ground

AIN Multi- A nalog input 0/4~20mA

FA FB FC Multi- Dig ital Output (Relay)

COM RS+ RS —

RS485 Com munication port

Default setting

setting

FA-FC:break

FA-FB:make

COM:Common for

RS+ and RS —

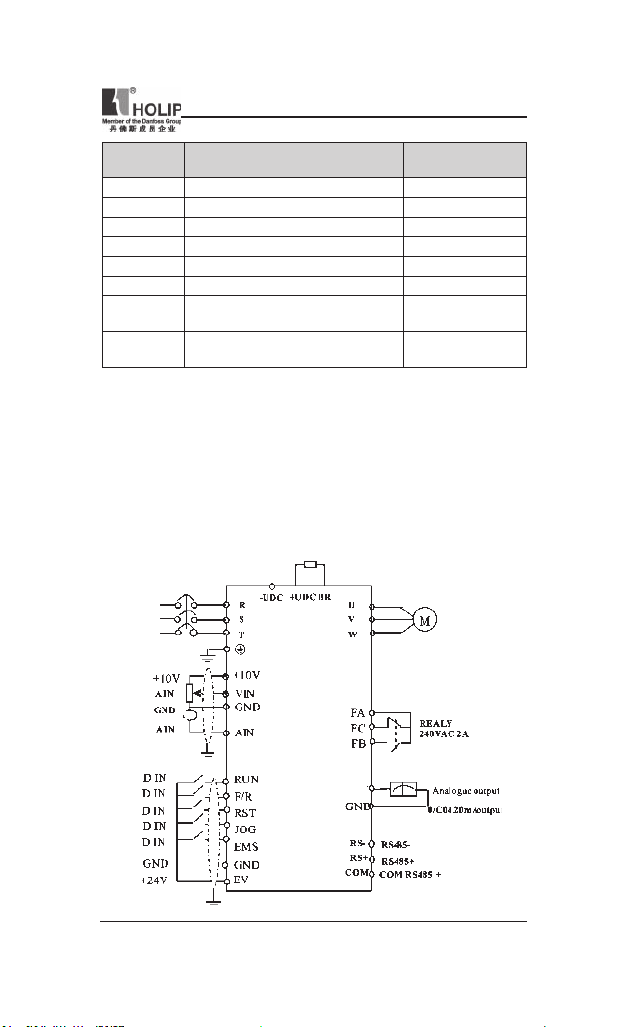

3. Basic Connection Diagram

The wiring of t he inver ter is d ivided i nto two parts, main circuit terminal

connectio ns an d cont rol ci rc uit te r mi na l connec tion s. The user can

see the m ai n ci rcuit terminal s an d th e contr ol circu it term in als af ter

remov in g the cover of encl os ur e. The ter mi nals must be co nnected

correctly as t he following wiring circuit diagrams.

The following diagram shows the Default setting standard con nection of

Model HLP-N V

HLP-NV Series

AO

— 15 —

HLP-NV Series

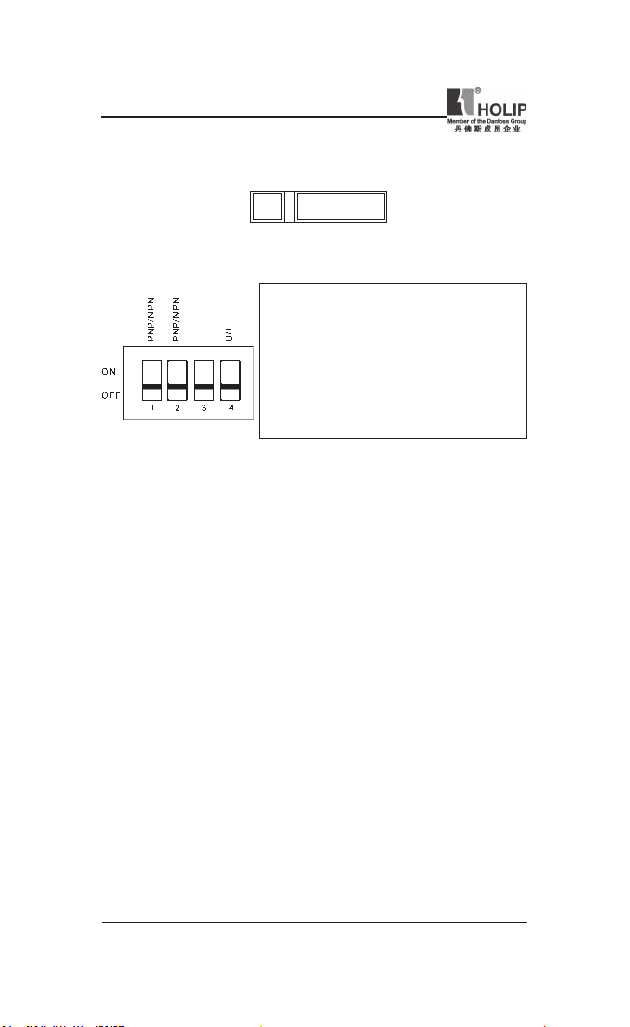

4. Switches

i. Bus ter mination:

OFF

Mark:Swit ch BUS TER enables termination of the RS485 port, term inals

RS+, RS-.

ii. Switches 1-4:

ATT EN TI ON: Para me te r C06.19 must be set acco rd in g to Switc h 4

position.

Warni ng: D o not oper ate swi tch es with pow er on the fr equ e nc y

converter.

BUS TER

ON

Switch 1: *OFF = PNP t erm inal JO G

ON = NPN te rmi nal JOG

Switch 2: *OFF = PNP t erm inals RUN,

F/R,R ST,EMS

ON = NPN te rmi nals RUN ,

F/R,R ST,EMS

Switch 3: No fun ction

Switch 4: *OFF = Termi nal VIN 0 — 10 V

ON = Termin al VI N 0/4 — 20 mA

* = default s etti ng

5. Precautions on Wiring

1) For the main circuit wiring:

● Wh ile wiring the sizes and specications of wires should be selected

an d the w iri ng sho ul d be exe cu t ed acc ord i ng to the elect ric al

engineeri ng regu lations to ensure the safety.

● It is better to use shielded wire or wire and conduit for power cord and

ground the shielded layer or t wo ends of wire conduit.

● Be sure to install a Non Fuse Breaker ( NFB) bet ween the power supply

and the in put te rminal s (L1.L2. L3). (If usin g grou nd fau lt circ ui t

inter rupter, please choose one corre sponding to high frequency)

● Ne ve r con ne ct AC powe r t o the outp ut ter min al ( U.V.W) of the

inverter.

● Outpu t wi res mus tn’t b e in tou ch of the metal part of t he inver ter

enclosu re, or it will result in ear th short-ci rcuit.

● Phase -s hift ing capacitors , LC, RC noise fi lte rs , etc, can never be

connected to t he output terminals of the inverter.

● The main ci rcuit wire must be enough far away from other control

equipments.

— 16 —

HLP-NV Series

HLP-NV Series

● W hen th e wiring be tw ee n the invert er and the motor exc ee ds 15

meter s (shielded wire) or 50 meters (No shielded wire), much higher

dV/dT will be produced inside the coil of t he motor, which wi ll cause

the destr uction to the interlay or insulation of t he motor. Please use a

dedicated AC motor for the inver ter or add a react or at the inverter.

● Plea se lower the car rier frequ enc y whe n there is a longer di stance

bet ween the inverter a nd the motor. Beca use t he higher t he carr ier

frequency is t he bigger t he leak age cur rent of h igh-order ha rmon ics in

the cables will b e. The leakage current will have unfavorable effect on

the inverter a nd other equipme nt.

Specications of Non Fuse Breaker and Wire

Model

(A)

Input wire

mm

2

Output wire

2

mm

Control wire

2

mm

NFB

HLPNV0D1821A 16 2.5 2.5 0.5

HLPNV0D3721A 16 2.5 2.5 0.5

HLPNV0D7521A 16 2.5 2.5 0.5

HLPNV01D521A 16 2.5 2.5 0.5

HLPNV02D221A 32 4 4 0.5

HLPNV0D2523A 16 2.5 2.5 0.5

HLPNV0D3723A 16 2.5 2.5 0.5

HLPNV0D7523A 16 2.5 2.5 0.5

HLPNV01D523A 32 2.5 2.5 0.5

HLPNV02D223A 32 4 4 0.5

HLPNV03D723A 32 4 4 0.5

HLPNV0D3743A 16 2.5 2.5 0.5

HLPNV0D7543A 16 2.5 2.5 0.5

HLPNV01D543A 16 2.5 2.5 0.5

HLPNV02D243A 16 2.5 2.5 0.5

HLPNV03D043A 16 2.5 2.5 0.5

HLPNV04D043A 32 4 4 0.5

HLPNV05D543A 32 4 4 0.5

HLPNV07D543A 40 6 6 0.5

HLPNV001143A 63 6 6 0.5

HLPNV001543A 100 6 6 0.5

HLPNV18D543A 100 10 10 0.5

HLPNV002243A 100 16 16 0.5

Attention: The parameters i n the list are only for reference and should not

be regarded as st anda rd.

HLP-NV Series

— 17 —

HLP-NV Series

2) For control circuit wi ring (signal line)

● The signal line should be separately laid in a different conduit with t he

main ci rcuit wire to avoid any possible i nterference.

● Please use the shielded cable wit h the size of 0.5-2mm2 for signal lines.

● Use the control terminals on the control panel correctly accor ding t o

your needs.

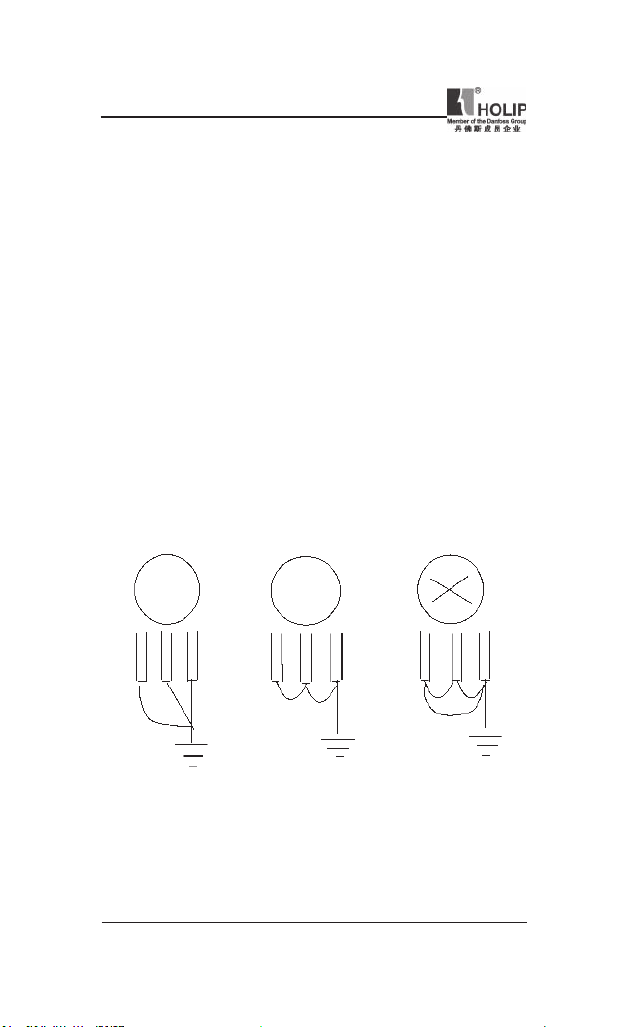

3) Grounding

● Grounding terminal E. Be sure to make cor rect g round ing

220V class: The third grounding method (Grou nding resistance should

be 100Ω or lower.)

380V class: The special third grounding met hod (Grounding resistance

should be 10Ω or lower.)

● Choose grounding w ires according to the basic length and siz e of the

technical require ments of the electric equipment.

● Do avoid shar ing ground ing wire with other large power equ ipment

such as el ec tr ic welder, power ma ch in e, et c. The gr ou nd in g wir e

should be kept away from the power supply wire s for la rge power

equipment.

● The grounding method for several inverters together should be done as

the rst and sec ond diag rams below. Avoid the third loop.

● The groundi ng wire must be as short as p ossible.

(1) Good (2) Good (3) Not good

— 18 —

HLP-NV Series

HLP-NV Series

VI. Instruction of the LCP Digital Operator

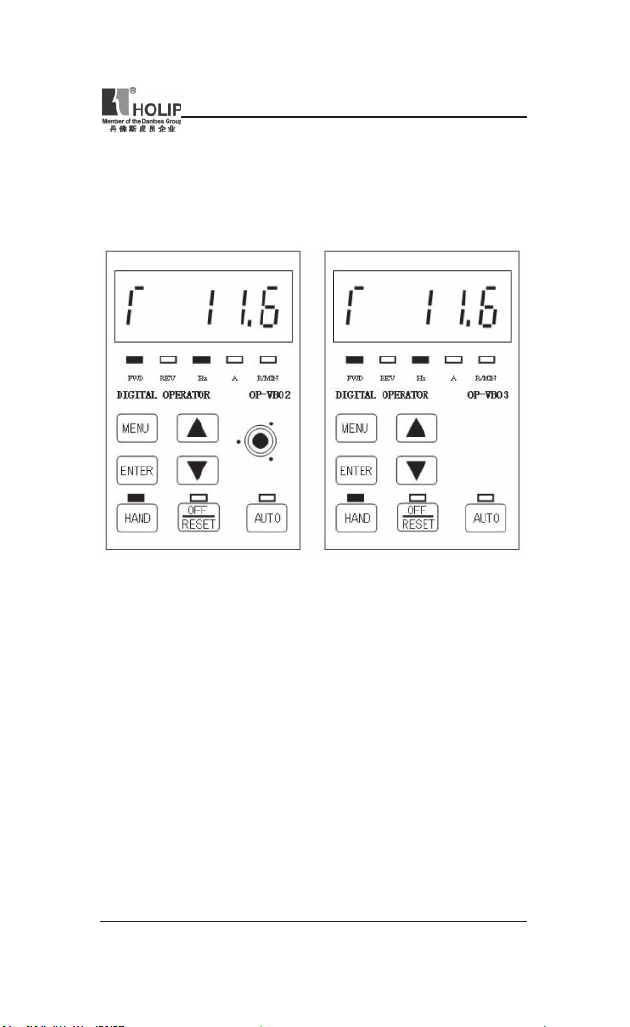

1. Description of the LCP Digital Operator

LCP with potentiometer

2. Programming with LCP

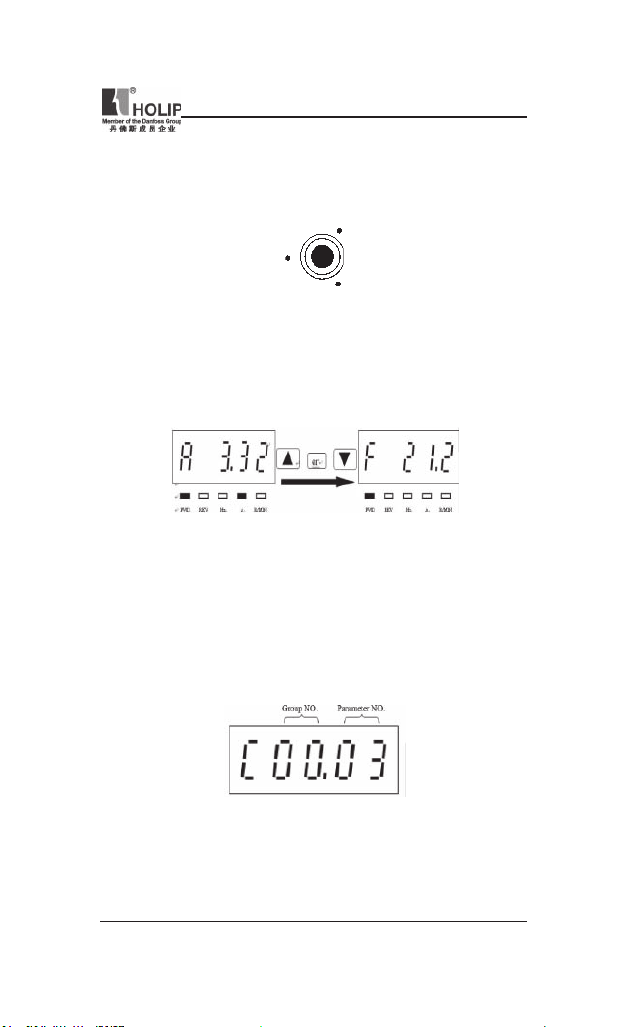

2.1. LCP introduction:

1. 5 numeric d isplays

2.

8 LEDs: FWD、REV、Hz、A、R/MIN、HAN D、OFF/RESET、AUTO

3. 7 keys: MENU、ENTER、▲、▼、HAN D、OFF/RESET、AUTO

4. 1 potent iometer (only for type OP-VB02).

LCP without potentiometer

HLP-NV Series

— 19 —

HLP-NV Series

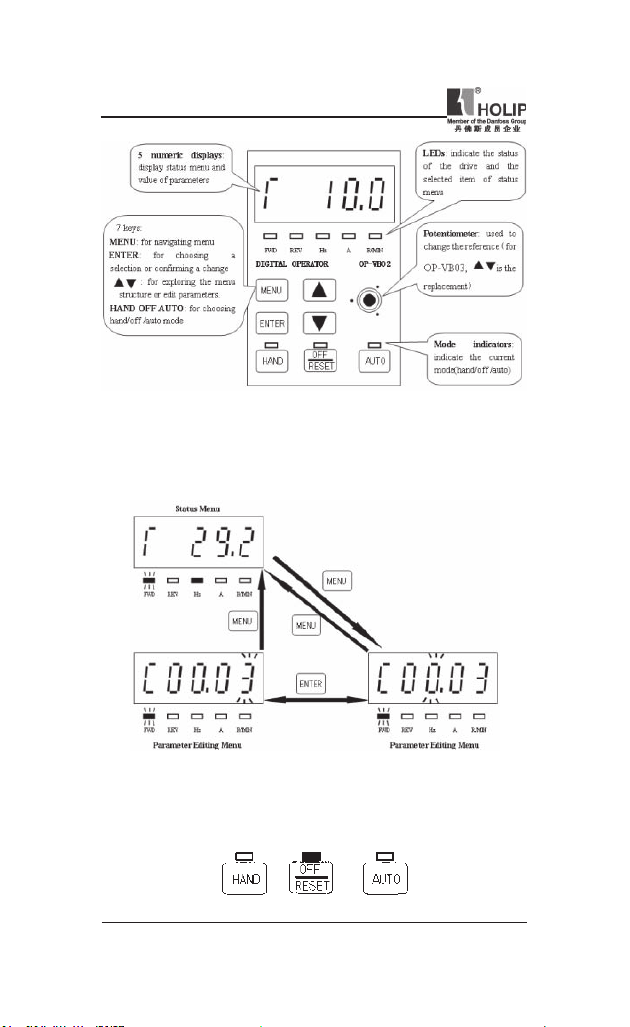

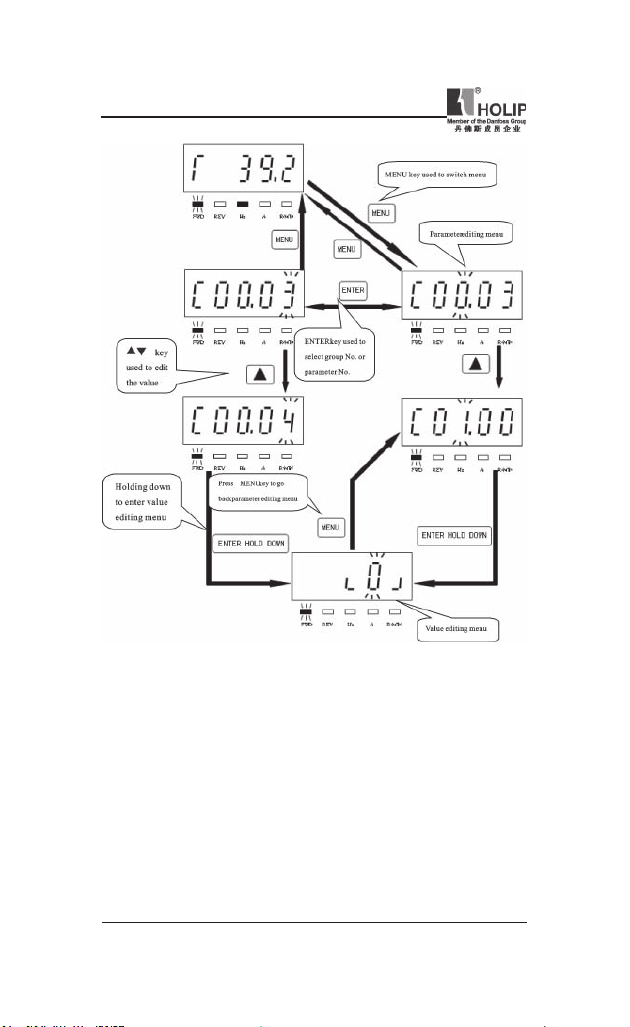

2.2

General Operation

.

The me nu syst em allows op er ators to nav igate th ro ug h hierarchica l

menus which contain related menu items. The top-level menu c onta ins

two menu items: statu s menu、parameter editing menu. These two items

can be explored by pressing MENU key:

2.3

Mode keys and potent iometer

.

Mode Keys are u sed to send Hand, OFF/Reset, Auto request to the dr ive.

It is related to the reference site selection ( Local or Remote).The yellow

LEDs ind icate the certain active mode.

— 20 —

HLP-NV Series

HLP-NV Series

The HAND, OFF/RESET a nd AUTO key ca n be dis abled by chang ing

parameter(C00.40、C00.41、C00.42).

Potentiometer: used for set ting t he refere nce only.

The pot entiometer can be used in bot h hand and auto mode wit h different

functionality:

In Ha nd mode the potentio me te r will work as the arr ow key s – i .e.

controlli ng the local refere nce fr om 0 to max reference (C03.03). If the

LCP does not c ont ain a pot entiom ete r, the ar row keys ar e used to set

reference:

In auto mode the potentiometer will act a s an ext ra analog input to the

system. It is selected/deselected as the other analog input s (see C03.15 to

C03.18).

C06.81, C06.82 are used to scale the potentiometer input.

2.4 Parameter editing menu and st atus menu

2.4.1 Parameter editing menu:

HLP-NV Series

— 21 —

HLP-NV Series

Parameter set ting example:

How to set C03.17 to 21

1. Pressing MENU key to let the display go to parameter ed iting menu.

2. Pressing▲▼key to select group No.(C03.00)

3. Pressing ENTER key t o edit par ameter No.,then p ressing▲▼key to

select paramet er No. (C03.17).

4. Hold in g down EN TER key to go to the va lue edtin g menu , then

pressi ng▲▼to edit the value of the parameter to 21,then holding down

ENTER key to conrm t he change till “END”was displayed.

— 22 —

HLP-NV Series

HLP-NV Series

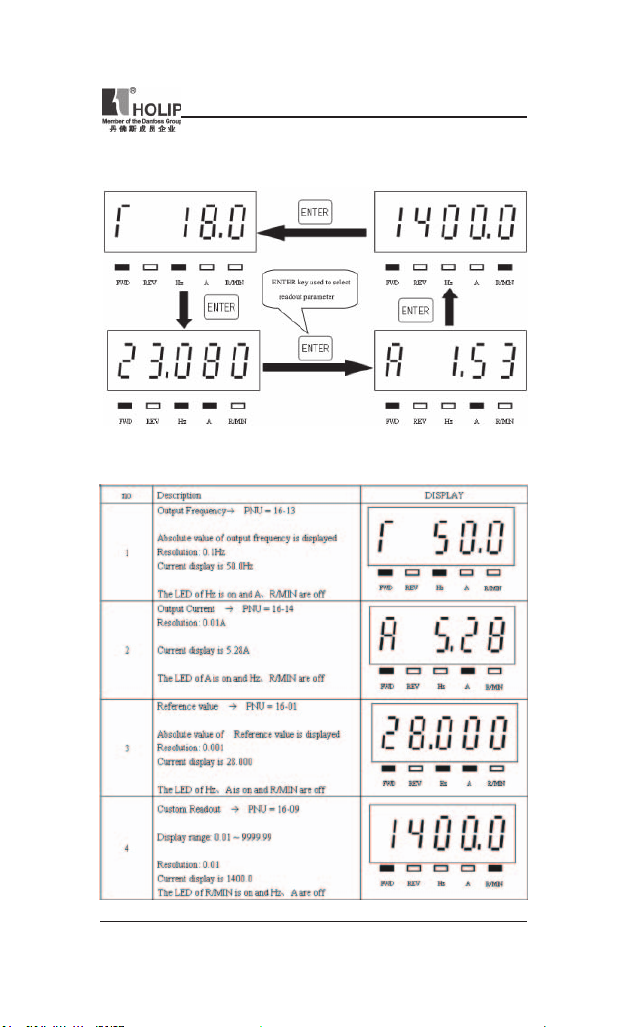

2.4.2 Readout and indicator:

The readout par amete rs toggled by pressing ENTER key:

The below table shows the screen of displayi ng every readout parameter

HLP-NV Series

— 23 —

HLP-NV Series

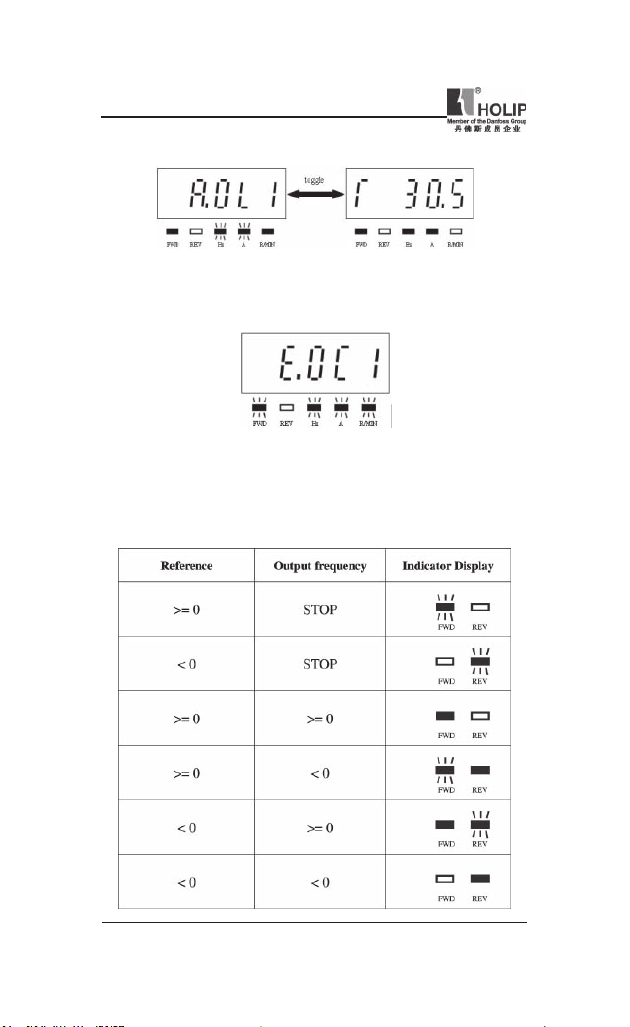

Warning descr iption:

when war ning o ccur red , the LEDs of Hz、A w ill ash a nd R/MIN will

be lit.

Alar m description:

when ala rm occur red, the LED s of Hz、A and R/ MIN will f lash,an d

the drive will trip. A trip ca n be cancelle d by pressing reset or, in some

cases, aut omatically. A locked trip ca nbe cancel led by cutting off mains

and restarting the drive.

The motor direction is indicated by the led s of FWD and REV:

— 24 —

HLP-NV Series

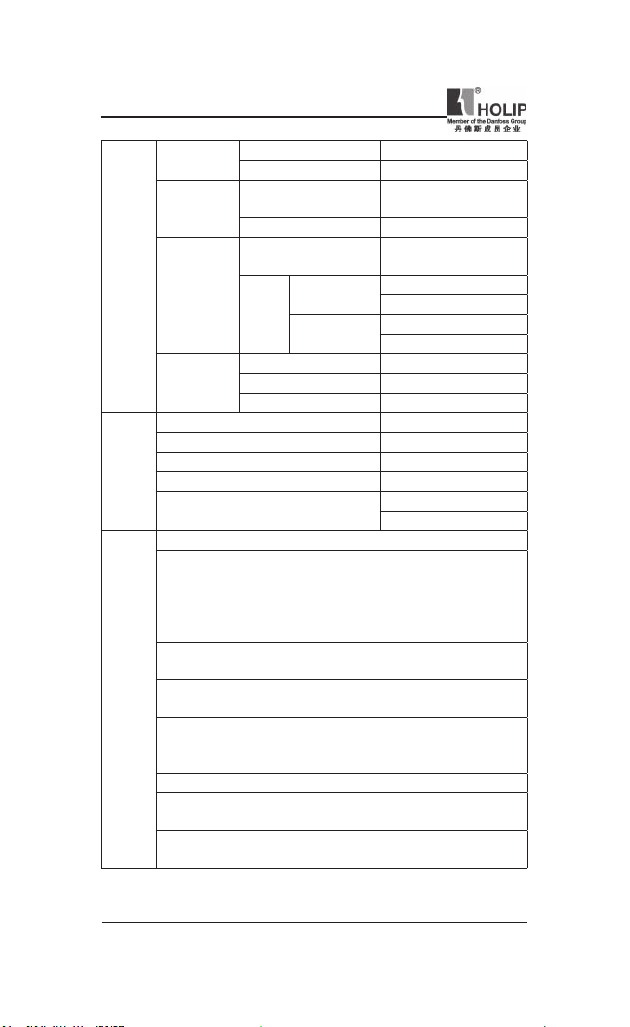

VII. Parameter Overview

Function

Item

Operation

/ Display

Load /

Motor

Fuction Description

Code

Op er. St at e at Power-

C00.04

up [Hand]

Cu st om Re ad ou t Min

C00.31

Scale

Custom Readout Max

C00.32

Scale

C00.40 [Hand on] Key on LCP

[Off / Re se t] Ke y on

C00.41

LCP

C00.42 [Auto on] Key on LCP

C00.60 Menu locked

C01.00 Conguration Mode

Motor Cont rol

C01.01

Principle

C01.03 Torque Character istics

Local Mode

C01.05

Cong urat ion

Motor Power

C01.20

[kW] [HP]

C01.22 Motor Voltage 50 — 999 V **

C01.23 Motor Frequency 20 — 400 Hz 50 Hz

C01.24 Motor Current 0.01 — 26.00 A **

C01.25 Motor Nom inal Sp eed 100 — 9999 r pm **

Automatic Motor

C01.29

Tuning (AMT )

C01.30 Stator Resistance (R s)

HLP-NV Series

Range&Function

explanation

[0] Resume

*[1] Forced sto p, ref =

old

[2] Forced stop, ref = 0

0.00 – 9999.00 0.00

0.00 – 9999.00 100.00

[0] Disabled

*[1] Enabled

[0] Disable All

*[1] Enable All

[2] Enable Reset O nly

[0] Disabled

*[1] Enabled

[0]Disabled

[1]Enabled

*[0] Speed open loop

[3] Process

[0] V/F

*[1] VVC+

*[0] Constant torque

[2] Automatic Energy

Optim.

[0] Speed Open Loop

*[2] As cong i n param.

C01.00

0.09 kW / 0.12 HP …. 11

kW / 15 HP

*[0] Off

[2] Enable AMT

[Ohm] * Dep. on mot or

data

Default

setting

1

1

1

1

0

0

1

0

2

**

0

**

HLP-NV Series

— 25 —

Loading…

- Addeddate

- 2021-02-05 22:19:32

- Identifier

- manuallib-id-1328

- Identifier-ark

- ark:/13960/t6455tj0d

- Ocr

- tesseract 4.1.1

- Ocr_autonomous

- true

- Ocr_detected_lang

- zh

- Ocr_detected_lang_conf

- 1.0000

- Ocr_detected_script

-

HanS

HanT

Japanese

Latin

- Ocr_detected_script_conf

-

0.3802

0.3802

0.0965

0.1121

- Ocr_module_version

- 0.0.11

- Ocr_parameters

- -l chi_sim+HanS

- Page_number_confidence

- 39.50

comment

Reviews

There are no reviews yet. Be the first one to

write a review.

688

Views

DOWNLOAD OPTIONS

Temporarily Unavailable

DAISY

For users with print-disabilities

Uploaded by

chris85

on

I. Introduction to Operation Panel Functions and Parameter Settings

The HOLIP Inverter HLP-A series boasts a comprehensive operation panel that allows users to perform parameter settings, monitor operating status, and diagnose faults. The operation panel primarily includes a display screen, directional keys, set keys, run keys, stop keys, and other functional keys.

Setting and Resetting Passwords

To protect against unauthorized modification of inverter parameters, the HLP-A series supports password protection. Users can enable password protection by setting parameter CD010 to 1, at which point all parameters except CD010 become unmodifiable. To reset the password, simply set CD010 back to 0.

Locking Parameters

To prevent non-maintenance personnel from accidentally modifying parameters, users can lock all parameters except CD010 by setting CD010 to 1. Once locked, only the correct password (set through parameter CD011) can unlock the parameters for modification.

Initializing Parameters

When it is necessary to restore the inverter to its factory settings, users can set parameter CD011 to 08 and then press the run and stop keys simultaneously. The inverter will automatically restart and revert to its factory settings.

II. Terminal Forward/Reverse Control and External Potentiometer Frequency Adjustment

Terminal Forward/Reverse Control

The HLP-A series inverter supports forward/reverse control via external terminals. Users need to set the multi-function input terminal FOR to forward (parameter CD050=02) and REV to reverse (parameter CD051=03). Then, by controlling the on/off state of these terminals with external switches, motor forward/reverse control can be achieved.

External Potentiometer Frequency Adjustment

External potentiometer speed control is a commonly used method for variable frequency speed control. Users need to set the inverter’s operation command source to external terminals (parameter CD033=1) and the operation frequency source to external analog (parameter CD034=1). Connect the potentiometer’s center tap to the VI terminal and its ends to the +10V and ACM terminals, respectively. By adjusting the potentiometer’s resistance, the inverter’s output frequency can be changed, thereby achieving motor speed control.

III. Fault Codes and Solutions

The HLP-A series inverter features comprehensive fault protection functions. When a fault occurs, the inverter will display the corresponding fault code. Below are some common fault codes, their meanings, and solutions:

E.OC.A (Overcurrent During Acceleration)

Meaning: The inverter experiences overcurrent during acceleration.

Solution: Check for short circuits or partial short circuits in the motor, and ensure good insulation of output wires; extend the acceleration time; check the inverter configuration for reasonableness and increase the inverter capacity if necessary; reduce the torque boost setting.

E.GF.S (Ground Fault)

Meaning: The inverter output is short-circuited to ground.

Solution: Check for short circuits in motor connections and ensure good insulation of output wires; if the fault cannot be resolved, contact the manufacturer for repair.

E.OU.S (Overvoltage During Stopping)

Meaning: The inverter experiences overvoltage during stopping.

Solution: Extend the deceleration time or install a braking resistor; improve the grid voltage quality and check for sudden voltage fluctuations.

E.OL.A (Inverter Overload)

Meaning: The inverter is overloaded.

Solution: Check if the inverter capacity is too small and increase it if necessary; check for stuck mechanical loads; reset the V/F curve.

E.OT.A (Motor Overtorque)

Meaning: The motor experiences overtorque.

Solution: Check for fluctuations in mechanical loads; check if the motor configuration is too small; check for deterioration in motor insulation due to overheating; check for significant voltage fluctuations; check for phase loss; check for increased mechanical loads.

IV. Conclusion

The HOLIP Inverter HLP-A series user manual provides users with detailed operation guides and fault solutions. By understanding the operation panel functions, mastering terminal control and potentiometer speed adjustment methods, and being familiar with fault code meanings and solutions, users can better utilize and maintain the inverter, ensuring its stable operation and extended service life. In practical applications, users should strictly follow the instructions in the manual for operation and maintenance to ensure the performance and safety of the inverter.

Holip HLP-A100 Series user guide recommended for: HLP-A Series, HLP-C100 Series, HLP-P Series, MG 2700, INVB Series.

The Holip HLP-A100 Series Inverter manual (Holip Operating manual, 187 pages) is completely safe to download (last scan date: 07/11/2024). You can rest assured of your safety when interacting with Holip HLP-A100 Series document.

1

30 FOOT (9 Meter) TOWER KIT for WHISPER 500

Owner’s manual Guide: Southwest Windpower 30 FOOT (9 Meter) TOWER KIT for WHISPER 500 (1DAYJ3, Upd.24/12/2024)

44

875

193

2

MA10K-PRO

Operation & user’s manual Airthereal Inverter Operation & user’s manual (File: airthereal-ma10k-pro-operation-user-s-manual-58, 31.03.2025)

58

871

210

3

PV-ezRack SolarRoof Isolator Shade

Installation manual #OIWD7A: PV-ezRack SolarRoof Isolator Shade Inverter Installation manual

11

533

118

5

U-140PEY1E8

100

710

135

6

S-36PU1E5A

Service manual #1DNW1R: S-36PU1E5A Air Conditioner Service manual

693

433

87

7

Onan HGJAA Series

Service manual CUMMINS Portable Generator Service manual (File: cummins-onan-hgjaa-series-service-manual-202, 03.12.2024)

202

971

204

8

BATTERY EXTENDER BE01257

19

485

73

9

MM AE Series

Owner’s manual MM AE Series (Inverter ePDF Guide, #7J5I86)

48

551

116

Holip HLP-A100 Series Operating manual

- Holip

- Inverter

- Operating manual for Holip HLP-A100 Series

- holip-hlp-a100-series-operating-manual-187_manual.pdf

- 187 |

Pages Preview:

Document Transcription:

See Details

Download