NEWLONG INDUSTRIAL CO., LTD.

BAG

SEWING

MACHINE

I

No.1

For Operator Safety

Thank you for purc h a s ing t he N LI

Model DHR-6 Bag Sewing Machine Head.

• This

manual

contains the instructions

using

the

Model

DHR-6 Bag Sewing

sure to read and understand this

use

the

machine

• Keep this manual near

reference.

when

lending

company.

• Please order this

lost.

• The contents

prior notice

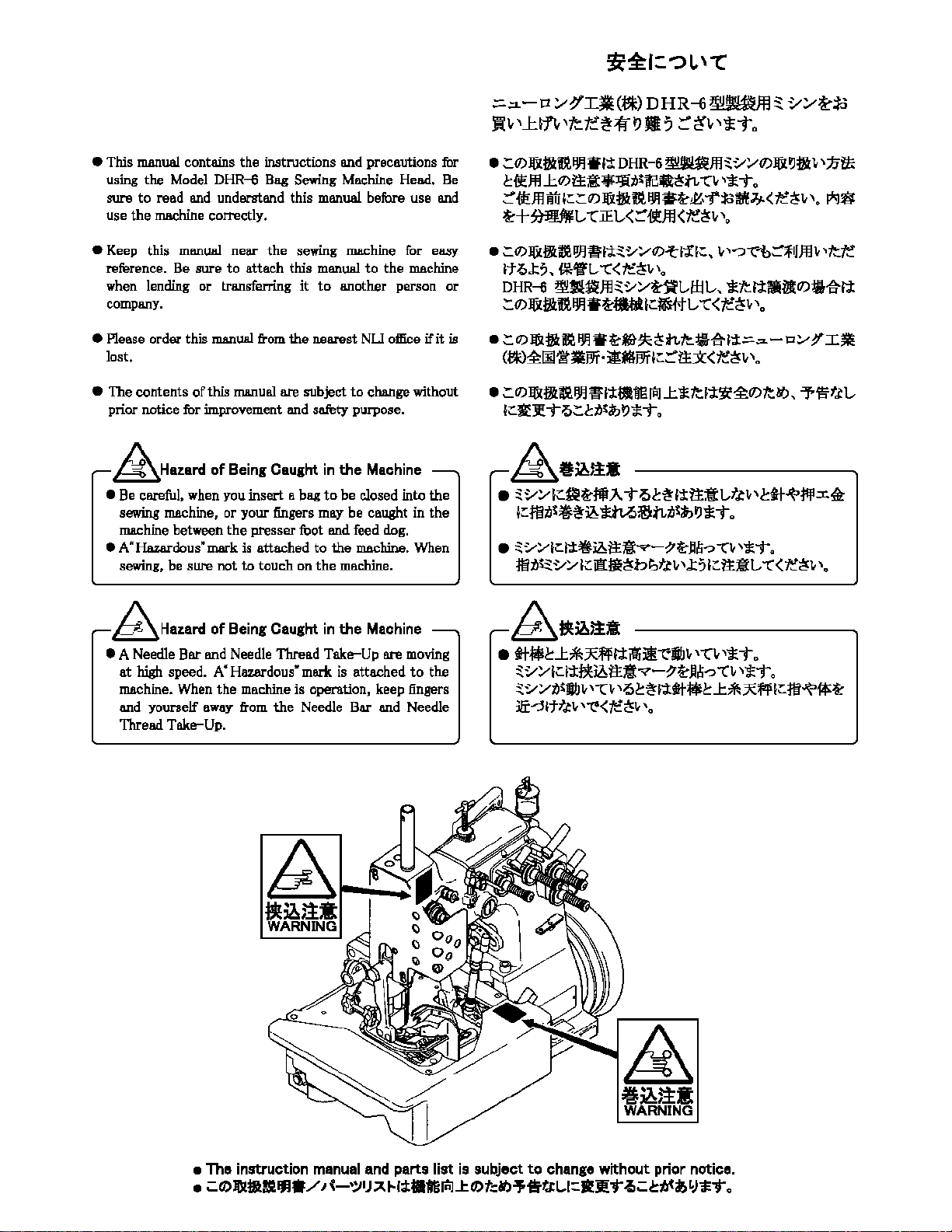

&Hazard

• Be careful, when

sewing

machine between

•A·

Hazardous·

sewing, be sure not

correctly.

the

Be

sure to attach this

or

transferring

manual

from

of

this manual are subject

for

improvement

of

Being

Caught

YoU

insert a bag to

machine, or your fingers

the

presser foot and feed

mark

is attached to the

to

touch on

the nearest NU

and safety purpose.

and

precautions

Machine

manual

sewing machine for easy

manual

it

to

another person

to

in the

be

ma:y

be caught

the

machine.

Head. Be

before use and

to the

office

change

Machine

closed into

dog.

machine.

for

machine

or

if it is

without

the

in

the

When

:=..::i.-rz :Y!>’°.I•(t*)

_R1,,J:l1″‘~tt~11~J1,

•

;:Q)Jtk•tt~•f:t

~fscffl

J:Q)ttt:•lJltilte.8~.tL -n,

DHR-6~

DHR-6

~

1/:Y~;td

:::-~1,»~T,,

~ffl~v~Q)Jlk~fl1,

‘*To

‘7i~

~fscfflKiH::;:Q)JlkflUM•~~,-ftdWf~<t.::~1,,0

~+~t,

•

;:Q)

11kffi~

lt-o.t;,

DHR-6

;:,Q)

11kffiit~-~,hl;:~L,

-CJE.t,<

IJJHIJ’1~v~Q),t

{*/fl,

::’ M

-c<r.:~1,,0

<te~v

J’f

l:::,

~,u~Jfl~v~Mfl,l:ijl,,

«(

‘o

1,

,—::i-c1,~1Jffl

*1tt.J:llill11J!l1tt.J:

<t.::~1,

,,,

1,

e;:Q)Jtk•U~-~~~~tLtt.•1tt.J:=.::i.-o~,I~

cm½1111t•m·i!llfm1:::.::-ttx<te~1,

•

:.11J

llilffili~

i!Fl’1M~

!Pl

J:

* ft.

,,,

1-x~½Q)ft.afJ,

7fit.t

1.:RJ! To:.ttit~t.>*T,,

&-~~-

•

~v~l.:a~t1JA-tot$f±tt:tL-t~11,l:tt~tfll.x~

l::tt)t,S~$l6*Mifctl,t,S~tJ*-t,,

• ~v~•~•’1~l6tt ……

m.o~~v~l;:a•~v~t.,!1,

-!l~Jli!i-:>-Cll

‘*i°»

,.t%:.tt•t-

a

-c

<~~1,

‘-·

P9~

,tt.te

t,

~

• A

Hazard

Needle

Bar and

at high speed.

machine. When the

and yourself

Thread Take-Up.

of

Being Caught in

Needle

A•

Hazardous»

machine

away

from

the

the

Machine

Thread Take-Up are

mark

is attached

is operation, keep fingers

Needle

Bar and

moving

to

the

Needle

.~

~]6~-

• tt-f*~..l:*~fft.J:itH!k~IIJ1,

~vYl;:•’;J:~JAtttl…,.-~~Jl~-:>

~v~t,11JJ1,

i!r—:Sltf~l,

,-c1,

,;s2::~1’1tH$~..l:*~ff

‘~<~~1,

,,,

,-c1,

‘*T.,

«Clt

‘°*To

l=ti~i*~

• The instruction manual and parts

•

~O)JDl

••

lJ.I.

/ I {-•:JIJ

At-lctatBtai

list

is subject

..t

O)f.:NJ~i!t(i:L.1::JIJ!»t

to

change

without prior notice .

-1,~ciJ(it)

‘:J;l;»t

0

WARNING

••

PERSONAL

RESULT

SAFETY

NOT

OBSERVED.

1.

BE

SURE

FREE

OF

ALL

OIL,

RUBBISH

INJURY.

2.

DO

NOT

OPERATE

AREA

OR

THE

MACHINE

TYPE

NOR

3.

DO

NOT

OPERATE

INSTRUCTION

4.

DO

NOT

OPERATE

THAN

SPECIFIED

5.

BE

SURE

MACHINE

ELECTRICAL

INJURY

IF

THE

PRECAUTIONS

THE

AREA

SURROUNDING

HAZARDS

OR

UNDER

IS

WATER-PROOF

MANUAL.

SAFETY

SUCH

ANYTHING

MACHINE

WET

NOT

IN

CONDITIONS.

AN

EXPLOSION-PROOF

TYPE.

MACHINE

MACHINE

FOR

IS

ON

THE

MACHINE.

CONNECTED

GROUND

MAY

FOLLOWING

ARE

MACHINE

AS

FIRE,

THAT

CAN

AN

EXPLOSIVE

BEFORE

VOLTAGES

TO

BUILDING

(EARTH).

IS

WATER,

CAUSE

READING

OTHER

~~©~~~§~~~L~~?~~~

l:::l~t:-Ml:©ffli~

L <

t::

~

I,

\0

1.

•

~

0)

)!] ill

~..

JJ<..

im..

(f;:~l,\o

2.

-~O)ffi;l!iO)

f.1,f.1,7a>.±Jl—c:l;t-ftffl

.:.0)-~l;t

..

c.

I=

$

i!it

i:iJ:I!~

if>

7a>•:tl

Rn-~.

t.;.

«)

a::»t©~~~

~

~

.:.

«t»

t.;

ct.it~

• ll<m!it.iti~Ji.~I=

L,tJl,\»»(:

Rnm!i~—C:l;tN.,

lvo

3.

Jljif&mBJ.lif~~»(McA,—c:f.l,

t ( f;:~

4. -~O)}~JE’.fflff

~l,\o

5.

7-7..~t.it~*.,’c~h t1.,7a>$~.fit~

f;:~l,\o

l,\o

J~H’l-

—c:l;tjifii

1:,—~jifii

mt

~

c.

t.;

1.

,t.i,.fitt.i,cY)

< t::~

(,\0

«)

Lt.;

I.’

—c:

Lt<

L

7a>

!k

t

‘tit

<

t::

L

6.

BE

SURE

POWER

BEFORE

PARTS

PERFORMING

REPLACEMENT,

CLEANING.

7.

DO

NOT

OPERATE

COVERS

8.

DO

AND

REMOVED.

NOT

TOUCH

MOVING

OPERATION.

9.

BE

SURE

MACHINE

(LEVEL)

SURFACE

MAINTENANCE,

ADJUSTMENTS,

10.

BE

SURE

THE

COMPLIES

11.

DO

»

NL!»

WITH

NOT

USE

GENUINE

(AND A IR

MACHINE

ADJUSTMENTS

MACHINE

KNIFE,

PARTS

NEEDLE,

WHEN

IS

PLACED

WHEN

PARTS

CLEANING

MATERIAL

THE

SPARE

TO

BE

MACHINE

PARTS

PARTS.

SUPPLY)

IS

OFF

MAINTENANCE,

OR

WITH

GUARDS

PULLEY,

MACH I NE

AND

BELT

IS

IN

ON A SMOOTH

PERFORMING

REPLACEMENT,

OR

STORAGE.

SEWN

OR

CLOSED

SPECIFICATIONS.

OTHER

THAN

6.

•~O)~iiffi

AAl=~»fffl;Ji

f;:~l,\o

7.

ii~1JJ{-t.i<~nt=~~—c:l;t·~~jifii

fJl,\»»(:( f;:~l,\o

8.

..O)jifji

~Ji.,

«-t

fJl,\»»(:( f;:~l,\o

9.

•~O)•iiffi·!B~3′.cm-~•-:m~~~~O)

~1=11:qr

10.

ifl;Js-3

7a,

f.1,-fitf.1,cY)

11.

«=-.:i.-Cl/~I~(*l)»

ilffl

Lt.;

• !B~3′.cm.

C.&ttI7-;Ji)

cp

l;j:

7.J

‘~

O)·fttt1.11., t 1.

i;

t.;:t1rffl=i’fi1.

c.

«t»

7a>~*1t.it-~O)f±~l=-€.—:i t

t <

t::

~

I.’

1: <

t::

~

5( -,.

,7a,

‘t

I,

\0

I.

‘o

ru11~

$t

._

~rffl=

<

t::

til!iE!B~~~l;t

• ~11:m~O)

~~-:it<

-;/-

11-¥

~

1.

,0

L

1) -._

~Mn

(,\

Identifying and Ordering Parts

Cautions When Using the Machine

Maintenance

Where the construction permits, each part

all

its part number. On

and

part name

Safety Rules

To prevent personal injury:

All

power sources to the machine must be turned

•

before threading, oiling, adjusting or replacing parts.

All

cover and guards must be

•

machine.

•

Do

not tamper with safety cover, guards, etc.,

machine

model name

is

in

orders, please include part number,

of

machine.

in

position before operating

operation.

is

stamped with

Safety Precautions

1)

Always

adjusting the machine or replacing parts.

2)

Wear safety glasses.

turn power off before threading, oiling, and

off

while

•

:=.=1-

-o:.,,~-I~

itililE

ti%fb

:a:-~-Om

:::·r±.x(J)~i-;:1:,

•

<tt~i.

\0

(~)

~OO~~ffl·~~ml;:.f’;:!: DHR-6

L,

—c

:Jo~

~To

/»-o/!J?-J—(1)/»-o/*%,1:~~—c:-:::·mjf-

•*fflL~~OO~~&O*ffl~(J)~-~~-~~-~

(J){i:!!l!f-0mftc1::—C:-/g¥~

f;:.

< v ,~_.g.l’i,

:Jo

J’l

v

‘LITv

‘tctc~

~L,tc:=.=1—01/~-I~(~)~OO~~Pfr·~mm1;:.~~m

<tt~v

‘o

j\!;j~(J)~.

1/1/:ffi:%:a:-:::·mjf-<tc~v

1>

~~~~

®&3′.t~.

• *mn(J),l:~(J)*ifilL,, *(1)3′.t~.

f*»‘f,¢.e~f’F~(J)irrr1;:.~,—rt7JJ:a:-m-::i—c<tt~

~fl~,

‘~T

~~:ffi:%, ~1/1/.lm®~,

J:5:Jol»lv

‘v

‘fcL,~»t»o

*1’i71:!l.

v’o

2)

W!Bl!ffp~(J),l:~l’i’ti:V:JJ

*(J)*ffl

:a:-:Jo»t»T~

L,~»t»

(J)

~

w.Bl!f.

o

3)

Make

sure, before starting the machine, that

and shields are

4)

Do

not touch on the machine when it

5)

Turn power

before you put your fingers under the cutter blades and

the needles to adjust.

6)

Do

not touch on the machine when it

in

place and closed.

is

off

and make sure the cutter does not operate

is

run.

run.

all

covers

in

mind

• Please keep

maintain the machine

• Thread fuzz or dust must be cleaned

throat plate,

after the day’s work.

• Wipe the area easy to rust with

• Check the machine for loose screws and tighten them, if

any, once a month.

• Good

maintenance

to handle the machine carefully and to

in

good condition.

with

air or brush on

in

the groove of feed dog or around looper

oil

cloth.

will

prolong

the

machine life.

4)

.iJ

/'{-ftc1::;vt1¥J~-::i

—Cv

,Q;:_,1::a:-~~

L,

—c;v,G~~L,

—c

tc~v\o

5) *(J)-fl;:.-¥:a:-AnQ,1:~1’i,

f~~W!ffl!f

:a:-~~L,

(J)

,1:~1’i,

~,

—c;v,Gf’F~:a:-rr-::i—c<tc~v’o

• ~1/1/llli’tf~l’i~!Wft1J,~ft$

r±.~~<

• —

~-

I&Wl5

,1:,1:t

f::l

(J)fp~;vt~TL,~L,tcG,

1v-/»-(J)~:b~1;:.~~-::itdi::.~~l’i~hv’l;:.I&~

~,—rt7JJ:a:-m-::i—c<tt~i.

—rt7JJ:a:-m

~~1/:.,,;vtllJ;v,ftv

Jl1=1;v>G/±:l*L;vt-::i—Cv

1;:. ~ 1;:.l!f-Om

1;:.,tA1Ht—c

*fi(J)L,

‘o

,;:_,1:

‘~To

<

tt~v

‘o

~!J~(J)r#(J)

~v’—C<tc~v\o

• -¥Ah(!).& L,~U’i~~(J)~~f;:.J&9L,~T(J)—c:’:::·r±.~

<tc~v\o

<

ii

CONTENTS/

1.

Specifications/fr~

2.

Threading/*ill,

3.

Lubrication/~nb 4

4.

A<tjusting/iffljg

1.

2.

3.

4.

5.

6.

7.

Setting

Setting

Setting

Setting

Setting

Setting

Setting

the

Needle

the

Overedging Lower Looper fitJ,tJ<LJffl»»FJL,-1{-0)~;E’. 6

the

Needle Bar Height

the

Overedging Spreader

the

Thread Retainer

the

Combined Chain-stitch Looper 2

the

Combined Chain-stitch Cross Looper 2 mJ1a1,

———————

——————~fO)Joli.tn)!——————5

~t,$0)

~

~

fiti,tJ<LJffiA:1v•;,1t-O)~JE’.——-7

~H.!JI]=\=-

A

O)~JE’.————-9

~

{X

m:J1a1,,Jt.,-1~-0)~JE’.——9

‘~H.IJI]=\=-

B

O)~;E’.

…………….

2

3

5

6

10

8 Setting

9.

Setting

10.

Installing

11.

Setting

12.

Setting

13.

Setting Edge Guide and Stitch Tongue

14.

Adjusting Stitch Length a

Parts

List/$~~····························································································································15,.,.,,,.,33

Numerical

Diagram

Screw ,Nut &

the

Needle Guard

the

Lower Feed

the

Throat Plate Support

the

Upper Feed

Presser

Index

of

Dog

Dog

Foot

Presser

Parts/

I

Washer/*~

~t:fl-~’O)~;E’.—————11

«»F~LJ~O)~JE’.————-11

~HJ.i~70)1fXi-t————11

..t~

LJ~O)~;E’.

:j:l:jl.I

~O)

ff.jJ

~;E

JE’.:ml=JE’.:mffiO)~;E’.

El

~;O)~;E’.

~-‘-Y~

S 1

·····················································································34,35

..

T’.:11—

..

r’J’:J~-‘t’-

···················································36

12

13

14

14

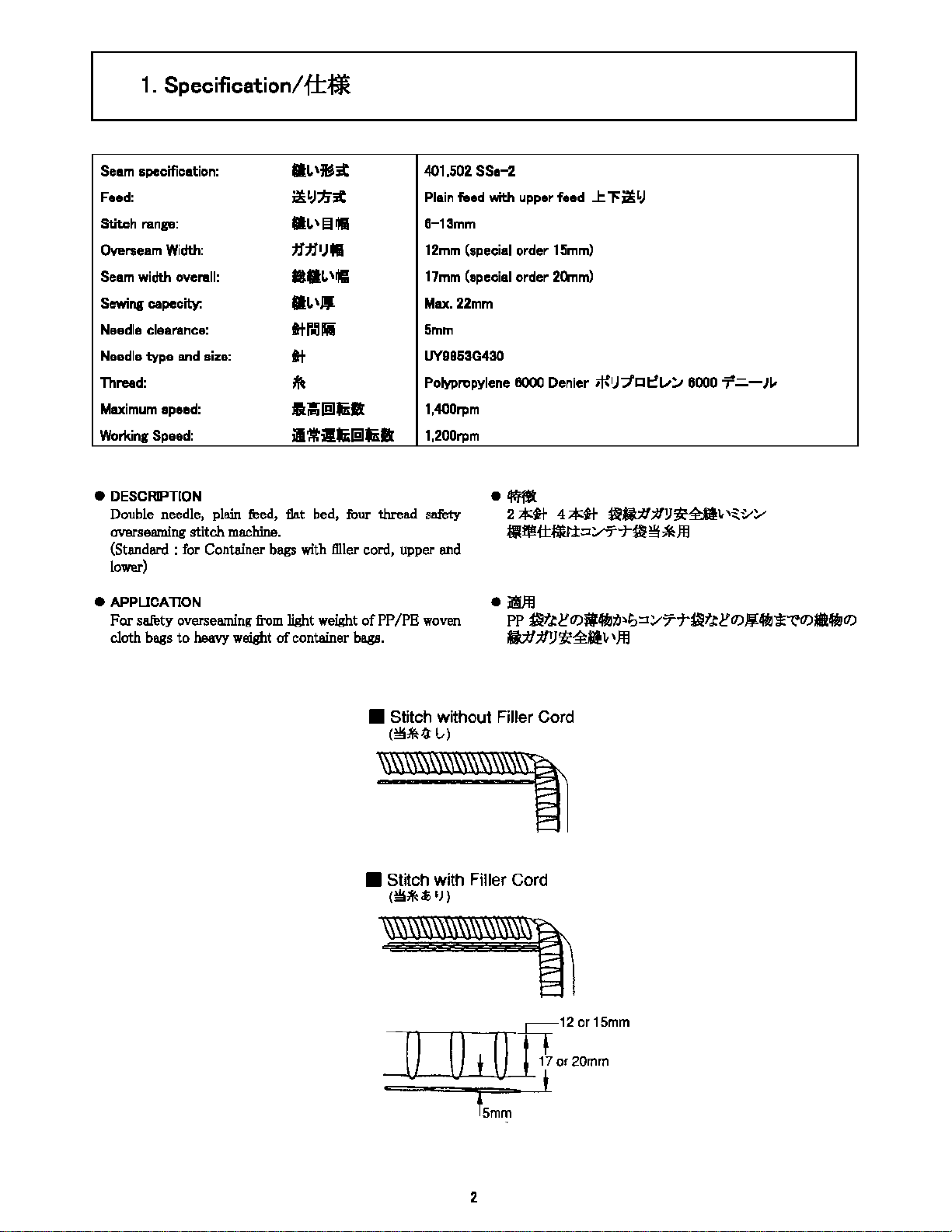

Seam

1.

Specification/

specification:

f.tW

a1.,~it

401,502

SSa-2

Feed:

Stitch

range:

Overseam

Seam

Sewing

Needle clearance:

Needle

Thread:

Maximum

Working

e

DESCRIPTION

Double

overseaming

(Standard :

lower)

e

APPLICATION

For safety overseaming

cloth

Width:

width

overall:

capacity.

type

apeed:

Speed:

needle,

bags

and size:

stitch

for

Container bags

to

heavy

plam

machme.

weight

m’:.11.iit

a1.,E1•

:fl:fl•J•

••

1,\ltl

.l,\jJ:

ttrii&:1111

tt

Kt

Aili!l&e

•’*•&11&•

feed,

from

tlat bed,

light

of

contamer

with

weight

four

filler

bags.

Plain

6-13mm

12mm

17mm

Max.

5mm

UY9853G430

Polypropylene

1,400rpm

1,200rpm

thread safety

cord, upper and

of PP /PB

woven

feed with upper feed

(special order

(special order

22mm

6000

15mm)

20mm)

Denier ;l’:

•U

2 ** 4 **

-~tt~t.t::J~’t»ti

iilJfl

•

pp

i!2fl~O)-*’t,~;::J~77″~fl~O))J1tJi~0)-4*/0)

ai/;f/!J’tc~-1,

..I:

«Fm

LJ

1

J:1cn:v!,,

6000

~aff#!J~~1,,~v~

~

*Jfl

,Jf.1

«T=.-JL,

• Stitch without Filler Cord

(

~,*~

~)

• Stitch with Filler Cord

(~*.i}IJ)

m~

TT12or15mm

] 0 I Q j

f

smm

‘{°’2omm

2

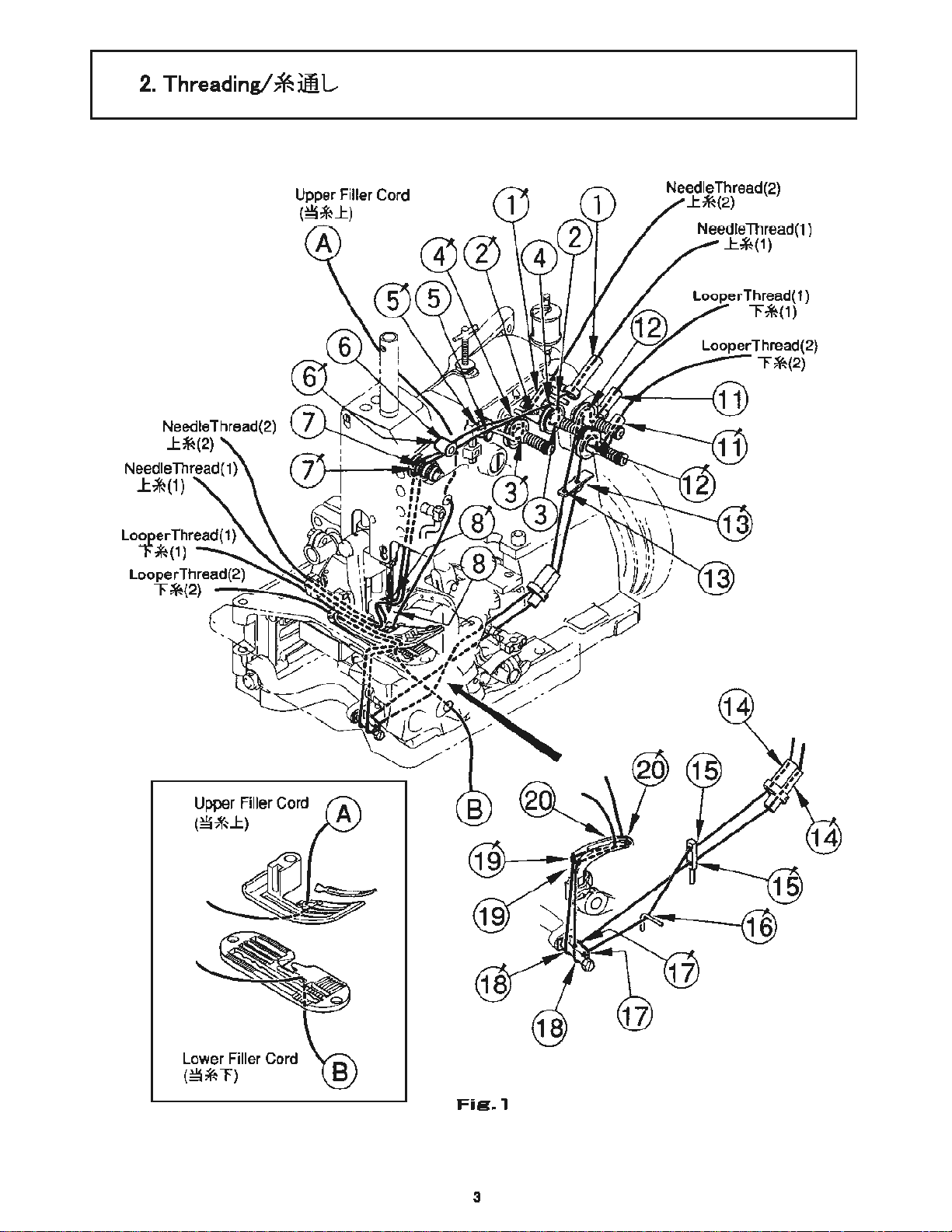

2.

Threading/*

ii

L,

T*-(2)

Upper

(Mi~d

Filler

Cord

Lower Filler Cord

(~*-1′)

Fig.1

3

Oil

machine

machine,

are

not,

troubles.

viscosity

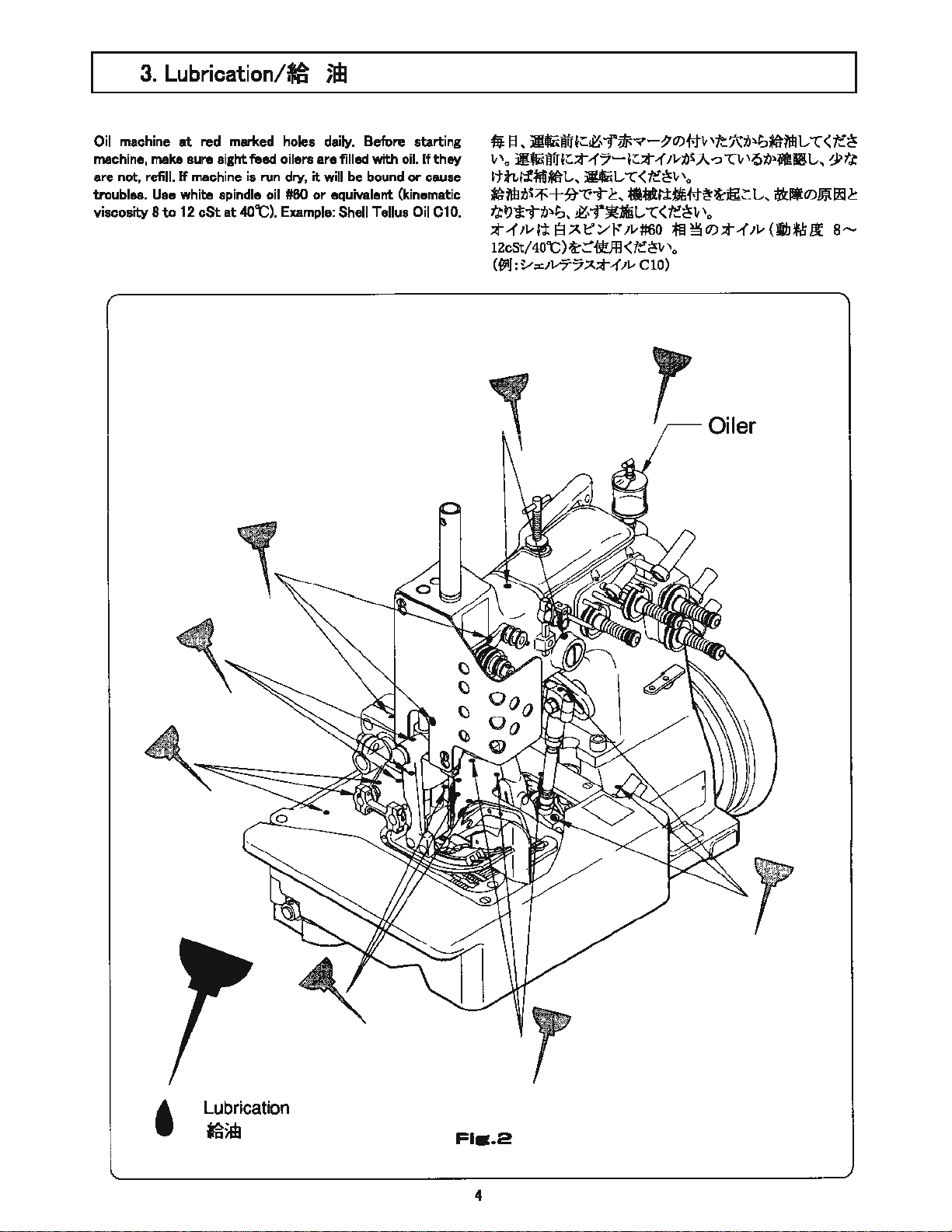

3.

Lubrication/M

at

red

marked

make

sure

sight feed oilers

refill. If

Uae

8

to

machine

white

12

cSt at

is

spindle

40″C).

holes

run

dry,

oil

#60 or

Example:

;Eb

daily.

are

tilled with

it

will

be

equivalent

Shell

Before starting

oil.

If

they

bound

or

cause

(kinematic

Tellus

Oil

010.

fi

1:1,

Jlliliairul.:.~i*$~-?O)#lt»lt1′:ti~;~ilbL:t=<~~

1,,0

-~fifl;::;;t-.-(7-l;::;;t-,f/v;bSJv:,»‘(l,’¢tJ~Ji1Jl,, /.Pft

•ttLt.fMML-,

~ilbilq;;+~»tiT~

tt~rt-tti~;,

;;f-.-(

Iv

12cSt/40″C)

(-011

:Vxlv’77A::t-.-f

~t,

«‘C<~~i.,

..

llilfi~#~ia:~~t,

~-i*~Ufiit, «‘C<t!~li’.,

f’;t

SA

t»:.,,

f:

Jv#60

~~U<~~1,

1v

ClO)

ffi

‘o

‘o

~

0)

;;f-.-(

..

‘M(liJO)_ffil!;I~

Iv

(

lb*6

r Oiler

lf

8-

Lubrication

*SjeJ

‘

Fl

4

•.

2

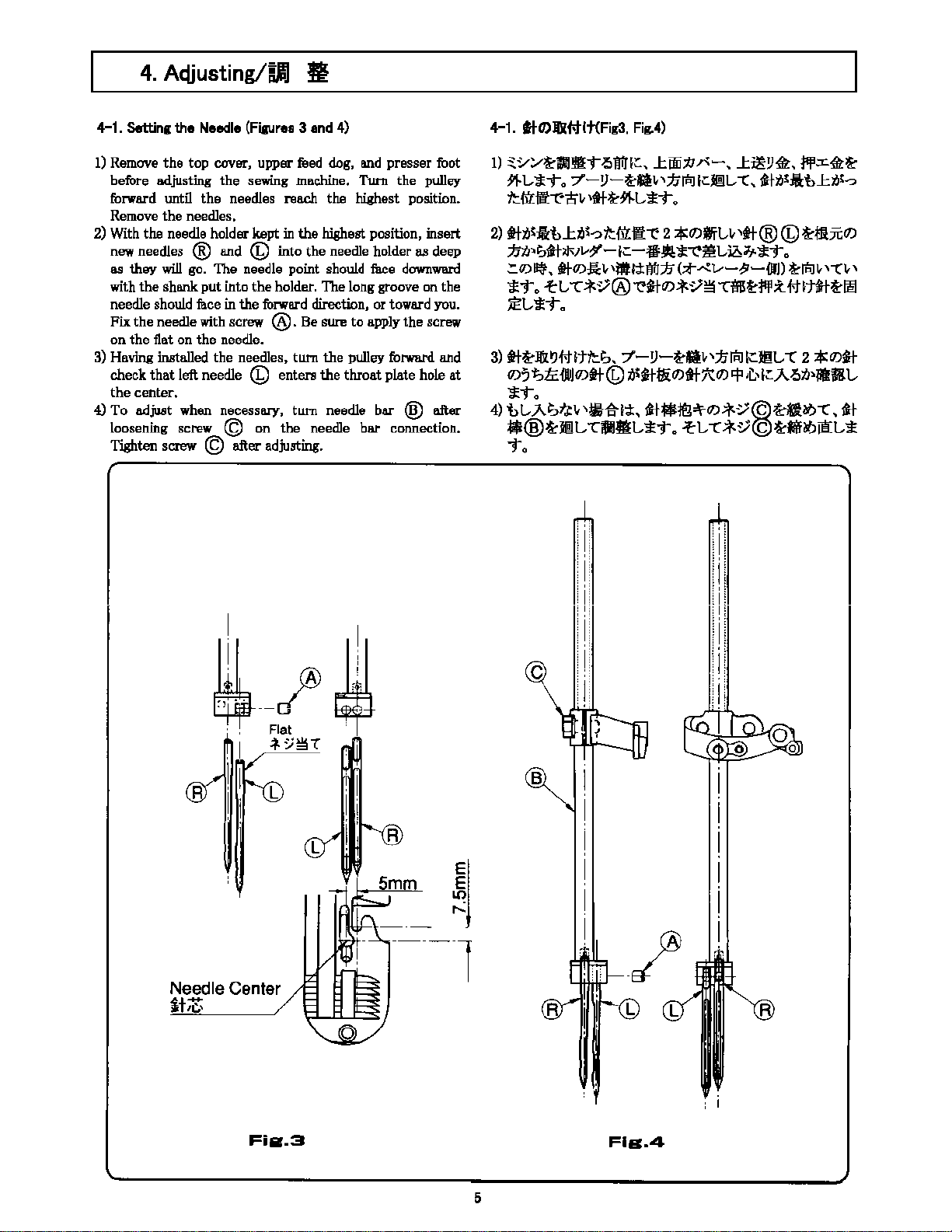

4.

Aqjusting/UJ m

4-1.

Setting

1)

Remove

before adjusting

forward until

Remove

2) With

new needles

as

with

needle should face in

Fix

on

3) Having installed

check

the

4)

To

loosening screw © on

Tighten screw © after adjusting.

the

Needle

the

top

the

needles.

the

needle holder kept in

(Fil\.lrea 3 and

cover, upper feed dog, and presser foot

the

sewing machine. Turn

the

needles reach

@ and © into

they

will go.

the

shank

the

needle with screw

the

flat on

that

center.

adjust when necessary,

The

needle point should face downward

put

into

the

the

forward direction,

the

needle.

the

needles, turn

left needle © enters

holder.

@.

the

4)

the

highest position.

the

highest position, insert

the

needle holder

The

long groove on the

or

toward

Be sure to apply

the

pulley forward and

the

throat plate hole

turn

needle

needle

bar

bar

coMection.

the

pulley

as

deep

YoU.

the

screw

@ after

4-1.

tf-O>af..tlt(Fig3,

Fig.4)

n ~V»~~••i»-0tim:, J:iii:b.,~—

~L,*i»o 7′-!J-~1i1,,7.1p!i}(~J@l,

at

~,(!LjR~»5″l,

2)

tf-t,Sif(t>..l:tl~»‘.Jit&M~

7.1’t,l~**’v1′-,~-••*»t’~L,ib~*i»o

;:(I)~,

*»t

..

;tt,»£i»a

fl-(1)~1,

-t-L-

-c-*~®

,tt~~L,*i»

‘fflf’;l:fiJn C*~v-~—OJJ)

~ft(I)-*~~

..

2

*(l)ifl,1,

J:~!J~,

«(,

l!Jl.x~~

tJ-t,1:fjU:>-.f:tll»‘.J

,tt@©t-*!5c(I)

~li!iJi,

-cS~l’JI

x.

#lffit-ml

,-ci,,

R

Needle Center

itZ

C

B

R

Fia.3

5

Fls.4

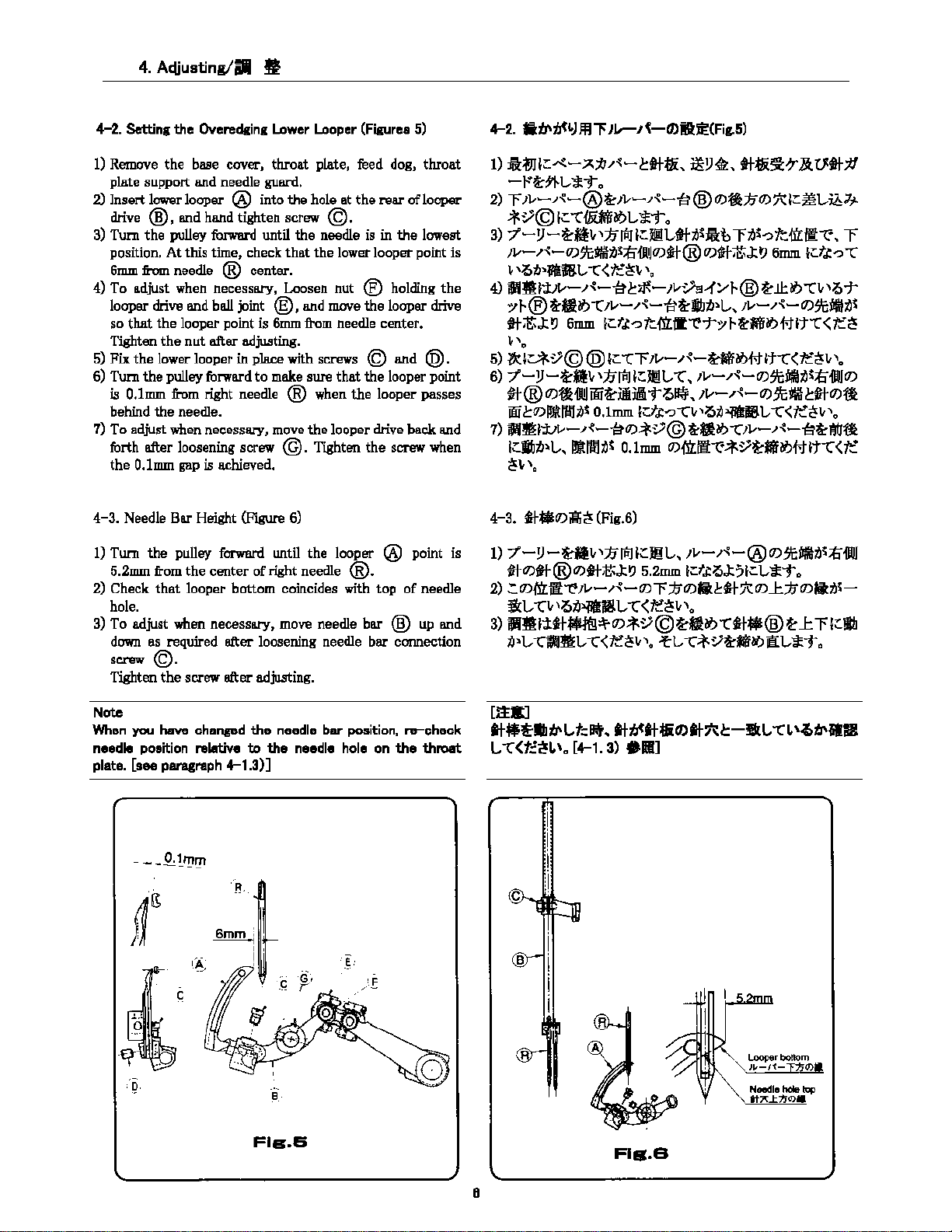

4-2.

4.

Acliusting/111

Setting

the

n

Overed&inc

Lower

Looper

(Figures

5)

4-2.

MfJ,titY

Jl:I

«»F

Jr1

<-O)il:JE:(Fig.5)

1) Remove

plate support and needle guard.

2)

Insert

drive

3) Turn

position.

6mm

4)

To

looper drive and ball joint

so

Tighten

Fix

5)

6) Turn

is

behind

7)

To

forth after loosening screw

the

4-3.

1)

Tum

5.2mm

2)

Check

hole.

3)

To

down

the

base cover.

lower looper @ into

@, and

the

from needle ® center.

adjust when necessary, Loosen

that

the

the

the

0.1mm

the

adjust when necessary, move

0.1mm

Needle

the

from

that

adjust when necessary, move needle

as

h1111d

pulley

foJward

At

this time, check

looper point is

the

nut

after adjusting.

lower looper in place with screws ©

pulley forward

lrom right needle @

needle.

gap

is achieved.

Bar

Height {Figure 6)

pulley

forward

the

center

looper bottom coincides with top

required after loosening needle

throat

tighten screw ©.

until

to

make sure

until

of

right needle

screw@.

Tighten

the

screw after adjusting.

plate, feed dog,

the

hole

the

needle is in

that

the

@,

and move

6mm

from

when

the

@.

Tighten

the

throat

at

the

rear

of

looper

the

lowest

lower looper point

nut

® holding

the

looper drive

needle

center.

and

that

the

looper point

the

looper passes

looper drive

the

screw when

looper @ point is

@.

back

the

and

@.

of

needle

bar

@

up

and

bar

connection

1) :&:im:~-A;b.1{-~ftai,

~!)~,

tt~~-7.&Vtt;(f

-~a>~L-*To

2) r 1v-.1.::-@~1v-.1{-,a@O)f&.n0)~,=~t..i6]j.

*~©

3) 7′-!J-~fl1,,jjlfill=J1It..tttisJ&:t rtis-=>tturtRi:, r

is

/v-/{-O)~-t,S;Ei».fl1JO)ft@O)tf-°$J:

1,

4) •••~i,-.,.::-,a~~-,v~-1:.—1-@a-J.1:ao-c1,,.r,r

:Yl-®~aao-c,1,-.1{-,a~ibti’llt.,, ,1,-.1{-0)~{ll~s

tl-‘$.J:!J

1,,0

5)

~·~~©@t=-cr

6)

7′-9-~*fi,

ti-@

ifi

1>

•••~v-.1~—aO)*V©~•ao-c,i,-.,.::—a~Mt&

l~lbti~t.,,

~\,’o

4-3.

1)

7-!J-t-ai,,jjlfill~JBL,,

ftO)ft@

2) .:.OJora'»l’,v-.1{-0)r.nOJlli.!:::tl-~O)J:.,nOJtiitJi-

j(l,

3)

illlH±tt~~(l)*v©

ti~t..

•=-ruao

,7.>t,’lliilit.,

,!::(l)lftfHJtl1

-r<r.:~1,

6mm

O)fl-ffl!J

iliia-iiHII

0.1mm

lmtfll1tJ1

tl-*-OJiii~

O)ft°$J:

«Clr

‘oil~8t.,

-CaJJIL,

«C(/i~l,

L-*’t’o

tJ

6mm

‘•

l::f.,e—::,tt1’Il:a»t’-t’o/f-~-af;#lt-C<r.:~

lv-.1~-~af)#lt-c<r.:~1,

‘.nlfil

i;:Jet.,

-c,

11,.,-.1.::-(l)~fl/Mt11~,t)IJJ(I)

‘t’-?>~,

l~f.t.-.:>»C~

0.1mm

(Fig.6)

1v-/{-O)

‘OXJ~i8l..

~Wit

-C<r.:~1,

OJOllR1:*Vf:*i~M•t-r<t-:

,1,.,-.,~-@0J~{lltJ~~,tllJJ

17

5.2mm

l:.fJ:-?>J:;

l::

L,j:»t

-c<r.:~1,,0

f:aao-rtt•®

‘o

~l,

-c*v~•aoat.-1:’t’.

t;:fJ:-:,

.!:::tf-O)tl

‘

..

f:

1:

r

«C

‘o

0

1::11.1

Note

When

you

have

changed

needle position relative

plate.

[see

paragraph

II,- .

4-1.3)]

6mm i

~ ,

(A~ I ‘

‘—7

the

needle bar position, re-check

to

the

needle hole

Flg.6

on

the

throat

B

Looper bottom

i~-,t

-JJi

o:>I

Needle hole top

&t7’J:1;o:>

II

Fis.a

8

4.

Actjusting/lJI

fl

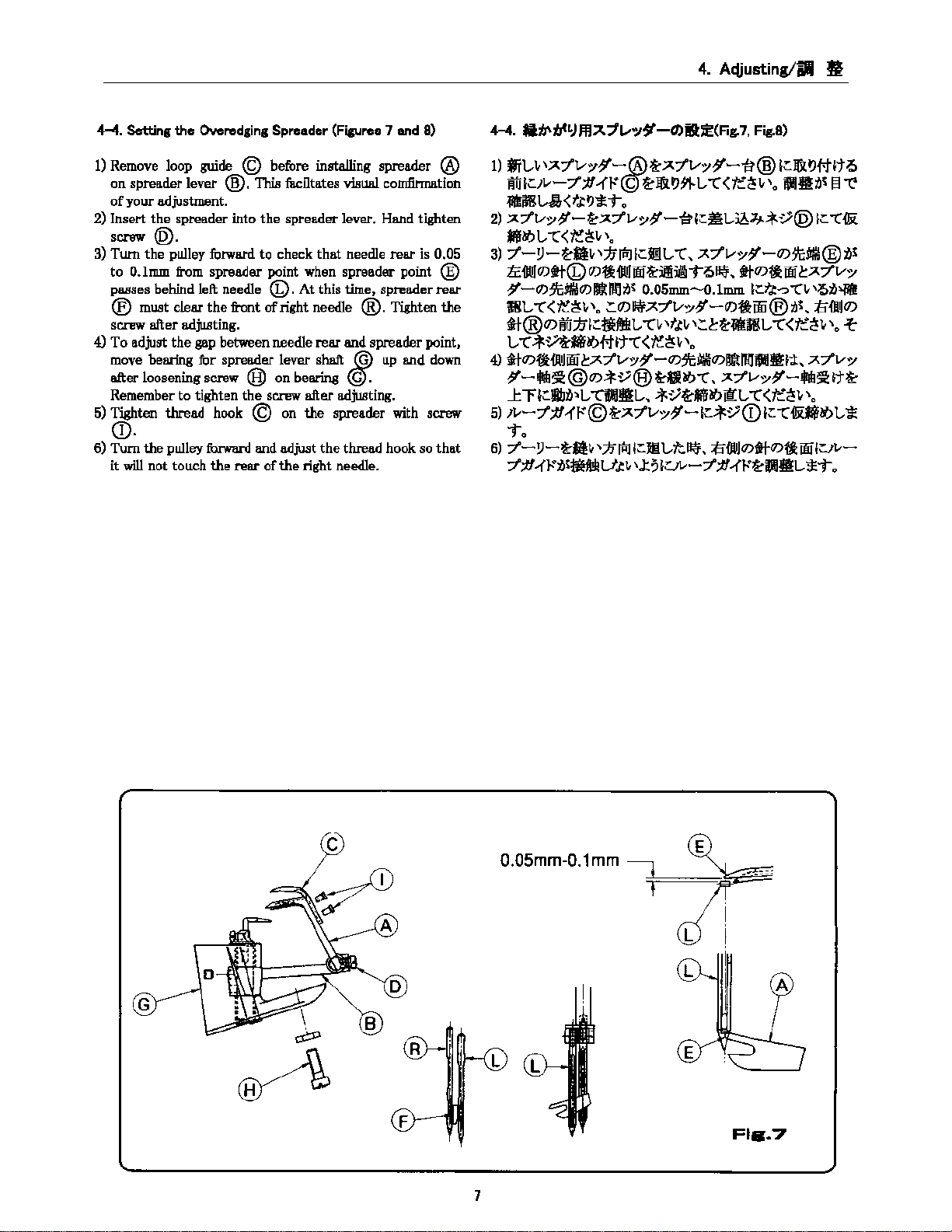

4-4. Setting the Overedging Spreader (Figures 7

1) Remove loop guide © before installing spreader @

on

spreader lever @. This faciltates visual comfirmation

of

your adjustment.

2) Insert

3)

4)

5) Tighten thread hook © on

the

spreader into

screw@.

Turn

the

pulley forward to check

to

0.1mm

from spreader point when spreader point @

passes behind left needle ©. At this time, spreader rear

® must clear

screw after adjusting.

To

adjust

move bearing for spreader lever shaft

after loosening screw @ on bearing

Remember to tighten

the

the

gap between needle

the

spreader lever. Hand tighten

front

of

right needle @. Tighten

the

screw after adjusting.

the

that

needle rear is 0.05

rear

and

@.

spreader with screw

and

spreader point.

@

up

and

the

down

(D.

6) Turn

it

will

the

not

pulley

touch

foJward

the

rear

and adjust

of

the

right needle.

the

thread hook

so

that

4-4. flt)\1,tl:)1′);;~::1v-:1~-0)il:,!(Fig.7,

1)

trL,1,

‘A:1’Vo/~-@~A:1’vo/~-i:r@l:J&t)#Jto

riil:1v-:1»JJ.{f-t@ ~l&tJ~L,

..

L-A<

ftt)’i:t»

2)

::A'»fvo/~ -~::A:1’v::,~

*fafJ

L,

«»C<ie~1,

3)

:1′-!J-~l11,,jjlfi)(;::ljl,»‘(«, A:1’v::,,,-0)1c;!/l@tl1

~

iJlll

O)tf-(1>

~

-0):S’c!IIO)

BL,

«»C<ie~l,\o

tJ-@O)ffli:1il:tfMt.,

t.,

«‘C’*~t*~t-t•t—c<r.:~1,,0

4)

tj-O)f&-fl1Jffij

o

‘o

O)f&iJlllffii~ifii{Qi'»oll~\ tf-O)ft

II:

111:1

ti~

0.05mm-O. lmm

~O)litA::fVo/~-O)f&ffii®iJ;,

—c1,

l;A:1’Vo/,,

_O);’i:J\IO)IIJtllQjlf!Jll±,

—c<~~1,,o

—t:r,:•L,~;,.;t.~@

,t,t1, \:.t~li’iBL,

~-!f!lll’.!Jl;@)O):.t-~@~af.>»‘C’,

J:

r

•=IIJtil

1.,

—cu!lli.,,

5)

,v-::t’JJ-fr©~A::tvo/~-•=-*~CD

*

~~•

Fig.8)

l’Hlti~

l:

ffii

l:A:1’v::,

l:f,t-:i

«‘(«1,

‘otl~

:E-fl~O)

—c<~~1,

::A:;fv::,

A:1’Vo/,,_!f!lll’.!Jl;•t~

atJ

it:L,

—c

<

~~1,

, •

•=—c-Oi*16~

To

6)

:1′-!J-~1,

:;t;t/ .{t;llSUffl!I! L,f,t1,

‘1i!Pl

i:JDL,*:llt, ti-OlJJO)ftO)fiffiil:Jv-

,J::?

lLJv-:;f ;ti .{~~PJ!IL,*i»

El

«t’

«‘C’-Oi

‘»

-t-

t.,~

0

C

7

L

Fls.7

4.

Actjusting/11

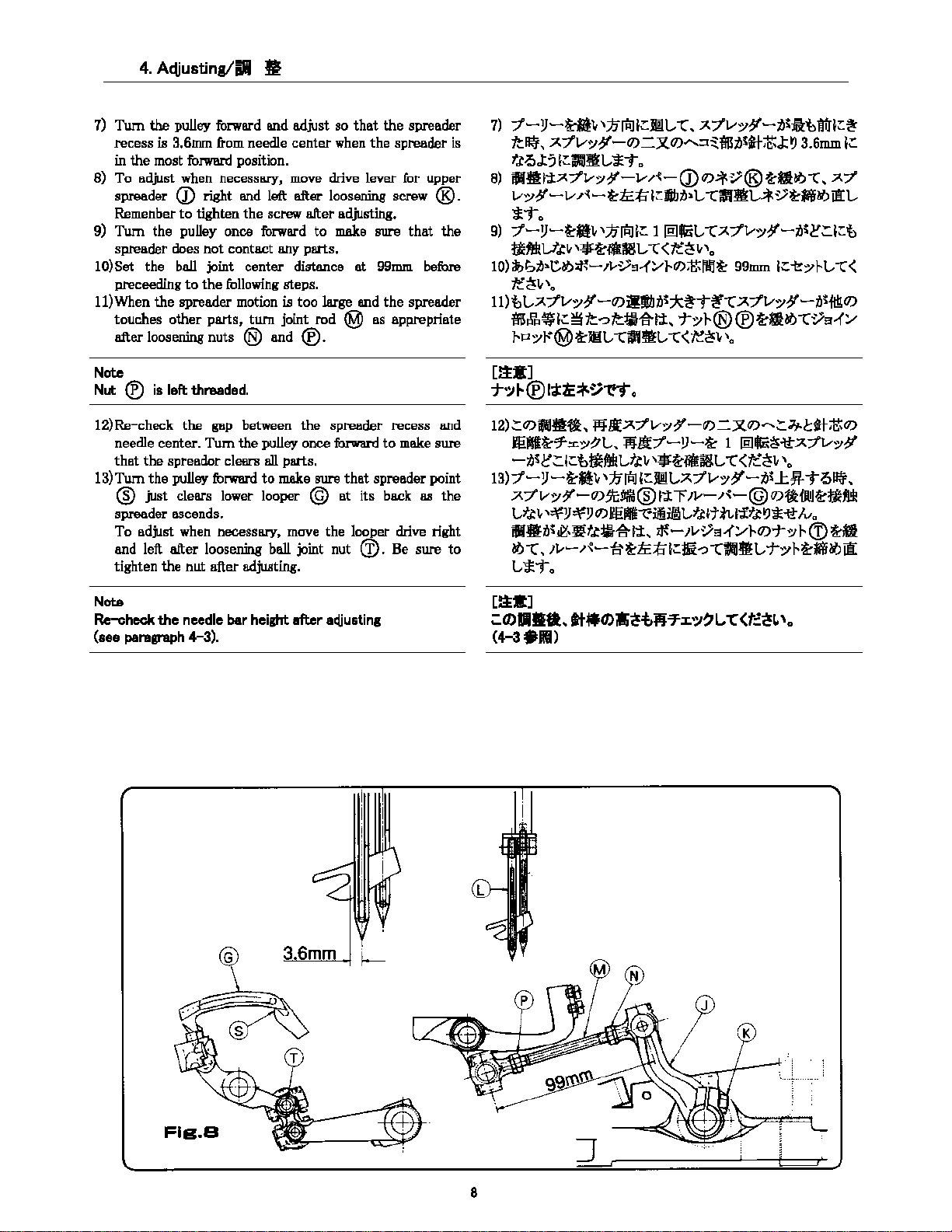

7)

Tum

the

pulley forward and adjust

recess

is 3.6mm from needle

in

the

most fo.nvard position.

spreader

Remenber

9)

Tum

spreader does not contact any parts.

lO)Set

proceeding

11) When

touches

after loosening

Note

Nut

®

Q) right and left after looserung screw ®.

to

tighten

the

pulley once forward to make sure

the

ball joint

to

the

the

spreader motion is

other

parts,

nuts

is

left:

threaded.

fl

center

the

screw after adjusting.

center

following steps.

twn

joint rod @

distance

too

® and ®.

so

that

when

the

at

large and

the

spreader

spreader is

that

the

99mm before

the

spreader

as

appropriate

7)

7′-!J-t-fll,

ft~,

A7’v:Y?’-O)=J{O)»‘-:::t~tfRt,1tJ-~J::~

f.toJ::;

•••±7-7’v:Y1′-v/{-(j)O>*~®~•~—c,

,jyjpJl;:JEL,

(;:all’EL-*-t D

«»(,

A7’v-.y¥-til:lil:1)fin;:~

3.6mm.

l;:

7-7′

v-:;¥-v/{-~~;t,l;:fibiJ•L—CtlHIL-*~~-~il:L-

*’t»o

9)

7′-!J-~-1,

~MV_ti,

l0)1>bifr•C~if—,t,,~9-{~J-O)~flU~

‘fe~lt’o

1l)t,L,A7’v-.y?’-0>iWI/Jti~*~’t»~—c;x.7’v-.y?’-ti~fl!l:0>

S&i-,;:~tt~ttf.1~1±,

}-P-:;r@~JIL,

‘n!Rl

‘*~$.Ml-

—CIIIEL,

l;: l lfflllzil, —C7-7’v-.y¥-iJ$~;:l;:t

—c

<tt:~1,

‘o

99mm

l;:-t?-.yJ-L,—C<

‘1—Yl-@

—c<~~l,

®~a~—cV::1-1’~

‘a

12)Re-check the gap between

needle center.

that

the

13)Tum

Note

Re-check

(see

the

@

just

spreader ascends.

To adjust when necessary, move the looper drive right

and left

tighten

paragraph

Tum

the

spreader clears all parts.

pulley

forwlll’d

clears lower looper @

after

loosening ball joint nut (I).

the

nut

after adjusting.

the

needle

bar

height

4-3).

the

spreader recess and

pulley once fonnird

to

make sure

after

that

at

its

a(tiusting

to

make

spreader point

back

Be

as

sure

sure

the

to

12);:0)PJJlt&, :;ifLl;A7’v-:;¥-0>=)(0),-..;:3j.}:t{-~O)

leMH.·7″:r.-:;!/L,,

-tJ~J:’;:l:.t>~ftlH

13)7′-!J-~ft»

llflff7′-!J-~

…

tii, ‘*~¥ii8L.

‘n!Rl

,;:J1t.,;x.7’v-:;¥-tii1:;,.

1 lffl«i~-\tA7’v-:;¥

—C

<ft:~1,

‘o

-to~,

A7’v:Y?’-0>.$’c:!IIM@l±T1v-/{-@0>~ffill~~M

L,fJ!

1,

,:¥!J

:¥!J

0)

ffilili:iffiil L,tJ:JttLl’ffJ:l’.J*-lt

illliJ~~—tif.l~l’i,

if—,v~a..-(~}-0)-j-:)f

Iva

l-(I) t-a

~—c, 1v-/{-‘&~1i:til:.1i-?—Cl\’IJ•L,-r-:;J-~M~ii:

L*To

[~-]

=co•••

C4-3illl)

..

tt•co•~ifli7::c.-:.,~1.,

-c<t::~1.

,0

@ 3. mm

f-

Fis.a

8

Loading…

- Описание

- Отзывы (0)

Оверлок промышленный

Оверлок NEWLONG DHR-6 для изготовления Биг-Бэгов мкр

Newlong DHR-6

Представляем отличный оверлок промышленный . Двуигольная, простая подача, плоское основание, четырехниточный овершов стежок. Для пошива четырехстропных биг-бэгов, оверлок+прямая строчка (две иглы). Для прошивки полипропиленовых и полиэтиленовых тканей большой и малой плотности со шнуром по верхнему и нижнему краю.

| Характеристика шва | 401, 502 Ssa — 2 |

| Подача материала | Простая подача сверху |

| Размер стежка | 6-13 мм |

| Ширина овер-шва | 12 мм (по заказу-15 мм) |

| Полная ширина шва | 17 мм (по заказу — 20 мм) |

| Толщина материала | макс. 22 мм |

| Зазор иглы | 5 мм |

| Тип и размер иглы | UY9853G 430 |

| Макс. скорость | 1400 об/мин |

| Раб. скорость | 1200 об/мин |

| Нитки | Полипропиленовые 3000 денье |

Машина с двумя иглами, выполняет комбинированный цепной стежок / стежок через край, простая подача с верхней подачей, плоская платформа, выполняет стежок стачивающе-обметочной строчки в четыре нити, предназначена для шитья очень толстых полипропиленовых текстильных контейнерных мешков.

| Модель: | DHR-6 |

|---|---|

| Рабочая скорость: | ~1200 об./мин |

| Максимальная скорость: | 1400 ход/мин |

| Размер стежка: | 6 ~ 13 мм |

| Толщина ткани: | до 22 мм |

| Количество игл: | 2 |

| Тип иглы: | UY9853G — 430 |

| Количество нитей: | 4 |

| Нитки: | Полипропиленовые 3000 денье |

| Вес: | 52 кг |

Combined Overedging & Chain Stitch Machine , Two Needles, Upper & Lower Feeding, Four Thread Safety Stitch Used for Sewing Very Thick materials such as Polipropylene Container Bags, Big Bags, FIBC (Flexible Intermediate Bulk Container)

Technical Specifications

| Max. Speed ※ | 1,400 rpm |

| Seam | Safety Stitch Type 515 (2 Thread Chain Stitch ・ 2 Thread Overseaming Stitch) |

| Stitch Width | 6.5 – 15 mm |

| Bag Material | Bulk Bags, FIBC, Big Bag, Container Bag |

| Thickness | Up to 22 mm |

| Cutter | Overseaming width 12,15 mm |

| Needle & Thread | UY9853G 430 ・ 5000-6000 Denier |

| Oiling | By hand ・Oiler (Machine Oil Tellus #10) |

| Weight | 38.0 kg |

| Feature | Upper & Lower Feed ・ Double needle |

| Clutch Motor Required | 400w 2Pole, 1 or 3 Phase |

| Motor Pulley Required | Ø70(50hz), Ø55(60hz) |

| V-Belt Size Required | M39(50hz) M38(60hz) |

※ depending on the sewing material and operation

Needle type for Newlong Industrial DHR6: Organ Needle Japan UY9853G /430

Newlong Industrial Sewing Machine

Made in Japan

Primary Menu

- Home

- About Us

- Products

- Bag Closing Sewing Machines

- Bag Making Sewing Machines

- Special Sewing Head

- Spare Parts

- Catalogs

- Machines

- BLog

- Contact

Primary Menu

- Home

- About Us

- Products

- Bag Closing Sewing Machines

- Bag Making Sewing Machines

- Special Sewing Head

- Spare Parts

- Catalogs

- Machines

- BLog

- Contact

Safety Stitch Machine Head for Sewing Jumbo Bags (Two Needle, Upper-Lower Feed, Flat Bed, Four Thread Safety Stitch Machine)

| Specifications | |

|---|---|

| Max Speed | 1,400rpm | 1,200rpm Rotational Speed In Normal Operation |

| Seam | Double thread chain stitch | Overseaming stitch |

| Stich Width | 6.5-15mm |

| Bag Material | Container Bag |

| Thickness | 17mm-20mm |

| Cutter | Over seaming width 12mm (15mm) |

| Needle | UY9853G 430 |

| Oiling | by Hand – Oiler |

| Oil | Tellus #32 |

| Weight | 38.0kg |

| Feature | Upper & Lower sending | Double Needle |

| Related Machines | THR-6 |

- Description

Safety Stitch Machine Head for Sewing Jumbo Bags (Two Needle, Upper-Lower Feed, Flat Bed, Four Thread Safety Stitch Machine)

Related products

-

NP-7A

-

DS-9A

-

HR-2A

-

1A01002 Ball Bearing

NEWLONG NLI FZC

We take great pride in manufacturing high quality, technically advanced equipment that allows our customers to produce their products faster, more efficiently and cost effective, with less downtime.

- Phone: +971 54 558 5377

- sales@newlongindustrial.com

Subscribe

Subscribe to our Newsletter and get bonuses for the next purchase

Copyright © 2021 | NEWLONG NLI FZC All Rights Reserved.