Доставка заказов от 7000₽ осуществляется бесплатно по всей России!

Компактная пленочная камера от Kodak – идеальное решение для тех, кто хочет начать снимать на пленку. Просто установите пленку и батарейки, и вы готовы к съемке одним нажатием кнопки. Отличный вариант для начинающих

Комплектация:

● Пленочный фотоаппарат Kodak Pro Star 222

● Фотопленка Kodak ColorPlus 200 (36 кадров)

● Батарейки AA (2 шт.)

● Ремешок на руку

● Заводская коробка

Характеристики камеры:

• Ширина пленки — 35 мм

• Фокусировка от 1,2 м до бесконечности

• Объектив 28 мм с диафрагмой f/5.6

• Выдержка 1/125 c

• Отключаемая вспышка

• Автоматическая перемотка пленки

• Возможность использовать ISO 100 — 400

• Питание от двух батареек (АА)

Фотоаппарат (б/у), в хорошем внешнем и техническом состоянии

На заводской коробке имеются потертости

Ваш город:

Доставка Почтой России ~ 450 ₽

Kodak PR0 Star 222 — винтажная компактная 35-миллиметровая камера с фиксированной фокусировкой.

Легендарная классическая «мыльница» с характерной ламповой картинкой из 90-х, именно с этих камер печатали снимки в лабораториях Kodak Экспресс по всей стране.

Широкоугольный объектив 28 мм с диафрагмой f/5.6, который защищен сдвижной крышкой. Конструкция объектива 3 элемента в 3 группах.

Дистанция фокусировки от 1,2 метров до бесконечности.

Выдержка 1/125 секунды.

Автоматическая перемотка и продвижение пленки.

Вспышка встроенная с возможностью выключения, со светодиодной индикацией заряда.

Использует пленку чувствительностью ISO 100-400 единиц.

Счетчик плёнки на 36 кадров.

Спуск кнопочный, с блокировкой затвора при закрытой защитной шторке объектива.

Питание от двух батарей АА (в комплект не входят).

Что входит в комплект: винтажная фотокамера Kodak PR0 Star 222, ремешок на руку, гарантийный талон, крафтовая коробка.

Состояние оптики: идеальное. Состояние автоматики: идеальное. Состояние механики: идеальное. Внешнее состояние корпуса: незначительные потертости.

Prostar

Archive Processor 220-240 V

Prostar

Archive Processor 120 V

Operator’s Manual

A-62051

Part No. 2E8257

Safety

User Precautions

• Place the processor on a sturdy, level work surface capable of supporting 63.5 kg (140 lbs) and a table height between 53 cm

(21 in.) and 68 cm (27 in.).

• Make sure the electrical power outlet is located within 1.52 meters (5 feet) of the processor and is easily accessible.

• Use only the power cord(s) that was provided with the processor. Using any other power cord may cause electrical shock

and/or damage the product.

• Be sure the power cord is securely plugged into the wall outlet. Failure to do so may cause electrical shock or fire.

• Do not damage, knot, cut or modify the power cord. This may cause electrical shock or fire.

• The scanner requires a dedicated power outlet. Do not use an extension cord or power strip with the scanner.

• Do not connect the processor to an extension cord of multi-plug power strip. Use a dedicated power outlet.

• Leave sufficient space around the power outlet so it can be easily unplugged in case of an emergency.

• Do not use the processor if it becomes inordinately hot, has a strange odor, emits smoke, or makes unfamiliar noises.

Immediately stop the processor and disconnect the power cord from the power outlet. Contact Kodak Service.

• Follow the Kodak recommended maintenance and cleaning procedures.

• Material Safety Data Sheets (MSDS) are available on the Kodak website at: www.kodak.com/go/msds. When accessing the

MSDSs from the website, you will be required to provide the catalog number of the consumable you want the Material Safety

Data Sheet for. See the section entitled, “Supplies and consumables” later in this guide for supplies and catalog numbers.

• For disposal or recycling information, contact your local authorities, or in the USA, visit the Electronics Industry Alliance

website: www.eiae.org.

CAUTION: Moving parts, avoid contact.

CAUTION: Hot surface, avoid contact

Acoustic emission

Maschinenlärminformationsverordnung – 3, GSGV

Der arbeitsplatzbezogene Emissionswert beträgt <70 db(A).

[Machine Noise Information Ordinance — 3, GSGV

The operator-position noise emission value is <70 dB(A).]

EMC statements

United States: This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part

15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

European Union: WARNING: This is a Class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

Japan: This is a Class A product based on the standard of the V oluntary Control Council for interference by information

Technology Equipment (VCCI). If this is used in a domestic environment, radio disturbance may arise. When such trouble

occurs, the user may be required to take corrective actions.

Taiwan: WARNING: This is a Class A product. In a domestic environment this product may cause radio interference in which

声明,该产

此为A级产品,在生活环境中品可能会造成无线电干扰。在这种情况下,可能需要

用户对其干扰采取切实可行的措施

case the user may be required to take adequate measures.

Peoples Republic of China: WARNING: This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Korean: Please note that this equipment has obtained EMC registration for commercial use. In the event that it has been

mistakenly sold or purchased, please exchange it for equipment certified for home use.

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Archive Processor Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Start-up Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Daily start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Uncovering the processing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Filling the fixer tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Filling the developer tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the processing racks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the dryer rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adjusting the inlet water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adjusting the developer temperature control. . . . . . . . . . . . . . . . . . . . . .11

Checking the dryer temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Checking the film transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating the Archive Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Attaching film to a take-up reel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Using a trailer holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Looping the film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

When to start processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Single-strand processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dual-strand processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replenishing the Archive Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replenishment tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Mixed film sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Changing chemicals during processing . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replenishment unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning the Archive Processor (daily) . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning the Archive Processor (periodic cleaning). . . . . . . . . . . . . . . . . . 31

Cleaning the developer racks and tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cleaning the fixer racks, wash racks, and fixer tanks. . . . . . . . . . . . . . . . . 33

Cleaning the air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Clearing a film jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Troubleshooting chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Accessories and Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

New Equipment Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

For installations in the United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

For installations outside the United States . . . . . . . . . . . . . . . . . . . . . . . . . 41

A-62051 May 2008 i

Introduction

The Kodak Prostar Archive Processor 220-240 V and the Kodak

Prostar Archive Processor 120 V are room-light-loading processors that

process 16 mm and 35 mm silver halide microfilms with Kodak Prostar

Chemicals (or equivalent).

The Archive Processors are self-threading, tabletop units with roller

transport.

The Archive Processors feature an energy conservation package that

automatically turns off the film transport, rinse water, and film drying

system after processing is complete.

Kodak Prostar Archive Processor with dual-strand take-up spindles

A-62051 May 2008 1

Specifications

Archive Processor 220-240 V Archive Processor 120 V

Power

requirements

Dimensions and

weight

220 to 240 VAC, 50 Hz, single phase,

7.5 amp

Two-prong electrical plug with ground

connection

Height: 91 cm (36 in.) with the cover open

Length: 110 cm (43 in.) with reel on take-up

spindle

120 VAC, 50 Hz, single phase, 12 amp

120 VAC, 60 Hz, single phase, 12 amp

Three-prong electrical plug with ground

connection

Height: 91 cm (36 in.) with the cover open

Length: 99 cm (39 in.) without reel on

take-up spindle

Operating

environment

Heat emissions

Noise emission

Depth: 56 cm (22 in.) with the cover open

Weight: 52.2 kg (1 15 Ib) empty

63.5 kg (140 Ib) with chemicals,

water, and processing racks

Support: Table or stand between

53 and 68 cm (21 and 27 in.) high

Ambient Temperature: 18.5 to 30°C

(65 to 86°F)

Relative Humidity: 20 to 76%

Maximum: 5100 BTU (5380 Kjoules)

Standby: 350 BTU (366 Kjoules)

Processing Film: 4100 BTU (4325 Kjoules)

Operator Position Standby Mode

• Sound Pressure Level (L

Operator Position Full System

Operating Mode

• Sound Pressure Level (L

• Instantaneous Peak Values 130 dB(C):

None

• Sound Power Level (L

• Standby: 63.4 dB(A)

• Full System: 69.6 dB(A)

): 51.2 dB(A)

A

): 59.3 dB(A)

A

)

WA

110 cm (43 in.) with large reel on

take-up spindle

Depth 61 cm (24 in.) with the cover open

Weight: 52.2 kg (115 Ib) empty

63.5 kg (140 Ib) with chemicals,

water, and processing racks

Support: Table or stand between

53 and 68 cm (21 and 27 in.) high

Ambient Temperature: 18.5 to 30°C

(65 to 86°F)

Relative Humidity: 20 to 76%

Maximum: 5100 BTU (5380 Kjoules)

Standby: 350 BTU (366 Kjoules)

Processing Film: 4100 BTU (4325 Kjoules)

Operator Position Standby Mode

• Sound Pressure Level (L

Operator Position Full System

Operating Mode

• Sound Pressure Level (L

• Instantaneous Peak Values 130 dB(C):

None

Sound Power Level (L

• Standby: 63.4 dB(A)

• Full System: 69.6 dB(A)

): 51.2 dB(A)

A

): 59.3 dB(A)

A

)

WA

2 A-62051 May 2008

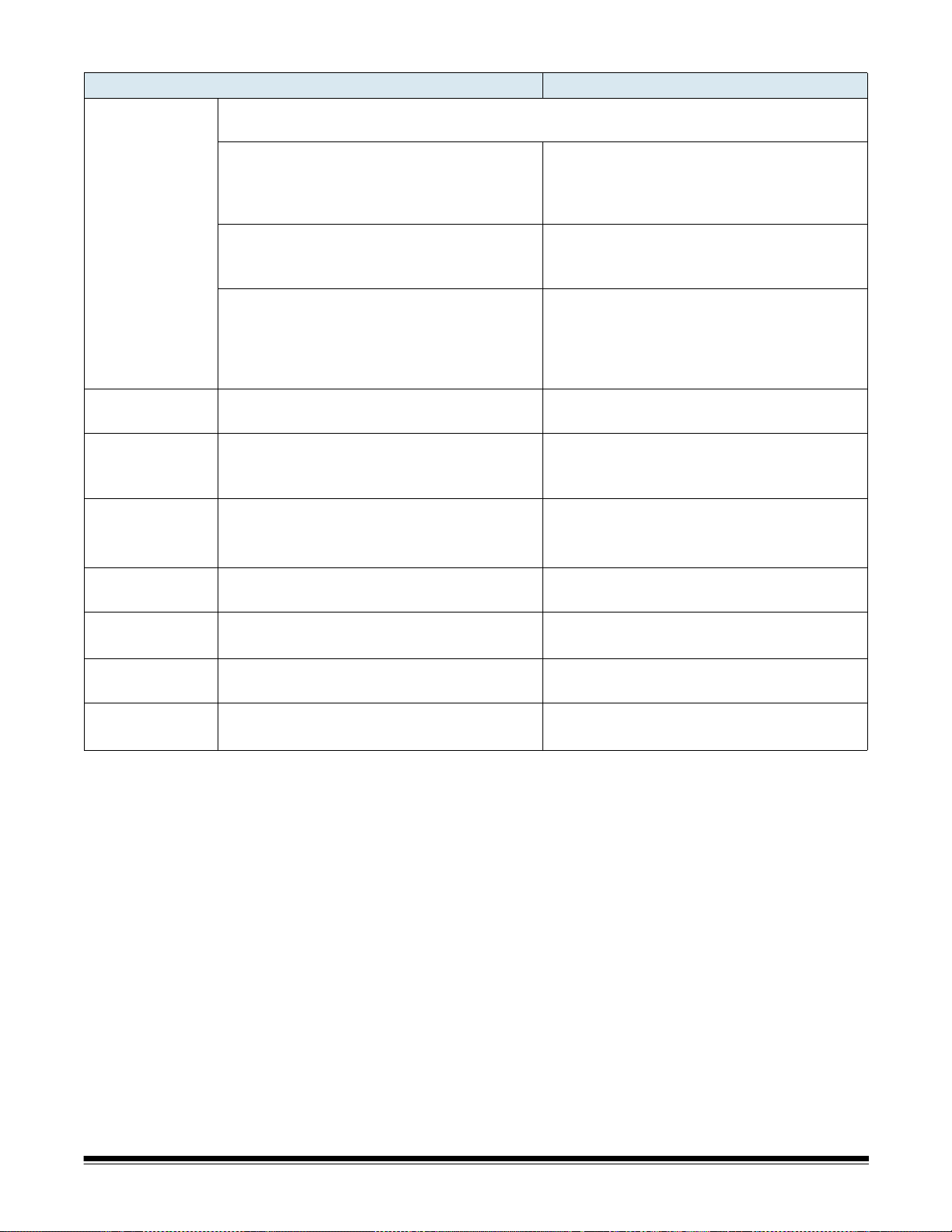

Water supply

Archive Processor 220-240 V Archive Processor 120 V

NOTE: An auxiliary hot water heater should be located within 6 m (20 ft) of the

Archive Processor to provide consistent water temperature.

Film Widths

Film Lengths and

Thicknesses

Film Transport

Speed

Film Processing

Time

Process

Duration

Film Loading

To Mixing Valve:

• Hot Water 46°C (114°F) minimum

• Cold Water 24°C (75°F) maximum

Pressure 276 to 621 kPa (40 to 90 psi)

From Mixing Valve:

• Mixed Water 34.5 to 36.5°C (94 to 98°F)

• Pressure 207 kPa (30 psi) minimum

Drain: Minimum 22.7 L/min (6 gal/min)

capacity floor drain or wall drain located a

minimum of 20 cm (8 in.) lower than the

Archive Processor to prevent wash water from

backing up

Water Consumption: 1.9 L/min (0.5 gal/min)

while processing

16 mm or 35 mm single strand

16 mm dual strand in lengths up to 65.5 m

(215 ft)

30.5 m (100 ft) of 0.14 mm/5.2 mil-thick film

38.1 m (125 ft) of 0.11 mm/4.2 mil-thick film

65.5 m (215 ft) of 0.07 mm/2.7 mil-thick film

3 m/min. (10 ft/min) 3 m/min. (10 ft/min)

30.5 m (100 ft): 11 minutes

65.5 m (215 ft): 22.5 minutes

Approximately 55 seconds for the selfthreader to exit from the Archive Processor

Room-light conditions with camera film spools

only

To Mixing Valve:

• Hot Water 46°C (114°F) minimum

• Cold Water 24°C (75°F) maximum

• Pressure 276 to 621 kPa (40 to 90 psi)

From Mixing Valve:

• Mixed Water 34.5 to 36.5°C (94 to 98°F)

• Pressure 207 kPa (30 psi) minimum

Drain: Minimum 22.7 L/min (6 gal/min)

capacity floor drain or wall drain located a

minimum of 20 cm (8 in.) lower than the

Archive Processor to prevent wash water from

backing up

Water Consumption: 1.9 L/min (0.5 gal/min)

while processing

16 mm or 35 mm single strand

16 mm dual strand in lengths up to 65.5 m

(215 ft)

30.5 m (100 ft) of 0.14 mm/5.2 mil-thick film

38.1 m (125 ft) of 0.11 mm/4.2 mil-thick film

65.5 m (215 ft) of 0.07 mm/2.7 mil-thick film

30.5 m (100 ft): 11 minutes

65.5 m (215 ft): 22.5 minutes

Approximately 55 seconds for the selfthreader to exit from the Archive Processor

Room-light conditions with camera film spools

A-62051 May 2008 3

Archive Processor Overview

Front Shown throughout this manual is an Archive Processor equipped with

Dual-Strand Take-up Spindles

A Processing Section Cover — light-tight cover for the film

processing section.

B Developer Temperature Control and Display — controls the

developer temperature and displays a value relative to the water

temperature surrounding the developer tank.

C Power Switch — turns the power on (l) and off (O).

D Mode Switch — the standby position (O) maintains the developer

temperature. The run position (l) activates the film transport, rinse

water, and film dryer blower.

E Film Dryer Temperature Control and Display — controls the

dryer air temperature and displays the air temperature in the drying

chamber.

F Tension Roller — loss of film tension after processing causes the

tension roller to be released, initiating a time delay prior to

activating energy conservation mode. Once energy conservation is

activated, the film transport, rinse water, and film dryer blower will

all turn off.

G Take-Up Spindles — mechanisms that wind the processed film

onto the take-up reel.

4 A-62051 May 2008

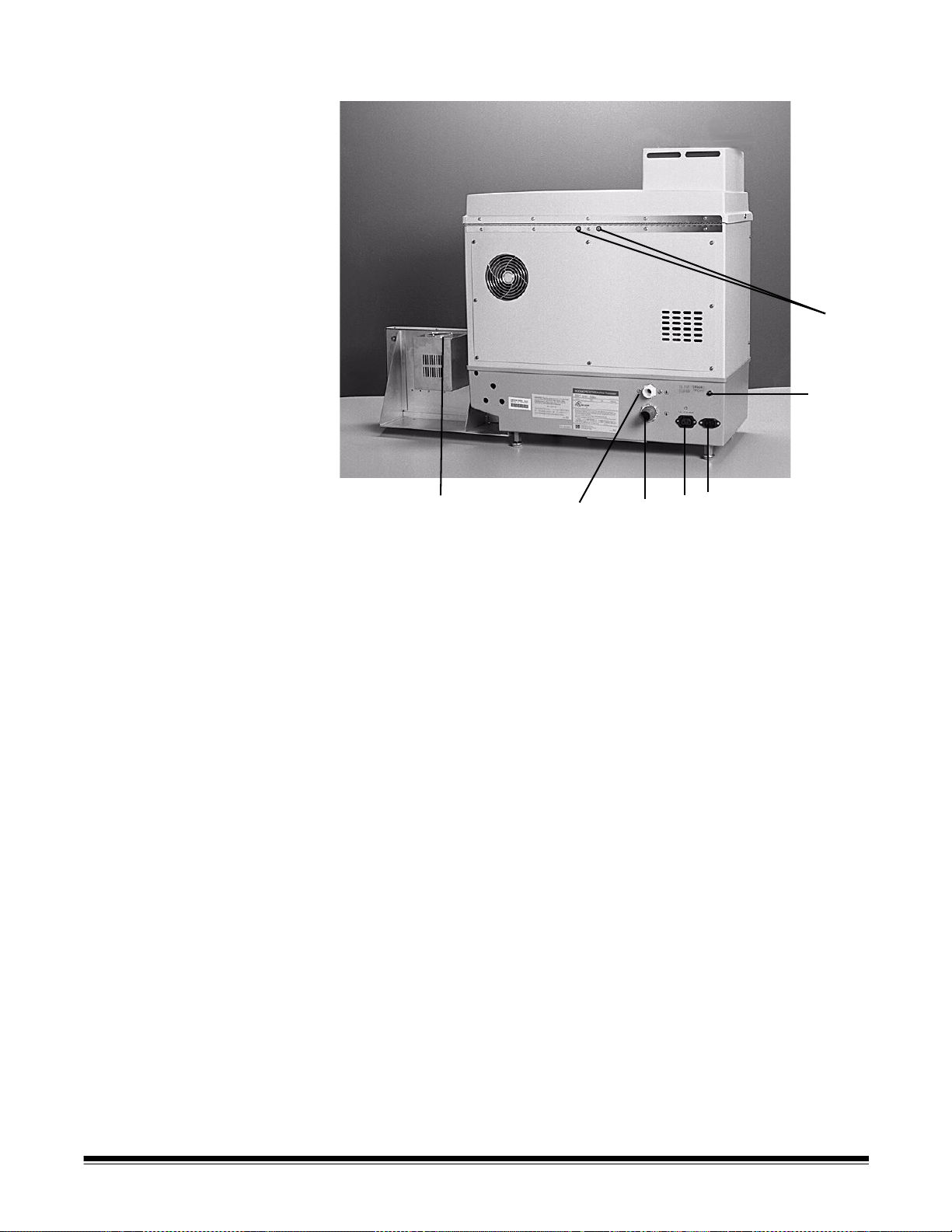

Rear

A Usage Meter — displays the total number of hours the film

transport motors have been operating. You can use the usage

meter to determine when to change the processing chemicals.

B Water Inlet — connection to thermostatic mixing valve.

C Water Outlet — connection to drain line.

D Accessory Receptacle — supplies power to the optional

automatic Replenishment Unit accessory.

E Power Receptacle — connection for main power cord.

F Circuit Breaker — safety feature in case of electrical overload.

G Hose Input — connectors for the optional automatic

Replenishment Unit accessory hoses.

A-62051 May 2008 5

Start-up Procedures

Dryer Section

(Rack #7)

Wash (Rack #6)

Fixer Tanks

(Racks #4 and 5)

Wash (Rack #3)

Developer Tank

(Racks #1 and 2)

Daily start-up Follow these procedures when starting up the Archive Processor at the

beginning of the day, assuming that the Archive Processor was

properly shut down.

Uncovering the processing

section

• Lift the processing section cover until it is in an upright position.

The inside of the Archive Processor is shown below without racks.

6 A-62051 May 2008

Filling the fixer tanks If the Archive Processor is powered up, shut it off before you

remove the fixer tanks or turn off the water. This reduces the

possibility of water overflowing the water jacket later when you reinsert

the tanks.

NOTE: Use proper precautions when using fixer. Review the MSDS for

the fixer.

1. Pull the gear cover back and lift the fixer tanks out of the

Archive Processor. Each fixer tank is labeled with an F.

2. Fill the fixer tanks with Kodak Prostar Plus Fixer, or equivalent, until

the level reaches the fill line (approximately ¼ gallon or 0.65 liters

per tank).

3. Hold the gear cover back and slowly and carefully lower the fixer

tanks into the fourth and fifth position in the Archive Processor.

NOTE: Make sure that the tanks are fully seated and level with the

fill lines toward the rear of the Archive Processor.

A-62051 May 2008 7

Filling the developer tank If the Archive Processor is powered up, shut it off before you remove

the developer tank or turn off the water. This prevents water from

overflowing the water jacket later when you reinsert the tank.

NOTE: Use proper precautions when using developer. Review the

MSDS for the developer.

1. Pull the gear cover back and lift the developer tank out of the

Archive Processor. The developer tank is labeled with a D.

2. Fill the developer tank with Kodak Prostar Plus Developer, or

equivalent, until the level reaches the fill line (approximately

½ gallon or 1.3 liters).

3. Wrap the overflow tubing closely around the right side of the

developer tank.

4. Hold the gear cover back and slowly and carefully lower the

developer tank into the first position in the Archive Processor.

NOTE: Make sure the tank is fully seated and level with the fill line

toward the rear of the Archive Processor.

5. Fill the squeeze bottle with developer.

The squeeze bottle will be needed later to top off the developer t ank

between processing rolls of film.

8 A-62051 May 2008

Installing the processing

Gear Cover

Dryer Rack (#7)

Dryer Section Cover

racks

1. Make sure that the rollers of each rack turn freely when you rotate

the drive gear.

2. Drain off any e xcess water if the ra cks were lef t submerged in water

since the last time film was processed.

3. Hold the gear cover back and lower the processing racks into the

processor (#6 rack first, then #5, #4, #3, #2, and #1).

The rack number is located just above the drive gear.

CAUTION: Lower the racks slowly and carefully into the

Archive Processor to avoid splashing any chemicals.

Installing the dryer rack 1. Lift off the dryer section cover.

2. Make sure that the rollers of the dryer rack turn freely when rotating

the drive gear.

3. Pull the gear cover back and lower the dryer rack into the dryer

section.

4. Replace the dryer section cover.

A-62051 May 2008 9

Adjusting the inlet water

Thermometer

Thermometer

Sleeve

temperature

1. Turn on the water supply using the thermostatic mixing valve.

2. Turn the power switch to the On position.

3. Insert the thermometer in the thermometer fixed measuring point

sleeve located in the front right corner of the #1 rack.

4. Install the standpipe in the Archive Processor tank after the water

temperature, indicated on the mixing valve, reaches 34.5 to 36.5°C

(94 to 98°F).

Installing the standpipe after the water reaches the proper

temperature at the mixing valve enables the developer solution to

reach operating temperature sooner.

5. Route the tubing from the developer tank through the notch in the

partition.

6. Insert the tubing into the standpipe.

7. Allow the water jacket to fill up.

8. A float switch automatically turns off the water flow when the water

level is just below the top of the standpipe.

9. Close the processing section cover.

10.Allow approximately 25 minutes for the developer temperature to

stabilize before adjusting the temperature control setting.

10 A-62051 May 2008

Loading…

Что из себя представляет?

Фотоаппарат пленочный «Kodak PROSTAR 222». Корпус пластиковый черного цвета со слегка скошенными углами, название и другие надписи сделаны красным и белым цветами. Под откидной крышкой в левой стороне ячейка для плёнки и чёрно-жёлтая наклейка с рисунком и текст: «Uses Kodak FILM». Встроенная вспышка с подавлением функции «красных глаз». Автоматическая перемотка. Считывание ISO пленки по DX-коду. Работает от двух батареек АА. Снимает на пленку 35 мм. Тканевый шнурок чёрного цвета 22 см.

История бытования: Представитель семейства камер с фиксированным фокусным расстоянием, прекрасный выбор для начинающего фотографа. Модель проста в использовании. Ее конструкция, включающая 3-элементный объектив со стеклянными линзами и большой видоискатель, позволяет получить четкое и точное отображение снимаемого объекта. Есть и различные режимы вспышки — «объемная» вспышка, уменьшение эффекта красных глаз и отключение вспышки.

- Авторы:

неизвестны - Категория:

предметы техники

- Материалы, техники:

пластмасса, стекло, тканевый шнурок

- Дата создания:

1990-е

- Место создания:

EASTMAN KODAK COMPANY Rochester. New York U.S.A. - Производители:

неизвестны - Место находки:

неизвестно - Размеры:

7,4×12,5×4,5

(сантиметры) - Количество частей:

1

- Вес:

неизвестен

Внешний вид

Используйте полосу прокрутки или кнопки под фотографией, чтобы листать снимки

В каком музее находится?

Муниципальное бюджетное учреждение культуры «Кимовский историко-краеведческий музей им. В.А. Юдина»

- Инвентарный номер:

неизвестен - Регистрационный номер Государственного каталога:

31023210

- Дата регистрации:

3 года назад (27 августа 2021 года в 15:05)

- Номер по ГИК:

КИКМ КП 1707