-

Уже зарегистрированы? Войти

-

Регистрация

Друзья! Форум не является новостной площадкой, поэтому прошу не размещать в разговорных разделах копипасту из инета и новости из разряда «сделаноунас». То, что где-то что-то поплыло, полетело, зажужжало и, наконец, куда-то залезло, можно обсудить на соответствующих новостных и развлекательных ресурсах.

Информация о файле

Руководство от производителя по системе чпу GSK 980tdi на русском языке. 2024 год.

Document Download |

‹

›

GSK 980TDi Manual Online:

3.6,

2587

votes

GSK 980TDi User Manual

GSK 980TDi User Guide

GSK 980TDi Online Manual

Text of GSK 980TDi User Guide:

Related Products and Documents (Control Systems):

-

GSK GSK928TEa Control Systems Operation & user’s manual

GSK928TEa

gsk/gsk928tea.pdf, 383 -

GSK GSK983Ma Control Systems Operation & user’s manual

GSK983Ma

gsk/gsk983ma.pdf, 373 -

GSK 988T Control Systems Operation & user’s manual

988T

gsk/988t.pdf, 216 -

VIPA System 200V Control Systems Manual

System 200V

vipa/system-200v.pdf, 100 -

GSK 988T Control Systems Operation & user’s manual

988T

gsk/988t.pdf, 416 -

OJ Electronics AHC-3000 Control Systems Instructions manual

AHC-3000

oj-electronics/ahc-3000.pdf, 56 -

GSK 983Ma-V Control Systems Connection manual

983Ma-V

gsk/983ma-v.pdf, 32 -

Fly Sky FS-GT2 Control Systems Instruction manual

FS-GT2

fly-sky/fs-gt2.pdf, 17

Comparable Devices:

| # | Manufacturer | Model | Document Type | File | Updated | Pages | Size |

|---|---|---|---|---|---|---|---|

| 1 | Samsung | HL-S5666W | Owner’s instructions manual | samsung/hl-s5666w-H3S.pdf | 15 Dec 2024 | 132 | 14.76 Mb |

| 2 | Texas Instruments | MSP-FET430X110 | Operation & user’s manual | texas-instruments/msp-fet430x110-KVK.pdf | 04 Sep 2024 | 80 | |

| 3 | Sub-Zero | 700TFI | Planning information | sub-zero/700tfi-829.pdf | 07 Apr 2024 | 15 | |

| 4 | Clevo | D400F | Service manual | clevo/d400f-HPB.pdf | 09 Dec 2023 | 126 | |

| 5 | Kenmore | 134914900 | Use & care manual | kenmore/134914900-N7Z.pdf | 25 Oct 2024 | 8 | |

| 6 | Topcon | GR-3 | Operator’s manual | topcon/gr-3-B54.pdf | 22 Mar 2025 | 28 |

Similar Resources:

Control Systems Instructions:

-

Zanussi Oven Cuisinair FB513M

Zanussi Cuisinair FB513M User Guide (Instructions for use and care manual), @323676

Cuisinair FB513M, 16

-

Dell Desktop Precision T5500

Dell Desktop Precision T5500 Service manual

Precision T5500, 80

-

Marantz Stereo Receiver SR5004

Stereo Receiver Service manual (Marantz SR5004)

SR5004, 207

-

Philips Vacuum Cleaner FC8476

#E2JF74 FC8476: Philips Vacuum Cleaner Owner Documentation

FC8476, 8

-

Toshiba Digital Camera PDR4300

#GVVJK8 PDR4300: Toshiba Digital Camera Owner Documentation

PDR4300, 137

-

Anritsu Network Hardware MT1000A Network Master Pro

Network Hardware #721ZKB

MT1000A Network Master Pro, 239

-

PhysioLogic Thermometer DiGiPro

Thermometer #7L2942

DiGiPro, 2

-

Amrel Tablet DK886EX

Tablet Operation & user’s manual (Amrel DK886EX)

DK886EX, 63

-

Panasonic Car Receiver Road Choice 1000-RIO160U

Road Choice 1000-RIO160U Operating instructions manual — 5ZRXN1

Road Choice 1000-RIO160U, 16

-

ODL Window Blinds Reduced Travel Unit

Reduced Travel Unit Installation & maintenance instructions manual — TOW8JV

Reduced Travel Unit, 6

-

York Heat Pump YVJC09DS-AAA

YVJC09DS-AAA (Heat Pump ePDF User Manual, #893OKS)

YVJC09DS-AAA, 32

-

Chonghan Modem CH-D3 Series

Chonghan Modem Operation & user’s manual (File: chonghan-ch-d3-series-operation-user-s-manual-18, 28/12/2024)

CH-D3 Series, 18

Comments, Questions and Opinions:

В конце 2018 года мне потребовалось около года изучать систему ЧПУ, от Adcom до Fanuc, от программирования до эксплуатации. Чтобы облегчить себе поиск и обмен этими учебными материалами в будущем, а также для справки других новичков, я буду записывать весь процесс обучения. Очевидно, что это не авторитетные технические данные, а запись нескольких ключевых моментов, особенно нескольких ключевых инструкций. Ошибки неизбежны. Пожалуйста, исправьте их, если найдете.

Вот общая часть GSK980TDa:

-

Урок 1. Основные понятия и инструкции.

Один, концепция

Начало: правая центральная точка заготовки

Во-вторых, инструкция

М инструкции:

М00: Пауза. Когда программа работает до M00, инструмент останавливается, шпиндель и смазочно-охлаждающая жидкость останавливаются, нажмите клавишу запуска, чтобы продолжить программу, без ограничения времени. Может быть записан как M0

M01: Должен остановиться. Когда программа дойдет до M01, нажмите M01, чтобы остановить режущий инструмент, шпиндель и смазочно-охлаждающую жидкость.

M03: Положительный шпиндель (против часовой стрелки). Формат инструкции: M03 S500

M04: Реверс шпинделя. Формат: M04 S500

M05: главный вал останавливается

M08: охлаждающая жидкость включена

M09: Охлаждающая жидкость отключена

M30: программа завершается, и курсор возвращается в начало

M98: Вызов подпрограммы

M00: Возврат к основной программе

F инструкции:

Формат инструкции 1:

G98 M03 S100

G01 X10 Z-10 F100 (100 мм в минуту)

Формат инструкции 2 (многоцелевой):

G99 M03 S100

G01 X10 Z-10 F0.2 (подача шпинделя 0.2 мм за оборот)

Шаг метрической резьбы: G92 X10 Z-20 F0.8 (шаг)

Инструкция T: укажите инструмент инструмента, формат: T0101

Инструкция O: указывает номер программы в формате O0001.

С инструкции:

1.указать скорость шпинделя, формат: M03 S500

2. указать постоянную линейную скорость, формат: G96 S180; Г50 С500

3. укажите время паузы (используется редко): G04 S10

G-инструкция

G00: Быстрое позиционирование, формат: G00 X0 Z1

G01: Резка по прямой линии, формат: G01 X18 Z-10 F200 (или F0.1)

G02: обратная дуговая резка, формат: G02 X10 Z-5 R5 F0.1

G03: формат дуговой резки G03 X10 Z-5 R5 F0.1

G04: пауза

G32 G92 G76: резьба

G50: перемещение заготовки

G70: отличная машина

G71: Грубый цикл, формат инструкции (внешний круг):

G71 УРРРФ

G71 P(номер начала процедуры) Q(конец процедуры) U(x направление штрафа для автомобиля) W(Z направление штрафа для автомобиля)

Пример:

Q0001

G99 M08

Т0101 М03 С500

G00 X110 Z1 (при условии, что диаметр прутка составляет 110 мм)

G71 U2 r0.5f0.1 // Цикл черновой обработки

G71 P123 Q321 U0.5w0.3

N123 G100 X50 // Программа Fine Car. Примечание: здесь нет положения Z, см. положение Z1 выше.

G01 X50 Z0 F0.1

G01 X50 Z-30 F0.1

G01 X100 Z-30 F0.1

N321 G01 X100 Z-50 F0.1

G70 P123 Q321 // Начало чистовой обработки

M09

M05

Г00 З100

M30

-

Второй урок, собственно боевой учебный нож, внешний круг G71.Простая заготовка.

Примечание по ножу: нет. 1 нож, торцевой вход Z0; Входные данные измерений по оси X. Фреза № 3 Z0 должна слегка касаться торца Z0. Обратите внимание, что T0303 ввод Z0 не отображается как Z0, потому что текущая система T0301.нужно: MDI-программа – ввод T0303- ввод – запуск цикла, а затем ввод дополнительных данных ножа.

Пример обработки:

Процедура следующая (бар од 35):

O0170

Т0101 М03 С600

G99

G00 X35 Z1

G71 u1.5R0.5f0.1 // Грубый пуск

G71 P01 Q02 u0.5w0.1

N01 G00 X0 //

G01 X0 Z0 F0.1

G03 X10 Z-5 R5 F0.1

G01 X10 Z-15 F0.15

G01 X16 Z-25 F0.1

G01 X16 Z-32 F0.15

G03 X22 Z-35 R3 F0.1

G01 X22 Z-41 F0.15

G02 X28 Z-44 R3 F0.1

G01 X28 Z-50 F0.15

N02 G01 x28.5Z-50 F0.2

G70 P01 Q02 // Начало чистовой обработки

Г00 З100

Т0303 М03 С600

G00 X28.5 Z-53

G01 X0 Z-53 F0.1

Г00 З100

M30

Эффект следующий:

-

Урок 3: Внутреннее отверстие G71. Радиальное отверстие G72. Практика нарезания канавок.

1. Несколько концепций.

Абсолютное позиционирование, например X20 Z-10; Относительное позиционирование, такое как U10, W-5, U и W соответственно, представляют собой приращения в направлениях X и Z; Смешанное расположение, такое как X20 W-5, то есть диаметр направления X 20 мм, направление Z слева 5 мм.

Обработка внешнего круга G71 подходит для увеличения внешнего диаметра; Внутреннее отверстие G71 можно только уменьшить (в новом устройстве это ограничение может быть нарушено).

Пример обработки внутреннего отверстия G71:

O0001

G99

Т0101 М3 С600

G00 X18 Z1 // Предположим, что отверстие просверлено до 18

G71 U2.5 R0.5 F0.25

G71 P123 Q321 u-1 W0.3 // Обратите внимание, что поле в направлении X здесь отрицательное, в отличие от U1 во внешнем круге

N123 G00 X40 // Не записывайте z-значение

G01 X40 Z0 F0.1

G03 X34 Z-3 R3 F0.1

F0.1 G01 X34 Z-11

G02 X26 Z-15 R4 F0.1

G01 X26 W-10 F0.1 //Относительное позиционирование в направлении Z

G01 X20 W0 F0.1

G01 U0 F0.1 Вт – 10

N321 G01 У-1 W0 F0.2

G70 P123 Q321

Г00 У0 Z100

M30

2. Радиальная циркуляция формата G72:

G72 W (количество подачи в направлении Z, а именно ширина ножа) R (количество заднего ножа) F

W (разница в направлении X) W (разница в направлении Z)

Пример обработки:

O0001

G99

Т0202 М3 С600

G00 X31 Z30

G01 x15.2w0 F0.08// Вставьте нож в середину и зарезервируйте количество ножа для следующего цикла

G01 X31 W0 F0.3

// Правая половина слота:

G72 W2.7R0.5F0.2 //Величина подачи в направлении Z соответствует ширине ножа

G72 P123 Q321 u0.2w-0.2 // В этом случае поле в направлении Z относится к торцу, указанному красной стрелкой, поэтому поле отрицательное

N123 G00 Z13 //1. зарезервированная ширина ножа; 2. здесь нет значения X

F0.1 G01 X15 Вт – 10

N321 G01 U0 Z-29.5F0.1

G70 P123 Q321

// Левая половина слота:

G72 W2.7 R0.5 F0.1

G72 P456 Q654 u0.2w0.2

N456 G00 Z-50

G01 X30 W0 F0.2

G01 X15 W10 F0.1

N654 G01 U0 W28 F0.1

G70 P456 Q654

Г00 З100

M30

Эффект заготовки выглядит следующим образом:

3. Последовательность и расположение черновой обработки G72. G72 сначала черновая обработка правой части канавки, а затем обработка левой части, перед обработкой позиционирование — третья линия G00 X30 Z30

-

Инструкция по сверлению и развертыванию G74 (Аксиальная циркуляция канавки)

Формат инструкции:

G74 R(e Величина осевого отвода на резец)

G74 X (приращение апертуры U) Z (приращение глубины отверстия W) P (количество подачи δ в направлении IX) Q (длина подачи δ в направлении KZ) R (δ D резание до конечной точки Z после количества резания в направлении X) F (скорость подачи)

Это слишком грязно. Вот как это упростить:

G74 Р(е)

G74 X(U) Z(W) P(δ I) Q(δ K) R(δ d) F

Примечание:

- Вырезание глухих отверстий, R(δ D) не должно существовать, иначе удар ножом и смерть.

- При сверлении инструкции опускают X(U), потому что апертура не изменилась; P(δ I) не имеет количества подачи X; R(δ D) Количество прямых входов и выходов без втягивания ножа.

- P и Q равны 0.001 мм, положительные числа

Например, просверлите следующую заготовку до 20*60 и снова увеличьте до 40*60:

O0001

G99 T0202 M03 S400

G00 X0 Z1

G01 Z0 F0.1// Ближе к торцу

G74 R0.5

G74 Z-60 Q10000 F0.08 // Просверлить отверстие

Г00 З100

Т0303 М03 С600

G00 X20 Z1

G01 Z0 F0.1 // Не полагайтесь на торец

G74 R0.5

G74 X40 z-60 P5000 Q20000 r0.5f 0.2

Г00 З100

M30

-

G75 Многоканальная циркуляция и резка

Формат (такой же, как G74, только направление транспонирования XZ):

G75 Р(е)

G75 X(U) Z(W) P(δ I) Q(δ K) R(δ d) F

Значения каждого параметра:

G75 R(e Радиальное количество фрез на фрезу)

G75 X(или U) Z (или W) P (глубина подачи по оси X) Q (смещение по оси Z) R (δ d после резания до конца направления Z задней части инструмента) F (скорость подачи)

Пример 1. многослотовый:

O0001

G99 M03 S500 T0202

G00 X52 Z-14

G01 Z50 Z-14 F0.1 // Не хочу этот раздел

G75 R0.25

G75 X40 z-56 P4000 Q14000 R0 F0.1 G75 X40 z-56 P4000 Q14000 R0 F0.1

G00 X80 Z100

M30

Пример 2. более широкий слот:

O0001

G99 M3 S500 T0202

G00 X52 Z-18

G75 R0.25

G75 X30 z-35 P5000 Q2500 R0 F0.1 // Фактическая эффективная ширина отвала 2.5

G00 X80 Z100

M30

Пример 3. резка заготовки (опущена):

…

G75 R0.5

G75 X0 P5000 F0.1// ZQR

…

-

Цикл литья G73

Формат следующий:

G73 U (общая величина обратного реза по оси δ IX) W (общая величина обратного реза по оси δ KZ) R (d количество раз резания)

G73 P(N123) Q(N321) U(δ допуск по оси UX) W(δ допуск по оси WZ) F_ S_ T_

N123… Программа Fine Car… N321

Январь 11.2021г.

Учитывая, что это примечание, вероятно, будет длинным и слишком непонятным для большинства посетителей-неспециалистов, даже если оно очень простое, оно обязательно запутает посетителя, не знающего, о чем статья. Поэтому сегодня принято решение, что эта статья не будет обновляться в этом блоге.

This user manual describes all items concerning the operation of

the system in detail as much as possible. However, it is impractical to give

particular descriptions of all unnecessary and/or unavailable operations of

the system due to the manual content limit, product specific operations and

other causes. Therefore, the operations not specified herein shall be

considered impossible or unallowable.

This user manual is the property of GSK CNC Equipment Co.,

Ltd. All rights are reserved. It is against the law for any organization or

individual to publish or reprint this manual without the express written

permission of GSK and the latter reserves the right to ascertain their legal

liability.

GSK980TDb Turning CNC System User Manual

FOREWORD

Dear user,

We are really grateful for your patronage and purchase of this GSK980TDb Turning

CNC system made by GSK CNC Equipment Co., Ltd.

The user manual describes the programming, operation, installation and connection

of this GSK980TDb Turning CNC system. Please read it carefully before operation in

order to get the safe and effective working.

Warning

This system can only be operated by authorized and qualified personnel as

improper operations may cause accidents.

Please carefully read this user manual before use!

Note: The power supply installed on (in) the cabinet is exclusive to GSK’S CNC

systems.

The power supply form is forbidden to be used for other purposes.

Otherwise, there may be extreme danger!

This user manual shall be kept by final user.

II

Notes

■ Delivery and storage

z Packing box over 6 layers in pile is unallowed.

z Never climb the packing box, neither stand on it, nor place heavy objects on it.

z Do not move or drag the product by the cables connected with it.

z Forbid collision or scratch to the panel and displayer.

z Packing box should be protected from damping, insolation and raining.

■ Open packing box to check

z Ensure things in packing box are the required ones.

z Ensure the product is not damaged in delivery.

z Ensure the parts in packing box are in accordance to the order.

z Contact us in time if the product type is inconsistent with the order, there is short of

Notes

accessories, or product damage in delivery.

■ Connection

z Only qualified persons can connect the system or check the connection.

z The system must be earthed, its resistance must be less than 4 Ω and the ground wire

cannot be replaced by zero wire.

z Connection must be correct and firm to avoid the product to be damaged or other

unexpected result.

z Connect with surge diode in the specified direction to avoid the damage to the system.

z Switch off power supply before pulling out plug or opening electric cabinet.

■ Troubleshooting

z Switch off power supply before troubleshooting or changing components.

z Troubleshoot and then startup the system when there is short circuit or overload.

z Do not switch on or off it frequently and an interval is 1 minute at least after the system is

powered on again.

III

GSK980TDb Turning CNC System User Manual

z This manual describes various items as much as possible. However,

operations allowable or unallowable cann’t be explained one by one due to

so many possibilities that may involve with, so the contents that are not

specially stated in this manual shall be considered to be unavailable.

z Please read this user manual and a manual from machine builder completely

before installation, programming and operation; do operate the system and

machine according to user manuals, otherwise it may damage the system,

machine, workpiece and even injure the operator.

z Functions, technical indexes described in this user manual are only for the

system. Actual functions and technical performance of machine tool with this

CNC system are determined by machine builder’s design, so refer to its user

manual.

z The system is employed with integrated machine control panel and the keys

on machine control panel are defined by PLC program. Functions of keys in

this user manual are for standard PLC program. Please notice it!

z Refer to user manual from machine manufacturer about functions and

meanings of keys on machine control panel.

Announcement!

Warning!

Cautions!

All specification and designs are subject to change without further notice.

IV

Summary

Volume Ⅰ Programming

GSK980TDb CNC Technical Specification, Product

Type, Command and Program Format

Volume Ⅱ Operation

GSK980TDb CNC Operation Use

Volume Ⅲ Installation and Connection

GSK980TDb CNC Installation, Connection and Setting

Appendix

CNC Ladder Function Allocation, Alarm Message Table

V

GSK980TDb Turning CNC System User Manual

Safety Responsibility

Manufacturer’s safety responsibility

——The manufacturer should be responsible for the cleared or the controlled safety in the design

and the structure of the CNC system and the accessories.

——The manufacturer should be responsible for the CNC system and the accessories.

——The manufacturer should be responsible for the message and the suggestion for the user.

User’s safety responsibility

——The user should study and train the system safety operation, master the safety operation

content.

——The user should be responsible for the danger caused by increasing, changing or modifying

the CNC system, the accessories by itself.

——The user should be responsible for the danger because of the mistaken operation, regulation,

maintenance, installation and storage.

VI

Contents

CONTENTS

Volume Ⅰ Programming

CHAPTER 1 PROGRAMMING ……………………………………………………………………………………………3

1.1 GSK980TDb introduction ………………………………………………………………………………………..3

1.1.1 Product introduction……………………………………………………………………………………… 3

1.1.2 Technical specification …………………………………………………………………………………..4

1.1.3 Environment and conditions…………………………………………………………………………… 6

1.1.4 Power supply ……………………………………………………………………………………………….7

1.1.5 Guard…………………………………………………………………………………………………………. 7

1.2 CNC system of machine tools and CNC machine tools ………………………………………………. 7

1.3 Programming fundamentals ……………………………………………………………………………………. 9

1.3.1 Coordinates definition …………………………………………………………………………………… 9

1.3.2 Machine coordinate system, Machine Zero and machine reference point …………….. 9

1.3.3 Workpiece coordinate system and Program Zero……………………………………………. 10

1.3.4 Interpolation function ………………………………………………………………………………….. 11

1.3.5 Absolute programming and incremental programming ……………………………………..12

1.3.6 Diameter programming and radius programming ……………………………………………. 12

1.4 Structure of an NC program ………………………………………………………………………………….. 13

1.4.1 General structure of a program …………………………………………………………………….. 14

1.4.2 Main program and subprogram…………………………………………………………………….. 17

1.5 Program run……………………………………………………………………………………………………….. 18

1.5.1 Sequence of program run …………………………………………………………………………….18

1.5.2 Execution sequence of word………………………………………………………………………… 19

1.6 Basic axis incremental system ……………………………………………………………………………….19

1.6.1 Incremental system speed of basic axis …………………………………………………………19

1.6.2 Incremental system unit of basic axis …………………………………………………………….20

1.6.3 Incremental system data range of basic axis ………………………………………………….. 20

1.6.4 Incremental system data range and unit of basic axis ………………………………………21

1.6.5 Program address value unit and range of incremental system of basic axis………… 22

1.7 Additional axis incremental system ………………………………………………………………………… 23

1.7.1 Additional axis being the current incremental system ………………………………………. 24

1.7.2 Additional axis being IS-A incremental system ………………………………………………..24

CHAPTER 2 MSTF COMMAND ………………………………………………………………………………………..25

2.1 M (miscellaneous function) ……………………………………………………………………………………25

2.1.1 End of program M02 ………………………………………………………………………………… 25

2.1.2 End of program run M30 …………………………………………………………………………… 25

2.1.3 Subprogram call M98 ……………………………………………………………………………….. 26

2.1.4 Return from subprogram M99 ……………………………………………………………………. 26

2.1.5 Macro program call M9000~M9999 ……………………………………………………………27

2.1.6 M commands defined by standard PLC ladder diagram …………………………………… 27

2.1.7 Program stop M00……………………………………………………………………………………. 28

2.1.8 Program optional stop M01………………………………………………………………………….. 28

2.1.9 Spindle CW, CCW and stop control M03, M04, M05 ………………………………………..29

2.1.10 Cooling control M08, M09 ………………………………………………………………………..29

2.1.11 Tailstock control M10, M11 ………………………………………………………………………. 29

2.1.12 Chuck control M12, M13 ………………………………………………………………………….29

VII

GSK980TDb Turning CNC System User Manual

2.1.13 Spindle position/speed control switch M14, M15…………………………………………… 29

2.1.14 Spindle clamped/released M20, M21……………………………………………………………30

2.1.15 The 2

2.1.16 Lubricating control M32, M33 ……………………………………………………………………..30

2.1.17 Spindle automatic gear change M41, M42, M43, M44…………………………………….30

2.1.18 Spindle 8-point orientation M50~M58…………………………………………………………. 30

2.1.19 The 2

2.2 Spindle function…………………………………………………………………………………………………..31

2.2.1 Spindle speed switching value control……………………………………………………………31

2.2.2 Spindle speed analog voltage control…………………………………………………………….32

2.2.3 Constant surface speed control G96, constant rotational speed control G97……….32

2.2.4 Spindle override………………………………………………………………………………………….35

2.2.5 Multiple spindle control function……………………………………………………………………. 35

2.2.6 Cs contour control funciton…………………………………………………………………………..36

2.3 Tool function ……………………………………………………………………………………………………….36

2.3.1 Tool control ………………………………………………………………………………………………..36

2.3.2 Tool life management…………………………………………………………………………………. 40

CHAPTER 3 G COMMANDS…………………………………………………………………………………………….50

nd

spindle position/speed switch M24, M25………………………………………… 30

nd

spindle rotation CCW, rotation CW , stop M63, M64, M65……………………31

3.1 Commands …………………………………………………………………………………………………………50

3.1.1 Modal, non-modal and initial mode……………………………………………………………….. 51

3.1.2 Omitting words……………………………………………………………………………………………51

3.1.3 Related definitions………………………………………………………………………………………53

3.2 Rapid traverse movement G00 …………………………………………………………………………… 53

3.3 Linear interpolation G01……………………………………………………………………………………..54

3.4 Circular interpolation G02, G03……………………………………………………………………………56

3.5 Three-point circular interpolation G05………………………………………………………………….. 59

3.6 Ellipse interpolation G6.2, G6.3……………………………………………………………………………60

3.7 Parabola interpolation G7.2, G7.3………………………………………………………………………..63

3.8 Plane selection G17~G19……………………………………………………………………………………65

3.9 Polar coordinate interpolation G12.1, G13.1…………………………………………………………….66

3.10 Cylindrical interpolation G7.1……………………………………………………………………………….69

3.11 Chamfering function……………………………………………………………………………………………72

3.11.1 Linear chamfering…………………………………………………………………………………….. 72

3.11.2 Circular chamfering……………………………………………………………………………………74

3.11.3 Special cases…………………………………………………………………………………………… 76

3.12 Dwell G04……………………………………………………………………………………………………….78

3.13 Machine Zero function ………………………………………………………………………………………..78

3.13.1 Machine 1st reference point G28 ………………………………………………………………78

3.13.2 Machine 2nd, 3rd, 4th reference point G30………………………………………………… 79

3.14 Skip interpolation G31………………………………………………………………………………………81

3.15 Automatic tool offset G36, G37………………………………………………………………………….83

3.16 Workpiece coordinate system G50 ……………………………………………………………………. 86

3.17 Fixed cycle command…………………………………………………………………………………………87

3.17.1 Axial cutting cycle G90……………………………………………………………………………. 87

3.17.2 Radial cutting cycle G94………………………………………………………………………….90

3.17.3 Caution of fixed cycle commands……………………………………………………………….. 92

3.18 Multiple cycle commands…………………………………………………………………………………….93

3.18.1 Axial roughing cycle G71……………………………………………………………………………93

VIII

Contents

3.18.2 Radial roughing cycle G72…………………………………………………………………………. 99

3.18.3 Closed cutting cycle G73……………………………………………………………………….. 103

3.18.4 Finishing cycle G70 …………………………………………………………………………………107

3.18.5 Axial grooving multiple cycle G74 …………………………………………………………… 108

3.18.6 Radial grooving multiple cycle G75……………………………………………………………. 111

3.19 Thread cutting commands ………………………………………………………………………………… 114

3.19.1 Thread cutting with constant lead G32……………………………………………………….. 115

3.19.2 Rigid thread cutting G32.1 ……………………………………………………………………….. 117

3.19.3 Thread cutting with variable lead G34……………………………………………………… 119

3.19.4 Z thread cutting G33 …………………………………………………………………………….. 121

3.19.5 Rigid tapping G84, G88 ……………………………………………………………………………122

3.19.6 Thread cutting cycle G92 …………………………………………………………………………. 125

3.19.7 Multiple thread cutting cycle G76………………………………………………………………. 128

3.20 Constant surface speed control G96, constant rotational speed control G97 ………..132

3.21 Feedrate per minute G98, feedrate per rev G99 …………………………………………………… 132

3.22. Additional Axis Function…………………………………………………………………………………… 134

3.22.1 Additional axis start…………………………………………………………………………………. 134

3.22.2 Motion of additional axis ………………………………………………………………………….. 134

3.22.3 Additional axis coordinates display ……………………………………………………………. 135

3.23 Macro commands …………………………………………………………………………………………….135

3.23.1 MACRO variables …………………………………………………………………………………… 135

3.23.2 Operation and jump command G65 ………………………………………………………… 140

3.23.3 Program example with macro command …………………………………………………….143

3.24 Statement macro command ……………………………………………………………………………….145

3.24.1 Arithmetic and logic operation…………………………………………………………………… 145

3.24.2 Transfer and cycle ………………………………………………………………………………….. 147

3.25 Metric/Inch Switch……………………………………………………………………………………………. 149

3.25.1 Functional summary ………………………………………………………………………………..149

3.25.2 Function command G20/G21……………………………………………………………………. 150

3.25.3 Notes ……………………………………………………………………………………………………. 150

CHAPTER 4 TOOL NOSE RADIUS COMPENSATION (G41, G42) ………………………………………151

4.1 Application ……………………………………………………………………………………………………….. 151

4.1.1 Overview…………………………………………………………………………………………………. 151

4.1.2 Imaginary tool nose direction ……………………………………………………………………… 152

4.1.3 Compensation value setting……………………………………………………………………….. 155

4.1.4 Command format ……………………………………………………………………………………… 156

4.1.5 Compensation direction …………………………………………………………………………….. 156

4.1.6 Notes ……………………………………………………………………………………………………… 158

4.1.7 Application ………………………………………………………………………………………………. 159

4.2 Tool nose radius compensation offset path……………………………………………………………. 160

4.2.1 Inner and outer side ………………………………………………………………………………….. 160

4.2.2 Tool traversing when starting tool ……………………………………………………………….. 160

4.2.3 Tool traversing in Offset mode ……………………………………………………………………. 162

4.2.4 Tool traversing in Offset canceling mode ………………………………………………………167

4.2.5 Tool interference check……………………………………………………………………………… 168

4.2.6 Commands for canceling compensation vector temporarily ……………………………. 170

4.2.7 Particulars……………………………………………………………………………………………….. 172

IX

GSK980TDb Turning CNC System User Manual

Volume Ⅱ Operation

CHAPTER 1 OPERATION MODE AND DISPLAY INTERFACE ……………………………………………175

1.1 Panel division…………………………………………………………………………………………………….175

1.1.1 State indication …………………………………………………………………………………………176

1.1.2 Edit keypad……………………………………………………………………………………………… 176

1.1.3 Menu display ……………………………………………………………………………………………177

1.1.4 Machine panel ………………………………………………………………………………………….177

1.2 Summary of operation mode ………………………………………………………………………………. 180

1.3 Display interface ………………………………………………………………………………………………..181

1.3.1 POS interface …………………………………………………………………………………………..183

1.3.2 PRG interface …………………………………………………………………………………………..186

1.3.3 TOOL OFFSET&WEAR, MACRO, TOOL-LIFE MANAGEMENT interfaces ……….188

1.3.4 ALARM interface ………………………………………………………………………………………190

1.3.5 Setting interface……………………………………………………………………………………….. 191

1.3.6 BIT PARAMETER, DATA PARAMETER, SCREW-PITCH COMP interfaces………194

1.3.7 CNC DIAGNOSIS, PLC STATE, PLC VALUE, TOOL PANEL, VERSION MESSAGE

interfaces …………………………………………………………………………………………………………..195

CHAPTER 2 POWER ON/OFF AND PROTECTION…………………………………………………………..199

2.1 System power on……………………………………………………………………………………………….199

2.2 System power off ……………………………………………………………………………………………….199

2.3 Overtravel protection ………………………………………………………………………………………….199

2.3.1 Hardware overtravel protection…………………………………………………………………… 200

2.3.2 Software Overtravel Protection……………………………………………………………………200

2.4 Emergency operation………………………………………………………………………………………….201

2.4.1 Reset ………………………………………………………………………………………………………201

2.4.2 Emergency stop………………………………………………………………………………………..201

2.4.3 Feed hold…………………………………………………………………………………………………201

2.4.4 Power-off …………………………………………………………………………………………………201

CHAPTER 3 MANUAL OPERATION………………………………………………………………………………..202

3.1 Coordinate axis move …………………………………………………………………………………………

3.1.1 Manual feed……………………………………………………………………………………………..202

3.1.2 Manual rapid traverse ………………………………………………………………………………..203

3.1.3 Speed tune ……………………………………………………………………………………………… 203

3.2 Other manual operations …………………………………………………………………………………….204

3.2.1 Spindle CCW, CW, stop control …………………………………………………………………..204

3.2.2 Spindle jog ……………………………………………………………………………………………….204

3.2.3 Cooling control………………………………………………………………………………………….205

3.2.4 Lubricating control …………………………………………………………………………………….205

3.2.5 Chuck control……………………………………………………………………………………………206

3.2.6 Tailstock control ………………………………………………………………………………………..206

3.2.7 Hydraulic control……………………………………………………………………………………….206

3.2.8 Manual tool change …………………………………………………………………………………..207

3.2.9 Spindle override………………………………………………………………………………………..207

202

X

Contents

CHAPTER 4 MPG/STEP OPERATION……………………………………………………………………………..208

4.1 Step feed…………………………………………………………………………………………………………..208

4.1.1 Increment selection……………………………………………………………………………………208

4.1.2 Moving direction selection ………………………………………………………………………….209

4.2 MPG(handwheel) feed………………………………………………………………………………………..209

4.2.1 Increment selection……………………………………………………………………………………209

4.2.2 Moving axis and direction selection……………………………………………………………..210

4.2.3 Other operations……………………………………………………………………………………….210

4.2.4 Explanation items ……………………………………………………………………………………..211

CHAPTER 5 MDI OPERATION ……………………………………………………………………………………….212

5.1 Code words input……………………………………………………………………………………………….212

5.2 Code words execution ………………………………………………………………………………………..213

5.3 Parameter setting……………………………………………………………………………………………….213

5.4 Data alteration……………………………………………………………………………………………………213

5.5 Other operations………………………………………………………………………………………………..214

CHAPTER 6 PROGRAM EDIT AND MANAGEMENT…………………………………………………………215

6.1 Program creation ……………………………………………………………………………………………….215

6.1.1 Creating a block number…………………………………………………………………………….215

6.1.2 Inputting a program……………………………………………………………………………………215

6.1.3 Searching a character………………………………………………………………………………..216

6.1.4 Inserting a character………………………………………………………………………………….218

6.1.5 Deleting a character…………………………………………………………………………………..219

6.1.6 Altering a character……………………………………………………………………………………219

6.1.7 Deleting a single block……………………………………………………………………………….220

6.1.8 Deleting blocks …………………………………………………………………………………………220

6.1.9 Deleting a segment……………………………………………………………………………………221

6.1.10 Macro program edit………………………………………………………………………………….222

6.2 Program annotation ……………………………………………………………………………………………222

6.2.1 Creating a program annotation ……………………………………………………………………222

6.2.2 Altering a program annotation……………………………………………………………………..224

6.3 Deleting program ……………………………………………………………………………………………….224

6.3.1 Deleting a program ……………………………………………………………………………………224

6.3.2 Deleting all programs…………………………………………………………………………………224

6.3.3 Initiation of program area……………………………………………………………………………224

6.4 Selecting a program……………………………………………………………………………………………224

6.4.1 Search…………………………………………………………………………………………………….224

6.4.2 Scanning………………………………………………………………………………………………….225

6.4.3 Cursor……………………………………………………………………………………………………..225

6.5 Execution of the program…………………………………………………………………………………….226

6.6 Renaming a program ………………………………………………………………………………………….226

6.7 Copy a program…………………………………………………………………………………………………226

6.8 Program management………………………………………………………………………………………..226

6.8.1 Program list………………………………………………………………………………………………226

6.8.2 Part-Prg number……………………………………………………………………………………….226

6.8.3 Memory size and used capacity…………………………………………………………………..227

XI

GSK980TDb Turning CNC System User Manual

6.9 Other operations available in Edit mode ………………………………………………………………..227

CHAPTER 7 TOOL OFFSET AND SETTING …………………………………………………………………….228

7.1 Tool positioning setting ……………………………………………………………………………………….228

7.2 Trial toolsetting ………………………………………………………………………………………………….229

7.3 Toolsetting by machine zero return ……………………………………………………………………….230

7.4 Setting and altering the offset value………………………………………………………………………232

7.4.1 Offset setting ……………………………………………………………………………………………233

7.4.2 Offset alteration ………………………………………………………………………………………..234

7.4.3 Offset alteration in communication mode………………………………………………………234

7.4.4 Clearing the offset values …………………………………………………………………………..235

7.4.5 Setting and altering the tool wear ……………………………………………………………….. 235

7.4.6 Locking and unlocking the offset value ………………………………………………………… 235

7.4.7 No.0 tool offset moving workpiece coordinate system ……………………………………. 236

CHAPTER 8 AUTO OPERATION…………………………………………………………………………………….238

8.1 Automatic run…………………………………………………………………………………………………….238

8.1.1 Selection of the program to be run ………………………………………………………………238

8.1.2 Start of the automatic run……………………………………………………………………………239

8.1.3 Stop of the automatic run……………………………………………………………………………239

8.1.4 Automatic run from an arbitrary block …………………………………………………………..240

8.1.5 Adjustment of the feedrate, rapid rate ………………………………………………………….240

8.1.6 Spindle speed adjustment…………………………………………………………………………..241

8.2 Running state…………………………………………………………………………………………………….241

8.2.1 Single block execution ……………………………………………………………………………….241

8.2.2 Dry run…………………………………………………………………………………………………….242

8.2.3 Machine lock…………………………………………………………………………………………….243

8.2.4 MST lock………………………………………………………………………………………………….244

8.2.5 Block skip ………………………………………………………………………………………………..244

8.3 Other operations ………………………………………………………………………………………………..245

CHAPTER 9 ZERO RETURN OPERATION………………………………………………………………………246

9.1 Program zero return……………………………………………………………………………………………246

9.1.1 Program Zero …………………………………………………………………………………………..246

9.1.2 Program zero return steps ………………………………………………………………………….246

9.2 Machine Zero return …………………………………………………………………………………………..247

9.2.1 Machine Zero (machine reference point) ………………………………………………………247

9.2.2 Machine Zero return steps………………………………………………………………………….247

9.3 Other operations in zero return …………………………………………………………………………….248

CHAPTER 10 DATA SETTING, BACKUP and RESTORE ……………………………………………………249

10.1 Data setting……………………………………………………………………………………………………..249

10.1.1 Switch setting …………………………………………………………………………………………249

10.1.2 Graphic display………………………………………………………………………………………. 249

10.1.3 Parameter setting …………………………………………………………………………………… 251

10.2 Data recovery and backup …………………………………………………………………………………256

10.3 Password setting and alteration………………………………………………………………………….257

10.3.1 Operation level entry ……………………………………………………………………………….258

XII

Contents

10.3.2 Altering the password ………………………………………………………………………………259

10.3.3 Setting the lower password level ……………………………………………………………….260

CHAPTER 11 U OPERATION FUNCTION ………………………………………………………………………..262

11.1 File catalog window …………………………………………………………………………………………..262

11.2 Commonly use file operation function introduction…………………………………………………262

11.2.1 File extension and return…………………………………………………………………………..262

11.2.2 File copy…………………………………………………………………………………………………263

11.2.3 Open CNC file…………………………………………………………………………………………263

CHAPTER 12 ADVANCED OPERATION(USB FUNCTION)…………………………………………….264

12.1 Entering the advanced operation window …………………………………………………………….264

12.2 Operation path …………………………………………………………………………………………………264

12.3 Operation explanation……………………………………………………………………………………….265

12.4 Note ……………………………………………………………………………………………………………….266

CHAPTER 13 COMMUNICATION ……………………………………………………………………………………267

13.1 TDComm2a communication software introduction of GSK980TDb ………………………….267

13.1.1 Files download (PC→CNC) ………………………………………………………………………268

13.1.2 Uploading files (CNC→PC)……………………………………………………………………….273

13.1.3 Setting option………………………………………………………………………………………….275

13.2 Preparation before communication ……………………………………………………………………..275

13.3 Data input (PC→CNC) ………………………………………………………………………………………276

13.3.1 Inputting a program………………………………………………………………………………….276

13.3.2 Inputting a tool offset………………………………………………………………………………..278

13.3.3 Input of the parameter………………………………………………………………………………279

13.4 Data output(CNC→PC)……………………………………………………………………………………..280

13.4.1 Output a program…………………………………………………………………………………….280

13.4.2 Outputting all programs ……………………………………………………………………………283

13.4.3 Outputting a tool offset……………………………………………………………………………..284

13.4.4 Outputting a parameter …………………………………………………………………………….285

13.5 Communication between CNC and CNC ……………………………………………………………..286

CHAPTER 14 MACHINING EXAMPLES …………………………………………………………………………..288

14.1 Programming …………………………………………………………………………………………………..289

14.2 Program input ………………………………………………………………………………………………….290

14.2.1 View a saved program ……………………………………………………………………………..290

14.2.2 Creating a new program …………………………………………………………………………..291

14.3 Checkout a program ……………………………………………………………………………………………292

14.3.1 Graphic setting………………………………………………………………………………………..292

14.3.2 Program check………………………………………………………………………………………..292

14.4 Toolsetting and running ……………………………………………………………………………………..293

XIII

GSK980TDb Turning CNC System User Manual

Volume Ⅲ Connection

CHAPTER 1 INSTALLATION LAYOUT…………………………………………………………………………….. 299

1.1 GSK980TDb system connection…………………………………………………………………………..299

1.1.1 GSK980TDb, GSK980TDb-V back cover interface layout……………………………….299

1.1.2 Interface explanation …………………………………………………………………………………300

1.2 GSK980TDb installation ……………………………………………………………………………………..300

1.2.1 GSK980TDb external dimensions ……………………………………………………………….300

1.2.2 Preconditions of the cabinet installation………………………………………………………..300

1.2.3 Measures against interference ……………………………………………………………………300

CHAPTER 2 DEFINITION & CONNECTION OF INTERFACE SIGNALS……………………………….302

2.1 Connection to drive unit ………………………………………………………………………………………302

2.1.1 Drive interface definition …………………………………………………………………………….302

2.1.2 Code pulse and direction signals…………………………………………………………………302

2.1.3 Drive unit alarm signal nALM ………………………………………………………………………302

2.1.4 Axis enable signal nEN………………………………………………………………………………303

2.1.5 Pulse disable signal nSET ………………………………………………………………………….303

2.1.6 Zero signal nPC………………………………………………………………………………………..303

2.1.7 Connection to a drive unit …………………………………………………………………………..305

2.2 Being connected with spindle encoder ………………………………………………………………….306

2.2.1 Spindle encoder interface definition……………………………………………………………..306

2.2.2 Signal explanation …………………………………………………………………………………….306

2.2.3 Being connected with spindle encoder interface…………………………………………….306

2.3 Being connected with MPG (Manual Pulse Generator) ……………………………………………307

2.3.1 MPG interface definition …………………………………………………………………………….307

2.3.2 Signal explanation …………………………………………………………………………………….307

2.4 Spindle interface ………………………………………………………………………………………………..308

2.4.1 Spindle interface definition………………………………………………………………………….308

2.4.2 Connection to inverter ………………………………………………………………………………….308

2.5 GSK980TDb/

2.5.1 Communication interface definition………………………………………………………………309

2.5.2 Communication interface connection……………………………………………………………309

2.6 Power interface connection …………………………………………………………………………………310

2.7 I/O interface definition…………………………………………………………………………………………310

2.7.1 Input signal ………………………………………………………………………………………………312

2.7.2 Output signal ……………………………………………………………………………………………313

2.8 I/O function and connection ………………………………………………………………………………… 315

2.8.1 Stroke limit and emergency stop………………………………………………………………….315

2.8.2 Tool change control …………………………………………………………………………………..317

2.8.3 Machine zero return………………………………………………………………………………….. 323

2.8.4 Spindle control………………………………………………………………………………………….330

2.8.5 Spindle switching volume control…………………………………………………………………333

2.8.6 Spindle automatic gearing control………………………………………………………………..333

2.8.7 Spindle eight-point orientation function…………………………………………………………335

2.8.8 Spindle Cs axis control function…………………………………………………………………..338

GSK980TDb-V being connected with PC …………………………………………309

XIV

Contents

2.8.9 Multiple spindle function …………………………………………………………………………….340

2.8.10 Rigid tapping function ………………………………………………………………………………343

2.8.11 External cycle start and feed hold………………………………………………………………344

2.8.12 Cooling control………………………………………………………………………………………..345

2.8.13 Lubricating control …………………………………………………………………………………..345

2.8.14 Chuck control………………………………………………………………………………………….347

2.8.15 Tailstock control ………………………………………………………………………………………349

2.8.16 Low pressure detection…………………………………………………………………………….350

2.8.17 Hydraulic control (only applied to 980TDb-V) ………………………………………………351

2.8.18 Safety door detection……………………………………………………………………………….352

2.8.19 Block skip……………………………………………………………………………………………….352

2.8.20 CNC macro variables……………………………………………………………………………….353

2.8.21 Tri-colour indicator…………………………………………………………………………………..353

2.8.22 External override……………………………………………………………………………………..354

2.8.23 External MPG …………………………………………………………………………………………354

2.8.24 Gear/tool number display (only applied to 980TDb-V )…………………………………..355

2.9 Commonly use symbol of electricity drawing ………………………………………………………….356

CHAPTER 3 PARAMETERS …………………………………………………………………………………………..357

3.1 Parameter description (by sequence)……………………………………………………………………357

3.1.1 Bit parameter……………………………………………………………………………………………357

3.1.2 Data parameter…………………………………………………………………………………………366

3.1.3 PLC K parameter(standard PLC definition) ……………………………………………….386

3.2 Parameter description (by function sequence)………………………………………………………..388

3.2.1 X, Z, Y, 4

th,5th

axis control logic……………………………………………………………………388

3.2.2 Acceleration&deceleration control ……………………………………………………………….390

3.2.3 Precision compensation……………………………………………………………………………..392

3.2.4 Machine protection ……………………………………………………………………………………395

3.2.5 Machine zero return…………………………………………………………………………………..395

3.2.6 Threading function…………………………………………………………………………………….400

3.2.7 Spindle control………………………………………………………………………………………….401

3.2.8 Tool compensation…………………………………………………………………………………….404

3.2.9 Tool life management function…………………………………………………………………….404

3.2.10 Tool wear parameter………………………………………………………………………………..405

3.2.11 Edit and display……………………………………………………………………………………….405

3.2.12 Communication setting…………………………………………………………………………….405

3.2.13 MPG Parameters…………………………………………………………………………………….406

3.2.14 PLC axis control function ………………………………………………………………………….406

3.2.15 Skip function…………………………………………………………………………………………..406

3.2.16 Automatic toolsetting function……………………………………………………………………407

3.2.17 Input and output function in metric and inch system……………………………………..407

3.2.18 Parameters related to arc turning ………………………………………………………………408

3.2.19 Parameters related to the additional…………………………………………………………..408

CHAPTER 4 MACHINE DEBUGGING METHODS AND MODES…………………………………………411

4.1 Emergency stop and limit…………………………………………………………………………………….411

4.2 Drive unit configuration ……………………………………………………………………………………….411

XV

GSK980TDb Turning CNC System User Manual

4.3 Gear ratio adjustment …………………………………………………………………………………………411

4.4 ACC&DEC characteristic adjustment……………………………………………………………………. 412

4.5 Mechanical (machine) zero adjustment …………………………………………………………………413

4.6 Spindle adjustment …………………………………………………………………………………………….415

4.6.1 Spindle encoder………………………………………………………………………………………..415

4.6.2 Spindle brake……………………………………………………………………………………………415

4.6.3 Switch volume control of spindle speed………………………………………………………..416

4.6.4 Analog voltage control of spindle speed ……………………………………………………….416

4.7 Backlash Offset………………………………………………………………………………………………….416

4.8 Tool Post Debugging…………………………………………………………………………………………..417

4.9 Step/MPG Adjustment…………………………………………………………………………………………418

4.10 Other adjustment ……………………………………………………………………………………………..418

CHAPTER 5 DIAGNOSIS MESSAGE ………………………………………………………………………………420

5.1 CNC diagnosis…………………………………………………………………………………………………..420

5.1.1 I/O status and data diagnosis message……………………………………………………….. 420

5.1.2 CNC motion state and data diagnosis message……………………………………………. 420

5.1.3 Diagnosis keys …………………………………………………………………………………………421

5.1.4 Others……………………………………………………………………………………………………..422

5.2 PLC state ………………………………………………………………………………………………………….422

5.2.1 X address (machine→PLC , defined by standard PLC ladders) ………………………. 422

5.2.2 Y address (PLC→machine, defined by standard PLC ladders) ……………………….. 424

5.2.3 Machine panel ………………………………………………………………………………………….426

5.2.4 F address(CNC→PLC) ………………………………………………………………………………428

5.2.5 G address(PLC→CNC) ……………………………………………………………………………..435

5.2.6 Address A (message display requiery signal, defined by standard PLC ladders) ..440

5.2.7 K address(K parameter, standard PLC definition)………………………………………441

5.3 PLC data…………………………………………………………………………………………………………..444

5.3.1 Timer address T(defined by standard PLC ladders) ……………………………………….444

5.3.2 Counter address C(Defined by standard PLC Ladders) ………………………………….445

5.3.3 Timer presetting address DT(Defined by standard PLC ladders) ……………………..445

5.3.4 Counter presetting address DC …………………………………………………………………..445

CHAPTER 6 MEMORIZING PITCH ERROR COMPENSATION …………………………………………..446

6.1 Function description……………………………………………………………………………………………446

6.2 Specification ……………………………………………………………………………………………………..446

6.3 Parameter setting ………………………………………………………………………………………………446

6.3.1 Pitch compensation …………………………………………………………………………………..446

6.3.2 Pitch error origin ……………………………………………………………………………………….446

6.3.3 Offset interval …………………………………………………………………………………………..447

6.3.4 Offset value ……………………………………………………………………………………………..447

6.4 Notes of offset setting …………………………………………………………………………………………447

6.5 Setting examples of offset parameters…………………………………………………………………..447

XVI

Contents

Appendix

Appendix 1 GSK980TDb, GSK980TDb-V contour dimension……………………………………………………. 453

Appendix 2 GSK980TDb-B outline dimension ……………………………………………………………………………454

Appendix 3 Outline Dimension of Accessional Panel AP01……………………………………………………….. 454

Appendix 4 Outline Dimension of Accessional Panel AP02……………………………………………………….. 455

Appendix 5 Outline Dimension of Accessional Panel AP03……………………………………………………….. 455

Appendix 6 Outline Dimension of I/O deconcentrator MCT01A…………………………………………………. 456

Appendix 7 Outline Dimension of I/O deconcentrator MCT02……………………………………………………. 456

Appendix 8 Delivery standard parameter…………………………………………………………………………………… 457

Appendix 9 Alarm list ………………………………………………………………………………………………………………… 463

Appendix 10 Operation list………………………………………………………………………………………………………… 471

XVII

GSK980TDb Turning CNC System User Manual

XVIII

Chapter 1 Programming

Volume Ⅰ Programming

1

GSK980TDb Turning CNC System User Manual

2

Chapter 1 Programming

CHAPTER 1 PROGRAMMING

1.1 GSK980TDb introduction

1.1.1 Product introduction

GSK980TDb is a new upgraded software, hardware product based of GSK980TDa, with 5 feed

axes(including C axis), 2 analog spindles, 2ms high-speed interpolation, 0.1μm control precision,

which can obviously improve the machining efficiency, precision and surface quality. It adds the USB

interface, U disc file operation and program run. As the upgrade product of GSK980TDa,

GSK980TDb (GSK980TDb-V) is the best choice of economic CNC turning machine.

Volum e Ⅰ Programming

GSK980TDb GSK980TDb-V

th

X, Z, Y, 4

2ms interpolation period, control precision 1μm, 0.1μm

Max. speed 60m/min(up to 24m/min in 0.1μm)

Adapting to the servo spindle to realize the spindle continuously positioning, rigid tapping, and

the rigid thread machining

Built-in multi PLC programs, and the PLC program currently running can be selected

G71 supporting flute contour cycle cutting

Statement macro command programming, macro program call with parameter

Metric/inch programming, automatic toolsetting, automatic chamfer, tool life management

function

Chinese, English, Spanish, Russian display can be selected by parameters.

USB interface, U disc file operation, system configuration and software

2-channel 0V~10V analog voltage output, two-spindle control

1-channel MPG input, MPG function

41 input signals and 36 output signals

Appearance installation dimension, and command system are compatible with GSK980TDa

, 5th ; axis name and axis type of Y, 4th, 5th can be defined

3

1.1.2 Technical specification

Controllable axes

Controllable axes: 5(X, Z, Y , 4

Volum e Ⅰ Programming

Link axes:3

PLC controllable axes:3(X, Z, Y)

Feed axis function

Least input unit: 0.001mm(0.0001inch)and 0.0001mm(0.00001inch)

Least command unit:0.001mm(0.0001inch)and 0.0001mm(0.00001inch)

Position command range: ±99999999× least command unit

Rapid traverse speed:max. speed 60m/min in 0.001mm command unit, max. speed

24m/min in 0.0001mm command unit

Rapid override: F0, 25%, 50%, 100%

Feedrate override: 0~150% 16 grades to tune

Interpolation mode: linear interpolation, arc interpolation(three-point arc interpolation),

thread interpolation, ellipse interpolation, parabola interpolation and rigid tapping

Automatic chamfer function

GSK980TDb Turning CNC System User Manual

th,5th

)

Thread function

General thread(following spindle)/rigid thread

Single/multi metric, inch straight thread, taper thread, end face thread, constant pitch

thread and variable pitch thread

Thread run-out length, angle, speed characteristics can be set

Thread pitch: 0.01mm~500mm or 0.06 tooth/inch~2540 tooth/inch

Acceleration/deceleration function

Cutting feed: linear

Rapid traverse: linear, S

Thread cutting: linear, exponential

Initial speed, termination speed, time of acceleration/deceleration can be set by

parameters.

Spindle function

2-channel 0V~10V analog voltage output, two-spindle control

1-channel spindle encoder feedback, spindle encoder line can be set(100p/r~5000p/r)

Transmission ratio between encoder and spindle:(1~255):(1~255)

Spindle speed: it is set by S or PLC, and speed range: 0r/min~9999r/min

Spindle override: 50%~120% 8 grades tune

Spindle constant surface speed control

Rigid tapping

Tool function

Tool length compensation

Tool nose radius compensation(C)

Tool wear compensation

Tool life management

Toolsetting mode: fixed-point toolsetting, trial-cut toolsetting, reference point return

toolsetting, automatic toolsetting

4

Chapter 1 Programming

Tool offset execution mode: modifying coordinate mode, tool traverse mode

Precision compensation

Backlash compensation

Memory pitch error compensation

PLC function

Two-level PLC program,up to 5000 steps,the 1st program refresh period 8ms

PLC program communication download

PLC warning and PLC alarm

Many PLC programs(up to 16PCS), the PLC program currently running can be

selected

Basic I/O:41 input signals /36 output signals

Man-machine interface

7.4″ wide screen LCD,resolution: 234×480

Chinese, English, Spanish, Russian display

Planar tool path display

Real-time clock

Volum e Ⅰ Programming

Operation management

Operation mode: edit, auto, MDI, machine zero return, MPG/single, manual, program

zero return

Multi-level operation privilege management

Alarm record

Program edit

Program capacity: 40MB , 10000 programs ( including subprograms and macro

programs)

Edit function: program/block word search, modification, deletion

Program format: ISO command, statement macro command programming, relative

coordinate, absolute coordinate and compound coordinate programming

Program call: macro program call with parameter, 4-level program built-in

Communication function

RS232:two-way transmitting part programs and parameters, PLC program, system

software serial upgrade

USB:U file operation, U file directly machining, PLC program, system software U

upgrade

Safety function

Emergency stop

Hardware travel limit

Software travel check

Data backup and recovery

5

GSK980TDb Turning CNC System User Manual

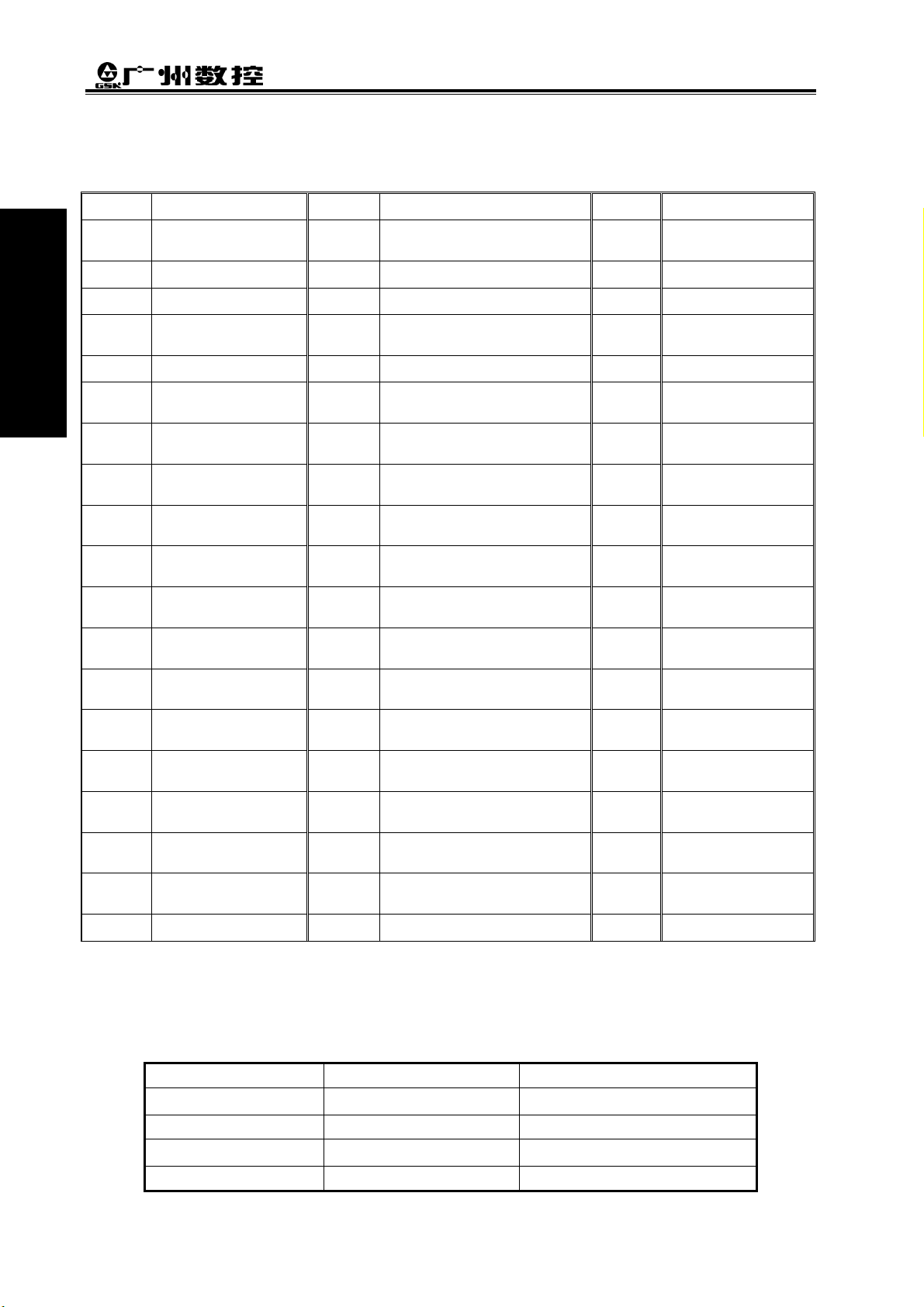

G command table

Table 1-1

Command Function Command Function Command Function

Volum e Ⅰ Programming

G00 Rapid traverse

G01

G02

G03

G04

G05

G6.2

G6.3

G7.2

G7.3

G12.1

G7.1

G15

G16

G17

G18

G19

G10

G11

G20

(positioning)

Linear interpolation

CW arc interpolation

CCW arc interpolation G30

Dwell, exact stop

Three-point arc

interpolation

Ellipse interpolation

(CW)

Ellipse

interpolation(CCW)

Parabola

interpolation(CW)

Parabola

interpolation(CCW)

Polar coordinate

interpolation

Cylinder interpolation

Polar coordinate

command cancel

Polar coordinate

command

Plane selection

command

Plane selection

command

Plane selection

command

Data input ON

Data input OFF

G21

G28

G31

G32

G32.1

G33

G34 Thread cutting with variable

G36

G37

G40 Tool nose radius compensation

G41 Tool nose radius compensation

G42 Tool nose radius compensation

G50 Workpiece coordinate system

G65 Macro command non-modal

G66 Macro program modal call

G67 Macro program modal call

G71

Input in inch

Input in metric

Reference point return

2nd, 3rd, 4threference point

return

Skip function

Constant pitch thread cutting

Rigid thread cutting

Z tapping cycle

lead

Automatic tool compensation X

Automatic tool compensation Z

cancel

left

right

setting

call

cancel

Axial roughing cycle(flute cycle)

G72

G73

G70

G74

G75

G76

G80

G84

G88

G90

G92

G94

G96

G97

G98

G99

Radial roughing cycle

Closed cutting cycle

Finishing cycle

Axial grooving cycle

Radial grooving cycle

Multiple thread cutting

cycle

Rigid tapping state

cancel

Axial rigid tapping

Radial rigid tapping

Axial cutting cycle

Thread cutting cycle

Radial cutting cycle

Constant surface speed

control

Constant surface speed

control cancel

Feed per minute

Feed per revolution

1.1.3 Environment and conditions

GSK980TDb storage delivery, working environment as follows:

Table 1-2

Item Working conditions Storage delivery conditions

Ambient temperature

Ambient humidity ≤90%(no freezing) ≤95%(40 )℃

Atmosphere pressure

Altitude ≤1000m ≤1000m

6

0℃~45℃ -40℃~+70℃

86 kPa~106 kPa 86 kPa~106 kPa

Chapter 1 Programming

1.1.4 Power supply

GSK980TDb can normally run in the following AC input power supply.

Voltage: within(0.85~1.1)×rated AC input voltage (AC 220V);

Frequency: 49Hz~51Hz continuously changing

1.1.5 Guard

GSK980TDb guard level is not less than IP20.

1.2 CNC system of machine tools and CNC machine tools

CNC machine tool is an electro-mechanical integrated product, composed of Numerical Control

Systems of Machine Tools, machines, electric control components, hydraulic components, pneumatic

components, lubricant, cooling and other subsystems (components), and CNC systems of machine

tools are control cores of CNC machine tools. CNC systems of machine tools are made up of

computerized numerical control(CNC), servo (stepper) motor drive devices, servo (or stepper) motor

etc.

Operational principles of CNC machine tools: according to requirements of machining

technology, edit user programs and input them to CNC, then CNC outputs motion control commands

to the servo (stepper) motor drive devices, and last the servo (or stepper) motor completes the cutting

feed of machine tool by mechanical driving device; logic control commands in user programs to

control spindle start/stop, tool selections, cooling ON/OFF, lubricant ON/OFF are output to electric

control systems of machine tools from CNC, and then the electric control systems control output

components including buttons, switches, indicators, relays, contactors and so on. Presently, the

electric control systems are employed with Programmable Logic Controller (PLC) with characteristics

of compact, convenience and high reliance. Thereof, the motion control systems and logic control

systems are the main of CNC machine tools.

GSK980TDb Turning Machine CNC system has simultaneously motion control and logic control

function to control two axes of CNC machine tool to move, and has nested PLC function. Edit PLC

programs (ladder diagram) according to requirements of input and output control of machine tool and

then download them to GSK980TDb Turning Machine CNC system, which realizes the required

electric control requirements of machine tool, is convenient to electric design of machine tool and

reduces cost of CNC machine tool.

Software used to control GSK980TDb Turning Machine CNC system are divided into system

software (NC for short) and PLC software (PLC for short). NC system is used to control the display,

communication, edit, decoding, interpolation and acceleration/deceleration, and PLC system for

controlling explanations, executions, inputs and outputs of ladder diagrams.

Standard PLC programs are loaded (except for the special order) when GSK980TDb Turning

Machine CNC System is delivered, concerned PLC control functions in following functions and

operations are described according to control logics of standard PLC programs, marking with

“Standard PLC functions” in GSK980TDb Turning CNC System User Manual. Refer to Operation

Manual of machine manufacturer about functions and operations of PLC control because the

machine manufacturer may modify or edit PLC programs again.

Volum e Ⅰ Programming

7

GSK980TDb Turning CNC System User Manual

Volum e Ⅰ Programming

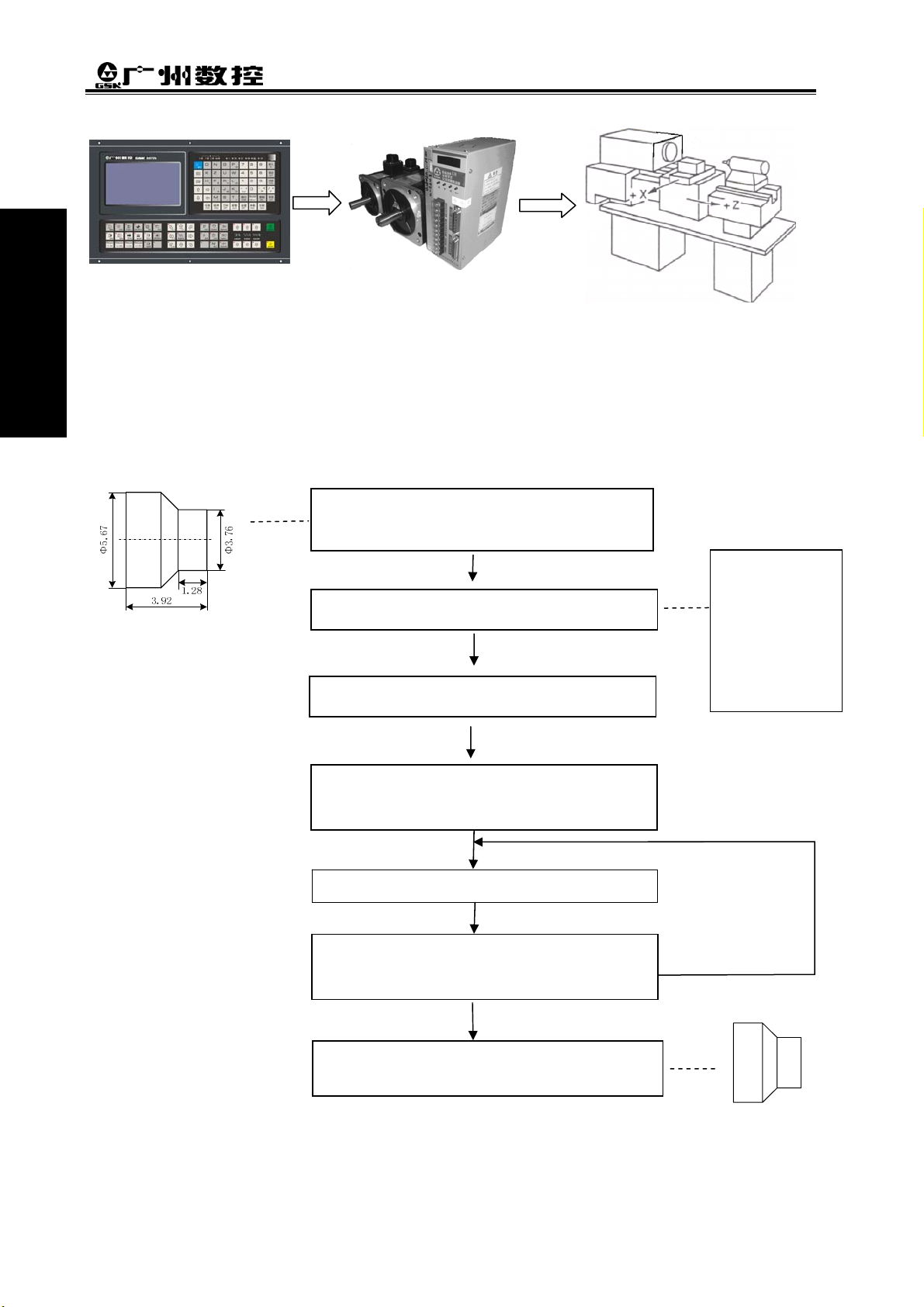

Fig. 1-1

Programming is a course of workpiece contours, machining technologies, technology

parameters and tool parameters being edit into part programs according to special CNC

programming G codes. CNC machining is a course of CNC controlling a machine tool to complete

machining of workpiece according requirements of part programs.

Technical flow of CNC machining is as following Fig. 1-2.

Analyse workpiece drawings and confirm

machining processing

O0001;

G00 X3.76 Z0;

Edit part programs and record into CNC

Test part programs and execute trial run

G01 Z-1.28 F50;

…

M30;

%

Execute toolsetting and set tool offsets and

coordinates

Run part programs and machine workpiece

Check part dimension and modify part

programs and compensations

The machining ends and the workpiece is

formed

Fig. 1-2

8

1.3 Programming fundamentals

1.3.1 Coordinates definition

Chapter 1 Programming

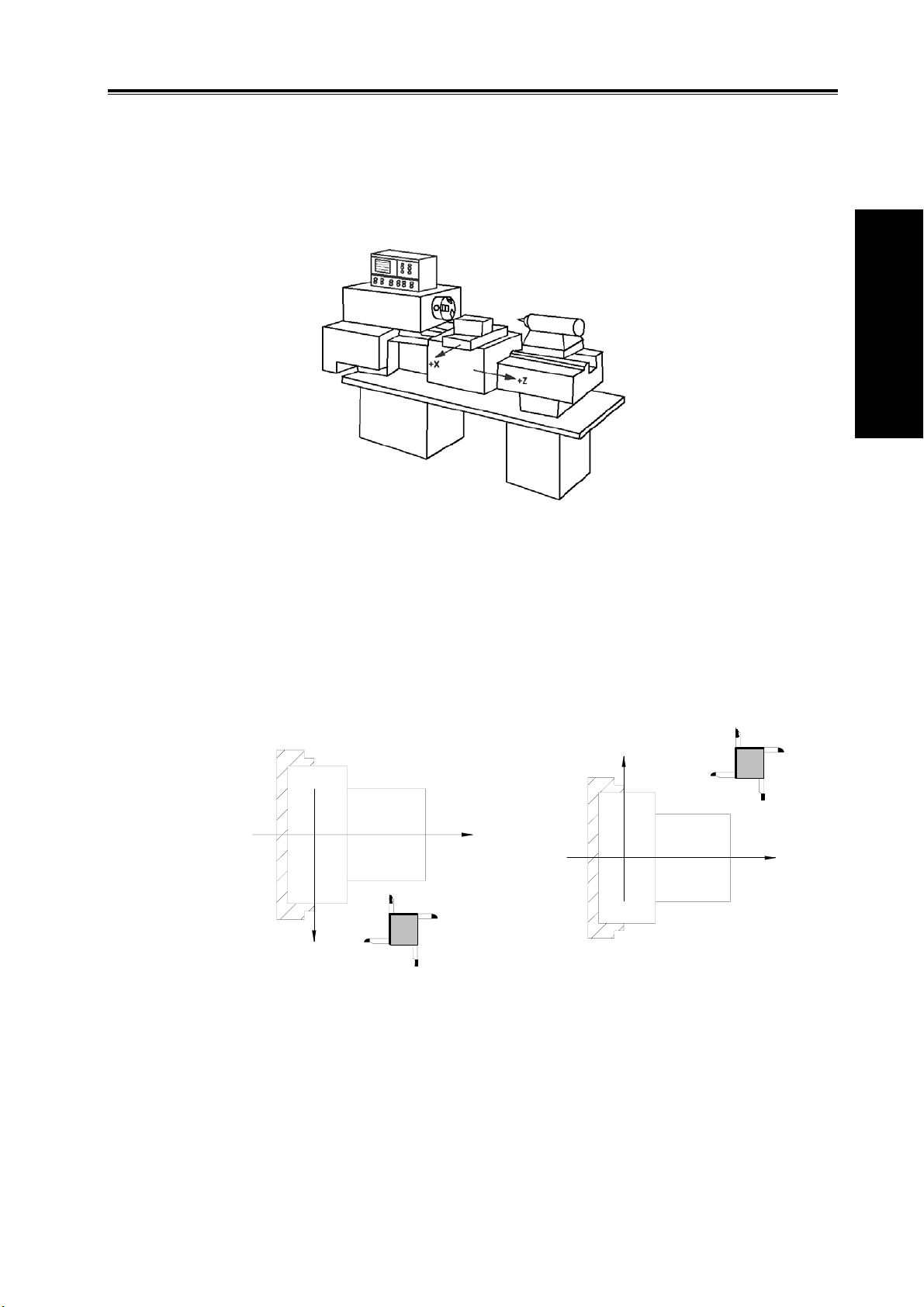

Sketch map of CNC turning machine is as follows:

Fig. 1-3

GSK980TDb uses a rectangular coordinate system composed of X, Z axis. X axis is

perpendicular with axes of spindle and Z axis is parallel with axes of spindle; negative directions of

them approach to the workpiece and positive ones are away from it.

There is a front tool post and a rear tool post of NC turning machine according to their relative

position between the tool post and the spindle, Fig. 1-5 is a coordinate system of the front tool post

and Fig. 1-6 is a rear tool post one. It shows exactly the opposite of X axes, but the same of Z axes

from figures. In the manual, it will introduce programming application with the front tool post

coordinate system in the following figures and examples.

Volum e Ⅰ Programming

X

Z

Z

X

Fig.1-4 Front tool post coordinate system Fig.1-5 Rear tool post coordinate system

1.3.2 Machine coordinate system, Machine Zero and machine reference

point

Machine tool coordinate system is a benchmark one used for CNC counting coordinates and a

fixed one on the machine tool. Machine tool zero is a fixed point which position is specified by zero

switch or zero return switch on the machine tool. Usually, the zero return switch is installed on max.

stroke in X, Z positive direction. Machine reference point is located at the position at which the

9

GSK980TDb Turning CNC System User Manual

machine zero value adding the data parameter No.114/No.115 value. When No.114/No.115 value is 0,

the machine reference point coincides with the machine zero. The coordinates of machine reference

point is the No.120/No.121 value. Machine zero return/G28 zero return is to execute the machine

reference point return. After the machine zero return/machine reference point return is completed,

Volum e Ⅰ Programming

GSK980TDb machine coordinate system which takes No.120/No.121 value as the reference point.

Note: Do not execute the machine reference point return without the reference point switch installed on the

machine tool, otherwise, the motion exceeds the travel limit and the machine to be damaged.

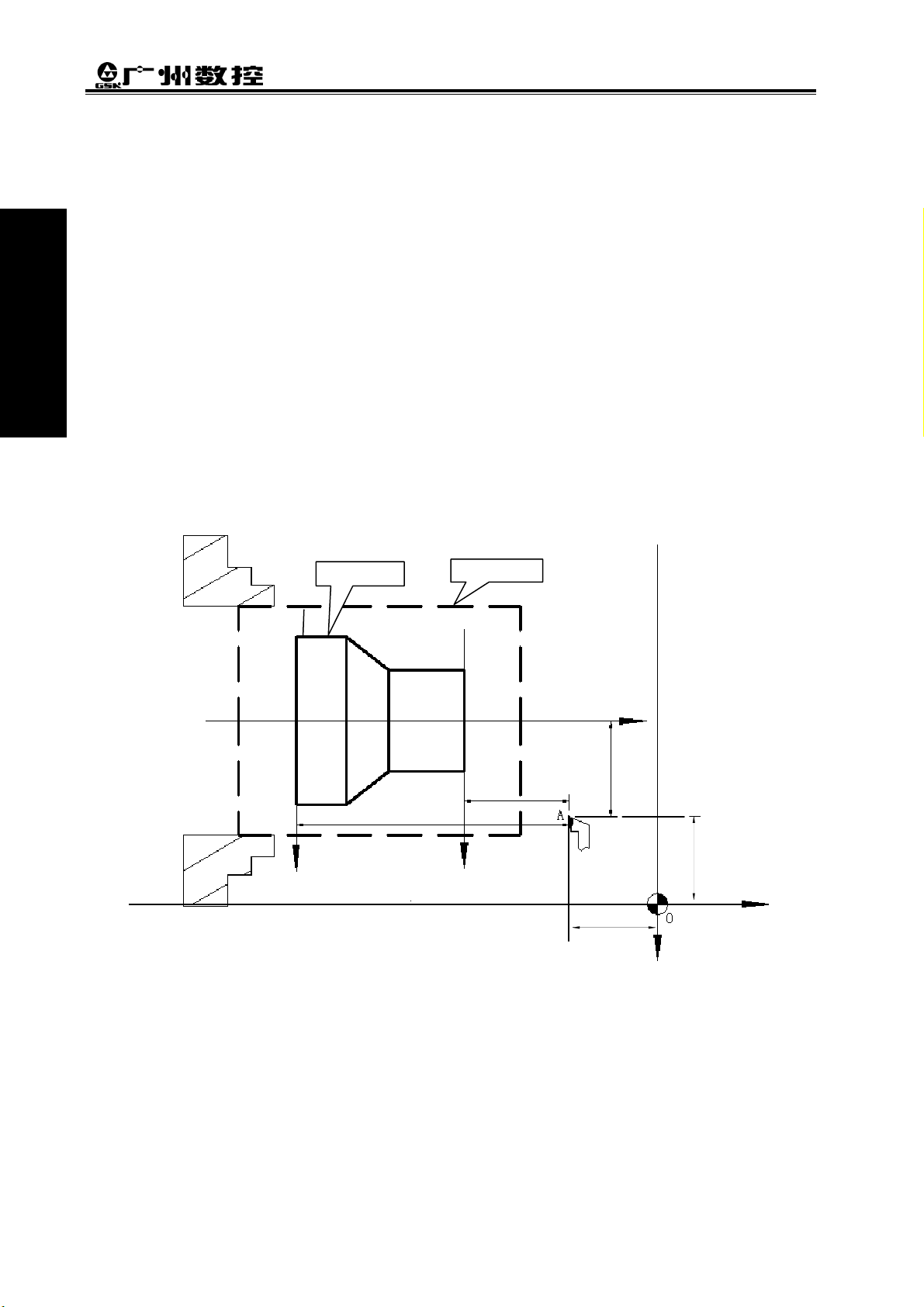

1.3.3 Workpiece coordinate system and Program Zero

The workpiece coordinate system is a rectangular coordinate system based on the part drawing,

also called floating coordinate system. After the workpiece is installed on the machine, the absolute

coordinates of tool’s current position is set by G50 according to the workpiece’s measure, and so the

workpiece coordinate system is established in CNC. Generally, Z axis of the workpiece coordinate

system coincides with the spindle axis. The established workpiece is valid till it is replaced by a new

one.

The current position of workpiece coordinate system set by G50 is the program zero.

Note: Do not execute the machine reference point return without using G50 to set the workpiece coordinate

system after power on, otherwise, the alarm occurs.

Workpiece

O2

z

2

Rod

O

1

Z1 (Z2)

x

/2 (x2/2)

1

z

1

(x,z)

X2

X

1

(x

1,z1

2,z2

)

X/2

)

(x

Z

(0,0)

Z

Fig. 1-6

In the above figure, XOZ is the coordinate system of machine tool, X

coordinate system of X axis located at the heading of workpiece, X

is the one of X axis located

2O2Z2

at the ending of workpiece, O point is the machine reference point, A point is the tool nose and

coordinates of A point in the above-mentioned coordinate systems is as follows:

A point in the machine tool coordinate system: (x,z);

A point in X

A point in X

coordinate system: (x1,z1);

1O1Z1

coordinate system: (x2,z2).

2O2Z2

X

is the workpiece

1O1Z1

10

Chapter 1 Programming

1.3.4 Interpolation function

Interpolation is defined as a planar or three dimensional contour formed by path of 2 or multiple

axes moving at the same time, also called Contour control. The controlled moving axis is called link

axis when the interpolation is executed. The moving distance, direction and speed of it are controlled

synchronously in the course of running to form the required Composite motion path. Positioning

control is defined that motion end point of one axis or multiple axes instead of the motion path in the

course of running is controlled.

GSK980TDb X and Z axis are link axes and 2 axes link CNC system. The system possesses

linear, circular and thread interpolation function.

Linear interpolation: Composite motion path of X, Z axis is a straight line from starting point to

end point.

Circular interpolation: Composite motion path of X, Z axis is arc radius defined by R or the circle

center (I, K) from starting point to end point.

Thread interpolation: Moving distance of X or Z axis or X and Z axis is defined by rotation angle

of spindle to form spiral cutting path on the workpiece surface to realize the

thread cutting. For thread interpolation, the feed axis rotates along with the

spindle, the long axis moves one pitch when the spindle rotates one rev,

and the short axis and the long axis directly interpolate.

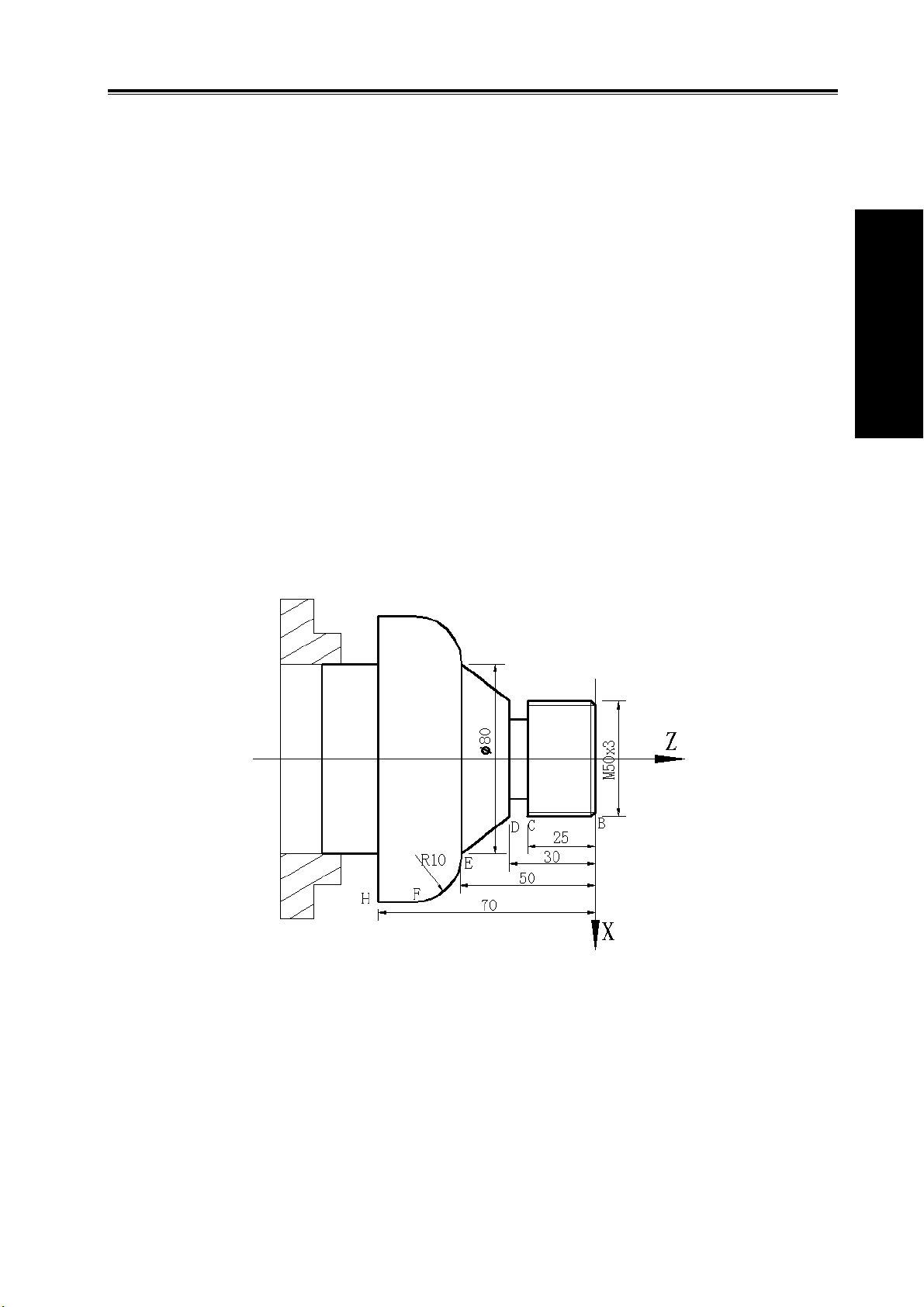

Example:

Volum e Ⅰ Programming

Fig. 1-7

…

G32 W-27 F3; (B→C; thread interpolation)

G1 X50 Z-30 F100;

G1 X80 Z-50; (D→E; linear interpolation)

G3 X100 W-10 R10; (E→F; circular interpolation)

…

M30;

11

Loading…

#1

OFFLINE

Zombie47

- Пользователи

- 6 сообщений

Абитуриент

- Из:Санкт-Петербург

Отправлено 08 Февраль 2015 — 05:40

Всем привет. Появилась возможность поучиться поработать на токарном ЧПУ станке GSK980TDb.

10 лет назад учился в колледже на технолога машиностроения. Как раз на специальность написание технологии обработки детали. А так же написание программ на G коде.

Но никогда по этой специальности не работал. Да и забыл многое, придется вспоминать.

Вообщем сейчас проблема в том что не хватает знаний связать все воедино.

Раньше мы писали программы для обработки детали вручную, сейчас я уже не помню все тонкости написания и вижу есть программы которые впринципе все делают гораздо проще.

Как я понимаю процесс таков:

1. Создание 3д модели по чертежам (с 3д работать умею проблем нет)

2. Написание программы для станка с ЧПУ. Я это решил делать через FeatureCAM. (есть проблемки но в целом принцип понятен.) Основная проблема столкнулся с тем что для выведения G кода нужен какой то постпроцессор. И как я понимаю нужен он под конкретный станок. Куда копать? Где взять? что нужно знать?

3. Далее чтобы не убить станок и тд я скачал CNC Simulator и там есть похожий станок GSK980TD на котором я бы мог попробывать изготовить деталь по моей программе. (Есть проблемы и в конкретном станке в тексте много вопросиков и иероглифов)

4. Если освою симулятор то думаю уже можно на реальном станке пробывать что то делать, думая над такими вещами как правильный ли резец выбрал, правильную ли глубину прохода взял и тд.

Может тут мне помогут в моем не легком деле? =)

-

0

- Наверх

#2

OFFLINE

sum@r

sum@r

- Пол:Мужчина

- Город:Стерлитамак

- Интересы:Фануковед,кладоискатель

- Из:Стерлитамак

Отправлено 09 Февраль 2015 — 10:59

Если металлообработка, то на токарном с 3д моделями лучше не заморачивайся. После постпроцессора дольше будешь редактировать, чем новую писать. Скачай проггу СIMCOEdit-6 и пробуй в нем.

Сообщение отредактировал sum@r: 09 Февраль 2015 — 11:01

-

0

- Наверх

#3

OFFLINE

Zombie47

Zombie47

- Пользователи

- 6 сообщений

Абитуриент

- Из:Санкт-Петербург

Отправлено 10 Февраль 2015 — 04:05

Спасибо уже что то, первая помощь из вне =))) Скачаю попробую, упрусь в проблему напишу.

Есть еще вопрос по наладке станка. Как я понимаю я станку должен дать понять где точка старта от которой пойдет программа. Вроде называется нуль станка. Это задается в программе или в станке как то? А так же знаю есть офсеты иснтрументов, вылет инструментов, но не очень помню как это реализуется. Вплане есть же отрезной резец а есть проходной. Так вот у них относительно зажима инструмента разная точка где будет контактировать резец с деталью. Куда копать что читать? Наладку станка? или наладка инструмента?

-

0

- Наверх

#4

OFFLINE

Zombie47

Zombie47

- Пользователи

- 6 сообщений

Абитуриент

- Из:Санкт-Петербург

Отправлено 10 Февраль 2015 — 14:45

Как я понял CIMCO Edit это просто блокнот с возможностью визуализации. Мне не совсем просто писать программу так как кучу всего не понятно. Например какие координаты надо ставить для G54 при наладке. Везде пишут разное, то расстояние от нуля до револьверной головке, то расстояние до заготовки. Вообщем не понятно. Да и не понятно сколько проходов делать какой глубины, так как я этого не помню. Получается надо пользоваться прогой Feature CAM для уточнения этих моментов или интернетом. Например для нержавейки нужен свой резец свои обороты и своя глубина прохода и своя подача.

-

0

- Наверх

#5

OFFLINE

Zombie47

Zombie47

- Пользователи

- 6 сообщений

Абитуриент

- Из:Санкт-Петербург

Отправлено 11 Февраль 2015 — 01:04

Как мне начать писать программу если я не знаю сколько по координатам мне идти до заготовки. Как вообще это правильно делается? В идеале я понимаю мне нужен инструмент которым я мягко упрусь в заготовку в центр и дам понять станку что вот центр заготовки, а дальше вылет инструментов диаметр заготовки и тд. Есть от чего плясать.

-

0

- Наверх

#6

OFFLINE

Ryoji

Ryoji

- Пол:Мужчина

- Из:Калининград

Отправлено 25 Январь 2019 — 00:59

Уважаемы, подскажите с каких книг начать изучение работы на токарном чпу (Fanuc Doosan серии lynx). Дело в том что с токарной обработкой совершено не знаком, но работал на 3х осевых фрезерах на раскрое материала. Дайте пожалуйста совет как и с чего начать что бы быстрее освоится.

-

0

- Наверх

#7

OFFLINE

2ar

2ar

- Пол:Мужчина

- Город:Новосибирск

- Интересы:Сервисное обслуживания станков

- Из:Новосибирск

Отправлено 25 Январь 2019 — 06:48

С теории токарной обработки

-

0

- Наверх

#8

OFFLINE

SNB

SNB

- Пол:Мужчина

- Город:Подольск

- Из:Подольск

Отправлено 25 Январь 2019 — 07:48

Определитесь с чем Вам помочь. Моделирование (это для Вас не проблема), написание программы и собственно металлообработка — это смежные, но все-таки разные вещи. Конечно, в идеале, это все должен делать один человек.

По-моему, для токарки программирование лучше сразу вручную в G-кодах делать. Хотя знаю человека, который с Solid постпроцессором сразу в станок проги грузил. Кому как. В свое время в нете покупал книгу «Руководство программиста». Правда некоторых страниц все-равно не хватает, но для программирования хватило, даже с избытком. Так там в книге по инструментам и режимам резания ничего не говорится. Если интересует книга, то обращайтесь. Страницу с содержанием прикладываю. Может она уже и в свободном доступе есть.

-

0

- Наверх