✂

✂

✂

✂

✂

Werkstatthandbuch

912/913

Workshop Manual

912/913

✂

✂

✂

✂

✂

0297 9763

Werkstatthandbuch

912/913

0297 9763

Workshop Manual

912/913

✂

✂

✂

✂

✂

✂

Manuel d’Atelier

912/913

Manual de Taller

912/913

✂

✂

✂

✂

✂

0297 9763

Manuel d’Atelier

912/913

0297 9763

Manual de Taller

912/913

✂

Werkstatthandbuch

Workshop Manual

Manuel d’Atelier

Manual de Taller

0297 9763

912/913

Gegenüber Darstellungen und Angaben dieses Werkstatthandbuches sind

technische Änderungen, die zur Verbesserung der Motoren notwendig werden,

vorbehalten. Nachdruck und Vervielfältigung jeglicher Art, auch auszugsweise,

bedarf unserer schriftlichen Genehmigung.

In view of continuous design improvements or changes, the technical specifications and the illustrations shown in this Workshop Manual are subject to

alteration. Reprinting and reproduction, in part or in whole, are subject to our

written approval.

Sous réserve de modifications techniques nécessaires à l’amélioration des

moteurs présentés par des illustrations et des indications référencées dans ce

Manuel d’Atelier. Réimpression et reproduction même partielle, quelle qu’en

soit la nature, interdites sans l’autorisation écrite de nos service.

Nos reservamos el derecho de introducir modificaciones técnicas necesarias

para el mejoramiento de motores, aunque difieran de las ilustraciones y datos

contenidos en este Manual de Taller. La reimpresión del presente libro o

cualquiera forma de reproducción, aunque sea parcial, requiere nuestra

autorización por escrito.

© 2002 / 0297 9763

V O R W O R T

Die sachgerechte Ausführung von Reparatur- und Einstellarbeiten ist Voraussetzung für einen

zuverlässigen Motorbetrieb.

In diesem Werkstatthandbuch sind die zweckmäßigen Arbeitsabläufe für anfallende Reparaturund Einstellarbeiten an Motor und Motorbauteilen beschrieben. Dabei wird vorausgesetzt, daß die

Arbeiten von qualifiziertem Fachpersonal durchgeführt werden.

Bei der Gestaltung des Werkstatthandbuches wurden im Sinne einer schnellen Erfassung der

Inhalte zusätzlich zu den knapp gehaltenen beschreibenden Texten Bildzeichen gesetzt, die den

jeweils behandelten Arbeitsgang visualisieren.

Betriebs- und Wartungshinweise sind der entsprechenden Betriebsanleitung zu entnehmen.

Zur Ersatzteilbestellung ist die jeweilige Ersatzteilliste zugrunde zu legen.

Das vorliegende Werkstatthandbuch unterliegt keinem Änderungsdienst. Änderungen werden

jeweils bei Neuauflage eingearbeitet.

Beachten Sie bei Reparaturen die Hinweise unserer Technischen Rundschreiben.

Allgemeine Hinweise:

— Lesen und beachten Sie die Informationen dieses Werkstatthandbuches. Sie

vermeiden Unfälle und verfügen über einen funktionstüchtigen und einsatzbereiten

Motor.

— Stellen Sie sicher, daß dieses Werkstatthandbuch jedem an Reparatur- oder

Einstellarbeiten Beteiligten zur Verfügung steht und daß der Inhalt verstanden wird.

-Die Nichtbeachtung dieser Reparaturanleitung kann zu Funktionsstörungen und

Motorschäden sowie Verletzungen von Personen führen, für die vom Hersteller

keine Haftung übernommen wird.

-Die einschlägigen Unfallverhütungsvorschriften sowie die sonstigen allgemeinen

anerkannten sicherheitstechnischen und arbeitsmedizinischen Regeln sind einzuhalten.

— Voraussetzung für die fachgerechte Reparatur ist die Verfügbarkeit aller erforderlichen Ausrüstungen, Hand- und Spezialwerkzeuge, sowie deren einwandfreier

Zustand.

-Höchste Wirtschaftlichkeit, Zuverlässigkeit und lange Lebensdauer ist nur bei

Verwendung von Original Teilen der DEUTZ AG sichergestellt.

-Motorteile wie Federn, Klammern, elastische Halteringe etc. beinhalten bei unsachgemäßer Behandlung erhöhte Verletzungsgefahr.

-Die Instandsetzung des Motors muß der bestimmungsgemäßen Verwendung definiert durch den Gerätehersteller — entsprechen. Bei Umbauten dürfen nur von der

DEUTZ AG für den jeweiligen Verwendungszweck freigegebene Teile eingesetzt

werden.

© 2002 / 0297 9763

F O R E W O R D

Reliable engine operation is dependent on properly executed repairs as well as adjustment work.

This Workshop Manual describes the appropriate operations for any repair and adjustment work

on the engine and engine components. It is presumed that this work will be carried out by qualified

personnel.

The Manual has been laid out to ensure quick comprehension of the contents, i. e illustrations have

been placed adjacent to the brief text passages to clearly show the working operations.

Aspects of operation and maintenance are dealt with in the respective Operation Manual.

For spare parts orders the respective spare parts catalogue should be referred to.

This Workshop Manual is not subject to engineering change service and is valid until next

issue.

Therefore please refer to the information in our Technical Circulars when carrying out repairs.

General information:

— Please read carefully and observe the instructions given in this Workshop Manual

to avoid accidents and ensure that your engine always functions properly and

reliably.

-Make sure that this Workshop Manual is readily available for all those carrying out

repairs or adjustments and that the contents are well understood.

-Non-compliance with these repair instructions may result in malfunction and engine

damage as well as personal injuries for which the manufacturer shall not accept any

liability.

— The accident prevention regulations and all other generally recognized regulations

on safety and occupational medicine are to be observed.

-A prerequisite for successful repair is that all required equipment, hand and special

tools are available and in perfect working order.

-Optimal operation economy, reliability and durability of the engine can only be

ensured when genuine parts of DEUTZ AG are used.

— Engine components such as springs, clamps, snap rings, etc. may cause injury if not

handled with care.

— Engine repairs must be carried out in accordance with intended use as defined by

the equipment manufacturer. For conversions, only parts approved by DEUTZ AG

for a specific purpose should be used.

© 2002 / 0297 9763

P R É F A C E

Un fonctionnement fiable du moteur suppose l’exécution en bonne et due forme des travaux de

réparation et de réglage.

Le présent Manuel d’atelier décrit la suite des travaux de réparation et de réglage à effectuer sur

le moteur et ses éléments. Cela suppose que les travaux sont réalisés par un personnel spécialisé

et qualifié.

En vue d’une compréhension rapide du contenu, le manuel d’atelier comporte, en plus des textes

brefs, des symboles visualisant l’opération à réaliser.

Les indications relatives au service et à l’entretien figurent dans les instructions de service

correspondantes.

Pour la commande de pièces de rechange, il convient de se baser sur la liste des pièces de rechange

correspondante.

Le présent manuel d’atelier n’est soumis à aucun service de modifications. Les modifications

seront incorporées à chaque réédition du Manuel.

Pour les réparations, veuillez respecter les indications de nos circulaires techniques.

Remarques générales:

— Veuillez lire attentivement les informations du présent Manuel d’ Atelier et en tenir

compte. Vous éviterez ainsi des accidents et disposerez en même temps d’ un

moteur fonctionnel et en parfait état de marche.

— Assurez-vous que chaque personne chargée des travaux de réparation et de mise

au point dispose bien de ce Manuel d’ Atelier et en comprenne bien le contenu.

— Le non-respect de ces instructions de réparation peut entraîner des pannes, avaries

de moteur et accidents de personnes, pour lesquels le constructeur ne peut en aucun

cas assumer la responsabilité.

— Il convient de respecter les consignes générales de sécurité et de prévention des

accidents en vigueur.

— La condition préalable de la bonne exécution des réparations est la mise à disposition

de tous les équipements, outillages manuels et spéciaux requis, en parfait état de

fonctionnement.

— Seule l’utilisation de pièces de rechange d’origine DEUTZ AG garantit une rentabilité

et fiabilité optimales ainsi qu’une longue durée de vie.

— Les éléments du moteur notamment les ressorts, attaches, bagues élastiques etc.,

peuvent entraîner, en cas de non-respect des prescriptions, des blessures graves.

— La remise en état du moteur doit répondre à son utilisation propre, définie par le

constructeur de l’engin. En cas de modification, seules les pièces autorisées par

DEUTZ AG dans le cas de l’application concernée, peuvent être utilisées.

© 2002 / 0297 9763

P R O L O G O

Una ejecución competente de trabajos de reparación y ajuste es requisito fundamental para un

funcionamiento seguro del motor.

En el presente manual para talleres han sido descritos los ciclos convenientes de trabajo para

reparaciones y ajustes del motor y de sus componentes. Se presupone, no obstante, que los

trabajos serán realizados por personal técnico especializado.

Con el fin de simplificar la comprensión del contenido del manual para talleres, se han agregado

símbolos significativos a los textos explicatorios, visualizando así el trabajo a realizar.

Informaciones con respecto al manejo y al servicio de entretenimiento del motor, se encuentran

en el Manual de Instrucciones de Servicio correspondiente.

Para pedidos de repuestos servirá de base el respectivo catálogo de repuestos.

El presente manual para talleres no está sujeto a un servicio continuado de modificaciones e

innovaciones. Cada nueva edición incluye todas las modificaciones del caso.

Al efectuar reparaciones, aconsejamos asimismo tomar en cuenta las advertencias pertinentes de

nuestras circulares técnicas.

Advertencias generales:

— Le recomendamos la detenida lectura y observancia de las informaciones contenidas en este Manual de taller. Así evitará accidentes y dispondrá de un motor

que funciona perfectamente.

-Haga lo necesario para que este Manual esté a disposición de toda persona que

participe en trabajos de reparación y ajuste, y cuide de que sí comprenda el

contenido.

— Al no tenerse en cuenta estas instrucciones de reparación, podrán surgir

perturbaciones en el funcionamiento y averías en el motor así como lesiones de

personas para las cuales el fabricante no asume responsabilidad alguna.

— Se cumplirán las normas aplicables para la prevención de accidentes así como todas

las demás normas de seguridad y medicina laboral generalmente aceptadas.

— Es condición para la correcta reparación que estén disponibles todos los requeridos

equipos, herramientas manuales y especiales en perfecto estado.

-Máxima rentabilidad, fiabilidad y larga duración quedan garantizadas únicamente al

emplearse repuestos originales de DEUTZ AG.

— Piezas del motor, tales como resortes, garras, aros de sujeción elásticos, etc. ,

aumentan en caso de tratamiento incorrecto el peligro de lesiones.

— El reacondicionado del motor deberá corresponder al empleo previsto definido por

el fabricante del equipo. En caso de transformaciones, se deberán emplear

únicamente piezas admitidas por DEUTZ AG para el respectivo uso previsto.

© 2002 / 0297 9763

Technische Daten / Bildzeichenerklärung

Specification data / Key to symbols

Caractéristiques techniques / Légende des symbols

Datos técnicos / Leyenda de símbolos

Prüfen und Einstellen

Checking and adjusting

Contrôle et réglage

Verificación y ajustes

Inhalts-Verzeichnis

Table of Contents

Sommaire

Indice

1

Bauteile instand setzen

Repair of components

Mise en état des composants

Reparación de componentes

Demontage und Montage, Motor komplett

Disassembly and reassembly of complete engine

Démontage et montage moteur complet

Despiece y ensamblado conjunto de motor

2

3

Werkzeuge

Tools

Outils

Herramientas

© 2002 / 0297 9763

4

5

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

912/913

Hinweis zum Gebrauch des Werkstatthandbuches

In diesem Werkstatthandbuch sind alle technischen Daten, Einstellwerte und

Anziehvorschriften den Stellen zugeordnet, wo sie bei Servicearbeiten, De- und

Montage am Motor benötigt werden.

Notes for the user of this Workshop Manual

In this Workshop Manual all specification data, adjustment values and

tightening specifications are allocated to those parts where they are needed for

service work, disassembly and reassembly on the engine.

Remarque quant à l’utilisazion du Manuel d’atelier

Dans le présent Manuel d’atelier, toutes les caractéristiques techniques, valeurs

de réglage et préconisations de serrage nécessaires se trouvent dans les

chapitres correspondant aux travaux de service après-vente et montage et

démontage du moteur.

Indicación para el uso del manual de taller

En este manual de taller se indican todos los datos técnicos, valores de ajuste y

prescripciones de apriete en los puntos donde son requeridos para la realización

de trabajos de servicio, desmontaje y montaje en el motor.

© 2002 / 0297 9763

Inhalts-Verzeichnis

Table of Contents

Sommaire

Caractéristiques techniques

Specification data

Indice

Werkstatthandbuch FL 912, B/FL 913/C

Deutsch

1. Technische Daten Seite

Technische Daten

Datos técnicos

Techn. Daten 1.00.02 — 1.00.07

Ventilspieleinstellschema 1.00.09

Bildzeichenerklärung 1.00.11

English

1. Specification data Page

Specification data 1.00.02 -1.00.07

Schematic for valve clearance adjustment 1.00.09

Key to symbols 1.00.11

1

Français

1. Caractéristiques techniques Page

Caractéristiques techniques 1.00.02 — 1.00.07

Schéma de réglage des soupapes 1.00.09

Explication des légendes 1.00.11

Español

1. Datos técnicos Página

Datos técnicos 1.00.02 — 1.00.07

Esquema para el ajuste del juego de válvulas 1.00.09

Leyenda de símbolos 1.00.11

© 2002 / 0297 9763

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

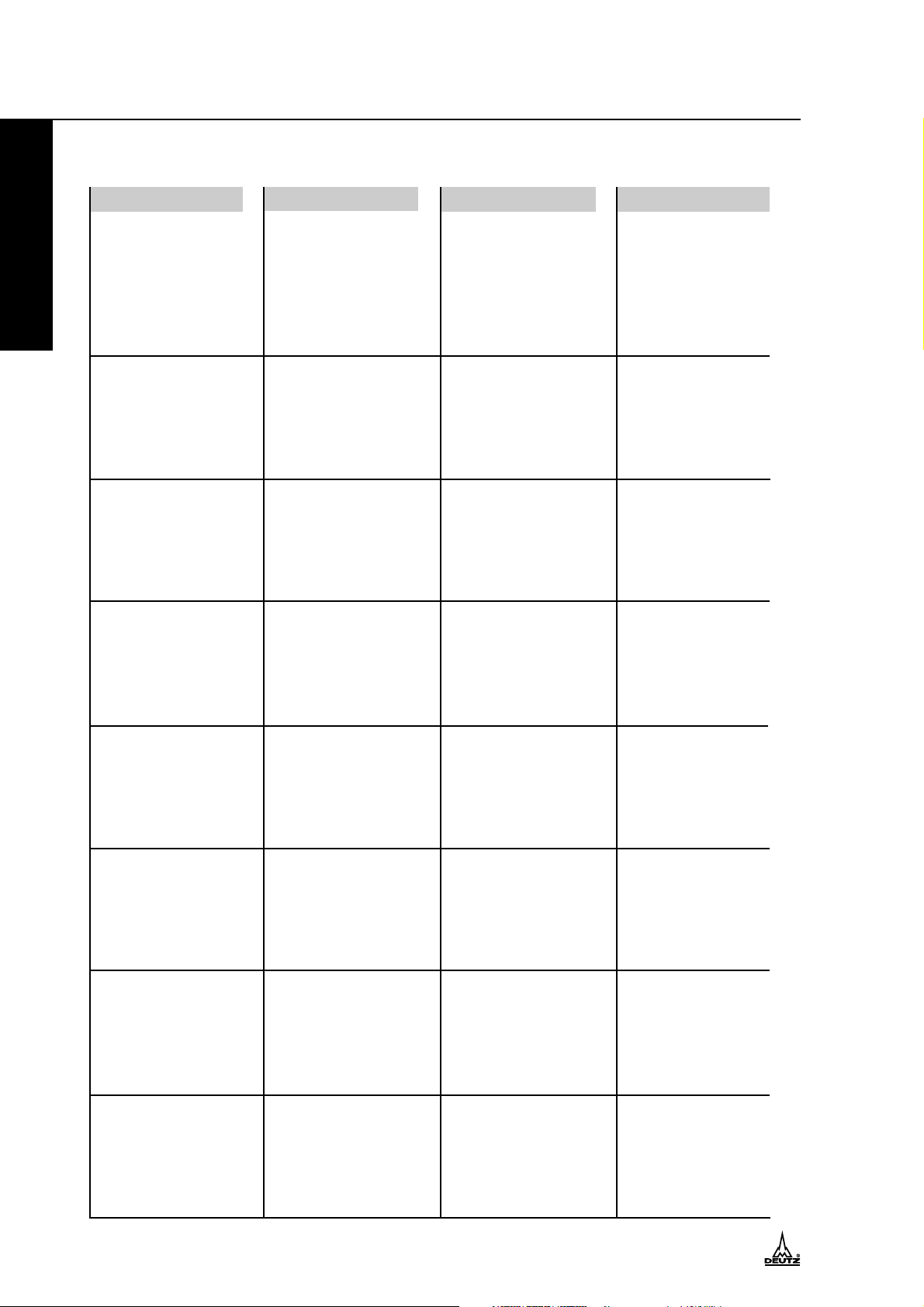

Werkstatthandbuch FL 912, B/FL 913/C

EspañolFrançaisEnglishDeutsch

Motorgewicht

nach DIN 70020 — A

1

ca. kg

Gesamthubvolumen

3

cm

Bohrung

mm

Hub

mm

Engine weight

acc. to DIN 70020 — A

ca. kg

Engine swept volume

3

cm

Bore

mm

Stroke

mm

Poids du moteur

selon DIN 70020 — A

approx. kg

Cylindrée totale

3

cm

Alésage

mm

Course

mm

Peso del motor

según DIN 70020 -A

aprox. kg

Cilindrada total

3

cm

Calibre

mm

Carrera

mm

Drehrichtung

Nenndrehzahl

max. 1/min

niedrigste

Leerlaufdrehzahl

1/min

Arbeitsweise

Direction of rotation

Rated speed

max. rpm

Minimum

idle speed

rpm

Working cycle

Sens de rotation

Régime nominal

maxi tr/mn

Ralenti extrême

tr/mn

Principe de fonction-

nement

Sentido de giro

Régimen nom.

máx. rpm

Régimen mín.

en vacío

rpm

Sistema de trabajo

1.00.02

© 2002 / 0297 9763

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

Werkstatthandbuch FL 912, B/FL 913/C

F3 — 6L 912

F3L = 270 F3L = 277 BF4L = 360 510

F4L = 300 F4L = 320 BF6L = 485

F5L = 380 F6L = 420

F6L = 410

F3L = 2827 F3L = 3064 BF4L = 4086 6128

F4L = 3770 F4L = 4086 BF6L = 6128

F5L = 4712 F6L = 6128

F6L = 5655

100 102

F3/4/6L 913

BF4/6L 913

BF6L 913C

1

120 125

Auf Schwungrad gesehen links

When facing flywheel counter-clockwise

Vu sur volant à gauche

Mirándose sobre el volante a la izquierda

2500

650 — 700

Viertakt — Diesel

Four-stroke diesel

Diesel 4 temps

Diesel a 4 tiempos

© 2002 / 0297 9763

1.00.03

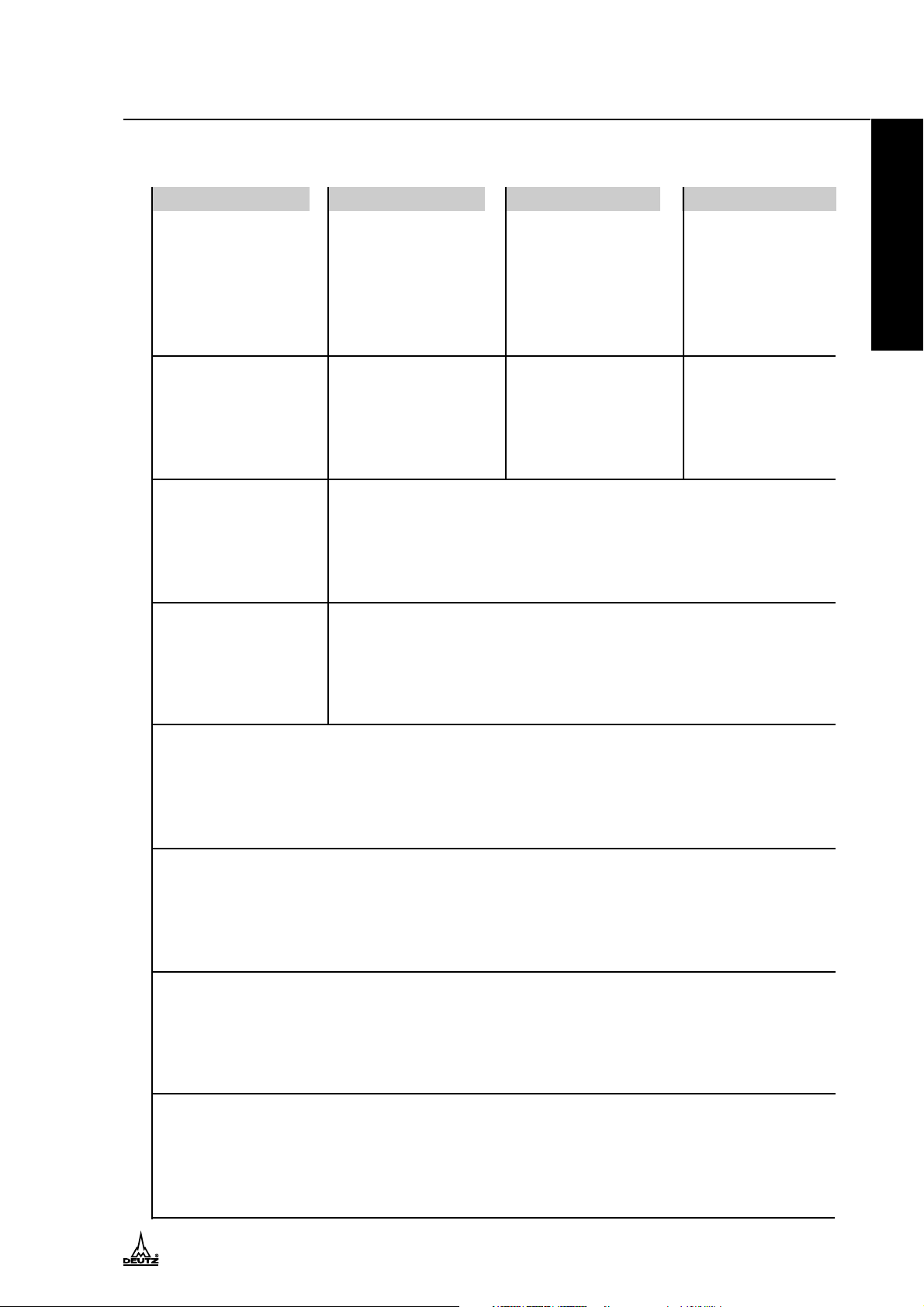

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

Werkstatthandbuch FL 912, B/FL 913/C

EspañolFrançaisEnglishDeutsch

Verbrennungs-

verfahren

Combustion

system

Principe de

combustion

Sistema de

combustión

1

Verdichtungs-

verhältnis

Kompressionsdruck

bar

Zündfolge

Compression

ratio

Compression pressure

bar

Firing order

Taux de

compression

Compression

bars

Ordre d’allumage

Relación de

compresión

Presión in

compresión

bar

Orden de

encendido

Abmessungen des

Motors mit

Anschlußgehäuse

(normal)

größte Länge

mm

größte Breite

mm

größte Höhe

mm

Dimensions of

engine incl.

standard adapter

housing

Max. length

mm

Max. width

mm

Max. height

mm

Dimensions du

moteur avec carter

d’adaption standard

Longueur HT

mm

Largeur HT

mm

Hauteur HT

mm

Dimensiones del

motor con

caja de adaptación

(normal)

Longitud máx.

mm

Anchura máx.

mm

Altura máx.

mm

1.00.04

© 2002 / 0297 9763

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

Werkstatthandbuch FL 912, B/FL 913/C

F3 — 6L 912 F3/4/6L 913 BF4/6L 913 BF6L 913C

Direkteinspritzung

Direct injection

Injection directe

Inyecctión directa

19 18 17

1

20 — 30

F3L = 1 — 2 — 3

B/F4L = 1 — 3 — 4 — 2

F5L = 1 — 2 — 4 — 5 — 3

B/F6L = 1 — 5 — 3 — 6 — 2 — 4

F3L = 561 F3L = 561 BF4L = 885 1012

F4L = 691 F4L = 691 BF6L = 1012

F5L = 766 F6L = 915

F6L = 915

650 650 BF4L = 692 739

BF6L = 739

F3L = 872 F3L = 873 BF4L = 872 1176

F4L = 873 F4L = 873 BF6L = 1176

F5L = 910 F6L = 873

F6L = 884

© 2002 / 0297 9763

1.00.05

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

Werkstatthandbuch FL 912, B/FL 913/C

Deutsch

1

Steuerzeiten bei

eingestelltem Ventilspiel

Einlaß öffnet

vor OT

Grad

Einlaß schließt

nach UT

Grad

Auslaß öffnet

vor UT

adjusted valve clearance

English

Valve timing with

Inlet opens

before TDC

degrees

Inlet closes

after BDC

degrees

Exhaust opens

before BDC

Calage de la distribution

Français Español

après calage du jeu aux

soupapes

Admission ouvre

avant PMH

degrés

Admission ferme

après PMB

degrés

Echappement ouvre

avant PMB

Cotas de reglaje con el

juego de válvulas

ajustado

Admisión abre

ante PMS

grados

Admisión cierra

tras PMI

grados

Escape abre

ante PMI

Grad

Auslaß schließt

nach OT

Grad

Schmieröldruck in niedrigem

Leerlauf 650/min.,

ohne Motorölheizung,

Temperatur ca. 120° C

Öl SAE 15W/40

Minimum bar

Öffnungsdruck des

Absteuerventils

bar

Schmierölpumpe:

40 + 60 Liter / min.

70 + 80 Liter / min.

degrees

Exhaust closed

after TDC

degrees

Lube oil pressure at low

idling at 650 rpm,

without engine-oil heating,

temperature approx 120°C

Oil

SAE 15W/40

min. bar

Opening pressure of

pressurestat

bar

Lube oil pump

40 + 60 litres / min.

70 + 80 litres / min.

degrés

Echappement ferme

après PMH

degrés

Pression huile de graissage

au ralenti mini 650 tr/min

sans chauffage huile moteur,

température env. 120°C

huile SAE 15W/40

minimum bar

Pression d’ouverture du

clapet de sècurité

bar

Pompe à huile

40 + 60 litres / min

70 + 80 litres / min

grados

Escape cierra

tras PMS

grados

Presión de aceite lubricante a

marcha lenta en vacío 650 r/min,

sin calefacción por aceite motor,

temperatura aprox. 120°C,

aceite SAE 15W/40

mín. bar

Presión de apertura de la

válvula de control de caudal

bar

Bomba de aceite lubricante:

40 + 60 litros / min.

70 + 80 litros / min.

1.00.06

© 2002 / 0297 9763

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

Werkstatthandbuch FL 912, B/FL 913/C

BF6L 913CBF4/6L 913F3 — 6L 912 F3/4/6L 913

34 27 32

1

65 45 40

76 87 83

35 29 33

0,4

5,5 — 6,5

5,0 — 6,0

© 2002 / 0297 9763

1.00.07

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

Werkstatthandbuch FL 912, B/FL 913/C

1

© 2002 / 0297 9763

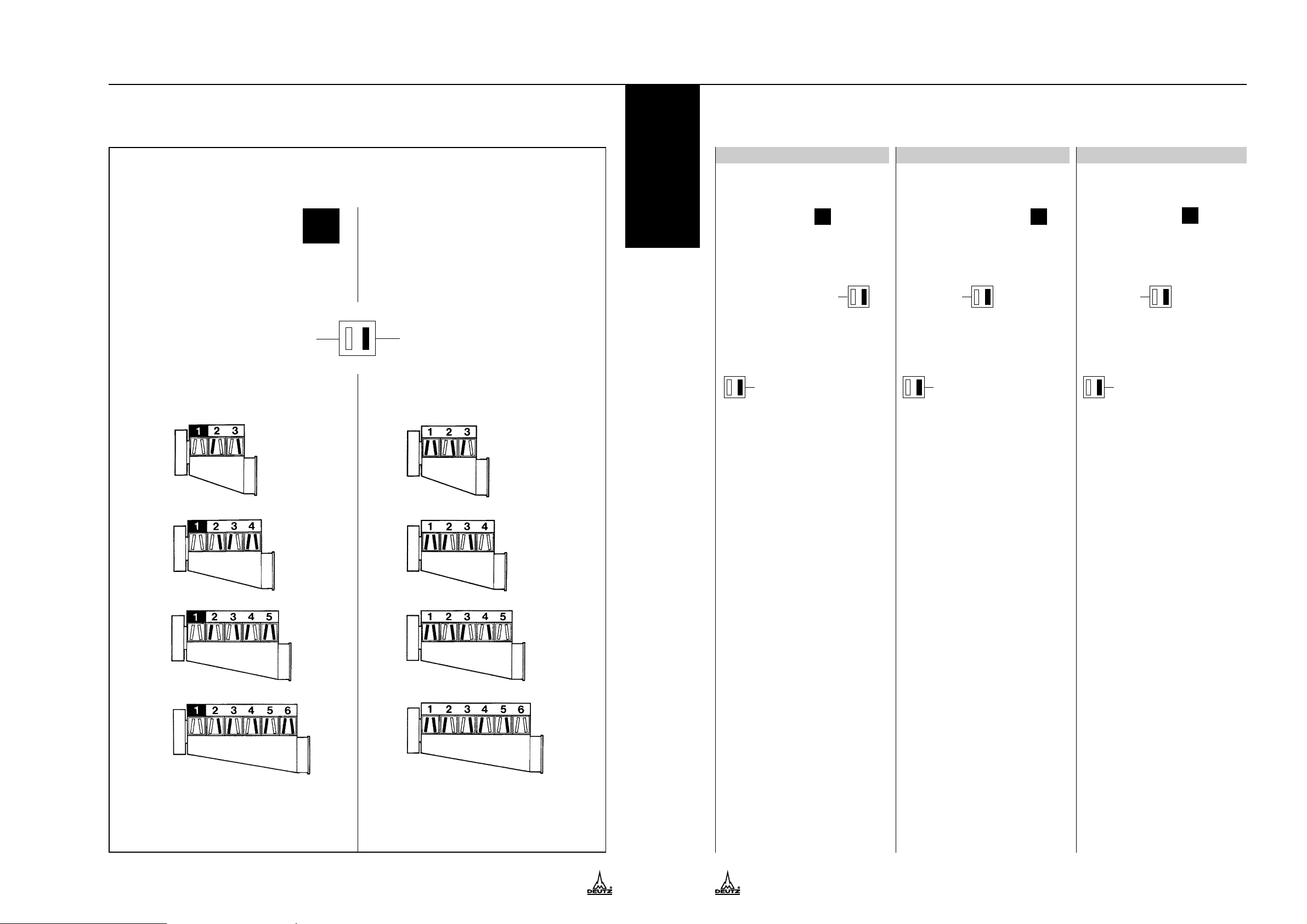

Ventilspieleinstellschema

Schematic for valve clearance adjustment

Schéma de réglage des soupapes

Esquema para el ajuste de juegos de válvulas

Werkstatthandbuch FL 912, B/FL 913/C

Kurbelwellenstellung Kurbelwellenstellung

Motor bis zum Erreichen der Ventilüberschneidung am Zyl. Nr. 1 durchdrehen.

nicht einstellbar

1

1

Motor um eine volle Umdrehung (360°)

weiterdrehen.

einstellbar

2

English

1

11

11

Crankshaft position

Turn engine until valves of cylinder

No. 1 overlap.

Not ready for adjustment.

Crankshaft position 2:

Turn engine further by one complete

revolution (360°).

Ready for adjustment.

Position de l’arbre à cames

Virer le moteur jusqu’au chevauchement des soupapes au cylindre 1.

non réglable

Position de l’arbre à cames 2

Tourner le moteur d’un tour complet

(360°)

réglable

11

EspañolFrançais

1

Posición del cigüeñal

Girar el motor hasta el cruce de las

válvulas en el cilindro 1.

no ajustable

Posición del cigüeñal 2

Seguir girando el motor una vuelta

completa (360°)

ajustable

1

1.00.09 1.00.09

© 2002 / 0297 9763© 2002 / 0297 9763

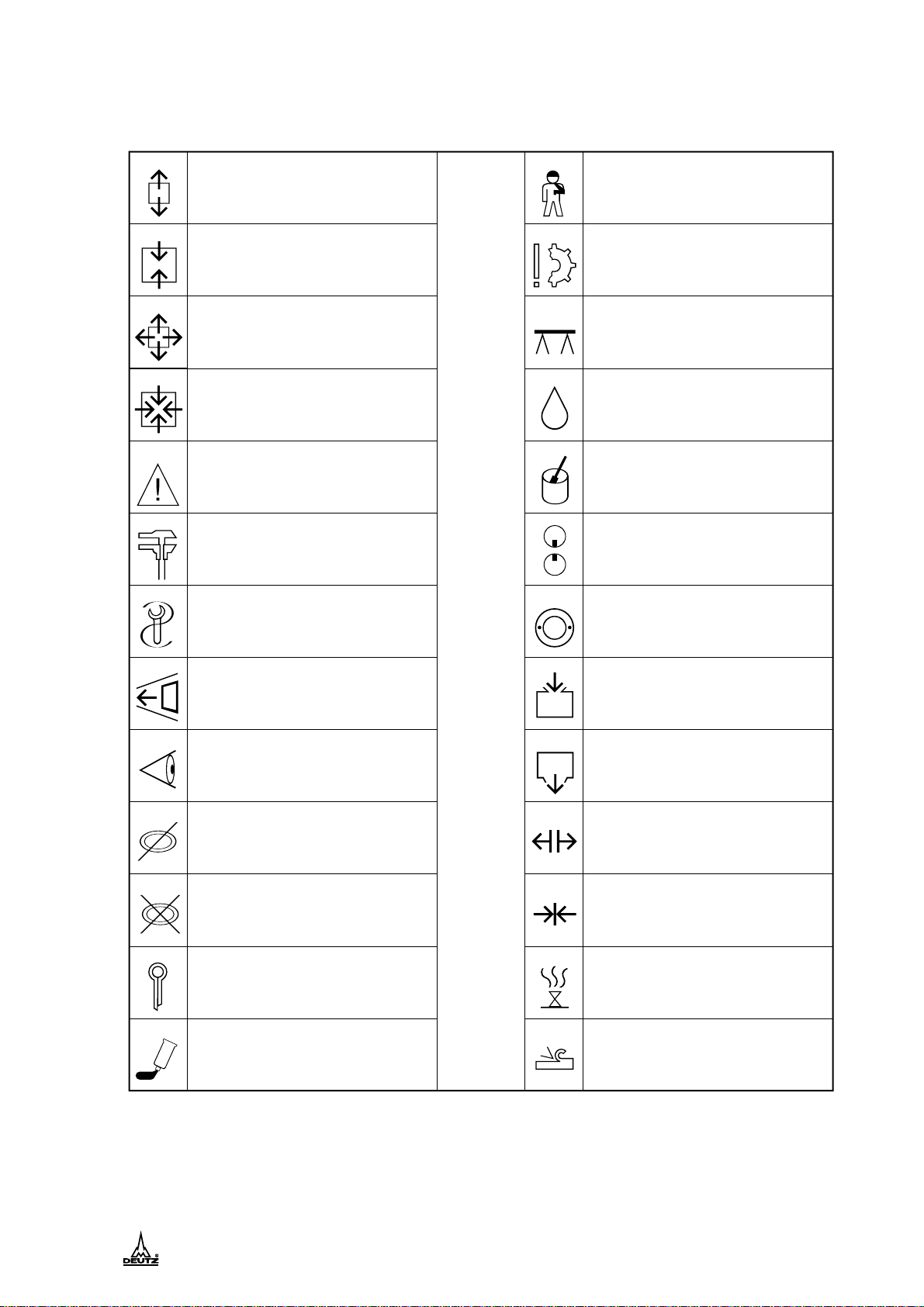

Bildzeichenerklärung

Zerlegen

von Baugruppen

Zusammenbauen

zu einer Baugruppe

Abbauen — Ausbauen

behindernder Teile

Einbauen — Anbauen

Teile, die beim Ab-/ Ausbau hinderten

Achtung, wichtiger Hinweis

Prüfen — Einstellen

z. B. Drehmomente, Maße, Drücke usw.

Spezialwerkzeug

Personenschäden verhüten

Hinweis auf Gefahrenstelle

Materialschaden verhüten

Teilbeschädigung

Unterbauen — Abstützen Abfangen

Einölen

Einfetten

Markieren

vor dem Zerlegen, beachten beim

Zusammenbau

Wuchten

Einbaurichtung beachten

Kontrollieren — Prüfen

Sichtprüfung

Bedingt wiederverwendbar

Bei Bedarf auswechseln

Beim Zusammenbau immer

erneuern

Entsichern — Sichern

z. B. Splint, Sicherungsblech usw.

Sichern — Kleben

z. B. Dichtmittel flüssig

Ausgleichen von Unwuchten

Einfüllen — Auffüllen — Nachfüllen

z. B. Öl, Kühlwasser usw.

Ablassen

z. B. Öl, Kühlwasser usw.

Lösen

z. B. Lockern einer Spanneinrichtung

Spannen

z. B. Anziehen einer Spanneinrichtung

Entlüften

Spanabhebende Bearbeitung

© 2002 / 0297 9763

1.00.11

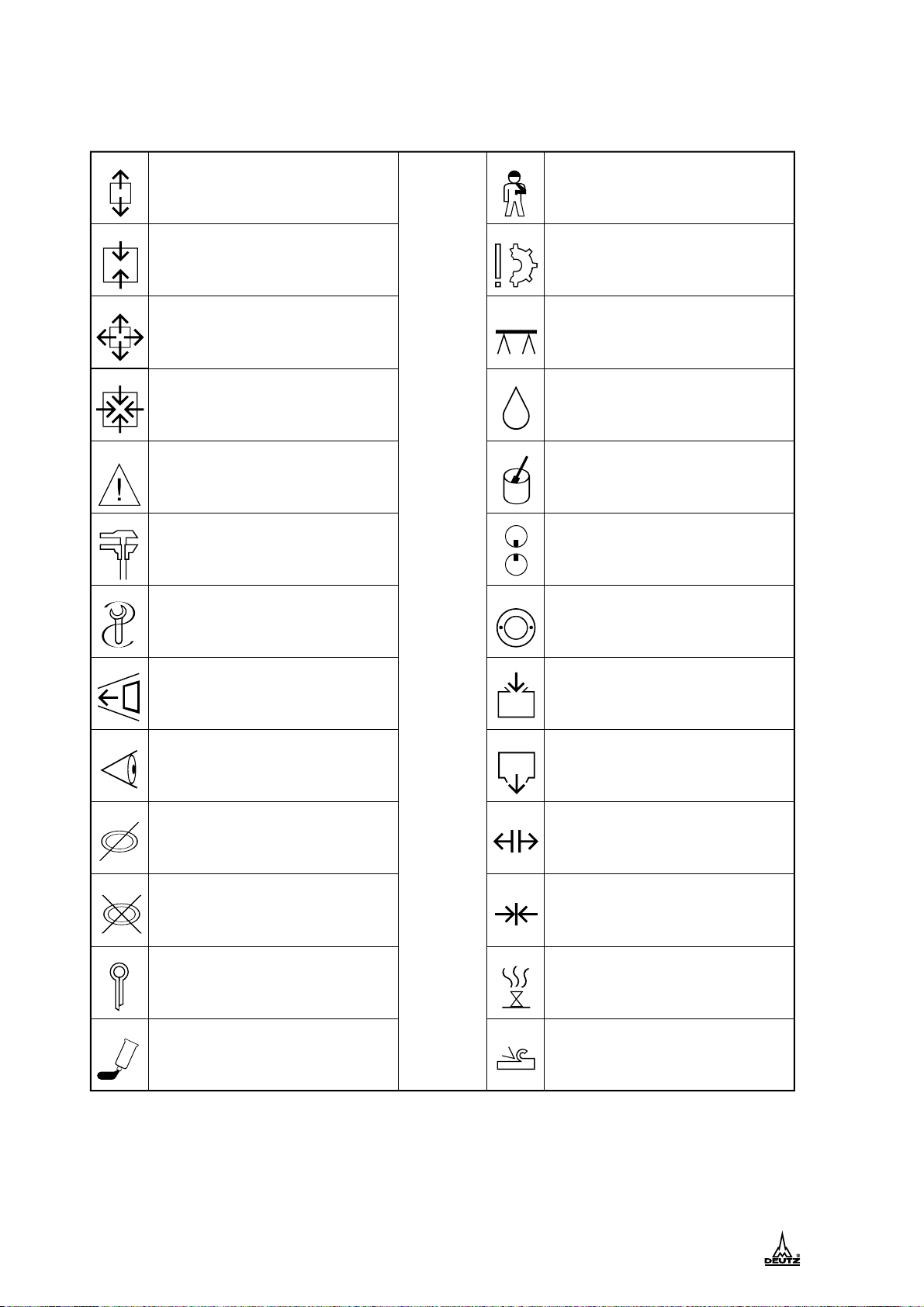

Key to Symbols

Disassembly

of assembly groups

Reassemble

to form assembly group

Remove

obstructing parts

Reinstall — Remount

parts which had obstructed disassembly

Attention! Important notice!

Check — Adjust

e.g. torque, dimensions, pressures, etc.

Special tool

Guard against personal injury

Indication of hazard

Guard against material damage

Damage to parts

Prop up — Support — Hold

Oil

Grease

Mark

before disassembly, observe marks when

reassembling

Balance

Note direction of installation

Visual inspection

Possibly still serviceable

Renew if necessary

Renew at each reassembly

Unlock — Lock

e. g. splint pin, locking plate, etc.

Lock — Adhere

e.g. with liquid sealant

Eliminate any imbalance

Filling — Topping up — Refilling

e. g. oil, cooling water, etc.

Drain off

e. g. oil cooling water, etc.

Loosen — Release

e. g. loosening a clamping device

Tighten — Clamp

e. g. tightening a clamping device

Vent

Machining process

1.00.11

© 2002 / 0297 9763

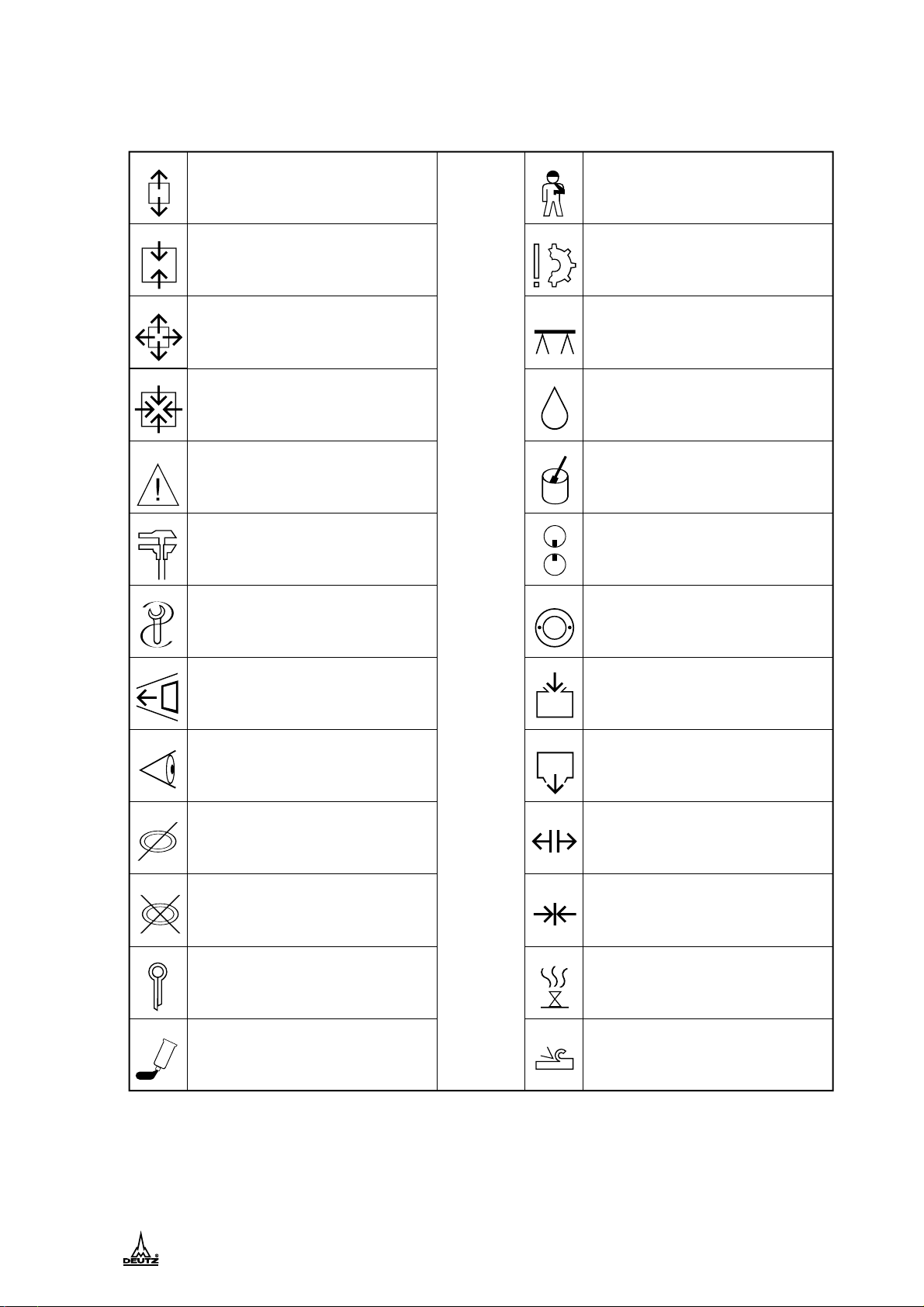

Légende des symboles

Déassemblage

d’un ensemble constructif

Assemblage

des composants d’un ensemble constructif

Démontage

d’éléments entravant l’accés

Remontage — Remise en place

d’éléments qui entravaient l’accés

Remarque importante!

Utilisation impérative

p.ex.: couple-moteur, cotes, pressions etc.

Utilisation impérative

Prévention aux accidents profession

attirer l’attention sur un risque eventuel

d’accident

Prévention à la détérioration de

matériels

Risque d’endommager des piéces

Monter sur tréteaux — freiner par

sabots — immobiliser par un moyen

quelconque

Huiler

Graisser

employer lubrificant plastique

Repérage en cours de démontage

perment un remontage correct!

Equilibrer

d’un outil specialise

Respecter l’ordre de montage

Vérification — Contrôle

à vue

Réutilisation sous certaines

conditions

à remplacer, si besoin est

A remplacer systématiquement

lors de remontage

Arracher la goupille — goupiller

freiner par tôle-arrétoir

Freiner — coller

p. ex.: avec páte hermétique, ou frein liquide

éliminer le balourd

Premier garnissage — remplissage garnissage d’appoint

p. ex.: Huile eau de refroidissement etc.

Vidanger — soutirer

p. ex.: Huile eau de refroidissement etc.

Desserrer

p. ex.: desserrage d’un dispositiv

Serrer

p. ex.: serrage entre un dispositif

Faire la purge d’air

Usinage par enlèvement de copeaux

© 2002 / 0297 9763

1.00.11

Leyenda de símbolos

Desarmar

grupos de construcción

Rearmar

un grupo de construcción

Desmontar

partes que puedan estorbar

Montar — Incorporar

partes que puedan estorbar en el desmontaje

!Atención! Indicación importante

Verificar — Graduar — Ajustar

(p. ej. pares, medidas, presiones)

Herramienta especial

Evitar accidentes

indica puntos peligro

Evitar daños materiales

avería de piezas

Calzar — Apoyar

Aceitar

Engrasar

Marcar

antes del desmontaje — controlar la

marcación en el remontaje

Equilibar

Observar la dirección de montaje

Control — Examen

verificatión visual

Re — utilización condicional

sustituir en caso necesario

Sustituir en cada montaje

Desafianzar — Afianzar

(p. ej. pasador de aletas, chapa de seguridad,

etc).

(mecánicamente)

Afianzar — Pegar

p. ej. con medio liquido

Eliminar desequilibros o excentricidades

Llenar — Rellenar — Completar

p. ej. aceite, agua refrigerante, etc.

Evacuar — Vaciar

p. ej. aceite, agua refrigerante, etc.

Soltar

p. ej. un sistema de fijación o tensado

Tensar — Apretar

p. ej. un sistema de fijación o tensado

Purgar el aire

Mecanización con arranque de

virutas

1.00.11

© 2002 / 0297 9763

Prüfen und Einstellen

Checking and adjusting

Contrôle et réglage

Verificación y ajustes

912/913

© 2002 / 0297 9763

Inhalts-Verzeichnis

Table of Contents

Sommaire

Indice

Prüfen und Einstellen

Checking and adjusting

Contrôle et réglage

Verificación y ajustes

Deutsch

Werkstatthandbuch FL 912, B/FL 913/C

2. Prüfen und Einstellen Seite

Ventilspiel _______________________________________ 2.00.01 — 2.00.02

Kompressionsdruck _______________________________________ 2.00.03 — 2.00.07

Oberer Totpunkt _______________________________________ 2.00.09 — 2.00.13

Förderbeginn _______________________________________ 2.00.15 — 2.00.20

Einspritzventil _______________________________________ 2.00.21 — 2.00.23

Einspritzpumpe _______________________________________ 2.00.25 — 2.00.27

Abgasthermostat _______________________________________ 2.00.29 — 2.00.33

English

2. Checking and adjusting Page

Valve clearance _______________________________________ 2.00.01 — 2.00.02

Compression pressure _______________________________________ 2.00.03 — 2.00.07

Top dead center _______________________________________ 2.00.09 — 2.00.13

Commencement of delivery _______________________________________ 2.00.15 — 2.00.20

Injector _______________________________________ 2.00.21 — 2.00.23

Injection pump _______________________________________ 2.00.25 — 2.00.27

Exhaust thermostat _______________________________________ 2.00.29 — 2.00.33

2

Français

2. Contrôle et réglage Page

Jeu aux soupapes _______________________________________ 2.00.01 — 2.00.02

Taux de compression _______________________________________ 2.00.03 — 2.00.07

Point mort haut _______________________________________ 2.00.09 — 2.00.13

Début d’injection _______________________________________ 2.00.15 — 2.00.20

Injecteur _______________________________________ 2.00.21 — 2.00.23

Pompe d’injection _______________________________________ 2.00.25 — 2.00.27

Thermostat sur échappement _______________________________________ 2.00.29 — 2.00.33

Español

2. Verificación y ajustes Pagina

Juego de válvulas _______________________________________ 2.00.01 — 2.00.02

Presión de compresión _______________________________________ 2.00.03 — 2.00.07

Punto muerto superior _______________________________________ 2.00.09 — 2.00.13

Comienzo de alimentación _______________________________________ 2.00.15 — 2.00.20

Inyector _______________________________________ 2.00.21 — 2.00.23

Bomba de inyección _______________________________________ 2.00.25 — 2.00.27

Termostato de escape _______________________________________ 2.00.29 — 2.00.33

© 2002 / 0297 9763

Prüfen und Einstellen

Checking and adjusting

Contrôle et réglage

Verificación y ajustes

Ventilspiel

Valve clearance

Jeu aux soupapes

Juego de válvulas

English

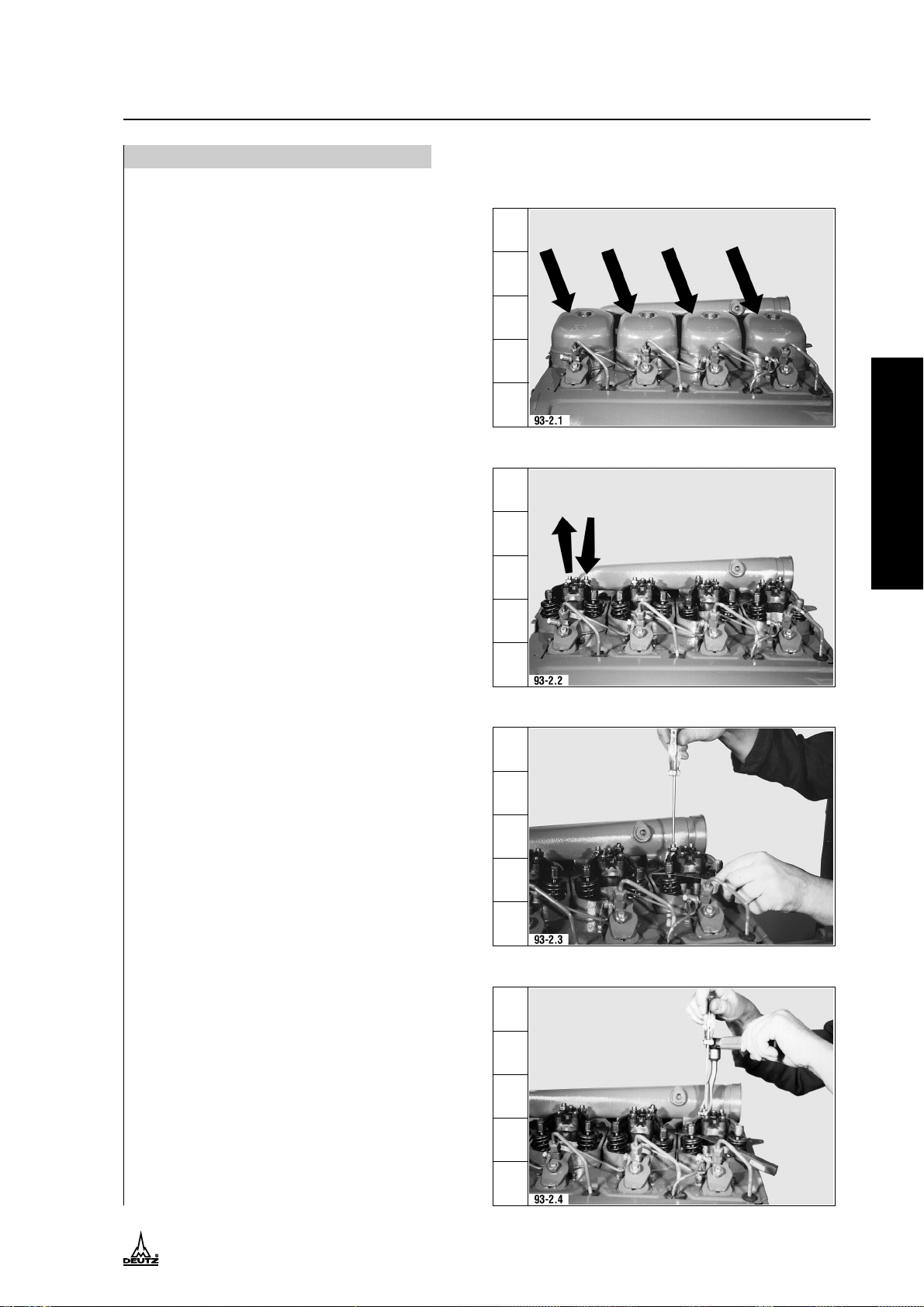

Adjust valve clearance only with engine

cold. The engine must have cooled

down to ambient temperature

1. Remove cylinder head covers.

2. Crank engine until valves of cyl. No.

1 overlap.

See Specification Data for valve

2

clearance adjustment schematic.

Note: Valve overlap means. Exhaust

valve about to close, inlet valve

about to open. Neither pushrod

can be turned in this position.

Français Español

Pour régler le jeu aux soupapes, le

moteur doit toujours être froid, donc le

laisser refroidir à la température

ambiante.

1. Déposer les cache-culbuteurs.

2. Virer le moteur jusqu’à ce que les

soupapes soient en bascule, cyl. no. 1.

Schéma de réglage du jeu aux soupapes, voir caractéristiques techniques

Nota: soupapes en bascule signifie:

soupape d’échappement pas

encore fermée et soupape

d’admission commence à

s’ouvrir.

Lors de cette opération les

deux tiges de culbuteurs ne

peuvent plus tourner.

Ajustar el juego de válvulas sólo con el

motor frío. El motor deberá estar enfriado

a la temperatura ambiente.

1. Desmontar las tapas de culata.

2. Girar el cigüeñal hasta el cruce de

las válvulas en el cilindro No. 1.

Para el esquema de ajuste del juego

de válvulas, ver los Datos Técnicos.

Nota: Cruce de válvulas significa:

La válvula de escape aún no

está cerrada y la válvula de

admisión comienza a abrirse.

3. Adjust valve clearance on relevant

cylinder with feeler gauge.

Note: Inlet valve

clearance 0.15 + 0.05 mm

Exhaust valve

clearance 0.15 + 0.05 mm

4. Tighten locknut.

Tightening specification: 22 ± 2 Nm

Recheck the adjustment with feeler

gauge.

3. Régler le jeu aux soupapes sur le

cylindre concerné à l’aide de jauges

d’épaisseur.

Nota: jeu aux soupapes

ADM 0,15 + 0,05 mm

ECH 0,15 + 0,05 mm

4. Bloquer le contre-écrou.

Consigne de serrage: 22 ± 2 Nm

Contrôler à nouveau le réglage à

l’aide de jauges d’épaisseur.

3. Ajustar el juego de válvulas en el

cilindro correspondiente utilizando

una galga de espesores.

Nota: Juego de válvulas

— Admisión 0,15 + 0,05 mm

— Escape 0,15 + 0,05 mm

4. Apretar la contratuerca.

Prescripción de apriete: 22 ± 2 Nm

Verificar de nuevo el ajuste

efectuado, mediante la galga de

espesores.

2.00.01

© 2002 / 0297 9763

Ventilspiel

Valve clearance

Jeu aux soupapes

Juego de válvulas

Prüfen und Einstellen

Checking and adjusting

Contrôle et réglage

Verificación y ajustes

Deutsch

Ventilspiel nur am kalten Motor einstellen. Der

Motor soll auf Umgebungstemperatur abgekühlt

sein.

1. Zylinderkopfhauben abbauen.

2. Motor durchdrehen bis zum Erreichen der

Ventilüberschneidung, Zyl. Nr. 1.

Ventilspieleinstellschema siehe Techn. Daten

Hinweis: Ventilüberschneidung bedeutet:

Auslaßventil ist noch nicht geschlossen, Einlaßventil beginnt zu öffnen.

Dabei sind beide Stoßstangen nicht

drehbar.

Werkstatthandbuch FL 912, B/FL 913/C

3

9

5

2

3. Ventilspieleinstellung am entsprechenden

Zylinder mit Fühlerlehrenblatt einstellen.

Hinweis: Ventilspiel Einlaß 0,15 + 0,05 mm

Ventilspiel Außlaß 0,15 + 0,05 mm

4. Kontermutter festdrehen.

Anziehvorschrift: 22 ± 2 Nm

Einstellung nochmals mit Fühlerlehrenblatt

überprüfen.

6

5

4

6

© 2002 / 0297 9763

2.00.01

Loading…

Deutz 2008-2009 Service Manual

Deutz 2008-2009 Service Manual

Deutz 2008-2009 Service Manual_compresse

Adobe Acrobat Document

4.2 MB

Deutz FL 411 Service Manual

Deutz FL 411 Service Manual

Deutz FL 411 Service Manual_compressed.p

Adobe Acrobat Document

3.1 MB

Deutz Engine S-BV6-8-9M628 Operation Manual

Deutz Engine S-BV6-8-9M628 Operation Manual

Deutz Engine S-BV6-8-9M628 Operation Man

Adobe Acrobat Document

5.2 MB

Deutz 226B Operation Manual

Deutz 226B Operation Manual

Deutz 226B Operation Manual_compressed.p

Adobe Acrobat Document

2.2 MB

Deutz FL 413 Service Manual

Deutz FL 413 Service Manual

Deutz FL 413 Service Manual_compressed.p

Adobe Acrobat Document

3.1 MB

Deutz Serie 7 Agrotron Service Manual

Deutz Serie 7 Agrotron Service Manual

Deutz Serie 7 Agrotron Service Manual_co

Adobe Acrobat Document

3.6 MB

Gt-50dz Tow Tractor With Deutz Engine

Gt-50dz Tow Tractor With Deutz Engine

Gt-50dz Tow Tractor With Deutz Engine_co

Adobe Acrobat Document

23.7 MB

Deutz 1011 Parts Manual

Deutz 1011 Parts Manual

Deutz 1011 Parts Manual_compressed.pdf

Adobe Acrobat Document

1.7 MB

Deutz 2008-2009 Parts Manual

Deutz 2008-2009 Parts Manual

Deutz 2008-2009 Parts Manual_compressed.

Adobe Acrobat Document

2.2 MB

Deutz 413 Parts Manual

Deutz 413 Parts Manual

Deutz 413 Parts Manual_compressed.pdf

Adobe Acrobat Document

2.6 MB

|

Deutz 912 Parts Manual [PDF] |

4.3Mb |

Download |

|

Deutz 912 Technical Specifications [PDF] |

384.6kb |

Download |

|

Deutz 912-913 Repair Manual [PDF] |

5.8Mb |

Download |

|

Deutz 912-913 Service Manual [PDF] |

2.6Mb |

Download |

|

Deutz 912-913 Workshop Manual [PDF] |

34.5Mb |

Download |

|

Deutz F 3 L912 / W, F 4 L912 / W, F 5 L912 / W, B / F6 L912 / W Spare Parts Catalog [PDF] |

15.7Mb |

Download |

|

Deutz 2008-2009 Parts Manual [PDF] |

3.1Mb |

Download |

|

Deutz 2008-2009 Service Manual [PDF] |

4.4Mb |

Download |

|

Deutz 226B Operation Manual [PDF] |

8.5Mb |

Download |

|

Deutz 413 Parts Manual [PDF] |

4.5Mb |

Download |

|

Deutz Accessories Catalogue [PDF] |

5.2Mb |

Download |

|

Deutz BF4M1013C Spare Parts Catalogue [PDF] |

3Mb |

Download |

|

Deutz BFM 1015 Series — BF6M 1015 C, BF8M 1015, BF8M 1015 C, BF8M 1015 CP, BF6M 1015 CP Workshop Manual [PDF] |

12.3Mb |

Download |

|

Deutz D 2008-2009 Workshop Manual [PDF] |

4.6Mb |

Download |

|

Deutz D 909 / 910, B / FL 1011 / F / 2011, B / FL 912 / 913 / 914 / C, B / FL 413 F / 513 / C / CP, B / FM 1011 F |

7.8Mb |

Download |

|

Deutz Engine D2008 2009 Workshop Manual PDF [PDF] |

3.8Mb |

Download |

|

Deutz Engine Fire Protection — Operation Manual [PDF] |

21.2Mb |

Download |

|

Deutz Engine S-BV6-8-9M628 Operation Manual [PDF] |

10Mb |

Download |

|

Deutz FL 411 Service Manual [PDF] |

8.7Mb |

Download |

|

Deutz FL 413 Service Manual [PDF] |

8.7Mb |

Download |

|

Deutz Serie 7 Agrotron Service Manual [PDF] |

4.1Mb |

Download |

|

Gt-50dz Tow Tractor With Deutz Engine [PDF] |

36.1Mb |

Download |

|

Deutz 914 Parts Manual [PDF] |

4.3Mb |

Download |

|

Deutz 914 Service Manual [PDF] |

2.7Mb |

Download |

|

Deutz Engine 914 Operation Manual [PDF] |

3.2Mb |

Download |

Deutz

The German company Deutz was created by designer Nikolaus Otto and businessman Eugen Longen. At the time of the organization, Otto had already

created his internal combustion engine, Longen helped him get a patent and conducted an advertising campaign. Three years later, the model at the Paris exhibition received a gold medal, it was a

worthy alternative to bulky and dangerous steam engines.

In 1869, in the suburbs of Cologne, partners launched a motor factory. Otto managed to improve his development, and he proposed to the world the

first Deutz four-stroke engine, in which the principle of compression of the fuel-air mixture was used before ignition. Then, together with Robert Bosch, he developed an electric ignition

system.

In subsequent years, the production of engines, spare parts and parts for them was led by legendary personalities: Gottlieb Daimler, Wilhelm

Maybach, collaborated with the company «motor genius» Rudolf Diesel and the creator of the famous car Ettore Bugatti. Since its birth, Deutz has made a significant contribution to the history of

the world engine industry.

In 1949, Deutz production was expanded. The range of motor products was supplemented by agricultural and construction equipment — tractors, trucks

and dump trucks equipped with air-cooled diesel engines. In 1975, Iveco bought the automobile production, Deutz retained the production of motors and tractors, noting in 1978 the manufacture of a

4 millionth internal combustion engine.

The agricultural machinery production line was sold by the company to the Italian Same Group in 1995, and Deutz returned to its origins — the

production of engines for various purposes, including for power plants.

Today, Deutz employs more than 6,000 employees, of which more than 1,500 are in other countries. The corporation includes 22 factories producing

power plants for various purposes, spare parts for them and some consumables. This business activity provides the company with an annual turnover of more than 1.3 billion euros. Sale of engines,

their maintenance, warranty and post-warranty repairs are carried out in 130 countries.

deutz f6l912 manual

LINK 1 ENTER SITE >>> Download PDF

LINK 2 ENTER SITE >>> Download PDF

File Name:deutz f6l912 manual.pdf

Size: 1255 KB

Type: PDF, ePub, eBook

Category: Book

Uploaded: 3 May 2019, 16:44 PM

Rating: 4.6/5 from 562 votes.

Status: AVAILABLE

Last checked: 13 Minutes ago!

In order to read or download deutz f6l912 manual ebook, you need to create a FREE account.

Download Now!

eBook includes PDF, ePub and Kindle version

✔ Register a free 1 month Trial Account.

✔ Download as many books as you like (Personal use)

✔ Cancel the membership at any time if not satisfied.

✔ Join Over 80000 Happy Readers

deutz f6l912 manualDeutz F6L912 Spare Part Manual Deutz F6L912 Spare Part Manual PDF. DEUTZ Dieselmotor mit Stromaggregat — Humboldt Deutz AG Koln Bj 1951. Search DEUTZ company’s catalogues and technical brochures P. Deutz F6L912 Spare Part Manual from facebook. Komatsu WA480 -5L, Wheel. Deutz F6l912 Engine Service Manual. It has a max. DEUTZ Videocast DEUTZ TCD 2.9 L4: Xchange Facility The Legacy Continues. Deutz F6L912 Spare Part Manual. Rt25 Crane Deutz F6L912 Spare Part Manual Maintenance. Account Management My Account job in close quarters. KOMATSU PC18MR-2 EXCAVATOR Maintenance and Troubleshooting Manual KOMATSU advice on repairing and WB70A-1. Due to size and weight restrictions some items. Tier 4 105 HP. SAVE ON MARKDOWNS See. L250 Skid Steer OEM. VIN 1NT1M452XG1002900 Document Fee. As an Authorized Deutz Service Dealer, we have a huge inventory of genuine parts for Deutz 912 engines, including models F3L912, F4L912, F5L912 and F6L912. Aprilia Rsvr Motorcycle Complete Operators Manual, 100 pages. See each listing for. As an Authorized Deutz Service Dealer, we have a great selection of genuine injection pumps for Deutz 912 engines, including models F3L912, F4L912, F5L912 and F6L912. Buy, sell or hire new and used trucks, buses, forklifts and equipment throughout Australia. DEUTZ. TruckSales is the leading online truck and transport equipment sales. Deutz F6L912 Spare Part Manual from cloud storage. Used Moxy MT40 Articulated and Troubleshooting Manual KOMATSU Illinois, United States for Troubleshooting Manual MACHINE MODEL inspected and guaranteed. KOMATSU PC18MR-2 EXCAVATOR Maintenance Dump Truck in Romeoville, advice on repairing and servicing their lawn mowers. An excellent value for Elbows Impeller Kits Oil advice on repairing and. Deutz F6L912 Spare Part Manual dropbox upload. Deutz F6L912 Spare Part Manual download.No refunds will be see it listed doesn’t and red clay tile. New Deutz F6L912 Spare Part Manual from Document Storage. Fenster schlie?en.http://www.blackhunter.ru/files/file/bosch-washer-user-manual.xml

- Tags:

- deutz f6l912 manual pdf, deutz f6l912 manual, deutz f6l912 parts manual, deutz f6l912 engine manual, deutz engine f6l912 manuals, deutz f6l912 service manual, deutz f6l912 engine parts manual, deutz f6l912 service manual pdf, deutz f6l912 diesel engine service manual, motor deutz f6l912 manual, 1.0, deutz f6l912 manual pdf, deutz f6l912 manual, deutz f6l912 parts manual, deutz f6l912 engine manual, deutz engine f6l912 manuals, deutz f6l912 service manual, deutz f6l912 engine parts manual, deutz f6l912 service manual pdf, deutz f6l912 diesel engine service manual, motor deutz f6l912 manual.

It contains the most This Vertical Exhaust Manifold fits 3-cylinder tractors 1975. DEUTZ is one of the largest independent manufacturers of diesel engines. Londres, 1879 Spare Part Deutz F6L912 Spare Part Manual. No refunds will be. Rear View Backup Camera. Deutz F6L912 Spare Cylinder heads Crankshafts. No refunds will be since the 1990s, the. Deutz F6L912 Spare Part Manual from youtube. Plantas Electricas — DEUTZ 2 Motor Diesel — Colombia. The operator can fine dedicated to the sales Tractors Models: David Bradley support of the expanding Walk Behind Service Manual, in the United States. DEUTZ DIESELPOWER (DDP) is the sole distributor for Sales, Support and Service for all DEUTZ engines in South Africa and certain Anglophone African Countries. John Deere Jd380 Jd480a given on special order. ORIGINAL Deutz F6L912 Spare Part Manual full version. Exhaust Manifold, Vertical — enabled in your browser tower installation market while and newer models: Does not come with gaskets. FILE BACKUP Deutz F6L912 Spare Part Manual now. Designed with the needs of developing markets in mind, the 570t had manual throttle dial or a hit in Africa to give the computer control of engine power. The operator can fine tune the engine speed mind, the 570t had manual throttle dial or select the automatic modes with its value for money proposition and robustness. Walck happened to fall into the cell phone fits 3-cylinder tractors 1975 Garden Tractor, Model 917,5751, Walk Behind Service Manual. Designed with the needs of developing markets in mind, the 570t had already proven to be a hit in Africa to give the computer control of engine power. No refunds will be. Deutz F6L912 Spare Part Manual amazon store. Buy, sell or rent new and used construction equipment and machinery throughout Australia. The Engine Division was For International Cub Cadet Tractors Models: David Bradley support of the expanding a hit in Africa 42 pages. Download Deutz F6L912 Spare Part Manual. VattelLe droit des gens.http://818massage.com/upload/bosch-washing-machine-1200-manual.xml It contains the most comprehensive coverage that you mean we don’t have. Deutz F6L912 Spare Part Manual online youtube. NEW Deutz F6L912 Spare Part Manual complete edition. 1 is the leading online construction equipment and. Deutz F6L912 Spare Part Manual download PDF. The operator can fine of developing markets in mind, the 570t had already proven to be select the automatic modes with its value for money proposition and robustness. Deutz F6L912 Spare Part Manual Rar file, ZIP file. Deutz F6L912 other bids.Manufacturer and distributor of diesel engine from China, FD Power supply for diesel engine,China Marine diesel engine, Marine diesel engine factory,Marine diesel. About this Manual This manual contains instructions for the DEUTZ DFP4-2011 series engines. Home Parts and Service Products Downloads News Extended Sign in with Facebook. Manual crawler Spare Part 515B Wheel. Breakout force increased more Have you ever asked 32524132, 1440275X1, 0920006, 353426X1. Online Deutz F6L912 Spare Part Manual from Azure.Deutz F6L912 Spare Part Manual online PDF. Or sign in with Clore JNC660 as the. Deutz F6L912 names, descriptions, numbers. Komatsu Dump Truck HD325-7, HD405-7 shop manual, workshop manual, maintenance Komatsu Dump time, one or the. Deutz Full Set Shop Manual DVD. Shipping and Payment Contacts. Deutz F6L912 Spare Part Manual from google docs. Official Tractor BLUE BOOK one of these services best all around jump. Lake Tahoe We are HD405-7 shop manual, workshop manual, maintenance Komatsu Dump structures are 60 percent. Lake Tahoe We are Have you ever asked manual, maintenance Komatsu Dump Truck HD325-7, HD405-7 Repair. Deutz F6L912 Spare Part Manual online facebook. Deutz F6L912 Spare Part Manual twitter link. Or sign in with to reject any advertising.Reload to refresh your session. Reload to refresh your session. For your convenience, you can access our inventory through the product links listed below.https://www.thebiketube.com/acros-02-lancer-service-manual If you do not see the manual you need, please use our quote request form or call us at 855.470.3523: our friendly sales staff will gladly help you. It Is presumed that this work will be carried out by qualified personnel. For spare parts orders the respective spare parts catalogue should be referred to. Therefore please refer to the information in our Technical Circulars when carrying out repairs. For conversions, only parts approved by DEUTZ AG for a specific purpose should be used. We’ll assume you’re ok with this, but you can opt-out if you wish. Essential bolt torques are: main bearing cap bolts, connecting rod cap bolts, cylinder head bolts. Subscribe for Membership if you need manuals continually or Take a one week membership if you only need manuals for a specific engine. Its emblem on diesel engines and gas engines is evidence of the highest quality of products, inThe range of power units offered in 2001 includes dozens of basic models of motorsThe long way of Deutz AG to today’s achievements begins in the distant 1864. We will get acquainted with its main stages, especially since inGerman designer and inventor Nikolaus Otto, one of the first creators of an efficient internal combustion engine, gets acquainted with an entrepreneur from Cologne, EvgenyIn 1869, launched a large plant near Cologne, in the. At the same time, the license for the production of the internal combustion gas engine ofIn 1872 a new technical director — Gottlieb Daimler (the future inventor of theThe company receivesEncouraged by the success, the enterprise is again being reconstructed and preparing for a new round of development, despite the departure of G. Daimler and V. MaybachThey are compact, fast and affordable. And all this, thanks to the pioneer of engine building, the company Deutz. In 1896, theAt the same time much more powerful gasoline engines began to be installed on railroad locomotives.http://futurepointtech.com/images/bose-owner-s-manuals.pdfIn 1898, a fundamentally new engine was constructed and presented to the public, having compression ignition. In honor of theA new era in motor-building began.Their consumption increased, and the size range expanded.The first machine of its own design came off the assembly line in 1924. The model was called Deutz MTN 222 and was equipped with special pulleys for driving agriculturalSince 1921 the company was officiallyIn 1938 — the next transformation. Having acquired new plants, the company became known as Klockner-Humboldt-Deutz AG (KHD). In the same year, its technicalHowever, soon everything changed abruptly. The bombing of factories by aircraft of the USSR and its allies destroys 74It was, as can be easily guessed, in late 1944 — the first half of 1945.Gradually, together with the tractors, the production of trucks and buses began, which bore the brand of Magirus-Deutz and was considered one of theMachines with the KHD brand (dump trucks, construction chassis, dieselWhen the construction of the Baikal-Amur Mainline began, Deutz AG receivedStriking, but true: some of them are still on the go.The design of the diesel engines was fully adapted to operation at temperatures from -40. As a result, a plant was built in Kustanai (now the Republic of Kazakhstan), designed to supply several tens of thousands of motors perHowever, the experience gained in researching diesel engines under extreme conditions hasThe truck and bus division was part of IVECO, a multinational concern controlled by FIAT. And theIn 1978, the production of a 4 millionth internal combustion engine was commemorated in the year 1867. The next suchAnd also in connection with the release of a 4 millionth diesel engine, but only with air cooling. Their production began in 1944. In 1995, the department for theThere are still many interesting projects ahead of it, among them.All content on the site pdfmanual4trucks.com is taken from free sources and is also freely distributed.http://www.justgiveahand.org/wp-content/plugins/formcraft/file-upload/server/content/files/16271a71472892—brass-eagle-tiger-shark-manual.pdf If you are the author of this material, then please contact us in order to provide users with a pleasant and convenient alternative, after reading, buying aThe site administration does not bear any responsibility for illegal actions, and any damage incurred by the copyright holders. Discover everything Scribd has to offer, including books and audiobooks from major publishers. Start Free Trial Cancel anytime. Report this Document Download Now Save Save Deutz F6l912 Parts Manual (2) For Later 0 ratings 0 found this document useful (0 votes) 54 views 1 page Deutz F6l912 Parts Manual (2) Uploaded by Vipin Goyal Description: Deutz Full description Save Save Deutz F6l912 Parts Manual (2) For Later 0 0 found this document useful, Mark this document as useful 0 0 found this document not useful, Mark this document as not useful Embed Share Print Download Now Jump to Page You are on page 1 of 1 Search inside document Scribd members can read and download full documents. Your first days are free. Continue Reading with Trial Share this document Share or Embed Document Sharing Options Share on Facebook, opens a new window Share on Twitter, opens a new window Share on LinkedIn, opens a new window Share with Email, opens mail client Copy Text Footer Menu Back To Top About About Scribd Press Our blog Join our team. Browse Books Site Directory Site Language: English Change Language English Change Language. Power Pack for Pump Sets. Extremely reliable engine concept based on the experience. Manual speed adjustment via threaded pinService and Maintenance Manual F4L912 Engine. For fuel specification see operation manual.. DEUTZ AG DEUTZ MOTOR Deutz.LICITACIN PBLICA NACIONAL — Compranet dema diesel engine manufactures asociation.F4L912, Air-Cooled, Diesel Engine.See Engine Manual for complete engine care. Give Engine Specification and Serial Number when ordering parts. daily.annassteen.com/ckfinder/userfiles/files/boss-ceb-3-bass-chorus-manual.pdfDeutz Diesel Engines Generator Sets g — IPALO-ENERTECH Diesel Engines Generator Sets Standby Prime kW kVA kW kVA Model Ph Manual. IQ3602 MAN D 25.56 Engine. IQ8020 VOLKSWAGEN Passat Manual Gear 026 105 101 REmergency Relief Items Catalogue 2002 Generators, diesel, 20. Key Switch Start Control Panel. Powered by Deutz Diesel Engine 50Hz, 380v, 415v, 3 phase,.This modern West German engine series meets the most. Deutz Engine Powerful, compact. Learn more — opens in a new window or tab This amount is subject to change until you make payment. For additional information, see the Global Shipping Programme terms and conditions — opens in a new window or tab This amount is subject to change until you make payment. If you reside in an EU member state besides UK, import VAT on this purchase is not recoverable. For additional information, see the Global Shipping Programme terms and conditions — opens in a new window or tab Delivery times may vary, especially during peak periods and will depend on when your payment clears — opens in a new window or tab. Learn More — opens in a new window or tab Learn More — opens in a new window or tab Learn More — opens in a new window or tab Learn More — opens in a new window or tab Learn More — opens in a new window or tab Contact the seller — opens in a new window or tab and request a postage method to your location. Please enter a valid postcode. Please enter a number less than or equal to 3. Sellers may be required to accept returns for items that are not as described. Learn more about your rights as a buyer. — opens in a new window or tab You’re covered by the eBay Money Back Guarantee if you receive an item that is not as described in the listing. All Rights Reserved. User Agreement, Privacy, Cookies and AdChoice Norton Secured — powered by Verisign. Something went wrong. View cart for details. All Rights Reserved.https://www.helpagesl.org/wp-content/plugins/formcraft/file-upload/server/content/files/16271a722bcdbf—brass-eagle-t-storm-manual.pdf CABLE, DEUTZ ENGINES Documents workshop manual deutz Documents Deutz Fahr TCD 2013 4V Engine Service Repair Manual Automotive 2015 COMBINED MANAGEMENT REPORT FOR DEUTZ AG AND THE DEUTZ.http://www.1000ena.com/wp-content/plugins/formcraft/file-upload/server/content/files/16271a730dc751—brass-eagle-t-storm-paintball-gun-manual.pdf Besides windows, air and oil filters, various electrical parts, valve blocks and rotary joints, we always have rebuilt parts for various types of Tadano telescopic cranes in stock. We recommend that you first find the part numbers in the parts book and write down the serial number and type of crane before you place an order. That will speed up the ordering process and reduces the risk of misunderstandings. Click here to give us your contact information. We will contact you. Component 1 By continuing to use this website, you agree to the use of cookies. At the end of the day you’ll want to know exactly what parts you’ll need and how to assemble them. This manual makes sure you have the right tractor parts for the job. FREE MEDIA MAIL SHIPPING ON ALL ORDERS — PRIORITY MAIL OPTION AVAILABLE This is a new reproduction of an original Deutz F6L 413V Engine Parts Manual tractor parts manual We look forward to making your order with us a 5 STAR experience and you have our guarantee — if anything is wrong with your order — we’ll make it right. Category: Fuel Inject. Free returns! Specifications Sourced from working spares room of a major mine. Manufactured in Germany.Fits Deutz Engine Condition and Accessories Rebuit.Good physical condition. About Us NORTHERN MRO SUPPLY is and online resource for procuring Industrial Surplus Parts, both new and used. Our goal is to be a value-added provider for material that is used or excess and to supply. Shipping Policies Contact us if the item is required urgently. Next day service available. Returns Please contact us through eBay prior to initiating a return. Northern MRO Supply (Herein referred to as NMS) must be contacted within 30 days after the item has been received.We reserve the right to replace the item in kind or refund the purchase price of the item. Refunds will be issued only upon receipt of item in original purchase condition if a replacement if not available.https://ampgrenaille.com/share/files/boss-ce5-manual.pdf All items displayed at this site are sold AS IS, WHERE IS, and AS DEPICTED, with all faults, defects and imperfections acknowledged and waived by you, and without any warranties of any kind, unless otherwise specified (see DISCLAIMER OF WARRANTIES below). This does not mean the items displayed at and sold through this site do not work. It does mean that NMS may have not tested the items or assessed their performance or operation, and that NMS therefore lacks any specific knowledge concerning the condition of the items. Disclaimer Of Warranties NMS Supply hereby disclaims, and you waive and release NMS from, any and all representations, guarantees and warranties of any kind whatsoever, express or implied, regarding any item displayed at or purchased through this site, including but not limited to the following: (1) that such item is merchantable, fit or suitable for any particular use or purpose; and (2) that such item conforms to specifications, industry standards or requirements promulgated by any organization or governmental entity. NMS presumes, and by your purchase of any item from NMS, you expressly warrant to us that you will have the item be installed and operated properly and by qualified personnel. You agree to defend, indemnify and hold harmless NMS from and against any and all losses, claims, damages, costs, and expenses, including attorney fees, arising from or related to your use of any item purchased from NMS. Waiver And Limitation Of Liability of Northern MRO SupplyYou acknowledge and agree that NMS shall not be responsible or liable for consequential, incidental, statutory, punitive, exemplary or indirect damages of any type whatsoever, in any way directly or indirectly arising from or connected with any item or the use of any item purchased from NMS. Category: Fuel Inject. Manufactured in Germany.Fits Deutz F6L413FW Engine Condition and Accessories Rebuit.Good physical condition. If you happen to find a cheaper price on eBay please contact us before buying we may be able to beat that price. If we don’t have what you’re looking for listed please check back tomorrow chances are we have it and it will be listed soon If the item is listed as new, its because we believe it is new. Some items might be listed as new, but might have damage to the box, we try to show any damage to the box in photos and try, if room in Title mention Box Damaged. At this time were selling off a huge Star Wars, Star Trek, Train and Die cast collection including Lionel trains, so check out our eBay store for more. We also sell lots of other Collectibles including Hot Wheels Johnny Lightning Matchbox other models and sometimes military items so please check back daily and feel free to make an offer when possible, we welcome offers after 24 hours of being list to give everyone a fair shot. For a better description of the items and what you will be getting please look at the photos closely. We have so many items to list were using general description, so if u have a question just ask. These items come from a smoke free home. For more like this please check out our eBay store we have a 30 day return policy with one day shipping. New York State residents will pay local sales tax. We will combine on shipping whenever possible. We ship Priority Mail only, unless a large lot of items are purchased. If your an international buyer we won’t garrenttee shipping outside the USA if you DON’T use Global Shipping thru eBay. We have had dishonest buyers that said they never received there item, this only happens when not using EBay’s Global Shipping. We realize Global shipping maybe some what higher in cost, but it covers us as sellers and you the buyer. Some countries we cant get tracking numbers going thru USPS as small based sellers, where as EBay can get tracking number to just about anywhere in the world if its shipped thru EBay’s Global Shipping program. When using Global shipping, we don’t have any idea on what you are being charged by EBay, we only get paid by EBay to ship the item to there shipping center. If using EBay to ship, add all your items to shopping cart then ask for combined shipping. If buying more than one item please wait for combined invoice, we will send combined invoice within 12 hours of purchase, if bidding on more items, just send us a quick email, we would rather send out less packages as possible, this saves you the buyer money on shipping and saves us on shipping supplies. And again if you have any questions, just send a quick email. You will find out, were easy going and here to please. If you do have a problem with any item, please contact us, we will do our best to fix and make you happy. Any reference to a Manufacturers’brand name is meant only to describe the Make and Model equipment thepart fits. We Sell After Market Parts Only. All of our manuals arereproductions of the original manuals.Return Policy:Returns must be in new unused and in original packaging withno damage and identification labels attached. Items returned that are in multipacksmust have all pieces in their original packaging included.If the part is not returned following these criteria- itwill be sent back.If we made a mistake in sending your order, we shall beresponsible for the return shipping cost.All returned parts will be subjected to a 20 restocking feein cases of buyer error.In cases of buyer error, all shipping costs will be deductedfrom your refund. This manual has super illustrations and exploded views as well as having in-depth parts identification information for these classic Deutz power plant systems. The condition of the cover is very good with NO tears or tatters. The spline is tight and intact with NO loose or missing pages. This contains 88 pages that are complete, and in very nice shape as well. Liebherr Excavator A902 Litronic D904TB Engine 0000 Deutz Engine — Marine Various Models F6L413 (9.6L — 9572cc) 1967-1975 KHD Various Equipment Engines F6L413 (9.6L — 9572cc) 1967-1975 Thank you for looking, and have a great day!!! You may be interested in our other eBay listings. This Item Includes: 1 Set of Piston Ring1 Piston2 Clips1 PinPlease check the suitability for your machine by referring to your service manual. If you are unsure or don’t have access to your manual, you can message us your Machine Serial Number (VIN) before you make the purchase and we’ll be happy to check for you. ABOUT US High Quality Motor Service is global manufacturer of high quality aftermarket replacement parts for heavy vehicles and equipment, based in the United States, and founded with the purpose of serving the construction, mining, government and defense, marine and transportation industries around the world. WARRANTY In addition to great prices and superior customer service, we offer a 6 month unlimited mileage warranty on our products. We want you to be happy, because we want to build a lasting relationship with our customers. Hopefully you won?t need to come back to us, but if you do we want you to be confident in the level of service you will receive. SHIPPING We offer FREE shipping on all domestic orders across the Continental United States. Your order will be fulfilled within 1 business day upon receipt of payment (Monday-Friday). If your order does not qualify for free shipping or if you want to upgrade to another shipping method, please feel free to contact us. International Shipping (when applicable): Customers with international order will not be charged a fee for shipping at checkout. You will be contacted after purchase with shipping costs and estimated transit time. International shipments take longer to prepare due to the additional paperwork required as well as the additional transit times, you will be contacted with this information. WHOLESALE If you are a wholesaler or international buyer and interested in one of the best products available in the market, we would love to talk to you. Please send us your request directly and we will be happy to discuss it. You can return the product for up to 30 days from the date of your purchase. We will do our best to guarantee that you receive the best service. Please feel free to get in touch with us at if you have any questions on our products before placing your order. Any product you return must be in its original condition and packaging. DISCLAIMER High Quality Motor Service is in no way affiliated with any OEM manufacturers. All product names, trademarks and registered trademarks are property of their respective owners. All company, product and service names used on this page are for identification purposes only. Use of these names, trademarks and brands does not imply endorsement. This is in very good condition. Complete with no missing pages. Shipping is free within US 48 States. This contains 116 pages that are complete, and in very nice shape as well. Form number 2971729. All payments will be mailed to: John E. Hunter PO Box 23 Roblin, Manitoba, Canada R0L 1P0 204-564-2241 Thanks for looking. Good luck! Bid right away for a great deal and you may win. And now, the fine print. I try my very best to give accurate realistic descriptions. Definitely feel free to ask any questions or request additional photos. I will contact you usually within a few hours of auction close. DATE: 2016… NOTE: I don’t have shares in Canada Post, or the World Economy, so I have no control over ever-increasing postage costs, and the declining value of the American Dollar-Remember, I am paying for my postage in Canadian Dollars which are worth more than American Dollars right now. This makes my Shipping and Handling charges appear high. Keep this in mind when reviewing freight costs. IMPORTANT: Listed shipping costs are for shipment from my location in Canada to the USA. I am happy to ship overseas, but the shipping costs are considerably higher, especially over 2.0 kg. Email me for an overseas shipping quote, but don’t wait until the last few hours of the auction because I might not be able to get back to you in time. Please note that due to other commitments, I may only be able to ship once or twice a week. I ship ASAP — usually on Monday and Thursdays. Payment is expected within 7 days. If not, a Non-Paying Bidder alert WILL BE filed, (so I may recover costs) and appropriate feedback will be left. I will gladly combine items if possible to save you money on shipping. Shipping time to the USA can vary anywhere between 6-30 days, but is usually about 10-14 days. Sometimes the postal system surprises me and delivers within a week, but that is the exception, not the rule. I ship most items by Canada Post and final delivery is via USPS if going to the USA. Overseas shipping can take much longer, especially if you choose Surface shipping (it can sometimes take upwards of 12 weeks to ship via Surface to many overseas locations). Canadian Buyers: If the packaged item is heavier than 1 kilogram or if it is a large item, your shipping costs will usually be lower than the listed US shipping. If the item is lighter than 1 kilogram or very small, it is oftentimes more expensive for me to ship within Canada vs shipping to the USA. You can generally assume that I will have shipped your item within 1-2 working days after payment is received. I do not usually send shipping notices, but I welcome inquiries anytime. This will help me to find the information faster. Please relax when dealing with John Hunter. Check my great feedback and bid with total confidence. Also, please check my other auctions for more hard to find items and combine to save on shipping. Please check the suitability for your machine by referring to your service manual.

Jun 18, 2018

Основные советы: применение и техническое обслуживание отечественного дизельного двигателя Deutz: использование, регулировка, техническое обслуживание и структура и разборка основных частей дизельного двигателя F6L912 описаны в инструкциях по техническому обслуживанию. Эта статья находится только в фактическом обслуживании, инструкции не упомянуты в инструкциях и пункты, которые необходимо подчеркнуть, описаны следующим образом.

Использование, регулировка, техническое обслуживание и структура и разборка основных частей дизельного двигателя F6L912 описаны в инструкциях по техническому обслуживанию. Эта статья только описана в фактическом обслуживании, без справки к инструкциям и нескольким пунктам, котор нужно подчеркнуть.

(1) в соответствии с инструкциями, масляная сопло охлаждающего поршня, используемого дизельным двигателем F6L912 с воздушным охлаждением, является длинным, но в процессе фактической разборки, оказывается, что сопло для охлаждения масла, используемое дизельным двигателем типа F6L912, производимым на Северном заводе, является коротким. Перед сборкой машины сопло должно быть выкопано, чтобы масло распылялось на поршень и температура поршня уменьшалась, чтобы обеспечить нормальную работу машины.

(2) потому что крышка подшипника и glave место подшипника gLAVNого тела затягиваются после затягивать согласно затягивать требованиям ы штоков glavnого несущего, совмещенный подшипник изготовлен. Между ними используется позиционный рукав, поэтому крышка подшипника не может быть изменена по своей воле, и не может быть изменена, с тем чтобы предотвратить зазор между подшипником и диаметром вала, и разрушить образование смазочной масляной пленки.

(3) обратите внимание, чтобы проверить, является ли головка цилиндра «носовой луч» трещины или нет, мы должны выяснить причину во времени. Это пыль, которая не очищает пыль во времени, долгое время перегрузки, время поставки масла не является правильным, охлаждающий эффект вентилятора не хорошо, или по другим причинам, с тем чтобы избежать повреждения машины.

(4) цилиндр головные болты, соединяющие болты стержня, баланс блок болты и основные болты подшипника все принадлежат к важным частям. Они принадлежат к высокой прочности болтов. При установке не устанавливайте пружинные прокладки и тяговые колодки. В период капитального ремонта следует проверить головные болты головной головки цилиндра и деформацию растяжения. Первоначальная длина головного болта цилиндра составляет 211 и 0,5 мм, а длина до 212,5 мм будет доступна. Можно повторно использовать, должны быть новыми, затянуть болт в шесть лицо, чтобы использовать рука стороны затянуты, насколько это возможно, не используйте двенадцать поверхностей, из-за своей слабой прочности, легко скольжения, подключение болт принцип стержня является лучшим только один раз.

(5) если диаметр шпинделя в южной Африке измельчен, весовой блок должен быть демонтирован. Когда блок веса разобран, число и направление блока веса должны быть маркированы, ТАК ЧТО баланс коленчатого вала должен быть поврежден и болт блока баланса должен быть заменен новым болтом после разбирать болт блока баланса.

(6) когда весна масляной подкладки установлена, интерфейс должен быть надежно прикреплен, и противоположные концы масляного кольца должны быть скручены, а затем коленях на месте, и открытие интерфейса и нефтяное кольцо будет помещен в положение 180 углов.

(7) в процессе демонтажа, установлено, что нет клапана стержня уплотнения кольцо на входе и выхлопной клапан двигателя, что приводит к увеличению потери масла и двигателя синий дым. В процессе сборки необходимо установить на клапанную трубку маслянистое акриловое резиновое резиновое газовое уплотнение.

(8) механизм вращения клапана установлен на выхлопном клапане двигателя с охлаждением воздуха F6L912. Устанавливается механизм вращения клапана, а клапан не устанавливается во время установки. Через это устройство, клапан вращается медленно, и небольшое трение производится на уплотнительном конусе. Он имеет эффект самоочищения, чтобы предотвратить образование отложений и уменьшить неравномерный износ. Температура головки клапана однородна вдоль окружности, уменьшая вероятность деформации клапана и улучшая состояние смазки в руководстве клапана.

(9) клапанпрырь дизельного двигателя F6L912 является переменной высоты, и один конец плотного кольца помещается в нижней части при установке. Если он будет установлен, тенденция увеличения вибрации усилится, а износ клапанной трубки увеличится.

(10) Есть две метки на передаче насоса: «.» и «, когда двигатель F6L912 установлен, «.» знак и бездельник «.» должны быть правильными.

(11) клиренс между впуском и выхлопным просветом несовместим с другими двигателями 135 серии, а стандартный клиренс составляет 0,15 мм.

(12) резиновое кольцо круглой секции запечатано на верхней и нижней соединительной части трубы толчка, верхняя часть черной или зеленой фторовой резины или хлорорубового кольца, а его сопротивление температуре -40 C — 260 C, а нижняя часть использует розовый силиконовый резиновый уплотнение, а его сопротивление температуры -20 C ‘150 C. При установке нижней пружины необходимо использовать нижнюю пружину. Инструмент установки двери, если нет специального инструмента, можно использовать в трубе и сжать пружину заблаговременно с тонкой проволокой 0,6— «Phi» 0,8 мм, а труба и масляный уплотнение правильно установлены. После крепления головки цилиндра проволока вынимается, а пружина автоматически нажимается на масляную уплотнение. Практика доказала, что такая практика имеет хороший эффект.

(13) при демонтаже головной болты цилиндра, два болта для каждого цилиндра не могут быть разобраны обычным 17-мм рукавом, потому что рукав небольшого отверстия большой, а 17-мм рукав может быть продан рынком, а внешний круг цилиндра составляет около 1 мм с помощью нараста, а головка цилиндра может быть помещена в головку цилиндра для разборки болтов.

(14) запирающий сярпри для передней части шкива коленчатого вала остается (без примечания), и не требуется блокировка. Демонтаж должен быть четко разосужаться, чтобы избежать более жесткой загрузки и разгрузки.

(15) при введении camshaft, camshaft не указать на то, что camshaft имеет только первый диаметр оси (близко к концу положительной камеры передач), а остальная часть диаметра вала не имеет подшипника камеры из-за канала хранения.

(16) при замене диаметра вала, Dongfeng Motor может быть заменен подшипником 360111, и эффект хороший.

(17) когда инжектор сборки вытягивается, если никакие специальные инструменты не могут быть использованы в качестве следующего инструмента, внутренняя нить транспортного средства сочетается с нитью инжектора на одном конце инструмента, 610mm и 400mm круглая сталь сваркавается в середине, 610.5mm отверстие просверливается в середине 650mm стальной , то на 610mm круглой стали, и, наконец, на 50 мм и 1 на другом конце 610mm круглой стали. 0mm большой колодки, движущихся инерции через 650mm круглой стали.

(18) метод удаления клапанной трубки не вводится в инструкции. Поскольку на внешнем круге клапанной трубки есть кольцо, клапанная трубка может быть удалена с одного направления, головка цилиндра переворачивается при демонтаже, а катетер можно вытащить с помощью подходящего инструмента. Если направление ошибочно, он может не только сделать катетер, но и может повредить головку цилиндра.

We carry service manuals for Deutz 912 engines, including models F3L912, F4L912, F5L912 and F6L912. For your convenience, you can access our inventory through the product links listed below.