- June 6, 2024

- INTEX

Table of Contents

- TECHNICAL DATA

- GENERAL INFORMATION

- HOW TO READ THE MANUAL

- REFERENCES

- SAFETY REGULATIONS

- TRAINING

- PRELIMINARY PROCEDURES

- DURING OPERATION

- MAINTENANCE, STORAGE

- BATTERY / BATTERY CHARGER IMPORTANT

- ENVIRONMENTAL PROTECTION

- GETTING TO KNOW THE MACHINE

- DESCRIPTION OF THE MACHINE AND PLANNED USE

- SAFETY SIGNS

- IDENTIFICATION LABEL

- MAIN COMPONENTS

- ASSEMBLY

- ASSEMBLY COMPONENTS

- HANDLE ASSEMBLY

- CONTROLS

- SAFETY KEY (DEACTIVATION DEVICE)

- HANDLE

- CUTTING HEIGHT ADJUSTMENT

- USING THE MACHINE

- PRELIMINARY PROCEDURES

- SAFETY CHECKS

- START-UP

- OPERATION

- AFTER OPERATION

- ROUTINE MAINTENANCE

- GENERAL INFORMATION

- BATTERY

- CLEANING

- NUTS AND BOLTS

- CLEANING THE TRANSMISSION

- CLEANING THE AIR FILTER

- OCCASIONAL MAINTENANCE

- CUTTING MEANS

- STORAGE

- STORING THE MACHINE When the machine is to be stored away:

- STORING THE BATTERY

- HANDLING AND TRANSPORTATION

- ASSISTANCE AND REPAIRS

- WARRANTY COVERAGE

- MAINTENANCE TABLE

- PROBLEM IDENTIFICATION

- [FOR MACHINES WITH ELECTRONIC CONTROL]](#FOR+MACHINES+WITH+ELECTRONIC+CONTROL%5D)

- FOR MACHINES WITHOUT ELECTRONIC CONTROL

- ATTACHMENTS ON REQUEST

- BATTERIES

- BATTERY CHARGER

- References

- Read User Manual Online (PDF format)

- Download This Manual (PDF format)

INTEX ZX300 Deluxe Automatic Pool Cleaner

TECHNICAL DATA

- Nominal power

- Max. motor operating

- MAX supply voltage

- NOMINAL supply voltage

- Machine weight

- Cutting width

- Cutting means code

- Sound pressure level

- Measurement uncertainty

- Measured acoustic power level

- Guaranteed acoustic power level

- Vibrations level

- Optional attachments

- Mulching kit

- Battery, mod.

- Battery charger, mod.

- Table for the correct combination of batteries

- Single battery use

- Battery Slot 1

- Combined use with two batteries

- Battery Slot 2

Please refer to the data indicated on the machine identification label for the

exact figure.

GENERAL INFORMATION

HOW TO READ THE MANUAL

Some paragraphs in the manual contain important information regarding safety

and operation and are emphasised in this manner:

NOTE OR IMPORTANT these give details or further information on what has

already been said, and aim to prevent damage to the machine.

This symbol indicates danger. Failure to observe thewarning can lead to

possible personal and/or third party injury and/or damage.

The paragraphs highlighted with a grey dotted square indicate the optional

characteristics that are not available on all models documented in this

manual. Check if the characteristics are available on this model.

Whenever reference is made to a position on the machine “front”, “back”,

“left” or “right” hand side, this refers to the operator’s working position.

REFERENCES

Figures

The figures in these instructions for Buse are numbered 1, 2, 3, etc. The

components indicated in the figures are identified with letters A, B, C, and

so on. Reference to component C in figure 2 is indicated with the wording:

“See fig. 2.C” or simply “(Fig. 2.C)”. The figures are given as a guide only.

The actual pieces can differ from those illustrated in this document.

Titles

The manual is divided into chapters and paragraphs. The title of paragraph

‘2.1 Training” is a sub-title of “2. Safety regulations”. References to titles

or paragraphs are marked with the abbreviation chap. or par. and the relevant

number. Example: “chap. 2” or “par. 2.1″

SAFETY REGULATIONS

TRAINING

Become acquainted with the controls and the proper use of the machine. Learn

how to stop the motor quickly. Failure to follow the warnings and instructions

may result in fire and/or serious injury.

- Never allow children or persons unfamiliar with these instructions to use the machine. Local laws may establish a minimum age for users.

- This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or instructions concerning use of the appliance in a safe way and understand the hazards involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children without supervision.

- Never use the machine if the user is tired or unwell, or has taken medicine, drugs, alcohol or any substances which may slow their reflexes and compromise his judgement.

- Do not allow children or other passengers to ride on the machine.

- Bear in mind that the operator or user is responsible for accidents or unexpected events occurring to other people or their property. It is the user’s responsibility to assess the potential risk of the area where work is to be carried out and to take all the necessary precautions to ensure his own safety and that of others, particularly on slopes or rough, slippery and unstable ground.

- If the machine is sold or lent to others, make sure that the operator reads the user instructions contained in this manual.

PRELIMINARY PROCEDURES

Personal Protective Equipment (PPE)

-

Always wear suitable work attire, hard-wearing safety footwear with non-slip soles and long trousers.

-

Do not operate the machine barefoot or wearing open sandals. Wear hearing protection devices.

-

Use of hearing protections can reduce the ability to hear any warnings (shouting or alarms). Be careful of what occurs around you in the work area.

-

Wear protective gloves whenever your hands are at risk.

-

Never wear scarves, shirts, necklaces, bracelets, loose flowing clothing, laces or ties or any hanging or flapping accessory that could get caught in the machine or in any objects or materials in the work area.

-

Tie your hair back if it is long.

Work area/Machine -

Thoroughly inspect the entire work area and remove anything that could be thrown by the machine or damage the cutting means/rotating units (stones, branches, iron wire, bones, etc.).

DURING OPERATION

Work Area

- Do not use the machine in environments at risk of explosion, in the presence of flammable liquids, gas or powder. Power tools createsparks which may ignite the dust or fumes.

- Work only in daylight or with good artificial light in good visibility conditions.

- Keep persons, children and animals away from the working area. Children must be supervised by another adult.

- Avoid working with wet grass, in the rain and when there is a risk of a thunderstorm, especially lightening.

- Do not expose the machine to rain or wet environments. Water entering a power tool will increase the risk of electric shock.

- Pay careful attention to uneven ground (hills, dips), slopes, hidden hazards and obstacles that could limit visibility.

- Be very careful near ravines, ditches or embankments. The machine could overturn if a wheel slides over the edge or if the earth gives way.

- Always mow across a slope and never up and down it, being very careful when changing direction, making sure you have firm footage and that the wheels do not hit any obstacles (such as stones, branches, roots, etc.) that may cause the machine to slide sideways or make you lose control of it.

- Look out for traffic when using the machine near the road.

Behaviour

- Exercise caution when reversing or moving backwards. Look behind you to make sure there are no obstacles before and during operations in reverse gear.

- Never run, always walk.

- Do not allow the lawnmower to pull you along.

- Always keep hands and feet away from the cutting means, when starting and when using the machine.

- Attention: the cutting means will continue to rotate for a few seconds after disengagement or after you have switched off the motor.

- Keep away from the discharge opening.

WARNING If something breaks or an accident occurs during mowing, turn off

the motor immediately and move the machine away to prevent further damage; if

an accident occurs with injuries or third parties are injured, carry out the

first aid measures most suitable for the situa-tion immediately and contact

the medical authorities for any necessary health care. Carefully remove any

debris which could cause damage or injury to persons or animals if ignored.

Use limitations

- Never operate the machine with guards damaged, missing or incorrectly assembled (grass catcher, side discharge guards, rear discharge guards).

- Don’t use the machine if the attachments/ tools are not installed in their seats.

- Never disengage, deactivate, remove or tamper with the safety systems/micro switches installed.

- Do not strain the machine too much and do not use a small machine for heavy-duty work; if you use the right machine, you will reduce the risk of hazards and improve the quality of your work.

MAINTENANCE, STORAGE

Ensure regular maintenance and correct storage to maintain machine safety and

high performance levels. Maintenance

-

Never use the machine with worn or damaged parts. Faulty or worn-out parts must always

be replaced and never repaired. -

Be careful during adjustment of the machine to prevent entrapment of the fingers between moving parts of the cutting means and fixed parts of the machine.

CAUTION The noise and vibration levels shown in these instructions are

the maximum levels for use of the machine. The use of an unbalanced cutting

element, the excessive speed of movement, or lack of mainte-nance have a

significant influence on noise emissions and vibrations. Consequently, it is

necessary to take preventive steps to eliminate possible damage due to high

levels of noise and stress from vibration; Maintain the machine well, wear ear

protection devices, and take breaks while working.

Storage

- To reduce fire risks, do not leave containers with debris inside a room.

BATTERY / BATTERY CHARGER IMPORTANT

The following safety instructions are in addition to the safety requirements

provided in the specific battery and battery charger manual delivered with

this machine.

- Only use battery chargers recommended by the manufacturer to recharge batteries. An inadequate battery charger may cause electric shock, overheating or corrosive liquid to leak from the battery.

- Use only batteries specifically designed for your power tool. The use of other batteries may cause injuries and fire risks.

- Make sure that the machine is switched off before inserting the battery. Inserting a battery in a machine which is switched on can cause a fire.

- Keep all unused batteries at a distance from paper clips, coins, keys, nails, screws or other small metal objects as contact with the same can cause short circuits. Short circuits between battery contacts can lead to explosion or fires.

- Do not use the battery charger in places where there are inflammable vapours, substances or on easily inflammable surfaces like paper, fabric, etc. During recharge, the battery charger becomes heated and may cause fire.

- When transporting accumulators, make sure the contacts never come into contact with each other and never use metal containers to transport them.

ENVIRONMENTAL PROTECTION

Safeguarding the environment must be a relevant and priority aspect of machine

use, of benefit the community and the environment we live in.

- Avoid being a disturbance to the neighbourhood. Use this machine at reasonable times of the day only (not early morning or late evening when the noise could cause disturbance).

- Comply with local regulations for the disposal of packaging, deteriorated parts or any elements with a strong environmental impact; this waste must not be disposed of with regular waste, but must be separated and taken to collection centres, which will recycle the materials.

- Comply with local regulations for the disposal of waste materials.

When the machine is decommissioned, do not dispose of it in the environment,

but take it to a waste disposal facility in accordance with the local

regulations in force.

Do not throw electrical equipment away with domestic waste. According to the

European Directive 2012/19/EU on waste electrical and electronic equipment and

its implementation in compliance with national standards, old electrical

equipment must be collected separately, for eco-compatible recycling. If

electrical equipment is disposed of in dumps or in landfills, hazardous

substances can leak into the groundwater and contaminate the food chain,

damaging your health and well-being. For further information on the disposal

of this product, contact your dealer or a domestic waste collection service.

At the end of their working life, dispose of batteries paying due attention to

the environment. Batteries contain material classified as hazardous for

you and the environment. They must be removed and disposed of separately at a

facility that accepts lithium-ion batteries.

Separate waste collection of the products and packaging used allows the

materials to be recycled and reused. Reuse of recycled materials help to

prevent environmental pollution and reduces the demand for raw materials.

GETTING TO KNOW THE MACHINE

DESCRIPTION OF THE MACHINE AND PLANNED USE

This machine is pedestrian-controlled lawnmower. The machine is essentially

composed of a motor which drives a cutting means enclosed in a casing,

equipped with wheels and a handle. The operator is able to operate the machine

and use the main controls, always staying behind the handle at a safe distance

from the rotating cutting means. If the operator leaves the machine, the motor

and cutting means will stop within a few seconds.

Intended use

This machine is designed and built to cut grass in gardens and grassy areas,

having dimensions in proportion to its cutting capacity; it is driven by an

operator walking behind it. Generally speaking this machine can: Mow, chop and

deposit the grass on the ground (mulching effect). The use of special

attachments provided for by the Manufacturer as original equipment or which

may be purchased separately, allows this work to be done in various

operatingmodes, illustrated in this manual or the instructions that accompany

the single attachments.

Improper use

Any other usage not in keeping with the afore-mentioned ones may be hazardous

and harm persons and/or damage things. Examples of improper use may include,

but are not limited to:

- Allowing children, animals or other passengers to ride on the machine as they could fall off and injure themselves or compromise safe driving by the operator.

- Letting oneself be transported by the machine.

- Using the machine to tow or push loads.

- Using the cutting means on surfaces other than grass.

- Use the machine for leaf or debris collection.

- Using the machine to trim hedges, or for cutting vegetation other than grass.

- Use of the machine by more than one person.

IMPORTANT Improper use of the machine will invalidate the warranty,

relieve the Manufacturer from all liabilities, and the user will consequently

be liable for all and any damage or injury to himself or others.

User types

This machine is intended for use by consumers,i.e. non-professional operators.

It is intended for “DIY” use only. IMPORTANT The machine must be used

exclusively by one operator.

SAFETY SIGNS

The machine has various symbols on it (Fig. 2). Their function is to remind

the operator of the correct conduct for use, with due care and caution.

Meaning of symbols:

Warning. Read the instructions before operating the machine.

Danger!

- Risk of thrown objects. Keep all persons away from the work area whilst working. Only for lawn mower with combustion engine.

- Be careful when using the sharp cutting means. Do not put hands or feet near or under the opening of the cutting means. The cutting means continues to turn even after

- the motor has been switched off. Remove the safety key (deactivation device) before any maintenance is carried out.

- Danger of cutting yourself. Cutting means in motion. Do not put hands or feet near or under the opening of the cutting means.

IMPORTANT Any damaged or illegible decals must be replaced. Order replacement

decals from an Authorised Service Centre.

IDENTIFICATION LABEL

The identification label holds the following data (Fig.1).

- Sound power level.

- CE conformity marking.

- Year of manufacture.

- Type of machine.

- Serial number.

- Name and address of Manufacturer.

- Article code.

- Max. motor operation speed.

- Weight in kg.

- Power voltage and frequency.

- Electrical protection rating.

- Nominal power.

Write the identification data of the machine in the specific space on the

label on the back of the cover page.

IMPORTANT

- Quote the information on the product identification label whenever you contact an Authorised Service Centre.

- The example of the Declaration of Conformity is provided on the last pages of the manual.

MAIN COMPONENTS

The machine is composed of a series of main components that have the following

functions (Fig.1):

- Chassis: this is the casing that houses the rotating cutting means.

- The engine: drives both the cutting means and the wheel traction (if available).

- Cutting means: the element designed to cut the grass.

- Handle: this is the operator’s work station. It is long enough to ensure the operator remains at a safe distance from the rotary cutting means whilst working.

- Battery (if it is not supplied with the machine, see chapter 15 “accessories on request””): provides the energy for starting the motor; its specifications and regulations for use are described in a specific manual.

- Operator presence lever: this lever enables the cutting means and drive to be operated. The motor stops when both levers are released.

- Drive engagement lever: this lever engages the drive to the wheels and allows the machine to move forward

- Hatch for accessing the battery compartment

- Safety key (Deactivation device): The key enables / disables the machine electric circuit.

- Battery charger (if it is not supplied with the machine, see chapter 15 “attachments on request”): device used to recharge the battery.

ASSEMBLY

CAUTION

The safety regulations to follow are described in chap. 2. Strictly comply

with these instructions to avoid serious risks or dangers. For storage and

transport purposes, some components of the machine are not installed in the

factory and have to be assembled after unpacking. Follow the instructions

below.

Unpacking and completing the assembly should be done on a flat and stable

surface, with enough space for moving the machine and its packaging, always

making use of suitable equipment. Do not use the machine until all the

instructions provided in the “ASSEMBLY” section have been carried out.

ASSEMBLY COMPONENTS

The packaging includes assembly components.

Unpacking

- Carefully open the packaging, paying attention not to lose components.

- Consult the documentation in the box, including these instructions.

- Remove all the unassembled parts from the box.

- Dispose of the box and packaging in compliance with local regulations.

Before assembling, make sure the safety key is not inserted into its housing.

HANDLE ASSEMBLY

-

Type “I”

Assemble the handle according to the indications in (Fig.3). -

Type “II”

Assemble the handle according to the indications in (Fig.4). -

Type “III”

Assemble the handle according to the indications in (Fig.5).

CONTROLS

SAFETY KEY (DEACTIVATION DEVICE)

The key (Fig.6.A) found inside the battery compartment enables / disables the

machine’s electrical circuit. Removing the key, the electric circuit is

completely deactivated to prevent uncontrolled use of the machine.

IMPORTANT Remove the safety key whenever the machine is unused or left

unattended.

For certain models, if required, turn the key to “ON” position to activate the

electric circuit of the machine to activate its start-up. Turning the key to

“OFF”, the electric circuit of the machine is completely deactivated, to

prevent any uncontrolled use of the machine.

HANDLE

Operator presence lever

The operator presence lever (Fig.7.A) enables the cutting means. It is located

in front of the handle. Press the safety button (Fig.7.C) and bring the lever

towards the handle in order to start the cutting means. When the lever is

released, the motor automatically stops and all functions are disabled.

NOTE The cutting means engagement is possible only by pressing the yellow

button on the right side of the handle and bringing the operator presence

lever towards the handle.

Power button

The power button (Fig.8.A) is used to:

-

Machine start-up. By pressing the button (Fig.8.A) the LED (Fig.8.B) switches on and the machine is ready for use.

NOTE The machine can be switched on only if the operator presence lever

and the drive lever are released. In case the machine is not operated, the

LED turns off after 15 seconds and the above-mentioned operation must be

carried out again. -

Cutting means engagement.

NOTE The cutting means engagement is possible only by pressing the operator

presence lever against the handle (see par. 6.3). -

Cutting means disengagement. With the cutting means engaged, release the operator presence lever (Fig.7.A); the cutting means stops whilst keeping the machine powered on.

Drive ON lever

IMPORTANT The engine has to be always started with the drive disengaged.

This engages the wheel drive and allows the machine to move forward. It is

located behind the handle.

Drive engaged. The lawn mower is driven forward with the lever pulled

against the handle (Fig.7.B). The lawn mower stops moving forward when the

lever is released.

IMPORTANT Avoid moving the machine backwards when the drive is ON. For

certain models, the forward speed can be adjusted with the selection knob

located on the right side of the handle (Fig.8.C). You can select 6 different

levels of speed.

- Maximum speed (about 5 Km/h).

- Minimum speed (about 2.5 Km/h).

NOTE The last speed level selected remains set after the machine is turned

off.

“ECO” button

The “ECO” mode allows to save energy when cutting the grass, optimising the

battery life. Press the button (Fig.8.D) to enable or disable the “ECO”

function. This mode is automatically deactivated when the operator presence

levers are released.

NOTE It is not recommended to use the “ECO” function in heavy grass cutting

conditions (cutting of dense, high, humid grass).

CUTTING HEIGHT ADJUSTMENT

Lower or raise the chassis to cut the grass at different heights. Carry out

this operation when the cutting means is stationary. The cutting height is

adjusted by using the designated lever (Fig.9.A) that lifts or lowers the

chassis to the desired position.

USING THE MACHINE

The safety regulations to follow are described in chap. 2. Strictly comply

with these instructions to avoid serious risks or dangers.

PRELIMINARY PROCEDURES

Before starting work , it is necessary to carry out several checks and

operations to ensure you can work efficiently and in maximum safety: Make sure

that the safety key is not inserted in its slot. Place the machine in a stable

horizontal position on the ground.

Checking the battery

Before using the machine for the first time after purchase, fully charge the

battery following the instructions in the battery booklet. Before every use of

the machine, check the battery charge status according to the instructions in

the battery booklet.

Cutting height adjustment

Adjust the cutting height as indicated in (par. 5.3).

SAFETY CHECKS

Perform the following safety checks and check that the results correspond to

those outlined on the tables.

Always carry out the safety checks before use.

General safety check

| Object | Result |

|---|---|

| Grips | Clean, dry. |

| Handle | Fixed firmly to the machine. |

| Cutting means | Clean, not damaged or worn. |

| Switch command Operator presence lever Drive ON lever | The lever must move |

freely, it must not need forcing and should return automatically and rapidly

back to the neutral position.

Battery| No damage to the casing, no liquid leakage.

Screws/nuts on the machine and on the cutting means| Correctly tightened (not

loose).

—|—

Cooling air ducts| Not clogged.

Machine| No signs of damage or wear.

Machine operating test

| Action | Result |

|---|

1. Start the machine and engage the cutting means (par.6.3).

2. Release the op- erator presence lever (Fig.15.A).

| 1. The cutting means should move.

2. The lever should return automatically and rap- idly to the neutral po-

sition, the engine must switch off and the cut- ting means must stop

within a few seconds.

1. Start the machine (par. 6.3) and operate the drive lever (par. 5.2.3).

2. Disengage the

drive lever.

| 1. The wheels should move the machine forward.

2. The wheels should stop and the machine stops moving forward.

Test driving| No abnormal vibrations. No abnormal sound.

If any of the results fail to match the indications provided in the tables, do

not use the machine! Contact an Authorised Service Centre to have it checked

and repaired if necessary.

START-UP

NOTE

- Start up the machine on a flat surface without obstacles or high grass.

- Check if the battery combination is correct, following the instructions supplied in the “Technical data” table.

- Open the hatch for accessing the battery compartment (Fig.10.A).

- Fit the batteries correctly in their compartments (Fig. 7.2.3.A) pressing down until the end and until you hear it clicks firmly into position, ensuring thus the electrical contact.

- Insert the safety key until the end (Fig.11.A). If required, turn the key to “ON” position.

- Completely close the hatch again.

- For models that require using a power button for starting, use the power button (fig. 12. A). The LED stays on for 15 seconds.

- Engage the cutting means by first pressing the safety button (Fig.13.B) and then pressing the operator presence lever (Fig.13.A).

- To engage the traction, press the lever behind the handle (Fig.13.C).

OPERATION

IMPORTANT When working, always keep a safe distance from the cutting

means, given by the length of the handle. The battery power reserve (and

therefore the lawn surface to be mown before recharging) depends on many

factors, described in (par. 7.2.1).

During use, the charge status of the batteries is displayed (remaining charge

percentage) (Fig.8.E).

If the motor stops because it is overheated whilst mowing, you must wait

approximately 5 minutes before restarting it.

Grass cutting

-

Start moving forward and mowing the grass area.

-

Adjust speed and cutting height (para 5.3) in relation to lawn conditions (grass height, density and humidity) and the amount of grass to be cut.

For traction models (par. 5.2.3): It is recommended to avoid mowing on slopes

with a degree higher than 15°. -

The appearance of the lawn will improve if you alternate cutting in both directions at the same height (Fig.14).

- Always avoid removing a large quantity of grass. Never cut more than one third of the total grass height per single pass (Fig.14).

- Keep the chassis clean (par. 7.3.1).

Suggestions for maintaining your lawn

- To keep a lawn lush and green, it should be cut regularly. A lawn can be composed of different types of grass. If the lawn is cut frequently, grass and roots grow more vigorously, forming a solid grassy bed; if the lawn is cut is less frequently, higher grass and weeds start growing (clover and daisies, etc.). The frequency of mowing should be in relation to the rate of growth of the grass, which should not be left to grow too much between one cut and the next.

- 4- 5cm. With one mow, you do not need to remove more than a third of the total height. If the grass is very tall, it should be cut twice in a twenty-four hour period; The first time with the cutting means at maximum cutting height and the second cut at the height desired.

- Cutting too low tears and uproots the grass, giving it a “spotted” appearance.

- During hot and dry periods, the grass should be cut a little higher to prevent the ground from drying out.

- It is always better to cut the grass when it is dry. Do not cut wet grass; this could reduce cutting means efficiency due to sticky grass and tear the lawn.

- The cutting means must be in good state and well sharpened so that the grass is cut straight without a ragged edge that leads to yellowing at the ends.

STOPPING THE MACHINE

To stop the machine:

- Release the operator presence lever (Fig.15.A).

- For models that require using a power button for starting, use the power button (fig. 12.A).

- Wait until the cutting means stops.

After stopping the machine, it will take a few sec-onds for the cutting means

to stop.

IMPORTANT Always stop the machine.

- When moving between work areas.

- When driving on grass free surfaces.

- Every time it is necessary to overcome an obstacle.

- Before adjusting the cutting height.

- Any time the side discharge chute (if available) is removed or refitted.

AFTER OPERATION

- Stop the machine (par. 6.5).

- Open the hatch and remove the safety key.

- Remove the battery from its hous- ing and recharge it (par 7.2.2).

- Allow the motor to cool before stor- ing in an enclosed space.

- Clean (par. 7.3).

- Check there are no loose or damaged compo-nents. If necessary, replace the damaged com-ponents and tighten any screws and loose bolts or contact the authorised service centre.

IMPORTANT Remove the safety key whenever the machine is unused or left

unattended.

ROUTINE MAINTENANCE

GENERAL INFORMATION

WARNING

The safety regulations to follow are described in chap. 2. Strictly comply

with these instructions to avoid serious risks or dangers.

Before commencing any inspections, cleaning or maintenance/adjustments on the

machine:

- Stop the machine.

- Remove the safety key, (never leave the key inserted or within the reach of children or unauthorised persons).

- Make sure that all moving parts have come to a complete stop.

- Allow the motor to cool before storing in an enclosed space.

- Read the relevant instructions.

- Use suitable clothing, protective gloves and goggles.

- The frequency and types of maintenance are summarised in the “Maintenance Table”. The table will help you maintain your machine’s safety and performance. It summarises the main interventions to be made and the frequency applicable to each of them. Carry out the relevant task as soon as it is scheduled to be performed.

- The use of non-genuine and/or incorrectly assembled spare parts and attachments could adversely affect machine operation and safety. The manufacturer shall decline all liability in the event of injuries or damages caused by such parts.

- Genuine spare parts are supplied by Authorised Assistance Centres and Dealers.

IMPORTANT Any maintenance and adjustment operations not described in this

manual must be carried out by your Authorised Service Centre.

BATTERY

Battery power reserve

Battery power reserve (and therefore the lawn surface that can be mown before

recharging is required) mainly depends on:

- Environmental factors that cause higher energy requirements:

- Mowing dense, high and/or wet grass.

- Machine cutting width; wider settings involve higher energy consumption.

- Operator behaviour that should be avoided:

- Switching the machine on and off frequently whilst working.

- Setting a cutting height that is too low for the lawn conditions.

- Working at a speed that is too high in relation to the amount of grass to be removed.

NOTE During use, the battery is protected against total drainage with a

protective device that switches off the machine and stops it from working.

To optimise battery power reserve it is always recommended to:

- Cut the grass when the lawn is dry.

- Cut the grass frequently so that it doesn’t grow too tall.

- Set a higher cutting height when the grass is very tall, then set a lower height and cut the lawn again.

- Do not use the machine in “mulching” mode with very high grass.

- Use of the “ECO” mode (par. 5.2.4).

If the need arises to use the machine for sessions which exceed the capability

of a standard battery, it is possible to:

- Purchase a second standard battery to immediately replace the discharged battery, without compromising the continuity of operations.

- Purchase a battery with an extended power reserve compared to the standard version (par. 15.1).

Battery removal and recharging

- Open the battery compartment access hatch and remove the safety key.

- Press the button on the battery (Fig.16.A) and remove the battery (Fig.16.B).

- Insert the battery (Fig.17.B) in its housing in the battery charger (Fig.17.C).

- Connect the battery charger to a power socket with the voltage indicated on the rating plate.

- Fully charge the battery according to the instructions in the battery/battery charger booklet.

NOTE The battery is equipped with a guard that inhibits recharging if the

environmental temperature is not between 0 and +45 °C.

NOTE The battery can be recharged at any time, even partially, with no risk of

damaging it.

Refitting the battery on the machine

When recharging is completed:

- Remove the battery from the housing in the battery charger (do not keep recharg-ing when recharging is completed).

- Disconnect the battery charger from the mains power supply.

- Open the battery housing hatch (Fig.18.A), insert the battery (Fig.18.B) into its housing pressing down until you hear it click firmly into position and check the electrical contact.Completely close the hatch again.

CLEANING

Clean thoroughly following the instructions below every time it is used.

Cleaning the machine

- Always make sure the air intakes are free of debris.

- Do not spray water onto the motor and electrical components, prevent them from getting wet (Fig.19).

- Do not use aggressive liquids to clean the chassis.

- To reduce fire hazards, keep the lawnmower and, in particular, the motor free of grass, leaves, or excessive grease.

- Always keep the levers, display and buttons free of debris.

Cleaning the cutting means assembly

Remove grass debris and mud accumulated in the chassis to prevent it from

drying and causing problems the next time the lawnmower is used. Tilt the

machine laterally and make sure that it is stable before starting any work.

The paintwork of the internal part of the chassis may crack off over time due

to the abrasive action of the cut grass; In this case, take immediate action

by retouching the paintwork with rust-preventive paint, to prevent the

formation of rust which may corrode the metal.

NUTS AND BOLTS

Keep all nuts, bolts and screws tight to be sure the equipment is in a safe

working condition.

CLEANING THE TRANSMISSION

- Remove the guard once or twice per year (Fig.20.A) (Fig.21.A) by unscrewing the screws (Fig.20.B) (Fig.21.B).

- Only for the “MCS 500 Li 48 series” model: release the hooks (Fig.21.C).

- Then clean carefully using a brush or compressed air, removing the grass and dirt from theVarea around the transmission and belt.

- Always refit the guard (Fig.20.A) (Fig.21.A).

CLEANING THE AIR FILTER

The filter element must always be kept perfectly clean and must be replaced if

it is broken or damaged. Proceed as follows:

-

Clean around the air filter grid.

-

Unscrew the screw (Fig.22.B) to remove the grid (Fig.22.A).

-

Remove the filter element (Fig.23.A).

-

Blow on the filter to remove dust and debris. If the filter is still dirty, wash the filter (Fig.23.A) with water and dry it with a clean cloth.

IMPORTANT Do not use petrol, detergents or any other products to clean the

filter element. -

Clean the outside of the filter housing eliminating dust, debris or dirt.

-

Fit the filter element (Fig.23.A) into its housing (making sure it is completely dry).

-

Refit the grid (Fig.22.A) and tighten the screw (Fig.22.B).

OCCASIONAL MAINTENANCE

Before commencing any inspections, cleaning or maintenance/adjustments on the

machine:

- Stop the machine.

- Remove the safety key, (never leave the key inserted or within the reach of children or unauthorised persons).

- Make sure that all moving parts have come to a complete stop.

- Allow the motor to cool before storing in an enclosed space.

- Read the relevant instructions.

- Use suitable clothing, protective gloves and goggles.

CUTTING MEANS

An improperly sharpened cutting means pulls at the grass and causes the lawn

to turn yellow.

Do not touch the cutting means until the key has been removed and the cutting

means is completely sta-tionary.

All work on the cutting means (disassembly, sharpening, balancing, repairing,

reassembly and/or re-placing) are demanding jobs that require special skills

as well as special tools; For safety reasons, these jobs are best carried out

at a Authorised Service Centre.

Make sure damaged, misshapen or worn cutting means are replaced, together with

the securing screws, to preserve balance.

IMPORTANT

Always use original cutting means bearing the code indicated in the “Technical

Data”.

Given product evolution, the cutting means listed in the “Technical Data”

table may be replaced in time with others having similar interchangeable and

operating safety features.

STORAGE

STORING THE MACHINE When the machine is to be stored away:

- Wait for the engine to cool.

- Remove the safety key.

- Clean (par. 7.3).

- Check there are no loose or damaged compo-nents. If necessary, replace the damaged com-ponents and tighten any screws and loose bolts or contact the authorised service centre.

- Store the machine:

- In a dry place.

- Protected from inclement weather.

- Covered with a sheet where possible.

- In a place where children cannot get to it.

- Making sure that keys or tools used for maintenance are removed.

STORING THE BATTERY

The battery must be kept in a cool, shaded place without humidity.

NOTE If unused for any length of time, recharge the battery every two

months to prolong its working life.

HANDLING AND TRANSPORTATION

Whenever the machine is to be handled, raised, transported or tilted you must:

- Stop the machine (par. 6.5).

- Remove the safety key.

- Make sure that all moving parts have come to a complete stop.

- Wear heavy duty gloves.

- Hold the machine in the points offering a safe grip, taking into account the weight and its division.

- Use an appropriate number of people for the weight of the machine and the characteristics of the vehicle or the place where it must be placed or collected.

- Make sure that machine movements do not cause damage or injuries.

When transporting the machine on a vehicle or trailer, always:

- Use an access ramp of suitable strength, width and length.

- Load the machine with the motor switched off and pushed by an adequate number of people.

- Lower the cutting means assembly.

- Position it so that it cannot cause a hazard for anybody.

- Fasten firmly to the means of transport using ropes or chains to prevent it from tipping over.

ASSISTANCE AND REPAIRS

This manual provides all the necessary information to run the machine and for

correct basic maintenance operations which can be performed by the user. Any

regulations and maintenance operations not described herein must be carried

out by your Dealer or Authorised Service Centre, which have the necessary

knowledge and equipment to ensure that the work is carried out correctly,

maintaining the correct degree of safety and the original operating conditions

of the machine.

Any operations performed in unauthorised centres or by unqualified persons

will totally invalidate the Warranty and all obligations and responsibilities

of the Manufacturer.

- Only Authorised Service Centres can carry out guaranteed repairs and maintenance.

- The Authorised Service Centres only use genuine spare parts. Genuine spare parts and attachments have been designed specifically for machines.

- Non-original parts and attachments are not approved; use of non-original spare parts and attachments will jeopardise the safety of the machine and relieve the Manufacturer from all obligations or liabilities.

WARRANTY COVERAGE

The warranty conditions are intended for consumers only, i.e. non-professional

operators. The warranty covers all material quality and manufacturing defects

recognised during the warranty period by your Dealer or Authorised Service

Centre.

The warranty is restricted to the repair or replacement of components

recognised as faulty. It is advisable to send your machine once a year to an

Authorised Service Centre for servicing, assistance and safety device

inspection. The warranty only applies to machines subjected to regular

maintenance. The user must follow all the instructions provided in the

accompanying documentation. The warranty does not cover damages resulting

from:

- Failure to become familiar with the documentation accompanying the machine (Owner’s manual).

- Professional use.

- Carelessness, negligence.

- External causes (lightning, impact, presence of foreign bodies inside the machine) or incidents.

- Incorrect use or assembly or prohibited by the manufacturer.

- Poor maintenance.

- Modification to the machine.

- Use of non-genuine spare parts (adaptable parts).

- Use of accessories not supplied or approved by the manufacturer.

The warranty does not cover:

- The routine/occasional maintenance operationsv (described in the owner’s manual).

- Normal wear and tear of consumables such nas the drive belt, cutting means, headlights, wheels, safety bolts and wiring.

- Normal wear and tear.

- Deterioration in the appearance of the machine due to use.

- Cutting means supports.

- Any ancillary expenses related to the enforcement of the warranty, such as costs incurred to travel to the user’s location, transfer of the machine to the Dealer, rental of replacement equipment or calling of independent enterprises to perform maintenance work.

The user is protected by his or her own national legislation. The user’s

rights under the national laws or his or her own country are not in any way

restricted by this warranty.

MAINTENANCE TABLE

| Intervention | Frequency | Notes |

|---|---|---|

| MACHINE | ||

| Check all fasteners | Before each use | par. 7.4 |

| Safety checks/check controls | Before each use | par. 6.2 |

| Check the cutting means | Before each use | par. 6.2.1 |

| Check the battery charge status | Before each use | * |

| Recharge the battery | After each use | par. 7.2.2 * |

| General cleaning and inspection | After each use | par. 7.3 |

Checking for any damage to the machine. If necessary, contact the authorised

service centre.| After each use| –

Cleaning the air filter| Once a month| par. 7.6

Cleaning the transmission| 1-2 times a year| par. 7.5

—|—|—

Replacing the cutting means| –| par. 8.1

Drive adjustment| | **

- Refer to the battery/battery charger manual.

- The operation must be carried out by your Dealer or a specialised Authorised Service Centre

- The operation to be performed at the first signs of any malfunction

PROBLEM IDENTIFICATION

FOR MACHINES WITH ELECTRONIC CONTROL]

If problems persist after having performed the above operations, contact your

dealer.

PROBLEM| PROBABLE CAUSE| SOLUTION

1. After pressing the starter button, the LED does not come ON.| Safety

key is not inserted or is inserted incorrectly.| Insert the key (par. 6.3).

Safety key in “OFF” position.| Turn the safety key to “ON” position (par.

6.3).

Battery is not inserted or is inserted incorrectly.| Open the hatch and check

that the battery is fitted in its housing correctly (par. 7.2.3).

Low battery.| Check the battery status and recharge if necessary (par. 7.2.2).

Incorrect battery combination.| Check if the battery combination is correct,

following the instructions supplied in the “Technical data” table.

2. After pressing the starter button, the LED does not come ON and the

machine sets off a sound signal.| Internal motor anomaly.| Remove the safety

key and contact the Authorised Service Centre for checks, replacements or

repairs.

3. The motor shuts down whilst working.| Battery is not inserted

correctly.| Open the hatch and check that the battery is fitted in its housing

correctly (par. 7.2.3).

Low battery.| Check the battery status and recharge if necessary (par. 7.2.2).

4. The danger LED lights up (Fig. 24.A) and

the machine emits an acoustic signal.

| Cutting means blocked.| Turn the machine off, remove the safety key and wear

work gloves.

Check and eventually remove any obstructions in the machine lower side (par.

7.3.2) that prevent rotation of the cutting means.

If the problem continues, contact the Authorised Service Centre for checks,

replacements or repairs (par. 8.1).

Machine fault| Remove the safety key and contact the Authorised Service Centre

for checks, replacements or repairs.

Drive motor over current for heavy working conditions (drive under stress).| –

Make sure that the wheels are not blocked. Clean as needed.

– Check the slope of the land you

are working on (par. 6.4.1).

5. The danger LED lights up (Fig.24.A).| The thermal protection has

tripped due to overheating of the machine.| Wait for at least 5 minutes and

restart the machine.

6. Mowing is difficult.| The cutting means is not in good state.| Contact

the Authorised Service Centre for the sharpening or replacement of the cutting

means.

7. Excessive noise and/ or vibration is experi- enced whilst working.|

Cutting means fittings are loose or the cutting means is damaged.| Immediately

turn off the motor and remove the safety key.

Contact the Authorised Service Centre for

checks, replacements or repairs (par. 8.1).

—|—|—

8. Battery power re- serve is low.| Severe working conditions requiring

greater current absorption.| Optimise operations (par. 7.2.1).

Battery is insufficient for operating requirements.| Use a second battery or

extended battery (par. 15.1).

9. The battery charger is not charging the battery.| Battery is not

correctly inserted in the battery charger.| Check it is correctly inserted

(par. 7.2.3).

Unsuitable environmental conditions.| Recharge the battery in places with

suitable temperatures (see battery/ battery charger instruction manual).

Dirty contacts.| Clean the contacts.

The battery charger is not energised.| Check it is plugged in and the power

socket is energised.

Faulty battery charger.| Replace with an original spare part.

| If the problem persists, refer to the battery/battery charger manual.

FOR MACHINES WITHOUT ELECTRONIC CONTROL

If problems persist after having performed the above operations, contact your

dealer.

PROBLEM| PROBABLE CAUSE| SOLUTION

1. The engine does not start when using the switch| Safety key is not

inserted or is inserted incorrectly.| Insert the key (par. 6.3).

Safety key in “OFF” position.| Turn the safety key to “ON” position (par.

6.3).

Battery is not inserted or is inserted incorrectly.| Open the hatch and check

that the battery is fitted in its housing correctly (par. 7.2.3).

Low battery.| Check the battery status and recharge if necessary (par. 7.2.2).

Incorrect battery combination.| Check if the battery combination is correct,

following the instructions supplied in the “Technical data” table.

2. The engine stops and the machine emits

an acoustic signal.

| Battery is not inserted correctly.| Open the hatch and check that the

battery is fitted in its housing correctly (par. 7.2.3).

Low battery.| Check the battery status and recharge if necessary (par. 7.2.2).

The thermal protection has tripped due to overheating of the motor.| Wait for

at least 5 minutes and restart the machine.

Cutting means blocked.| Turn the machine off, remove the safety key and wear

work gloves.

Check and eventually remove any obstructions in the machine lower side (par.

7.3.2) that prevent rotation of the cutting means.

If the problem continues, contact the Authorised Service Centre for checks,

replacements or repairs (par. 8.1).

Machine fault| Remove the safety key and contact the Authorised Service Centre

for checks, replacements or repairs.

3. Mowing is difficult.| The cutting means is not in good state.| Contact

the Authorised Service Centre for the sharpening or replacement of the cutting

means.

—|—|—

4. Excessive noise and/ or vibration is experi- enced whilst working.|

Cutting means fittings are loose or the cutting means is damaged.| Immediately

turn off the motor and remove the safety key.

Contact the Authorised Service Centre for

checks, replacements or repairs (par. 8.1).

5. Battery power re- serve is low.| Severe working conditions requiring

greater current absorption.| Optimise operations (par. 7.2.1).

Battery is insufficient for operating requirements.| Use a second battery or

extended battery (par. 15.1).

6. The battery charger is not charging the battery.| Battery is not

correctly inserted in the battery charger.| Check it is correctly inserted

(par. 7.2.3).

Unsuitable environmental conditions.| Recharge the battery in places with

suitable temperatures (see battery/ battery charger instruction manual).

Dirty contacts.| Clean the contacts.

The battery charger is not energised.| Check it is plugged in and the power

socket is energised.

Faulty battery charger.| Replace with an original spare part.

| If the problem persists, refer to the battery/battery charger manual.

ATTACHMENTS ON REQUEST

BATTERIES

Different capacity batteries are available to suit specific operating

requirements (Fig.25). The list of approved batteries for this machine can be

found in the “Technical Data” table.

BATTERY CHARGER

Device used to recharge the battery (Fig.26).

References

- INTEX: The leader in Above Ground Swimming Pools, Air Mattresses and Inflatable Spas

Read User Manual Online (PDF format)

Read User Manual Online (PDF format) >>

Download This Manual (PDF format)

Download this manual >>

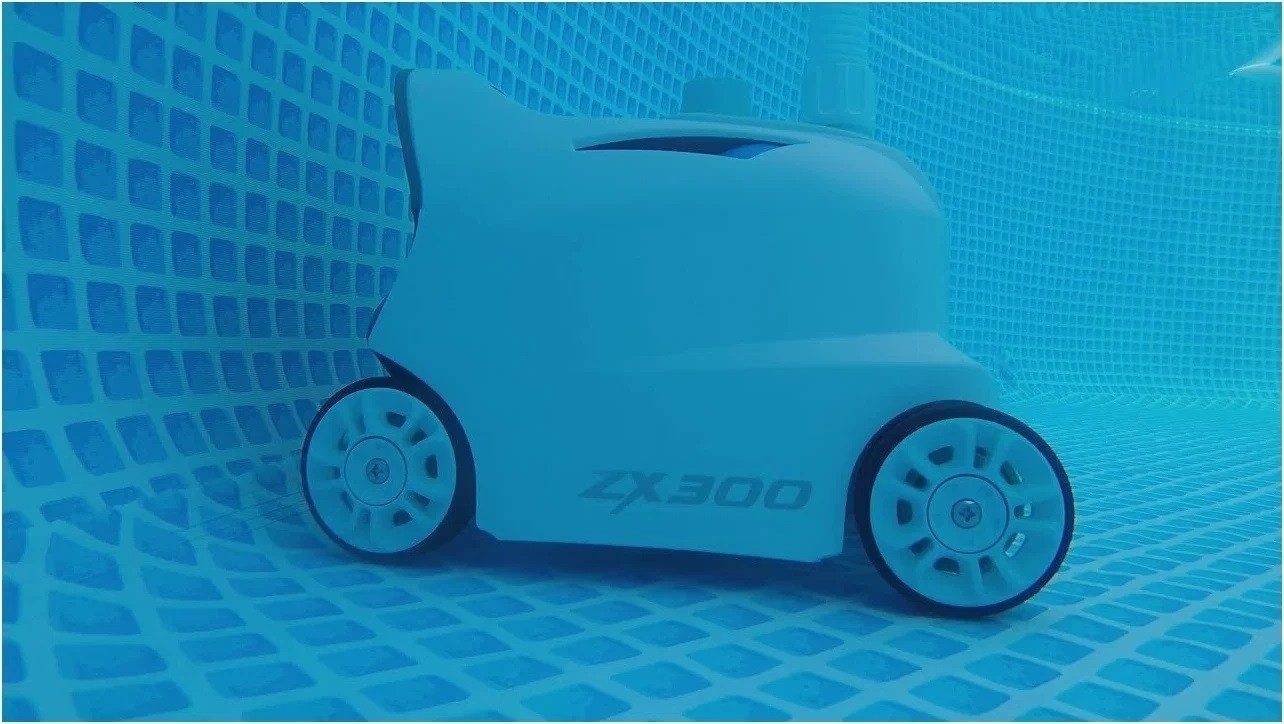

Если у вас большой бассейн, то очистка его дна — задача не из легких. Но не для Intex ZX300 28005.

Этот мощный вакуумный уборщик самостоятельно передвигается по чаше бассейна от одного борта к другому и засасывает грязь, осевшую на дно. Давайте знакомиться с ним подробнее.

5%скидка

Для читателей нашего блога

скидка 5% на весь

ассортимент

Ваш промокод:BLOGСмотреть все пылесосы

Упаковка и комплектация

Пылесос упакован в большую картонную коробку, на которую нанесена основная информация о модели.

Что внутри? Кроме самого уборщика, в комплект входят:

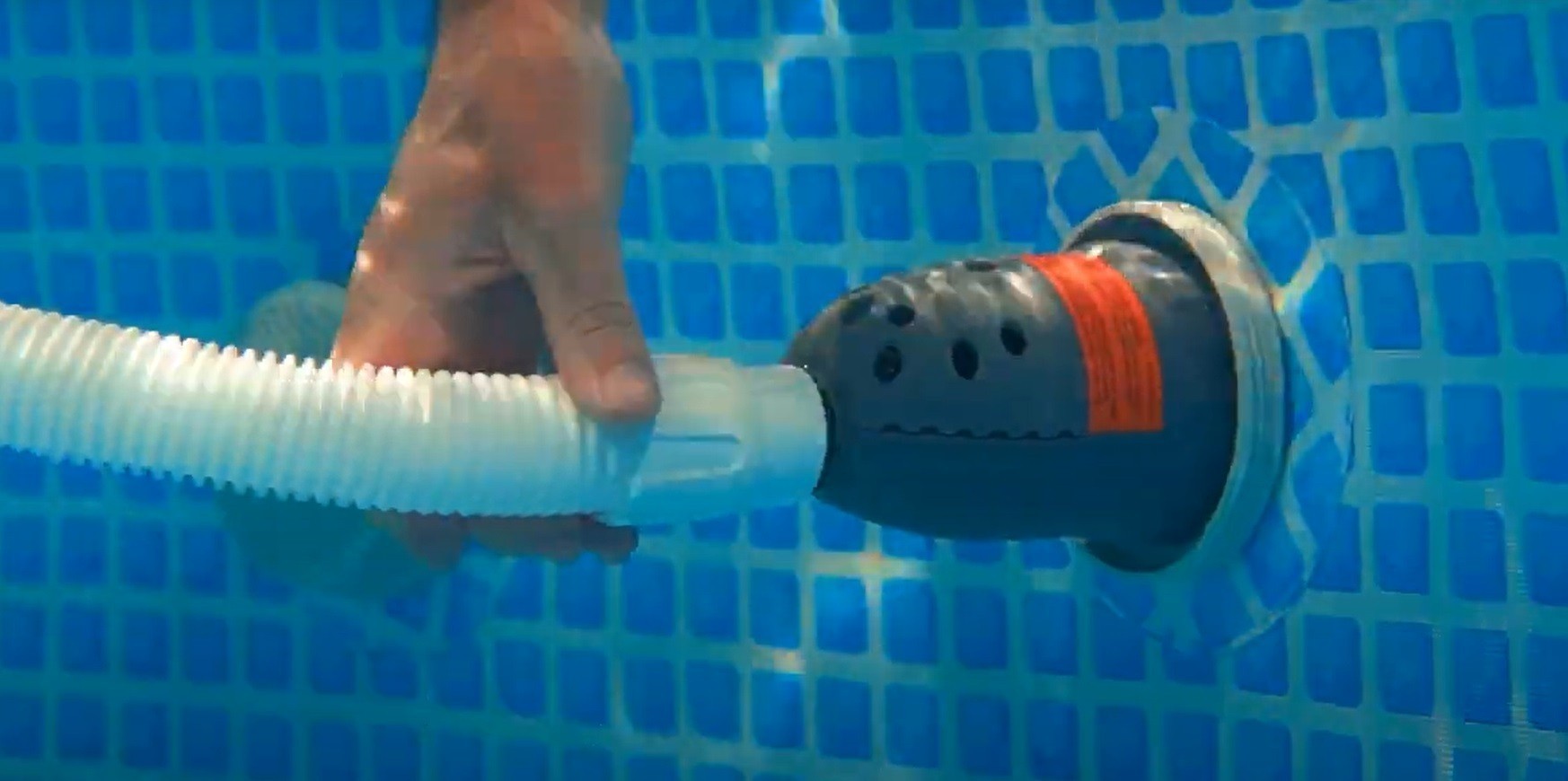

- не запутывающийся шланг длиной 6,5 м, с помощью которого пылесос крепится к выпускной форсунке в бассейне;

- щетки нескольких видов;

- спускной клапан давления с фильтром;

- заглушка.

Таким образом, в комплекте есть все необходимое для подключения. Модель подходит для надувных и каркасных бассейнов Intex с отверстиями для фильтра 38 мм.

Изделие предназначено как для круглых (до 7,92 м), так и для прямоугольных или овальных резервуаров (до 9,75×4,88 м), кроме разновидностей Easy Set с надувным верхним кольцом.

Шланг 6,5 метров может оказаться чересчур длинным. Чтобы излишки не болтались в воде и не мешали работе пылесоса, их нужно отрезать в соответствии с размерами бассейна. Длины должно быть достаточно, чтобы уборщик доезжал до противоположного борта без натяжения шланга.

Особенности

Как происходит очистка? Просто запустите робота-пылесоса в бассейн, и он будет ездить и собирать скопившуюся грязь.

Для работы понадобится подключение фильтрующего насоса с подачей воды от 6056 до 13 248 л/ч. Скорость перемещения может достигать 7 метров в минуту.

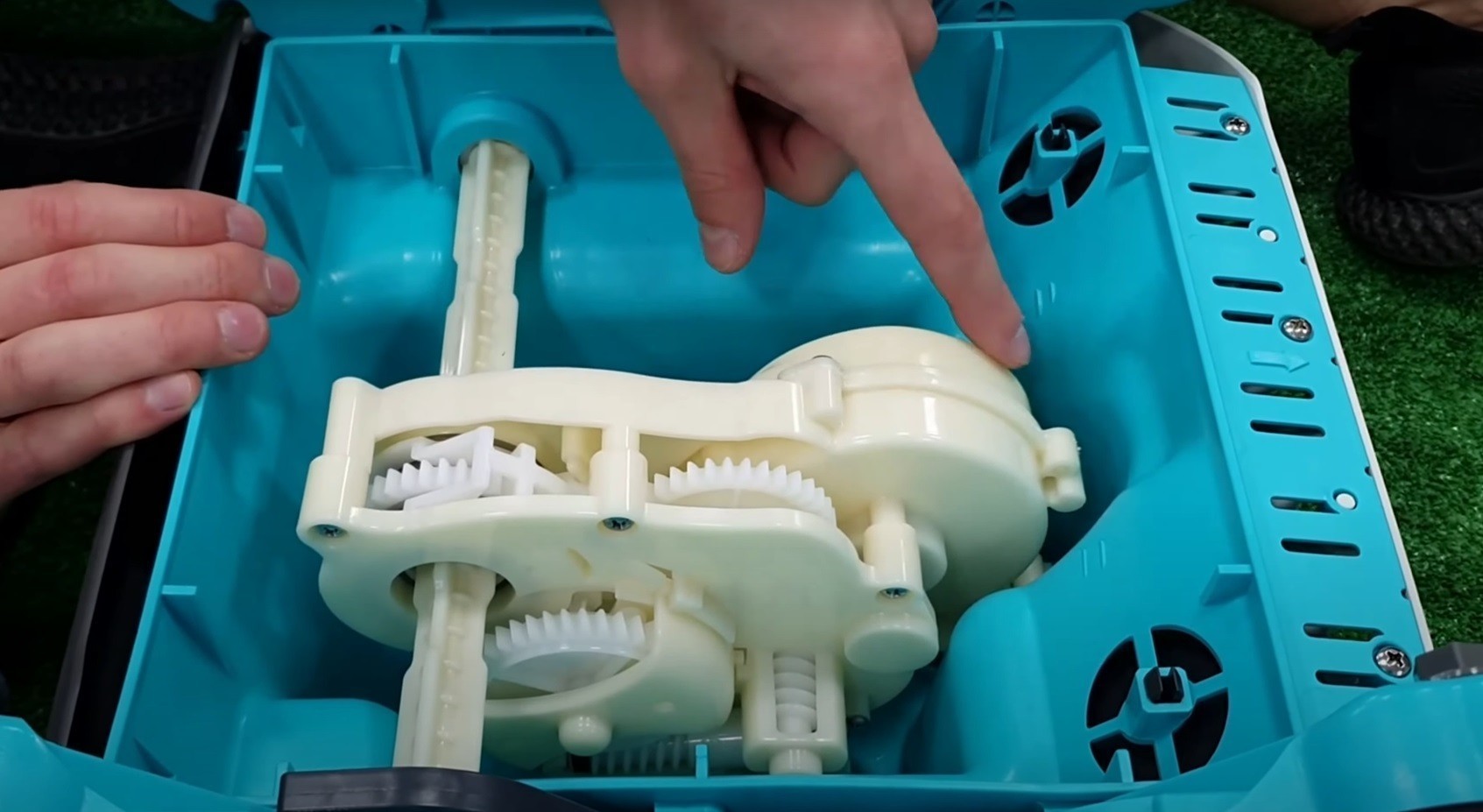

Уборщик ZX300 не является электрическим. Он работает за счет прижимной силы воды, когда та подается к пылесосу. Вот так механизм выглядит изнутри:

Вода поступает на гидротурбину, которая активирует редукторный механизм, а он, в свою очередь, приводит в движение колеса. Полный привод позволяет пылесосу двигаться не только по дну, но и заезжать даже на стенки бассейна до уровня воды! В этом и есть главное отличие Intex ZX300 28005 от предыдущей модели.

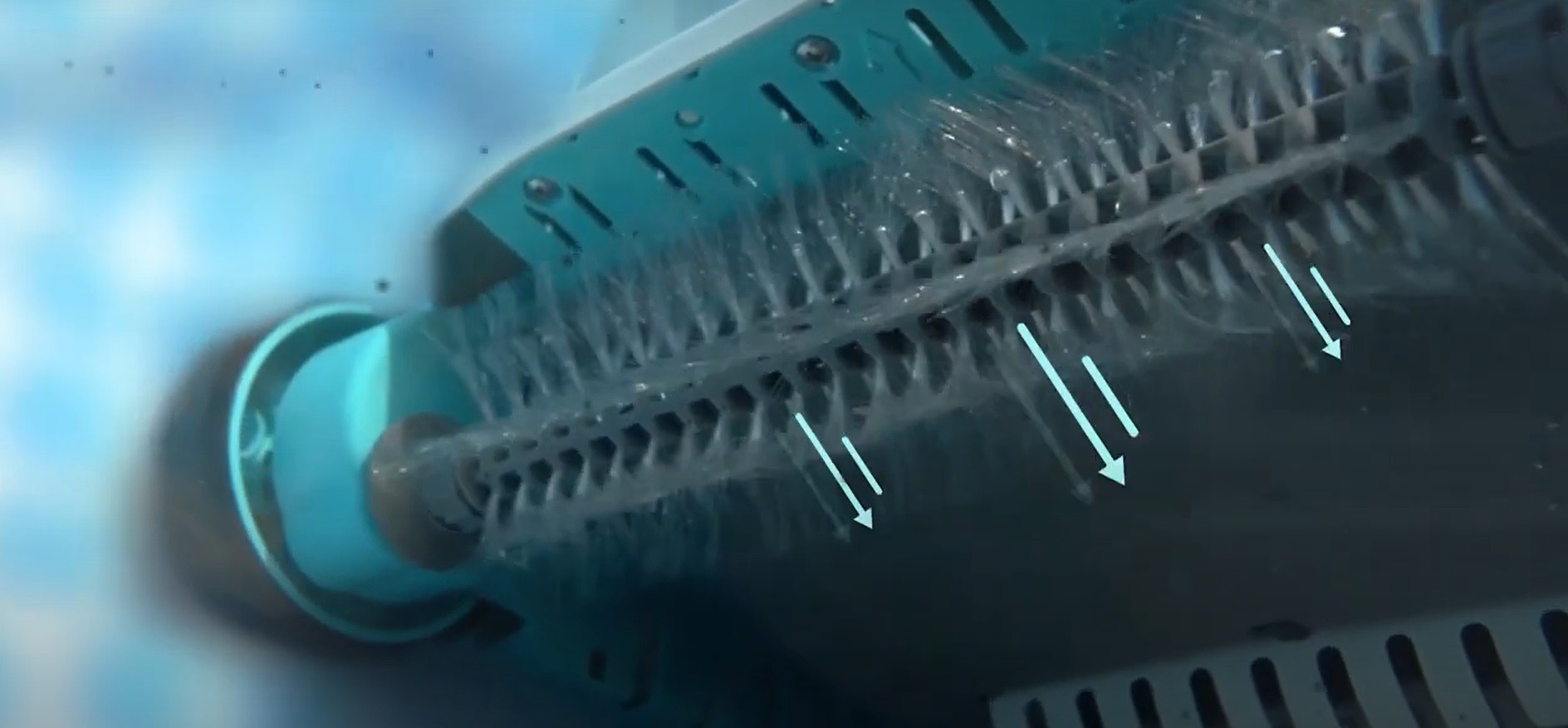

Для сбора мусора предусмотрено 2 валика-щетки.

Дополнительные виниловые элементы вставляются в специальный отсек. Эти щетки предназначены для сбора мелкого мусора. Устанавливается их также 2, но в комплекте предоставляются запасные.

Малый шаг фильтрующей сетки (0,15 мм) позволяет задерживать мелкие частицы и песок.

В емкость на 1,8 л помещается довольно много мусора, поэтому не придется прерывать рабочий процесс для очистки контейнера. Как правило, такого объема хватает на весь цикл уборки. После ее окончания снимите нижнюю панель пылесоса, это легко.

Далее удалите мусор из контейнера и промойте сетку водой.

5%скидка

Для читателей нашего блога

скидка 5% на весь

ассортимент

Ваш промокод:BLOGСмотреть все пылесосы

Заключение

Водный робот-пылесос Intex ZX300 28005 будет отличным помощником в чистке дна и стенок большого бассейна. Автоматический уборщик самостоятельно перемещается по чаше и меняет направление движения. Он не требует никакого вмешательства, кроме включения/отключения и промывания фильтра.

В комплект входит все необходимое. Источник питания не нужен — пылесос приводится в движение от напора воды, которая к нему поступает. Нейлоновые щетки продвигают мусор в нужном направлении, чтобы он всасывался в контейнер объемом 1,8 л.

Стоит отметить, что данный пылесос не предназначен для удаления налета со стенок резервуара, для этой цели понадобится специальная химия. Прибор будет особенно актуален для бассейнов на участке, расположенном рядом с лесом, так как в такой местности в воду попадает больше мусора, листьев и насекомых.

(178IO) ZX300 DELUXE AUTOMATIC POOL CLEANER ENGLISH SIZE: 4.875” X 7.25” PANTONE 295U 08/21/2020

178A

English

IMPORTANT

SAFETY RULES

Read, understand, and follow

all instructions carefully before

installing and using this product.

ZX300 Deluxe Automatic

Pool Cleaner

Don’t forget to try these other fine Intex products:

pools, pool accessories, inflatable pools and in-home

toys, airbeds and boats available at fine retailers or

visit our website.

Due to a policy of continuous product improvement,

Intex reserves the right to change specifications and

appearance, which may result in updates to the

instruction manual without notice.

OWNER’S MANUAL

©2020 Intex Marketing Ltd. — Intex Development Co. Ltd. — Intex Recreation

Corp.

All rights reserved/Tous droits réservés/Todos los derechos reservados/Alle

Rechte vorbehalten. Printed in China/Imprimé en Chine/Impreso en China/Gedruckt in China.

®™ Trademarks used in some countries of the world under license from/®™ Marques utilisées dans certains pays sous

licence de/Marcas registradas utilizadas en algunos países del mundo bajo licencia de/Warenzeichen verwendet in

einigen Ländern der Welt in Lizenz von/Intex Marketing Ltd. to/à/a/an Intex Development Co. Ltd., G.P.O Box

28829, Hong Kong & Intex Recreation Corp., P.O. Box 1440, Long Beach, CA 90801

durch/Intex Trading B.V., Venneveld 9, 4705 RR Roosendaal – The Netherlands

www.intexcorp.com 178-*A*-R0-2108

For illustrative purposes only.

Intex ZX300 Swimming Pool Vacuum PDF User Guides and Manuals for Free Download: Found (1) Manuals for Intex ZX300 Device Model (Quick Start Manual)

Intex ZX300 Quick Start Manual

Details:

- Manufacturer: Intex

- Product Name/ID: Intex ZX300 / #1909687

- Category: Swimming Pool Vacuum

- File Path: intex/zx300_1909687.pdf

- Last Updated: 22 May 2025

- Description: The Intex ZX300 manual offers essential guidance for mastering your device, including setup procedures, user interface navigation, and routine maintenance tips for optimal use.

- Document Type: User Manual

- Pages: 18

Download PDF

Read Online

The Intex ZX300 is a product that has garnered attention for its blend of innovation and user-friendly features, making it a suitable choice for various applications. Whether you are a professional looking for reliable equipment or a hobbyist seeking something tailored to your needs, the ZX300 stands out for its versatile capabilities and solid performance.

One notable aspect of the Intex ZX300 is its design. The sleek but functional build is both aesthetically pleasing and practical, ensuring that users can operate the product with ease. The thoughtful layout of buttons and controls allows even novices to get accustomed to its operations quickly. The ergonomic design not only contributes to comfort but also enhances usability during extended use.

Performance-wise, the Intex ZX300 impresses with its efficiency. Equipped with advanced features, it ensures that tasks are completed with minimal time and effort. The following are some key performance highlights:

- High Efficiency: The ZX300 boasts energy-saving technology that minimizes power consumption without compromising functionality.

- Durability: Crafted from high-quality materials, this product promises longevity and reliable performance over time.

- Multi-Functionality: The ZX300 is designed for a variety of applications, making it an all-in-one solution for users with diverse needs.

One of the most appealing features of the Intex ZX300 is its adaptability. Users have lauded its ability to cater to different environments and tasks, which is a significant advantage in today’s fast-paced world. From residential settings to commercial applications, it has proven itself to be a reliable choice.

In terms of ease of maintenance, the ZX300 shines brightly. With a user-friendly manual and straightforward maintenance procedures, users can easily handle routine upkeep. This aspect of the product is crucial, especially for those who may not have extensive technical skills. In effect, less time worrying about maintenance means more time to focus on productivity and satisfaction.

Moreover, customer support for the Intex ZX300 has received positive feedback. Should issues arise, the support team is responsive and helpful, smoothing the path for users when challenges occur. This reliable customer service adds significant value to the overall ownership experience, allowing users to feel secure in their purchase.

To summarize, the Intex ZX300 offers a compelling mix of design, performance, adaptability, and support. Here are some concluding thoughts:

- Pros:

- Stylish and practical design

- Energy-efficient performance

- Durable build quality

- Versatile for various applications

- Excellent customer support

- Cons:

- Initial learning curve for first-time users

- Higher upfront cost compared to basic alternatives

Overall, the Intex ZX300 is a wise investment for anyone in need of a dependable and efficient product. With its strengths significantly outweighing its minor drawbacks, this model deserves enthusiastic consideration. Users looking for quality and versatility will find the ZX300 meets their needs and expectations admirably.

FAQ: Types of Manuals and Their Contents

Intex ZX300 Manuals come in various types, each serving a specific purpose to help users effectively operate and maintain their devices. Here are the common types of Intex ZX300 User Guides and the information they typically include:

- User Manuals: Provide comprehensive instructions on how to use the device, including setup, features, and operation. They often include troubleshooting tips, safety information, and maintenance guidelines.

- Service Instructions: Designed for technicians and repair professionals, these manuals offer detailed information on diagnosing and repairing issues with the device. They include schematics, parts lists, and step-by-step repair procedures.

- Installation Guides: Focus on the installation process of the device, providing detailed instructions and diagrams for proper setup. They are essential for ensuring the device is installed correctly and safely.

- Maintenance Manuals: Provide guidance on routine maintenance tasks to keep the device in optimal condition. They cover cleaning procedures, part replacements, and regular servicing tips.

- Quick Start Guides: Offer a concise overview of the essential steps needed to get the device up and running quickly. They are ideal for users who need immediate assistance with basic setup and operation.

Each type of Intex ZX300 instruction is designed to address specific needs, ensuring users have the necessary information to use, maintain, and repair their devices effectively.

Related Instructions for Intex ZX300:

1

Krystal Clear 635T

Owner’s manual Intex Swimming Pool Filter Owner’s manual (File: intex-krystal-clear-635t-owner-s-manual-16, Saturday 08-03-2025)

16

261

42

2

CHALLENGER 3a

15

1046

199

3

PureSpa 128462

Quick start manual Intex PureSpa 128462 User Manual (Quick start manual), @83R4NH

2

427

90

4

Fast-Fill AP619C

3

1492

284

6

Quickfill Plus AP619D

6

809

130

7

28003

Owner’s manual #F7QJD7: 28003 Swimming Pool Vacuum Owner’s manual

10

202

35

8

Krystal Clear 604

16

507

122

9

ECO20110-2

Owner’s manual #1268VS: ECO20110-2 Water Filtration Systems Owner’s manual

36

944

180

10

Krystal Clear SF90220T

Owner’s manual Intex Water Pump Owner’s manual (File: intex-krystal-clear-sf90220t-owner-s-manual-112, 22.02.2025)

112

1201

265

Swimming Pool Vacuum Devices by Other Brands:

|

Hammerhead SERVICE-21 Operation & User’s Manual #RHANC1: SERVICE-21 Swimming Pool Vacuum Operation & user’s manual USER GUIDE 22 Apr 2025 | 14 |

|

|

Zodiac T3 Quick Start Manual T3 Quick start manual — M29GKB 0 1 2 3 4 5 6 30 Nov 2024 | 2 |

|

|

CPI Olympic Elix ACM-853 Manual #Y981QA: Olympic Elix ACM-853 Swimming Pool Vacuum Manual ~1~ 06 May 2025 | 8 |

|

|

TigrusELEC 45200 Installation And Maintenance Manual TigrusELEC 45200 User Manual (Installation and maintenance manual), @I358DC INSTALLATION AND MAINTENANCE MANUAL 13 Oct 2024 | 40 |

Categories:

Respiratory Product

Thermometer

Outdoor Cart

Sander

Safety Equipment

Medical Equipment