Терморегуляторы с установкой на DIN-рейку EMKO ESM-1510-N представляют собой простейшие двухпозиционные (ON/OFF) измерители-регуляторы температуры.

Простота настройки, стандартизованный размер корпуса (габариты совпадают с размерами стандартных автоматических выключателей) и невысокая стоимость позволяют применять данную серию регуляторов в самых различных областях.

Наиболее широко терморегуляторы ESM-1510-N на DIN-рейку используются в простейших системах вентиляции, в холодильном оборудовании, в простых печах и сушильных шкафах, а также для контроля температуры в шкафах автоматики и серверных помещениях.

Дополнительно терморегуляторы при работе в режиме «холодильник» имеют расширенный функционал для защиты компрессора и функцию задания состояния выхода при обрыве датчика. Благодаря этой особенности терморегуляторы ESM-1510-N нашли широкое применение в холодильной технике. Данный регулятор, с тем же функционалом, представлен контроллером температуры холодильного оборудования для монтажа в шкафу.

Измерители-регуляторы просты в настройке и дополнительно имеют функцию ограничения доступа от несанкционированного входа в параметры.

- установка терморегулятора на DIN рейку;

- легкий ввод в эксплуатацию;

- 2-х позиционное (ON/OFF) регулирование;

- тип входа определяется при заказе, не требует настройки;

- два режима работы: «нагреватель», «холодильник»;

- защита паролем от несанкционированного доступа к параметрам;

- функции управления и защиты компрессора:

- предохранение компрессора от частых запусков;

- предохранение компрессора при выходе датчика из строя;

- задержка включения компрессора при включении питания.

| Параметр | Значение |

|---|---|

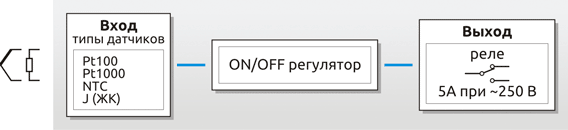

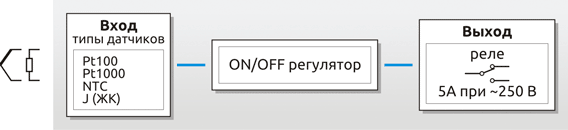

| Измерительный вход (выбирается при заказе) | ТП: J (ЖК); ТС: Pt100 (2-х пров.), Pt1000, NTC (10 кОм) |

| Предел основной приведенной погрешности | ±1% |

| Метод регулирования | ON/OFF (двухпозиционный) |

| Выход | реле (5 А при ∼250 В, активная нагрузка) |

| Напряжение питания | ∼230 В (±15%), 50/60 Гц |

| Потребляемая мощность | 1,5 ВА |

| Окружающая среда | рабочая температура: (0…+50) °C температура хранения: (-40…+85) °C относительная влажность: (0…90)% (без образования конденсата) |

| Индикация | красный 3-х разрядный LED индикатор |

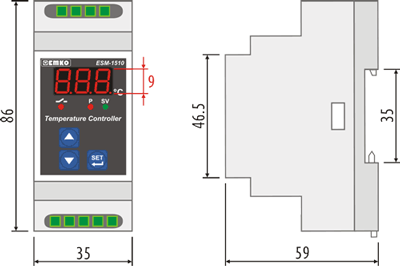

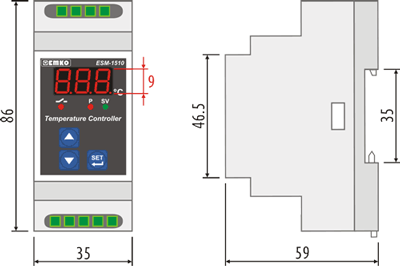

| Габаритные размеры (ШхВхГ) | 35×86×59 мм, пластиковый корпус с установкой на DIN-рейку |

| ESM-1510-N.5. | .0.1/00.00/2.0.0.0 | |

|---|---|---|

| Тип измерительного входа | ||

| J (ЖК) (0…800) °C | 05 | |

| Pt-100 (-19,9…99,9) °C | 09 | |

| Pt-100 (-50…400) °C | 11 | |

| Pt-1000 (-19,9…99,9) °C | 13 | |

| NTC (-19,9…99,9) °C | 18 |

Пример: ESM-1510-N.5.13.0.1/00.00/2.0.0.0

|

ESM 1510 Контроллеры температуры серии ESM-1510 разработаны для измерения и контроля температуры. Могут быть использованы в следующих отраслях промышленности: • Производство стекла контроль нагрева • Пищевая промышленность контроль температуры печей • Производство пластика поддержка темп-ры в инкубаторах • Нефтехимическое производство температура на складах • Текстильная промышленность вентиляция и кондиционирование • Автомобильная промышленность |

Скачать |

Контроллеры Emko предназначены для различных сфер деятельности: коммерческой, промышленной, бытовой. А значит в каждом аппарате с которым будет взаимодействовать данный технический элемент есть свои особенности. Для того, чтобы вникнуть во все тонкости, специалисты рекомендуют скачать инструкцию по эксплуатации, в которой выстроен целый алгоритм действ, позволяющие облегчить понимание работы установки. Инструкция предоставляется на русскому языке в знакомом всем формате pdf-файла. Даже самые продвинутые пользователи, которые ранее встречались с подобной техникой, все равно используют время от времени специальный мануал.

E

S

M

-1

5

1

0

D

IN

R

a

il

M

o

u

n

ti

n

g

T

e

m

p

e

ra

tu

re

C

o

n

tr

o

ll

e

r

— 3 Digits display

— NTC Input or,

PTC Input or,

J type thermocouple Input or,

K type thermocouple Input or,

2-Wire PT 100 Input or,

2-Wire PT 1000 Input (It must be determined in order)

— ON/OFF temperature control

— Selectable heating or cooling function

— Selection of operation with hysteresis

— Adjustable temperature offset

— Set value low limit and set value high limit boundaries

— Relay or SSR driver output

— Operation selection of compressor operates continuously, stops

or operates periodically in case of probe defect

— Compressor protection delays

— Password protection for programming mode

Instruction Manual. ENG ESM-1510 02 V08 08/14

ESM-1510 DIN Rail Mounting Type

Digital, ON / OFF Temperature Controller

ESM-1510-N.5.11.0.1/00.00/2.0.0.0 Измеритель-регулятор температуры, DIN рейка (вход Pt100 (-50…+400 C, 2-х пров.), выход: реле (НО+НЗ, 5А), питание 230 VAC, кл. 1)

Терморегуляторы с установкой на DIN-рейку EMKO ESM-1510-N представляют собой простейшие двухпозиционные (ON/OFF) измерители-регуляторы температуры.

Простота настройки, стандартизованный размер корпуса (габариты совпадают с размерами стандартных автоматических выключателей) и невысокая стоимость позволяют применять данную серию регуляторов в самых различных областях.

Наиболее широко терморегуляторы ESM-1510-N на DIN-рейку используются в простейших системах вентиляции, в холодильном оборудовании, в простых печах и сушильных шкафах, а также для контроля температуры в шкафах автоматики и серверных помещениях.

Дополнительно терморегуляторы при работе в режиме «холодильник» имеют расширенный функционал для защиты компрессора и функцию задания состояния выхода при обрыве датчика. Благодаря этой особенности терморегуляторы ESM-1510-N нашли широкое применение в холодильной технике. Данный регулятор, с тем же функционалом, представлен контроллером температуры холодильного оборудования для монтажа в шкафу.

Измерители-регуляторы просты в настройке и дополнительно имеют функцию ограничения доступа от несанкционированного входа в параметры.

| Параметр | Значение |

|---|---|

| Измерительный вход (выбирается при заказе) | ТП: J (ЖК); ТС: Pt100 (2-х пров.), Pt1000, NTC (10 кОм) |

| Предел основной приведенной погрешности | ±1% |

| Метод регулирования | ON/OFF (двухпозиционный) |

| Выход | реле (5 А при ∼250 В, активная нагрузка) |

| Напряжение питания | ∼230 В (±15%), 50/60 Гц |

| Потребляемая мощность | 1,5 ВА |

| Окружающая среда | рабочая температура: (0…+50) °C температура хранения: (-40…+85) °C относительная влажность: (0…90)% (без образования конденсата) |

| Индикация | красный 3-х разрядный LED индикатор |

| Габаритные размеры (ШхВхГ) | 35×86×59 мм, пластиковый корпус с установкой на DIN-рейку |

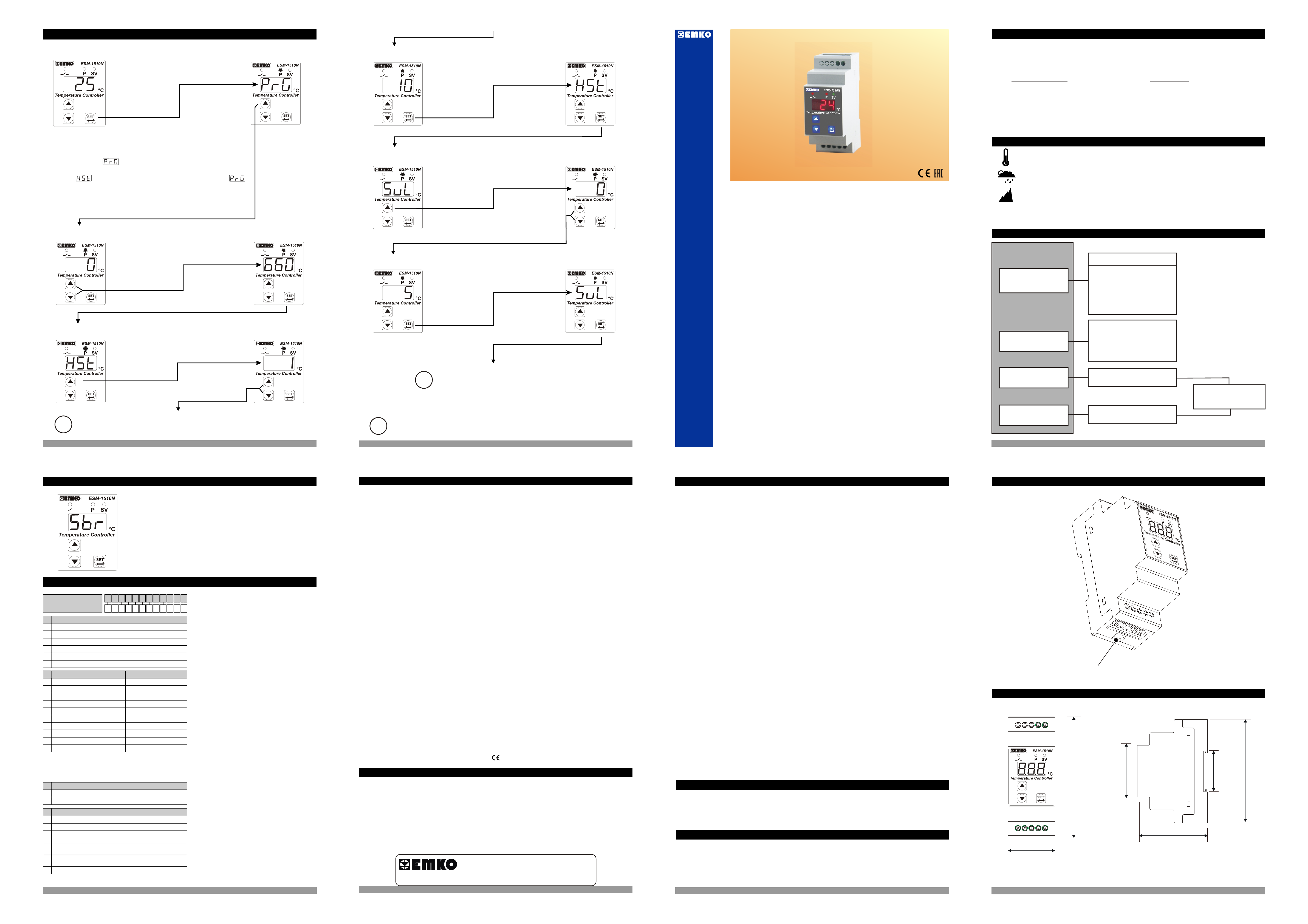

4.6 Entering To The Programming Mode, Changing and Saving Parameters

1.Preface

Operation Screen

Press increment button

for accessing to the

password entering

5 secs

screen.

When SET button is pressed for 5

seconds, “P” led starts to blink. If

programming mode entering password is

different from 0, programming mode

entering screen will be observed.

Note-1: If programming mode accessing password is 0, hysteresis

screen is observed instead of Programming screen

accessing password

Note-2: Parameters can be observed by pressing SET/OK button in

password entering screen without entering the programming mode

entering password. But parameters can not be changed.

Password Entering

Screeen

Enter programming

mode accessing

password with

increment and

decrement buttons

Press SET/OK button

for accessing to the

parameters

Hysteresis Parameter

Parameter is accessed

by pressing increment

button. If set button is

pressed, next

parameter is shown.

Change the

parameter with

increment and

decrement buttons

If no operation is performed in Programming mode for 20 seconds, device turns to

i

operation screen automatically

Programming Mode

Entering Screen

Password Entering

Screeen

Hysteresis Parameter

Value

Hysteresis Parameter

Value

saving the parameter

Minimum Set Value

Parameter

accessed by pressing

set button is pressed,

Minimum Set Value

saving the parameter

i

If no operation is performed in Programming mode for 20 seconds, device turns to

i

operation screen automatically

Hysteresis Parameter

Press Set button for

value

Press Set button for

accessing to the next

parameter

Minimum Set Value

Parameter is

increment button. If

next parameter is

shown.

Change the

parameter with

increment and

decrement buttons

Minimum Set Value

Parameter

Press Set button for

value

Other Programming mode parameters can be accessed

with the same method explained above, observed and

changed.

ESM-1510N DIN Rail Mounting Temperature Controller

ESM-1510N DIN Rail Mounting Type

Digital, ON / OFF Temperature Controller

— 3 Digits display

— NTC Input or,

PTC Input or,

J type thermocouple Input or,

K type thermocouple Input or,

2-Wire PT 100 Input or,

2-Wire PT 1000 Input (It must be determined in order)

— ON/OFF temperature control

— Selectable heating or cooling function

— Selection of operation with hysteresis

— Adjustable temperature offset

— Set value low limit and set value high limit boundaries

— Relay or SSR driver output

— Operation selection of compressor operates continuously, stops

or operates periodically in case of probe defect

— Compressor protection delays

— Password protection for programming mode

ESM-1510N series temperature controllers are designed for measuring and controlling

temperature. They can be used in many applications with their On / Off control form, heating and

cooling control form and easy-use properties. Some application fields which they are used are

below:

Application Fields Applications

Glass Heating

Food Baking Ovens

Plastic Incubators

Petro-Chemistry Storages

Textile, Automative Air Conditioning

Machine Production Industries Etc…

Etc…

1.1 Operating Conditions

Operating Temperature : 0 to 50 °C

Max. Operating Humidity : 90% Rh (non-condensing)

Altitude : Up to 2000 m.

Forbidden Conditions:

Corrosive atmosphere, Explosive atmosphere,

c

Home applications (The unit is only for industrial applications)

1.2 General Specifications

Standard

ESM-1510N

230 V V (±%15) , 50/60Hz

Optional Supply Input

Power Supply

Input

Temperature Sensor

Input

Standard

Output-1

(Relay Output)

Optional

Output-1

(SSr Driver Output)

115 V V (±%15) , 50/60Hz

24 V V (±%15) , 50/60Hz

24 V W (-%15, +%10),

50/60Hz

10…30 V Z

NTC

PTC

J or K Type TC

2-wire PT 100

2-wire PT 1000

Control Output

Alarm Output

Heating or Cooling

Function

ON/OFF Operation

Control Output

Alarm Output

5. Failure Messages in ESM-1510N Temperature Controller

Probe defect in analogue inputs. Sensor connection is wrong or

there is no sensor connection.

6. Ordering Information

U

V W Z/

/

Temperature Controller are given on the

All order information of ESM-1510N

ESM-1510N (77×35 DIN Size)

A BC D E FG HI /

0 00 2 0 0

00

/

table at left. User may form appropriate

Supply VoltageA

24V W ( -15%,+10% ) 50/60Hz

2

24V V ( ± 15% ) 50/60Hz

3

115V V ( ± 15% ) 50/60Hz

4

230V V ( ± 15% ) 50/60Hz

5

10…30 V Z

8

9

Customer

Input Type

BC

J ,Fe CuNi IEC584.1(ITS90)

05

10

K ,NiCr Ni IEC584.1(ITS90)

PT 100 , IEC751(ITS90)

11

PT 100 , IEC751(ITS90)

09

PTC (Note-1)

12

PTC (Note-1)

15

PT 1000 , IEC751(ITS90)

14

PT 1000 , IEC751(ITS90)

13

NTC (Note-1)

18

19

NTC (Note-1)

Note-1 : If input type is selected PTC or NTC (BC = 12, 15, 18, 19 ),

Temperature sensor is given with the device. For this reason,

If input type is selected as PTC, sensor type (V = 0,1 or 2) or

If input type is selected as NTC, sensor type (V = 0,3 or 4) must be

declared in ordering information.

E

Output-1

1

Relay Output ( resistive load 10 A@250 V V , 1 NO + 1NC )

2

SSR Driver Output (Maximum 28 mA, 15 V Z)

Temp. Sensor which is given with ESM 1510

V

None

0

PTC-M6L40.K1.5 (PTC Air Probe with 1.5 m silicon cable)

1

PTCS-M6L30.K1.5.1/8” (PTC Liquid Probe with 1.5 m silicon

2

cable)

NTC-M5L20.K1.5 (NTC Probe, thermoplastic moulded with

3

1.5 m cable for cooling application)

NTC-M6L50.K1.5 (NTC Probe, stainless steel housing with

4

1.5 m cable for cooling application)

Customer

9

Scale(°C)

0°C

0°C

-50°C

-19.9°C

-50°C

-19.9°C

-50°C

-19.9°C

-50°C 100°C

-19.9°C 99.9°C

800°C

999°C

400°C

99.9°C

150°C

99.9°C

400°C

99.9°C

device configuration from information and

codes that at the table and convert it to the

ordering codes.

Firstly, supply voltage then other

specifications must be determined. Please

fill the order code blanks according to your

needs.

Please contact us, if your needs are

out of the standards.

c

V Symbol means Vac,

Z Symbol means Vdc,

Symbol means Vac/dcW

13

15

14

7. Specifications

Device Type : Temperature Controller

Housing&Mounting : 86mm x 35mm x 59mm plastic housing for Rail Mounting.

Protection Class : IP20.

Weight : Approximately 0.14 Kg.

Environmental Ratings : Standard, indoor at an altitude of less than 2000 meters

with none condensing humidity.

Storage / Operating Temperature: -40 C to +85 C / 0 C to +50 C

oooo

Storage / Operating Humidity : 90 % max. (None condensing)

Installation : DIN Rail Mounting

Overvoltage Category : II.

Pollution Degree : II, office or workplace, none conductive pollution

Operating Conditions : Continuous

Supply Voltage and Power : 230 V V (± 15%) 50/60 Hz. 1.5 VA

115 V V (± 15%) 50/60 Hz. 1.5 VA

24 V V (± 15%) 50/60 Hz. 1.5 VA

24 V W (- 15%, + 10%) 50/60 Hz. 1.5 VA

10…30 V Z 1.5 W

Temperature Sensor Inputs : NTC, PTC, TC, RTD

NTC Input Type : NTC (10 kW @.25 °C )

PTC Input Type : PTC (1000 W @.25 °C )

Thermocouple Input Types : J, K (IEC584.1)(ITS90)

Thermoresistance Input Type : PT-100, PT-1000 (IEC751)(ITS90)

Accuracy : ±1% of full scale for thermocouple and thermoresistance

Cold Junction Compensation : Automatically ± 0.1°C/1°C.

Sensor Break Protection : Upscale

Sampling Cycle : 3 samples per second

Control Form : ON / OFF

Relay Output : Resistive Load 5 A@250 V V

(Electrical Life : 100.000 operation (Full Load)

Optional SSR Output : Maximum 28 mA, Maximum 15 V Z

Display : 9 mm Red 3 digits LED Display

Leds : SV (Green) , OUT (Red) , P(Red) 3 mm

Approvals : GOST-R,

8. Other Informations

Manufacturer Information:

Emko Elektronik Sanayi ve Ticaret A.Þ.

Demirtaþ Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA / TURKEY

Tel : +90 224 261 1900

Fax : +90 224 261 1912

Repair and maintenance service information:

Emko Elektronik Sanayi ve Ticaret A.Þ.

Demirtaþ Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA / TURKEY

Tel : +90 224 261 1900

Fax : +90 224 261 1912

Thank you very much for your preference to

use Emko Elektronik products, please visit our

Your Technology Partner

web page to download user manual.

www.emkoelektronik.com.tr

16

Instruction Manual. ENG ESM-1510N 01 V00 02/16

1.3 Installation

Before beginning installation of this product, please read the instruction

c

manual and warnings below carefully.

In package ,

— One piece unit

— One piece rail lock apparatus

— One piece instruction manual

A visual inspection of this product for possible damage occured during shipment is

recommended before installation. It is your responsibility to ensure that qualified

mechanical and electrical technicians install this product.

If there is danger of serious accident resulting from a failure or defect in this unit, power

off the system and separate the electrical connection of the device from the system.

The unit is normally supplied without a power supply switch or a fuse. Use power switch

and fuse as required.

Be sure to use the rated power supply voltage to protect the unit against damage and to

prevent failure.

Keep the power off until all of the wiring is completed so that electric shock and trouble

with the unit can be prevented.

Never attempt to disassemble, modify or repair this unit. Tampering with the unit may

results in malfunction, electric shock or fire.

Do not use the unit in combustible or explosive gaseous atmospheres.

During the equipment is putted in hole on the metal panel while mechanical installation

some metal burrs can cause injury on hands, you must be careful.

Montage of the product on a system must be done with it’s fixing clamps. Do not do the

montage of the device with inappropriate fixing clamp. Be sure that device will not fall

while doing the montage.

It is your responsibility if this equipment is used in a manner not specified in this

instruction manual.

1.4 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts from

the delivery date. This warranty is in force if duty and responsibilities which are determined in

warranty document and instruction manual performs by the customer completely.

1.5 Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the device

before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a cloth dampened in ethyl

alcohol or water to clean the external plastic case.

3

2 General Description

Rail Lock Apparatus

2.1 Front View and Dimensions of ESM-1510N Temperature Controller

78910

6

46.5 mm / 1.83 inch

90 mm / 3.54 inch

3

2

5

41

61.2 mm / 2.40 inch

35 mm / 1.38 inch

2

35.7 mm / 1.40 inch

90 mm / 3.54 inch

4

2.2 Installation onto the Rail

The unit is designed for rail mounting.

1- Put into the unit upper side of the

rail properly.

2- Pull down the rail lock apparatus

via a screw driver.

3.-Push the unit from the underside

for mounting to the rail.

During installation onto the rail, care should be taken to avoid injury from

mechanical part of the system. These precautions for the safety of the person

c

2.3 Removing from the Rail

2.5 Panel Mounting

who does the rai mounting.

Before starting to remove the unit from the rail, power off the unit and the

related system.

c

1- Pull down the rail lock apparatus

via a screw driver.

2- Pull the unit from the underside to

seperate the rail lock apparatus from

the rail

3.- Pull up the unit to remove from the

rail.

3. Electrical Wiring Diagram

Temperature Sensor Input

(TC, NTC, PTC, PT-100 or PT-1000)

7

6

TC

NTC, PTC, PT-100, PT1000

1

ÇIKIÞ

5 A@250 V V

aa

3

Supply Voltage Input

2

230 V V ( ± %15 ) 50/60 Hz — 1.5 VA

115 V V ( ± %15 ) 50/60 Hz — 1.5 VA

24 V V ( ± %15 ) 50/60 Hz — 1.5 VA

24 V W ( -%15, +%10 ) 50/60 Hz — 1.5 VA

10…30 V — 1.5 WZ

3.1 Supply Voltage Input Connection of the Device

L(+) N(-)

NONCC

2341

5

(+)

(-)

Relay or SSR Driver Output

For SSr Output

4.2 Changing and Saving Set Value

Operation Screen

When SET button is

pressed, SV LED

lights on and SET

value is shown on the

displays.

SET Value Screen

SET Value Screen

Change the SET value with

increment and decrement buttons.

Operation Screen

Y

a

1

External

Fuse

(1 A T)

3

Supply Voltage

230 V V (± 15%) 50/60 Hz or

115 V V (± 15%) 50/60 Hz or

24 V V (± 15%) 50/60 Hz or

24 V W (-15%,+10%) 50/60 Hz or

10…30 V — 1.5 WZ

Make sure that the power supply voltage is same indicated on the instrument.

Switch on the power supply only after that all the electrical connection have been completed.

Supply voltage range must be determined in order. While installing the unit, supply voltage range must be

controlled and appropriate supply voltage must be applied to the unit. Controlling prevents damages in unit

and system and possible accidents as a result of incorrect supply voltage.

2

1

There is no power supply switch or fuse on the device. So a power supply switch and a fuse must be added

to the supply voltage input. Power supply switch and fuse must be put to a place where user can reach

easily. Power supply switch must be two poled for seperating phase and neutral. On/Off condition of power

supply switch is very important in electrical connection. On/Off condition of power supply switch must be

signed for preventing the wrong connection.

NL

2

Note-2

Note-1

Power

Supply

Switch

c

Note-1:

24V Supply Voltage

Note-2: External Fuse is recommended

Note-3: External fuse must be on phase connection in

Vsupply input.

Note-4: External fuse must be on (+) line connection in

Zsupply input.

“L” is (+), “N” is (-) for 10…30V Z and

W

Press SET button for saving the

SET value

SET value is can be adjusted from minimum set value parameter to maximum set value

parameter , Which can be accessed from programming parameters.

If no operation is performed in Set value mode for 20 seconds, device turns to

i

operation screen automatically.

SV LED lights off and main

operation screen is shown.

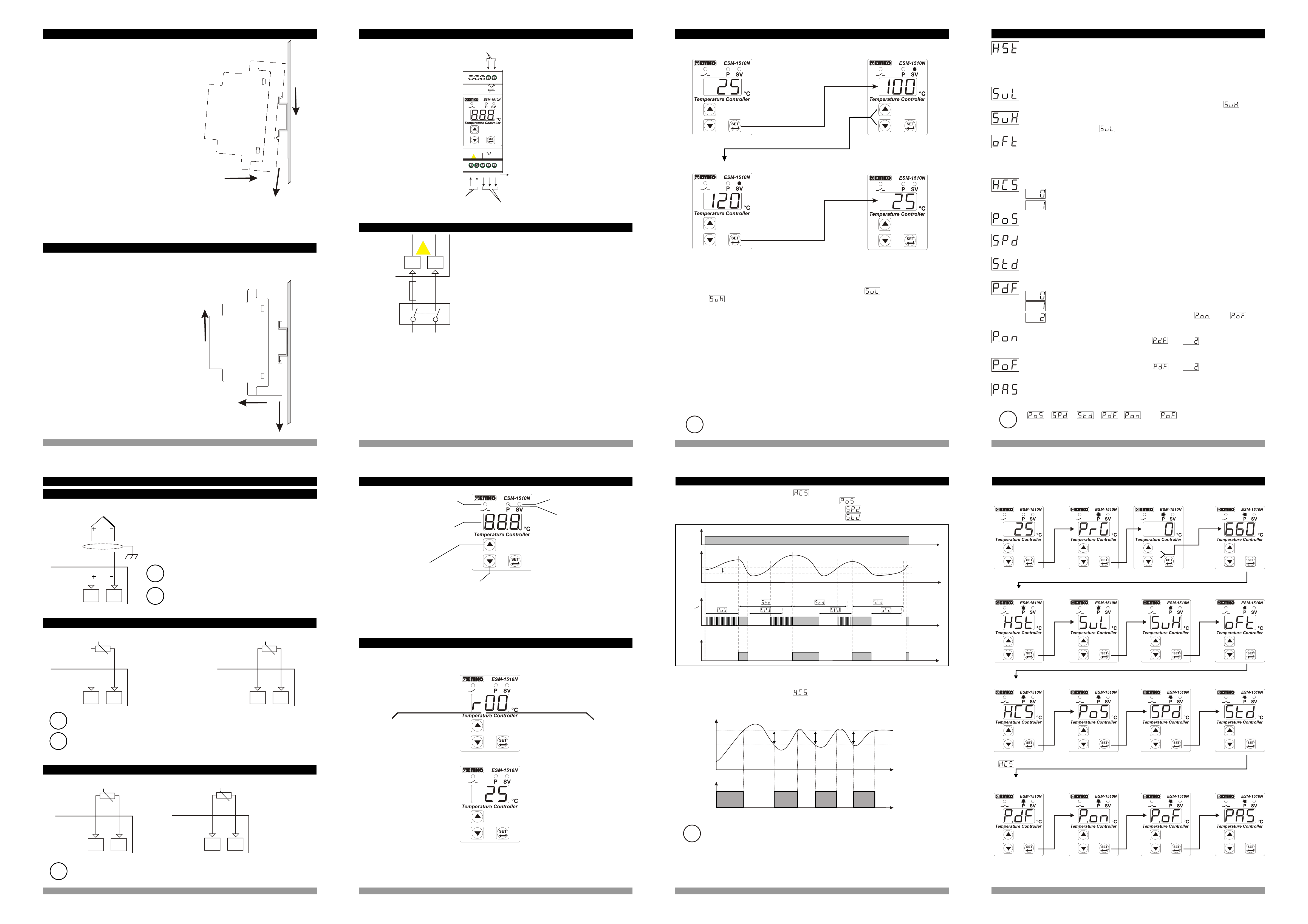

4.3 Program Parameters

Hysteresis Parameter for Output ( Default = 1 )

1 to 100 °C for TC Type Devices,

1 to 100 °C for PT-100 (-50°C, 400°C) and PT-1000 (-50°C, 400°C),

0.1 to 10.0 °C for PT-100 (-19.9°C, 99.9°C) and PT-1000 (-19.9°C, 99.9°C),

1 to 20 °C for PTC (-50°C, 150°C) and NTC (-50°C, 100°C),

0.1 to 10.0 °C for PTC (-19.9°C, 99.9°C) and NTC (-19.9°C, 99.9°C)

Minimum Set Value Parameter ( Default =Minimum value of device scale )

Set value can not be lower than this value. This parameter value can be adjusted

from minimum value of device scale to maximum set value parameter

Maximum Set Value Parameter ( Default = Maximum value of device scale )

Set value can not be greater than this value. This parameter value can be adjusted

from minimum set value to maximum value of the device scale

Process Offset Parameter ( Default = 0 )

-100 to 100 °C for TC Type Devices,

-100 to 100 °C for PT-100 (-50°C , 400°C) and PT-1000 (-50°C , 400°C),

-10.0 to 10.0 °C for PT-100 (-19.9°C, 99.9°C) and PT-1000 (-19.9°C, 99.9°C),

-20 to 20 °C for PTC (-50°C, 150°C) and NTC (-50°C, 100°C),

-10.0 to 10.0 °C for PTC (-19.9°C, 99.9°C) and NTC (-19.9°C, 99.9°C)

Operating Type Parameter ( Default = 0 )

Heating

Cooling

Switch On Delay After Power On Parameter ( Default = 0 )

When power is first applied to the device, this time delay must be expired for

activation of the compressor. It can be adjusted from 0 to 20 minutes

Compressor Stop/Start Time Delay Parameter ( Default =0 )

When compressor is inactive, this time delay must be expired for activation of the

compressor. It can be adjusted from 0 to 20 minutes.

Compressor Start/Start Time Delay Parameter ( Default =0 )

This time delay must be expired between two activation of the compressor.

It can be adjusted from 0 to 20 minutes.

Probe Defect Parameter ( Default = 0 )

Compressor is OFF in case of probe defect

Compressor is ON in case of probe defect

Compressor operates periodically according to and time

periods in case of probe defect.

Compressor is active during this time period in case of probe defect

( Default = 0 ) If Probe Defect Parameter is , then this parameter

can be observed. It can be adjusted from 0 to 99.

Compressor is inactive during this time period in case of probe defect

( Default = 0 ) If Probe Defect Parameter is , then this parameter

can be observed. It can be adjusted from 0 to 99.

Programming Mode Accessing Password ( Default =0 )

It is used for accessing to the programming mode. It can be adjusted from 0 to 999.

If it is selected 0, password is not entered for accessing to the parameters.

, , , , and parameters are observed if

i

Operating type is selected “ Cooling ”. If operating type is selected “ Heating ”

beginning of the parameters list is shown.

3.2 Temperature Sensor Input Connection

3.2.1 TC (Thermocouple) Connection

TC

ii

67

3.2.2 PTC and NTC Connection

ii

5

Connect the wires with the polarity as shown in

the figure left.

Always use compensation wire corresponding

to the thermocouple used. If present, the shield

must be connected to a proper ground.

Input resistance is greater than 10M W.

6

4. Front Panel Definition and Accessing to the Menus

Displays Temperature

Value,Temperature Set

Value and Parameters

Led indication of Output

is active (If blinks, Compressor

protection time is active)

Note-1

It is used to

increase the value

and access to the

parameter in

programming

mode.

Note-1: If increment or decrement button is pressed for 5 seconds continuously, increment and

decrement number become 10, if increment or decrement button is pressed for 10 seconds

continuously, increment and decrement number become 100.

Note-1

Decrement

Button

Led indication of SET value

changing mode

Led indication of

Programming Mode is active

It is used to enter to

the SET value

changing mode,

programming mode

and used as OK

button.

4.4 Working Graphics of ESM-1510N Temperature Controller

1-If Operating Type Parameter Value = 1 (Cooling),

Switch On Delay After Power On Parameter Value ³ 1 ,

Compressor Stop/Start Time Delay Parameter Value ³ 1 and

Compressor Start/Start Time Delay Parameter Value ³ 1;

Power

°C

SET

Output

Led

Hst

Time

Time

Time

9

4.5 Easy Access Diagram Of Programming Mode Parameters

Operation Screen

Hysteresis Parameter

Programming Mode

Entering Screen

5 sn

Minimum Set Value

Parameter

Password Entering

Screen

Enter Password

with increment

and decrement

buttons

Press SET/OK button for accessing parameters

Maximum Set Value

Parameter

Password Entering

Screen

Process Offset

Parameter

10

PTC

WHITERED

67

ii

ii

3.2.3 PT-100 and PT-1000 Connection

Input resistance is greater than 10M W.

Pay attention the cable colours of PTC probe while doing the PTC probe

connection.

PT-100

PT-1000

NTC

4.1 Observation of Software Revision on the Displays

When power is first applied to the temperature controller, software revision number is shown on

the displays.

Output

2-If Operating Type Parameter Value = 0 (Heating),

Time

Operating Type Parameter

Switch On Delay After

Power On Parameter

Compressor Stop/Start

Time Delay Parameter

Compressor Start/Start

Time Delay Parameter

67

Temperature

Value

“ r” ÞRevision

Software

revision

Number

SET

ON

HSt

HSt HSt

Time

If Operating Type Parameter Value

= 1 (Cooling)

Probe Defect

Parameter

Compressor is active

during this time period

In case of probe defect

Compressor is inactive

during this time period

In case of probe defect

Programming Mode

Accessing Password

OFF

Temperature Control Output

In ON/OFF control algorithm, temperature value is tried to keep equal to set

value by opening or closing the last control element. ON/OFF controlled system,

i

67

ii

Input resistance is greater than 10M W.

67

Operation Screen is shown

If there is an unexpected situation while opening the device, power off the

device and inform a qualified personnel.

temperature value oscillates continuously. Temperature value’s oscillation period or

amplitude around set value changes according to controlled system. For reducing

oscillation period of temperature value, a threshold zone is formed below or around

set value and this zone is named hysteresis. Action of control output is described with

figures above.

Time

c

7

8

11

12