SERVICE MANUAL

SERVICE MANUAL

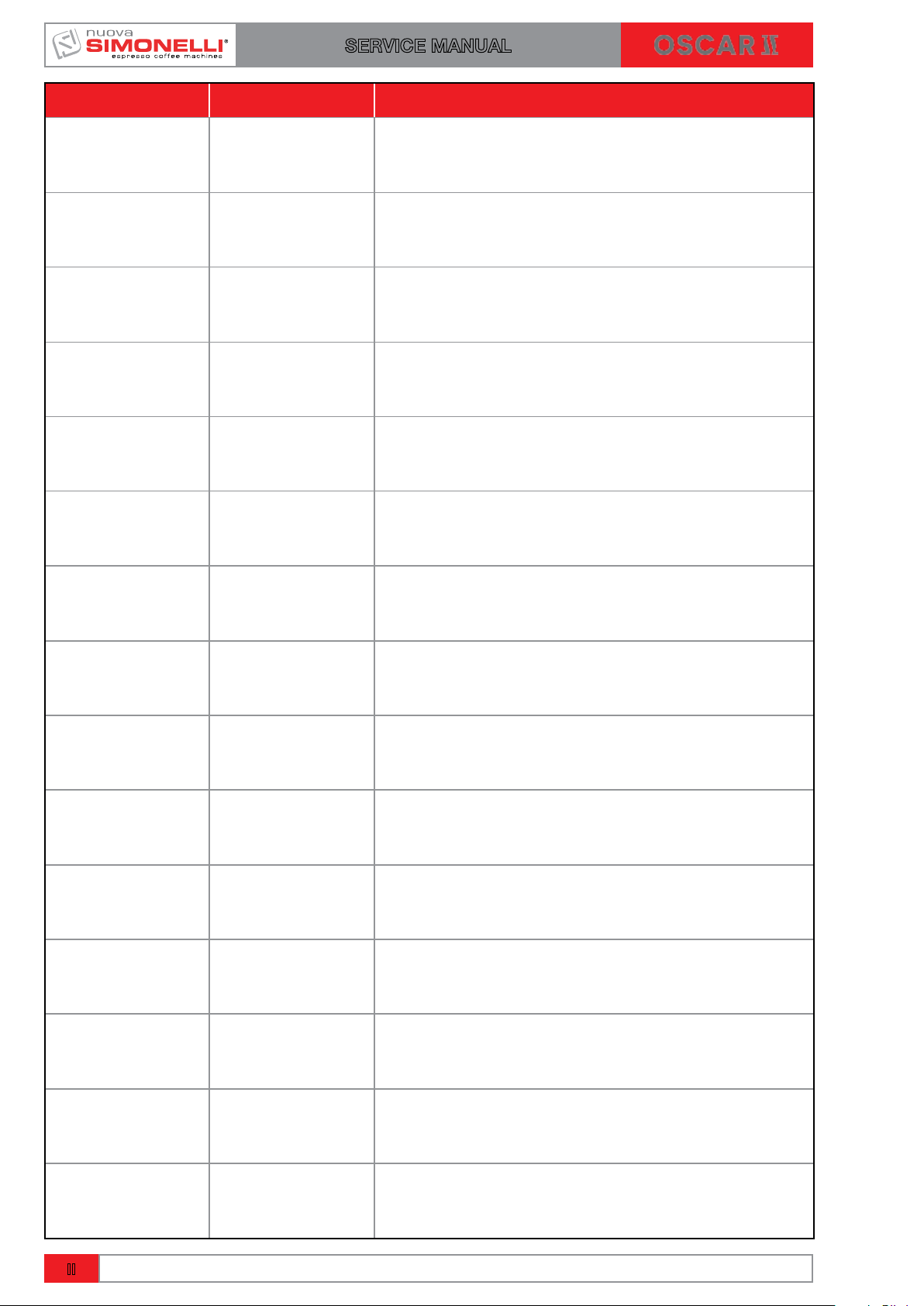

Edition Date Modifications

01 12/2015 First Edition

02 09/2016 Wiring diagram tank version updated

II

Ed. 02 of 09/2016

SERVICE MANUAL

MACHINE DESCRIPTION

FIRST INSTALLATION AND

PRELIMINARY OPERATIONS

REMOVAL OF THE EXTERNAL

SURFACE

INFUSION UNIT

HEATER

HYDRAULIC CIRCUIT

ELECTRIC COMPONENTS

TROUBLESHOOTING

1

2

3

4

5

6

7

8

DIAGRAMS

MAINTENANCE CHECKING

SPARE PART CATALOGUE

9

10

11

Ed. 02 of 09/2016

I

INDEX

SERVICE MANUAL

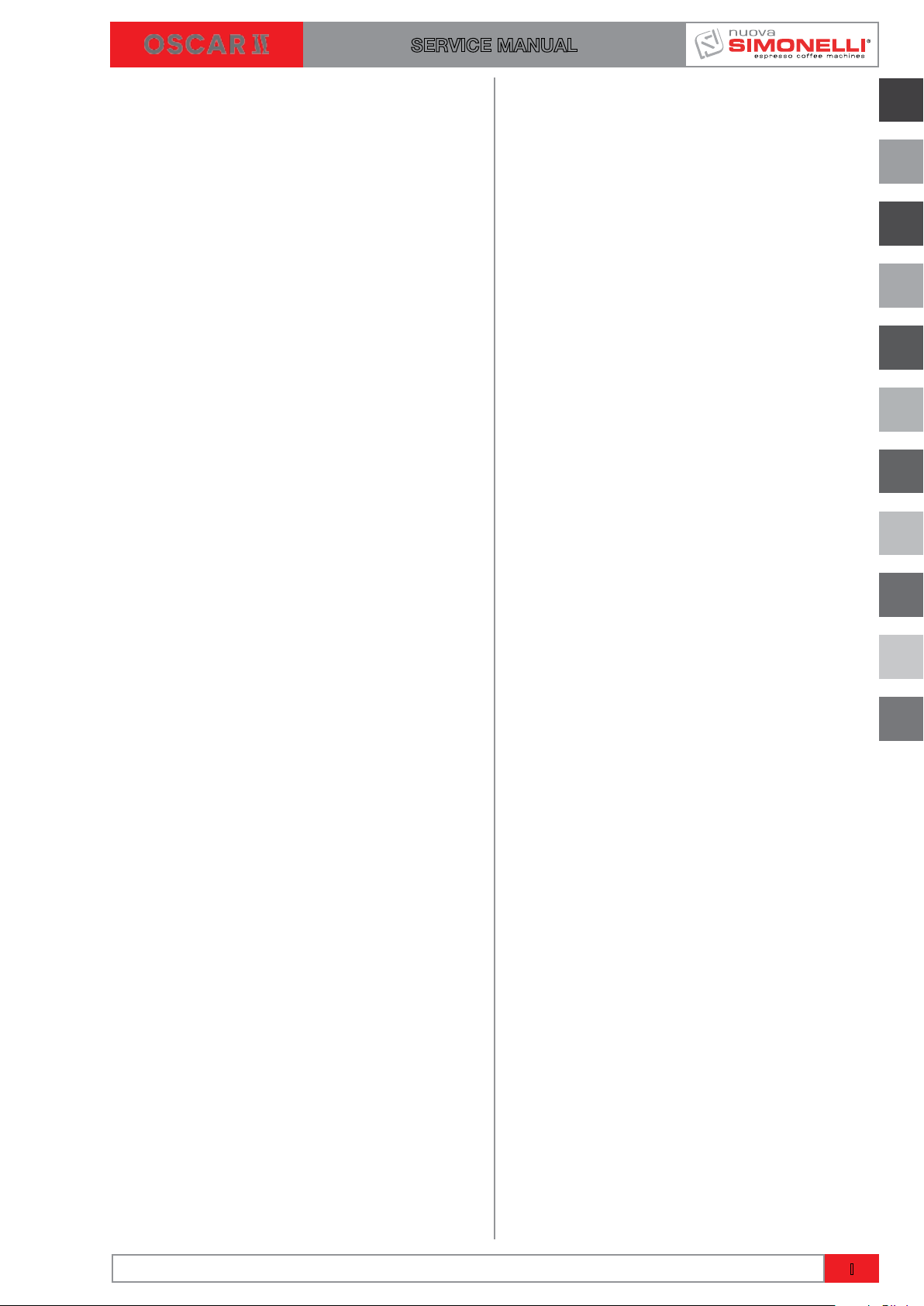

1. MACHINE DESCRIPTION ……..1.1

1.1 DESCRIPTION ……………….1.2

1.2 KEYBOARD DESCRIPTION

(Standard configuration)………..1.3

1.3 SAFETY REGULATIONS ………..1.4

1.4 MACHINE IDENTIFICATION ……..1.7

1.5 TRANSPORT ………………..1.8

1.5.1 HANDLING ………………1.8

2. FIRST INSTALLATION AND

PRELIMINARY OPERATIONS …..2.1

2.1 FIRST INSTALLATION ………….2.2

2.1.1 WEIGHT AND DIMENSIONS ….2.2

2.1.2 CONNECTION TO THE

WATERLINE AND DRAINAGE

SYSTEM ………………..2.3

2.1.3 TECHNICAL SPECIFICATIONS..2.4

2.1.4 CONNECTION TO THE POWER

LINE …………………..2.4

2.1.5 PROCEDURE OF FIRST

INSTALLATION……………2.4

2.2 ACCESSORIES BOX . . . . . . . . . . . . . . 2.5

2.2.1 FITTING THE FILTER HOLDER..2.5

2.3 PROGRAMMING DOSES ……….2.6

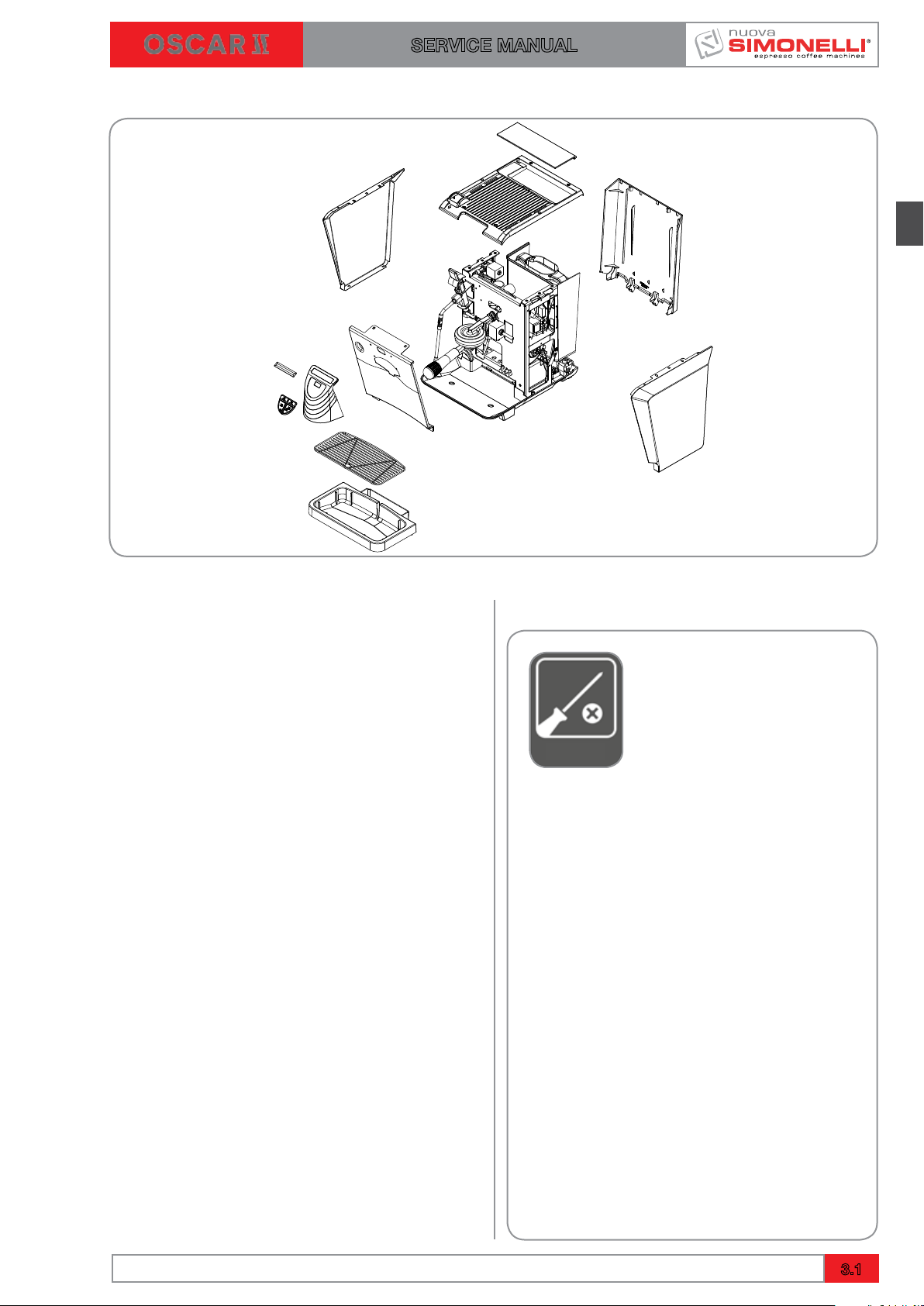

3. REMOVAL OF THE

EXTERNAL SURFACE ………..3.1

3.1 REMOVAL OF WATER TANK …….3.2

3.2 REMOVAL OF THE CUP

HOLDER SURFACE……………3.3

3.3 REMOVAL OF THE SIDE PANELS …3.4

3.4 REMOVAL OF THE REAR PANEL …3.4

3.5 TANK TO COLLECT WATER FILED ..3.4

3.6 REMOVAL OF THE FRONT PANEL ..3.5

3.6.1 REMOVAL OF KEYBOARD …..3.6

4. INFUSION UNIT …………….4.1

4.1 REMOVAL OF SHOWER

AND SEAL ………………4.2

4.2 COFFEE VALVE …………..4.3

4.3 EXPANSION VALVE ………..4.5

5. HEATER…………………..5.1

5.1 EMPTYING THE HEATER . . . . . . . . . . 5.2

5.2 REMOVAL OF THE HEATER ……..5.4

5.3 HEATING ELEMENT AND

HEAT PROTECTION …………..5.5

5.4 REPLACEMENT OF THE

LEVEL GAUGE ……………….5.6

5.5 ANTIVACUUM VALVE ………….5.7

5.6 SAFETY VALVE ………………5.8

6. HYDRAULIC CIRCUIT ………..6.1

6.1 PUMP DISASSEMBLY ………….6.2

6.2 REPLACING THE COFFEE VALVE …6.4

6.3 STEAM NOZZLE ……………..6.6

6.4 WATER TANK……………….6.11

6.4.1 REPLACEMENT OF

THE FLOAT……………..6.11

6.4.2 REMOVAL OF THE

MAGNETIC SENSOR………6.12

6.5 REMOVAL OF THE PRESSURE

SWITCH …………………..6.12

7. ELECTRIC COMPONENTS …….7.1

7.1 CONTROL UNIT………………7.2

8. TROUBLESHOOTING…………8.1

8.1 WATER LACK LIGHT…………..8.2

8.2 HEATING ELEMENT LIGHT ……..8.3

8.4 COFFEE DELIVERY ……………8.4

8.5 STEAM DELIVERY…………….8.4

8.6 HEATER ……………………8.5

9. DIAGRAMS ………………..9.1

9.1 HYDRAULIC DIAGRAM

TANK VERSION ………………9.2

9.2 HYDRAULIC DIAGRAM

DIRECT CONNECTION VERSION …9.3

9.3 WIRING DIAGRAM TANK VERSION..9.4

9.4 WIRING DIAGRAM DIRECT

CONNECTION VERSION………..9.5

10. MAINTENANCE CHECKING …..10.1

10.1 DAILY MAINTENANCE ………..10.2

10.2 WEEKLY MAINTENANCE ………10.2

10.3 YEARLY MAINTENANCE ………10.3

10.4 BIENNIAL MAINTENANCE ……..10.4

11. SPARE PART CATALOGUE ……11.1

11.1 CABINET PARTS …………….11.2

11.2 COMPLETE POURING UNIT ……11.3

11.3 TANK — FRAME COMPONENTS ….11.4

11.4 STOVE FILED COLLECT WATER …11.5

11.5 BOILER COMPONENTS ……….11.6

11.6 ELECTRICAL COMPONENTS …..11.7

Ed. 02 of 09/2016

III

SERVICE MANUAL

IV

Ed. 02 of 09/2016

1. MACHINE DESCRIPTION

SERVICE MANUAL

INDEX

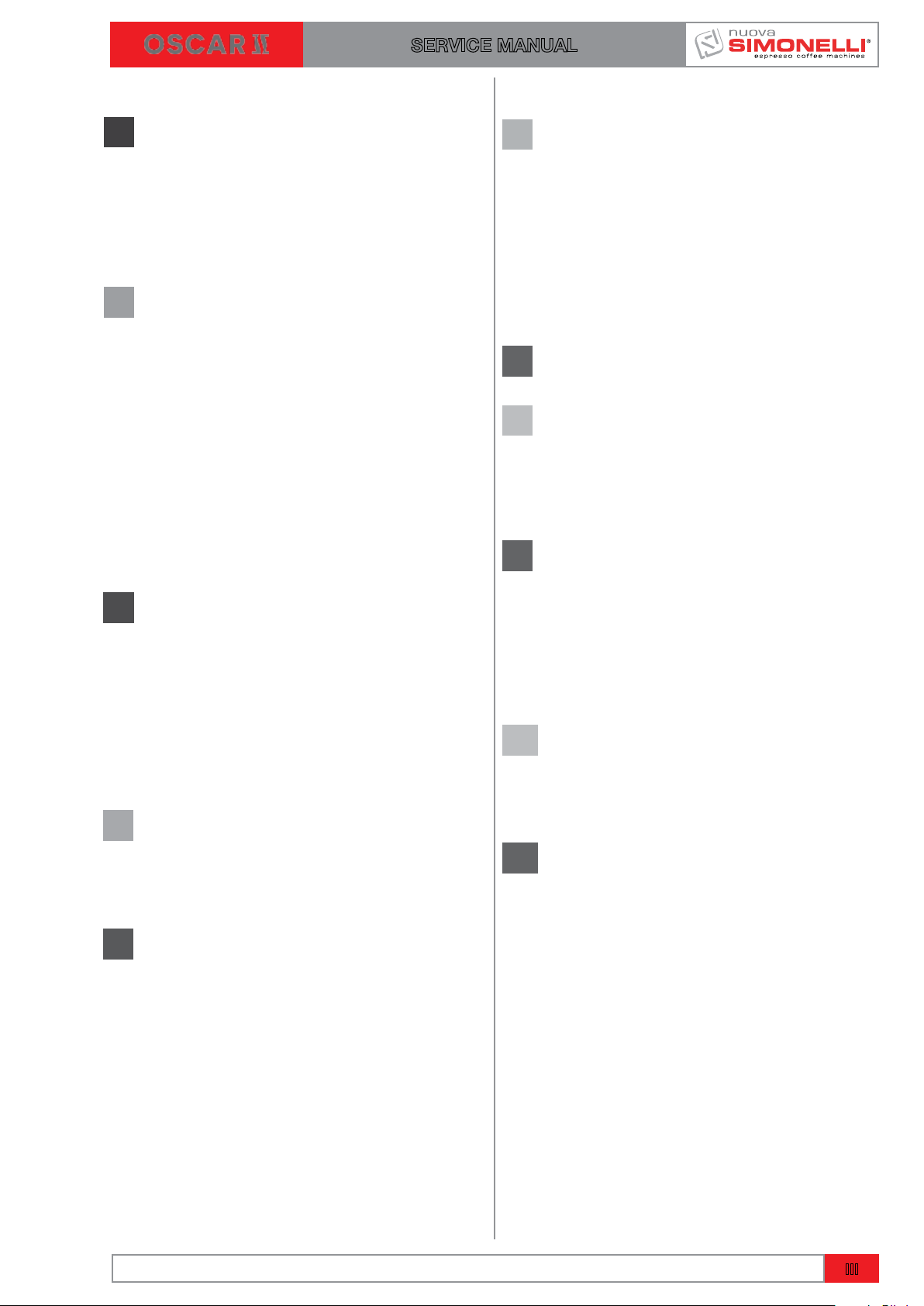

1. MACHINE DESCRIPTION ……..1.1

1.1 DESCRIPTION ……………….1.2

1.2 KEYBOARD DESCRIPTION

(Standard configuration)………..1.3

1.3 SAFETY REGULATIONS ………..1.4

1.4 MACHINE IDENTIFICATION ……..1.7

1.5 TRANSPORT ………………..1.8

1.5.1 HANDLING ………………1.8

Ed. 02 of 09/2016

1.1

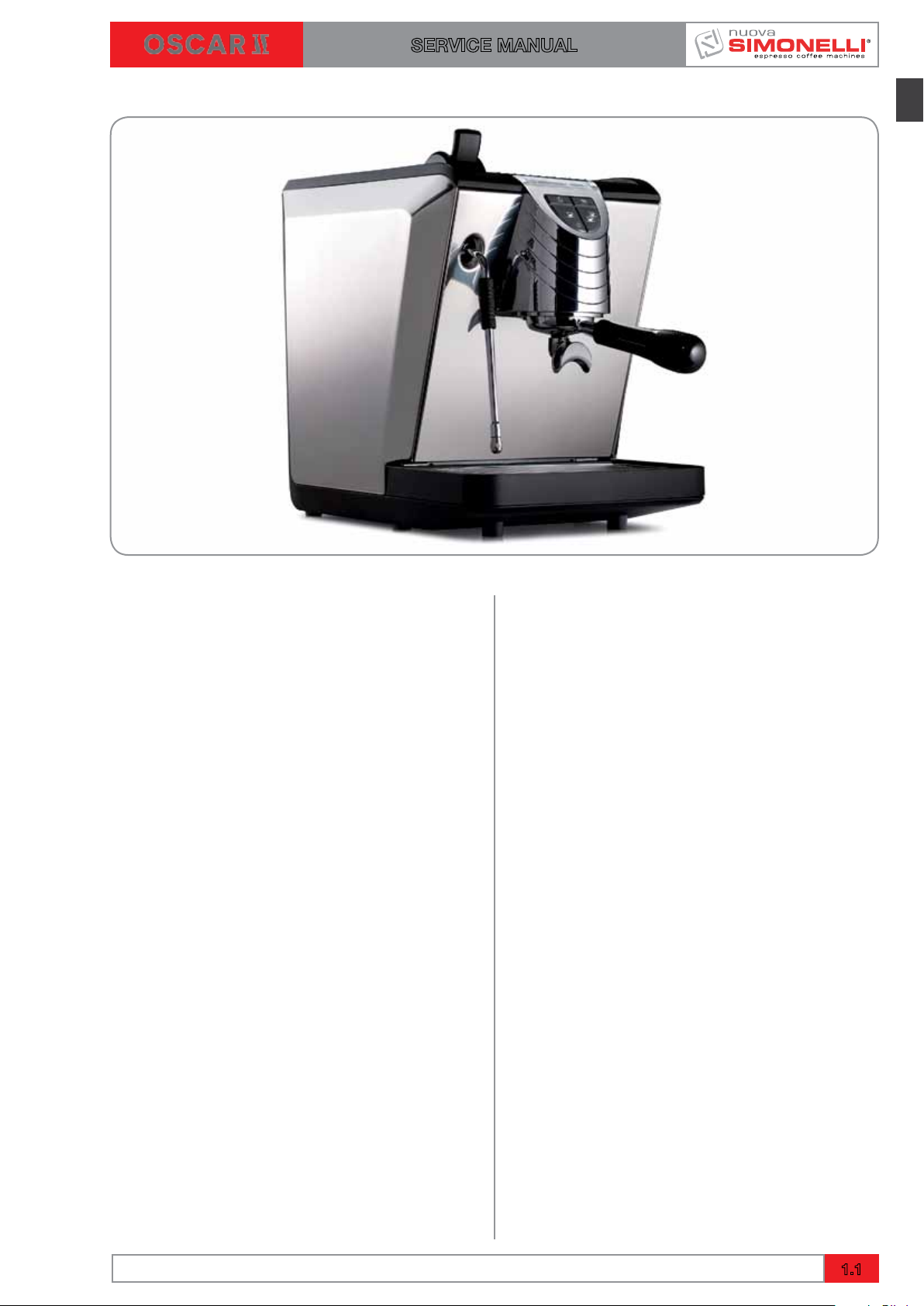

1.1 DESCRIPTION

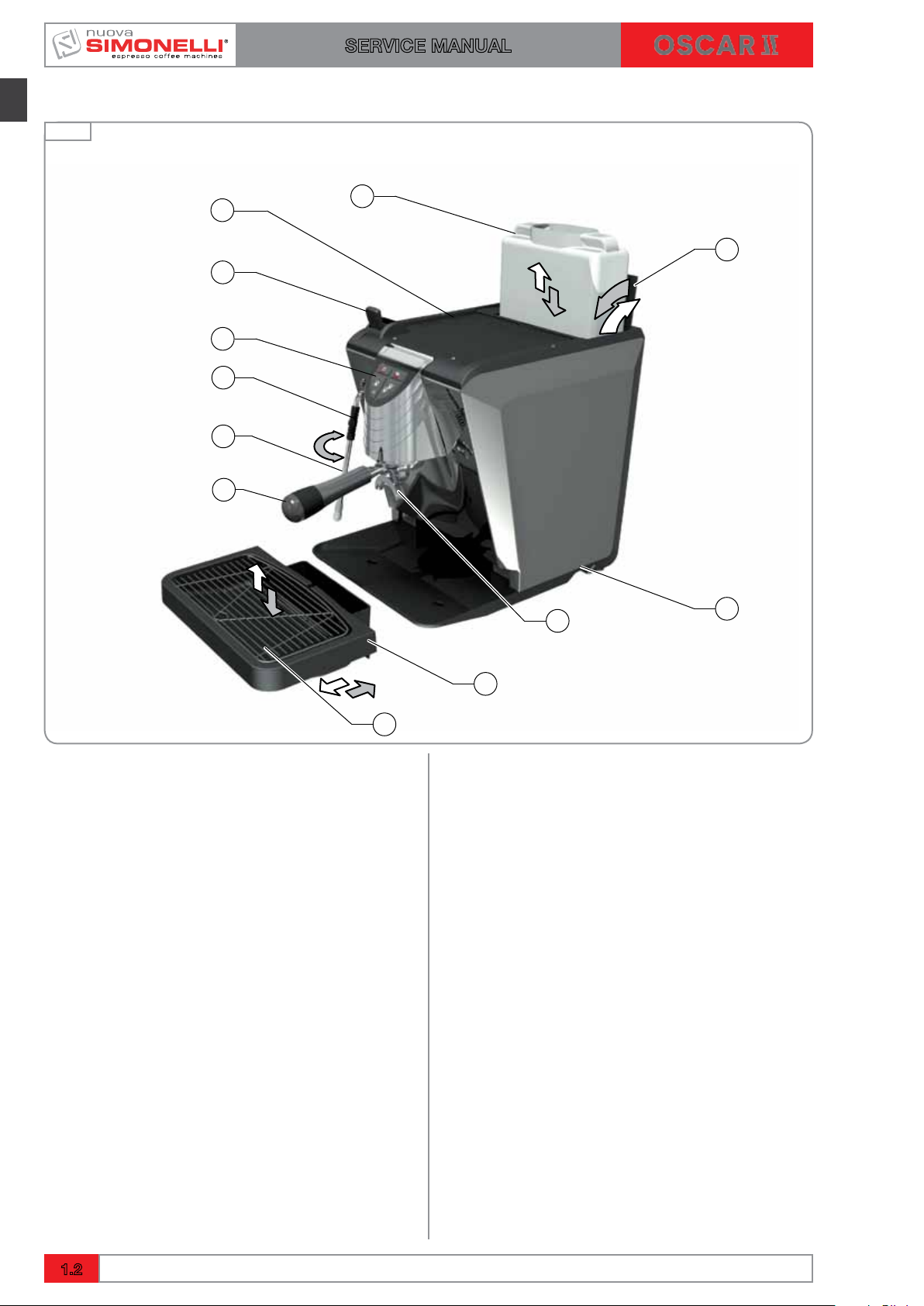

Fig. 1

SERVICE MANUAL

12

11

10

2

1

9

3

4

6

5

LEGEND

1 Steam lever

2 Cup warming grill

3 Water reservoir

4 Water reservoir hatch

5 Main switch

6 Dispensing unit

7 Water drain tank

8 Cup support grill

9 Filter holder

10 Steam wand

11 Steam wand insulating rubber

12 Control panel

7

8

1.2

Ed. 02 of 09/2016

SERVICE MANUAL

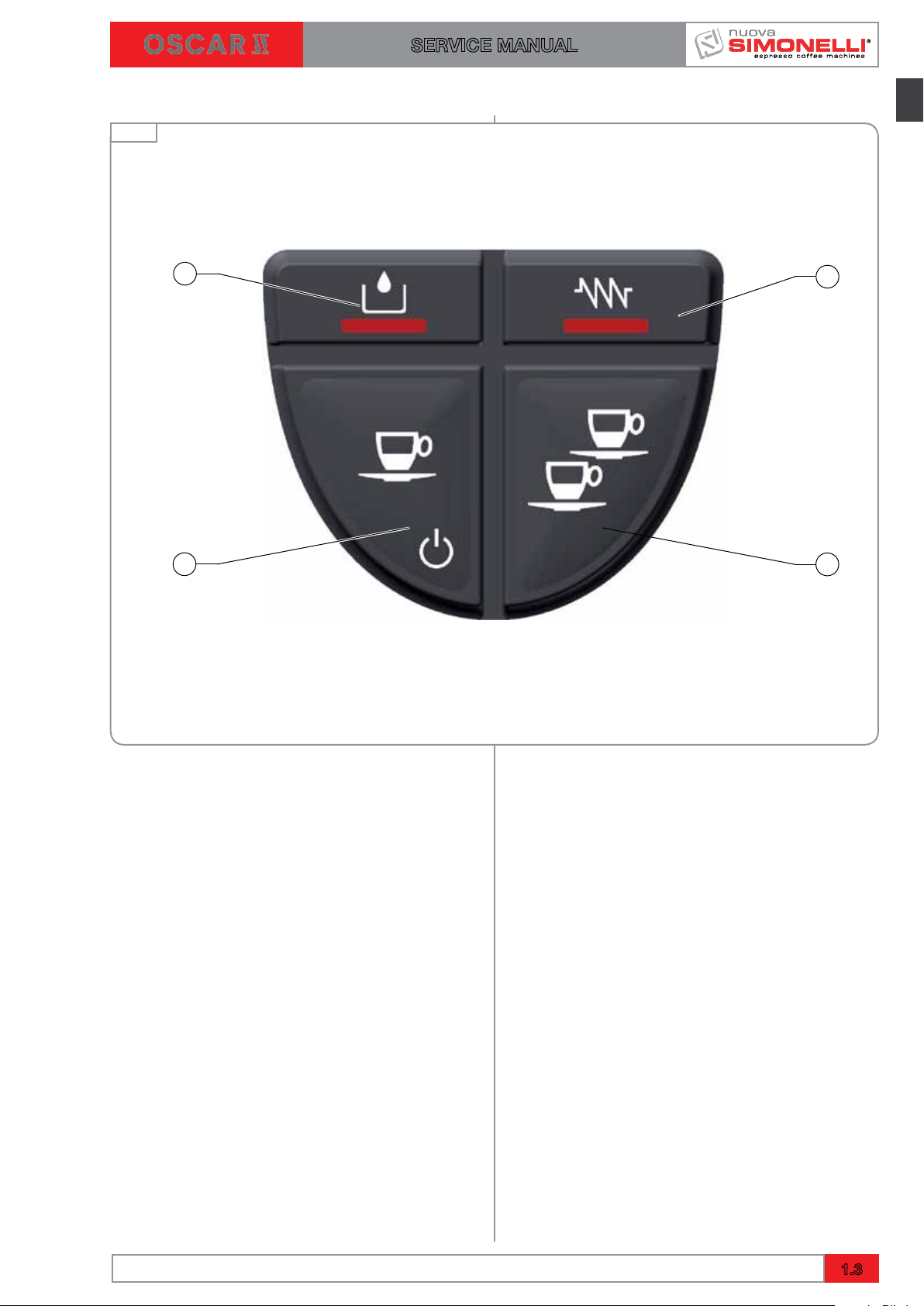

1.2 CONTROL PANEL DESCRIPTION (Configuration standard)

Fig. 2

1

4

2

3

LEGEND

1 Water level warning light

2 Heating resistance on warning light

3 Two coffee dispensing button / programming

entry

4 One coffee dispensing button / Standby

Ed. 02 of 09/2016

1.3

SERVICE MANUAL

1.3 SAFETY INDICATIONS

The present manual is an integral and essential part of the product and is to be delivered

to the user. Carefully read all warnings in

the manual as they provide important information required to install, use and maintain

the unit safely. Keep this manual in a safe

place for further consultation.

After having removed the packaging,

make certain that the unit is not damaged

in any way.

If you have any doubts, do not use the unit

and contact a professionally qualified person. Always keep all packaging (plastic

bags, polystyrene foam, nails, etc..) out of

the reach of children as they are a potential source of danger and never loiter the

environment with such materials.

DANGER OF POLLUTION

Fig. 3

The manufacturer cannot be held responsible for any damages incurred if the system is not grounded.

For electrical safety, this machine requires

a ground system. Contact a technically

certified electrician who must check that

the line electrical capacity is adequate for

the maximum capacity indicated on the

unit label.

Fig. 4

The qualified electrician must also check

that the section of the installation’s cables

is large enough for the absorbed power of

the appliance.

Never use adapters, multiple jacks or extension cords. When such items prove absolutely necessary, call in a qualified electrician.

The machine is can be installed in staff

kitchen areas in shops, offices and other

working environments, farm houses by

clients in hotels, motels and other residential type environments bed and breakfast type environments.

Before turning on the unit make certain

that the rating indicated on the label

matches the available power supply. The

nameplate can be seen inside the machine

when removing the water collection tray.

The machine must be installed according

to the applicable federal, state and local

standards (codes) in force with regard

to plumbing systems including backflow

prevention devices. For this reason, the

plumbing connections must be carried

out by a qualified technician.

The warranty expires if the characteristics

of the power supply do not correspond to

the nameplate data.

When installing the device, it is necessary

to use the parts and materials supplied with

the device itself. Should it be necessary to

use other parts, the installation engineer

needs to check their suitability for use in

contact with water for human consumption.

The installer must Make the hydraulic connections respecting the rules of hygiene

and water safety to environmental protection in force in the place of installation. So

for the hydraulic plant contact an authorized technician. Always utilise the new

hose supplied for connection to the water

supply. Old hoses must not be utilised.

The device needs to be supplied with

water that is suitable for human consumption and compliant with the regulations

in force in the place of installation. The

installation engineer needs confirmation

from the owner/manager of the system

that the water complies with the requirements and standards stated above.

This unit must only be used for the purposes described in the present manual.

The manufacturer cannot be held responsible for any damages caused by improper, mistaken and unreasonable use.

1.4

Ed. 02 of 09/2016

SERVICE MANUAL

The appliance is not to be used by children

or persons with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction.

Children must not play with the appliance.

Cleaning and maintenance must not be

carried out by children unless supervised.

This appliance is for professional use only.

The operating temperature must be within

the range of [+5, +35]°C.

At the end of installation, the device is

switched on and taken to rated operating

conditions, leaving it in a state in which it

is “ready for operation”.

After reaching the “ready for operation”

condition, the following dispensing operations are carried out:

• 100% of the coffee circuit through the

coffee dispenser (for more than one

dispenser, this is divided equally);

• Open the steam outlet for 1 minute.

Fig. 5

Fig. 6

At the end of installation, it is good practice to draw up a report of the operations.

CAUTION

Before using the machine, read this manual in its entirety or, at the very least, read

the safety and set up instructions.

There are some basic rules for the use of

any electrical appliance.

In particular:

• Never touch the unit with wet hands or

feet;

• Never use the unit with bare feet;

• Never use extension cords in areas

equipped with baths or showers;

• Never pull on the power supply cord to

unplug the unit;

• Never leave the unit exposed to atmospheric agents (rain, direct sunlight, etc.);

• Never let children, unauthorized personnel or anyone who has not read this

manual operate the unit.

Before performing any sort of maintenance, the authorized technician must

turn off the unit and unplug it from the

mains.

Before cleaning the unit set it in a state of

«0» energy: that is, «MACHINE SWITCHED

OFF AND UNPLUGGED». Follow the

instructions given in this manual carefully.

Refer to chapters 6 and 7 for periodical

cleaning and maintenance. The authorized technician must, before carrying out

any maintenance, disconnect the plug

after the switch off of the machine.

In case of breakdown or poor function,

turn off the unit. Never tamper with the

unit. Contact only professionally qualified

personnel.

Only the manufacturer or an authorized

service center can make repairs and only

using original spare parts.

Non compliance with the above can compromise machine safety.

On installation, the qualified electrician

must fit a circuit breaker switch as foreseen by the safety norms in force that has

a contact open distance that permits the

complete disconnection under conditions

of overload category III.

Ed. 02 of 09/2016

1.5

SERVICE MANUAL

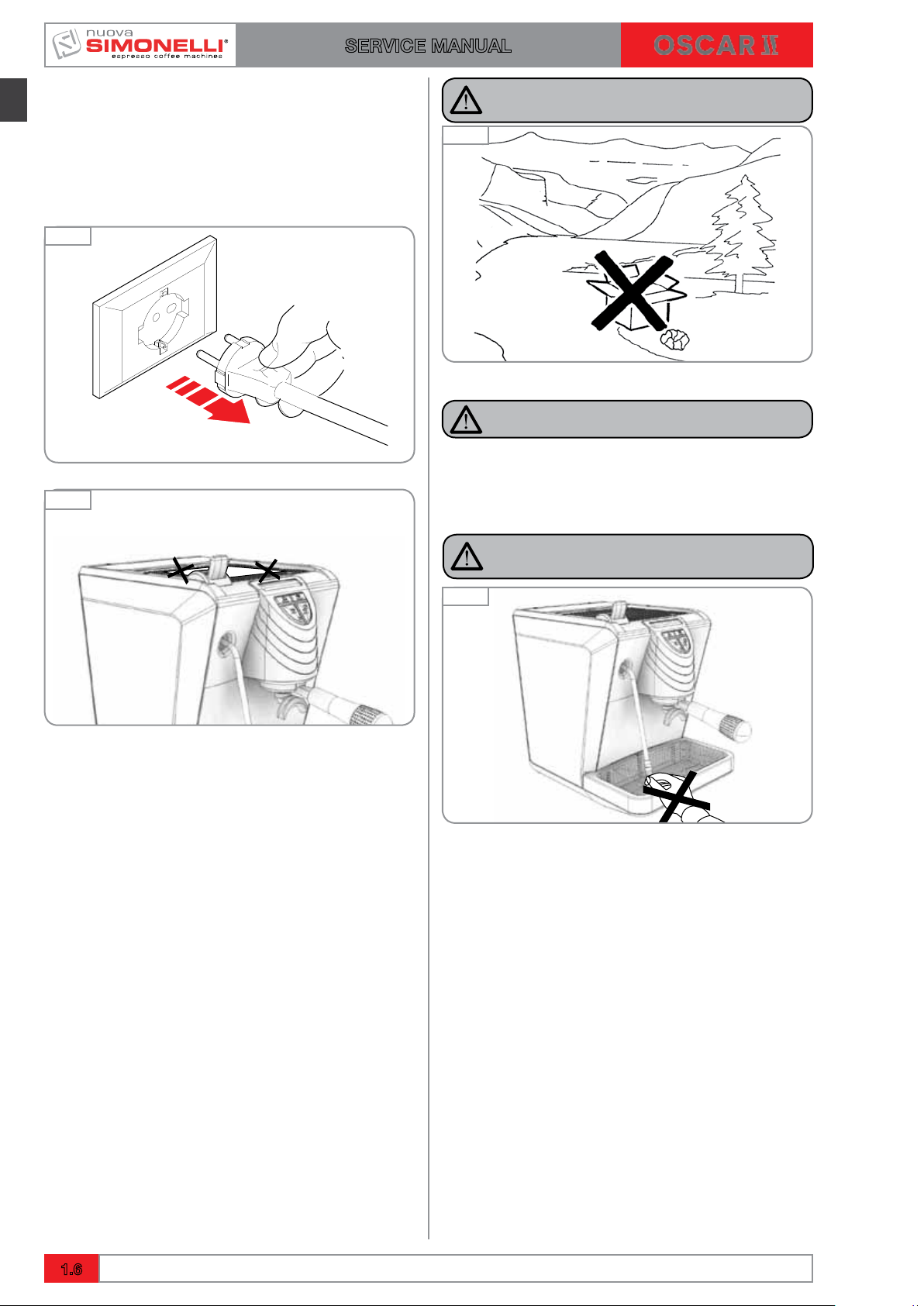

To prevent dangerous overheating, it is

advisable to fully extend the power supply

cord.

Never block the intake and/or heat dissipation grills, in particular those for the

cup warmer.

Fig. 7

OK

Fig. 8

WARNING

DANGER OF POLLUTION

Fig. 9

DANGER OF INTOXICATION

Once started the washing machine, do

not interrupt, the detergent residue may

remain inside the delivery unit.

The user must never replace the unit’s

power supply cord. If this cord is damaged, turn off the unit and have it replaced

by a professionally qualified technician.

Should it be necessary to replace the

power cord, this replacement operation

must only be performed by an authorized

service centre or by the manufacturer.

Should you decide to stop using this type

of unit, we suggest you render it inoperable by unplugging it and cutting the power

supply cord.

Do not throw the machine in nature for the

Elimination contact an authorized center or

contact the manufacturer who will provide

you the necessary information about it.

Never dispose of the machine in the environment: to dispose of the machine, contact an authorized center or contact the

manufacturer for pertinent indications.

CAUTION

DANGER OF BURNS

Fig. 10

To facilitate aeration of the unit, position

the aeration portion of the machine 15 cm

from walls or other machinery.

Be extremely careful when using the steam

nozzle. Never place your hands under the

nozzle and never touch it right after use.

Remember that to install, maintain, unload

and regulate the unit, the qualified operator must always wear work gloves and

safety shoes.

When adding the coffee, the operator must

never put his hands into the container.

The noise level of the machine is less than

70db.

1.6

Ed. 02 of 09/2016

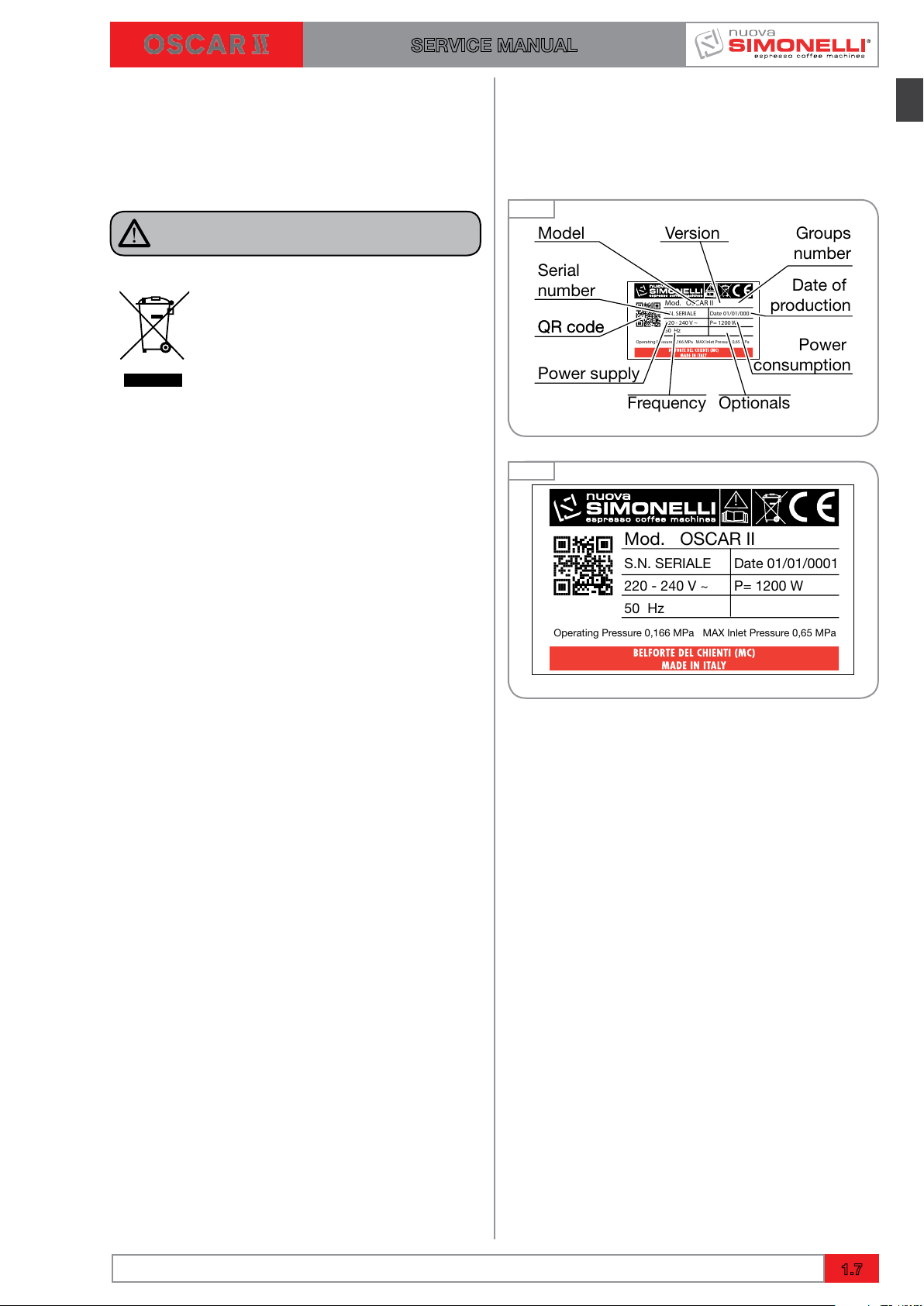

!

Mod. OSCAR II

S.N. SERIALE

220 — 240 V ~

50 Hz

Operating Pressure 0,166 MPa MAX Inlet Pressure 0,65 MPa

Date 01/01/0001

P= 1200 W

QR code

Version

Model

Serial

number

QR code

Power supply

Frequency Optionals

Groups

number

Date of

production

Power

consumption

!

Mod. OSCAR II

S.N. SERIALE

220 — 240 V ~

50 Hz

Operating Pressure 0,166 MPa MAX Inlet Pressure 0,65 MPa

Date 01/01/0001

P= 1200 W

SERVICE MANUAL

For machines connected to the mains

water supply, the minimum pressure must

be 2 bar and the maximum pressure

for correct machine operation must not

exceed 4 bar.

CAUTION

INFORMATION TO THE USERS

Under the senses of art. 13 of

Law Decree 25th July 2005,

n. 151 «Implementation of the

Directives/Guidelines 2002/95/

CE, 2002/96/CE and 2003/108/

CE, concerning the reduction

of the use of dangerous substances in electric and electronic equipment, as well as

the disposal of wastes».

1.4 MACHINE IDENTIFICATION

Always quote the machine serial number in all

communications to the manufacturer, Nuova

Simonelli.

Fig. 11

Fig. 12

The symbol of the crossed large rubbish container that is present on the machine points out

that the product at the end of its life cycle must

be collected separately from the other wastes.

The user for this reason will have to give the

equipment that got to its life cycle to the suitable

separate waste collection centres of electronic

and electro-technical wastes, or to give it back

to the seller or dealer when buying a new equipment of equivalent type, in terms of one to one.

The suitable separate waste collection for the

following sending of the disused equipment to

recycling, the dealing or handling and compatible environment disposal contributes to avoid

possible negative effects on the environment and

on the people’s health and helps the recycling of

the materials the machine is composed of. The

user’s illegal disposal of the product implies the

application of administrative fines as stated in

Law Decree n.22/1997” (article 50 and followings

of the Law Decree n.22/1997).

The machine internet page can be accessed

directly through the QR code.

By downloading and installing one of the apps to

read such codes on a mobile device.

Start the app and position the camera in front of

the code so that it can be clearly seen.

Wait some time while the app processes the result

and shows the internet page of the machine on

the display.

Ed. 02 of 09/2016

1.7

SERVICE MANUAL

1.5 TRANSPORT

The machine is transported on pallets which

also contain other machines — all boxed and

secured to the pallet with supports.

Before carrying out any transport or handling

operation, the operator must:

• putonworkglovesandprotectivefootwear,

as well as a set of overalls which must be

elasticated at the wrists and ankles.

The pallet must be transported using a suit-

able means for lifting (e.g., forklift).

1.5.1 HANDLING

WARNING

COLLISION OR CRUSHING HAZARD

During the entire handling operation, the operator must make sure no one or nothing is inside

the operating area.

Slowly lift the pallet to about 30 cm from the

ground and move to the loading area. After

making sure there are no obstacles, persons or

things, proceed with loading.

Once at destination, always using an adequate

lifting mechanism (e.g. fork-lift), after making

sure there is no one or nothing within the unloading area, lower the pallet to about 30 cm from the

ground and transport it to the storage area.

WARNING

COLLISION OR CRUSHING HAZARD

Before performing the following operation, make

sure the load is in place and is not likely to fall

when the straps are cut.

The operator, wearing safety gloves and footwear, must now cut the straps and store the

product. To perform this operation, check the

technical characteristics of the product to determine the weight of the machine to be stored and

take consequent precautions.

1.8

Ed. 02 of 09/2016

SERVICE MANUAL

2. FIRST INSTALLATION AND PRELIMINARY OPERATIONS

INDEX

2. FIRST INSTALLATION AND

PRELIMINARY OPERATIONS …..2.1

2.1 FIRST INSTALLATION ………….2.2

2.1.1 WEIGHT AND DIMENSIONS ….2.2

2.1.2 CONNECTION TO THE

WATERLINE AND DRAINAGE

SYSTEM ………………..2.3

2.1.3 TECHNICAL SPECIFICATIONS..2.4

2.1.4 CONNECTION TO THE POWER

LINE …………………..2.4

2.1.5 PROCEDURE OF FIRST

INSTALLATION……………2.4

2.2 ACCESSORIES BOX . . . . . . . . . . . . . . 2.5

2.2.1 FITTING THE FILTER HOLDER..2.5

2.3 PROGRAMMING DOSES ……….2.6

Ed. 02 of 09/2016

2.1

2.1

SERVICE MANUAL

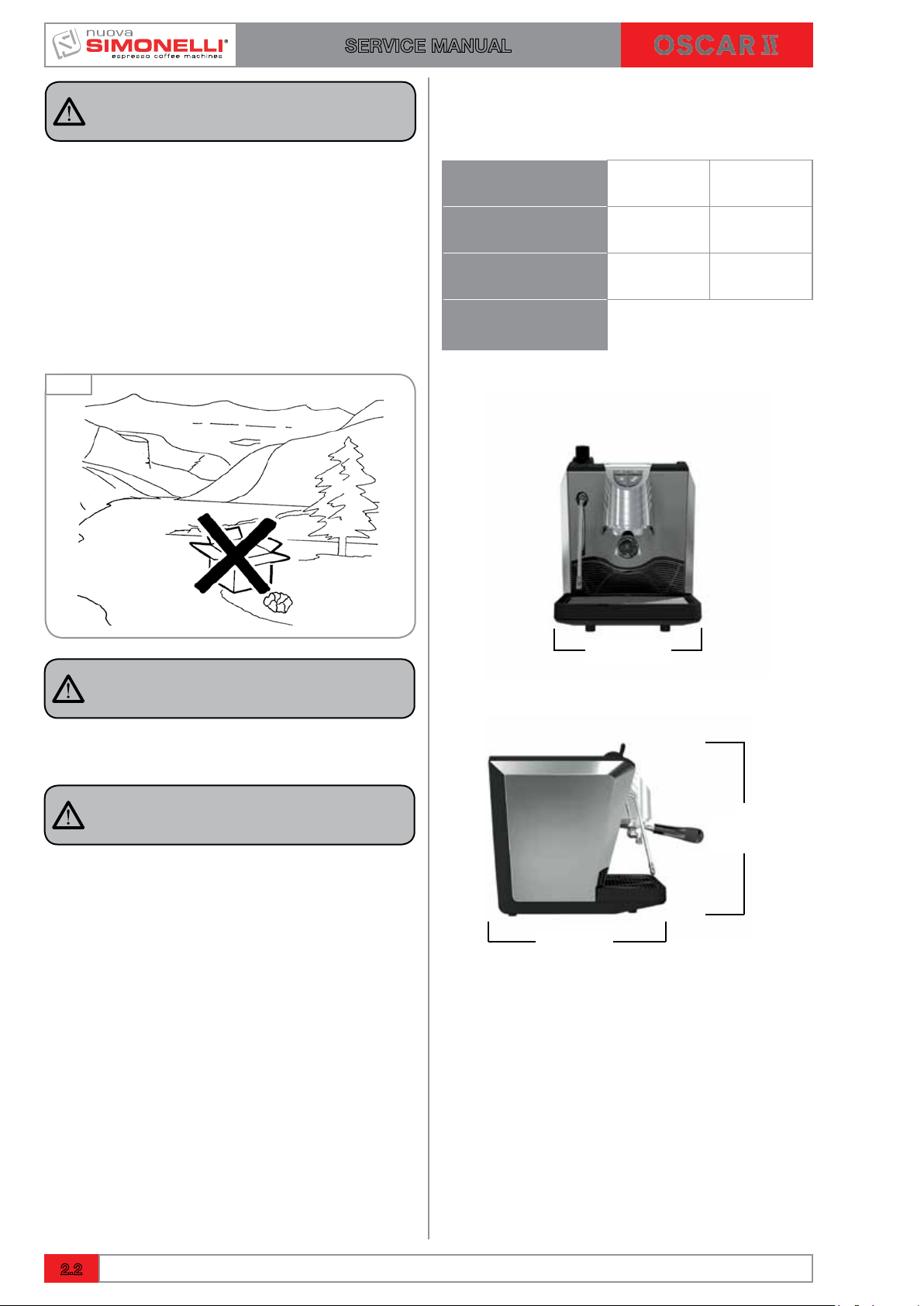

RISK OF POLLUTION

DO NOT DISPOSE PACKAGING in the environment.

2.1 FIRST INSTALLATION

2.1.1 WEIGHT AND DIMENSIONS

NET WEIGHT 14 kg 31 lb

Prior to installation please carefully read the

safety instructions in this manual. The company

cannot be held responsible for damage to persons or property arising from non-compliance

with safety regulations, either during installation

or maintenance of the machine described in this

manual.

Fig. 13

GROSS WEIGHT 17 kg 37 lb

POWER 1200 W 1200 W

DIMENSIONS

A

300 mm 12”

WARNING

Place the machine in an area where all risks of

malfunction can be avoided.

WARNING

Never install in areas where the machine may

be subject to jets of water.

C

400 mm

15,8”

B

408 mm

16”

2.2

Ed. 02 of 09/2016

SERVICE MANUAL

2.1.2 CONNECTION TO THE WATERLINE

AND DRAINAGE SYSTEM

The machine requires stringent specifications to

prevent the formation of limescale and to ensure

quality beverages. The main features required to

achieve high standards of performance are the

following:

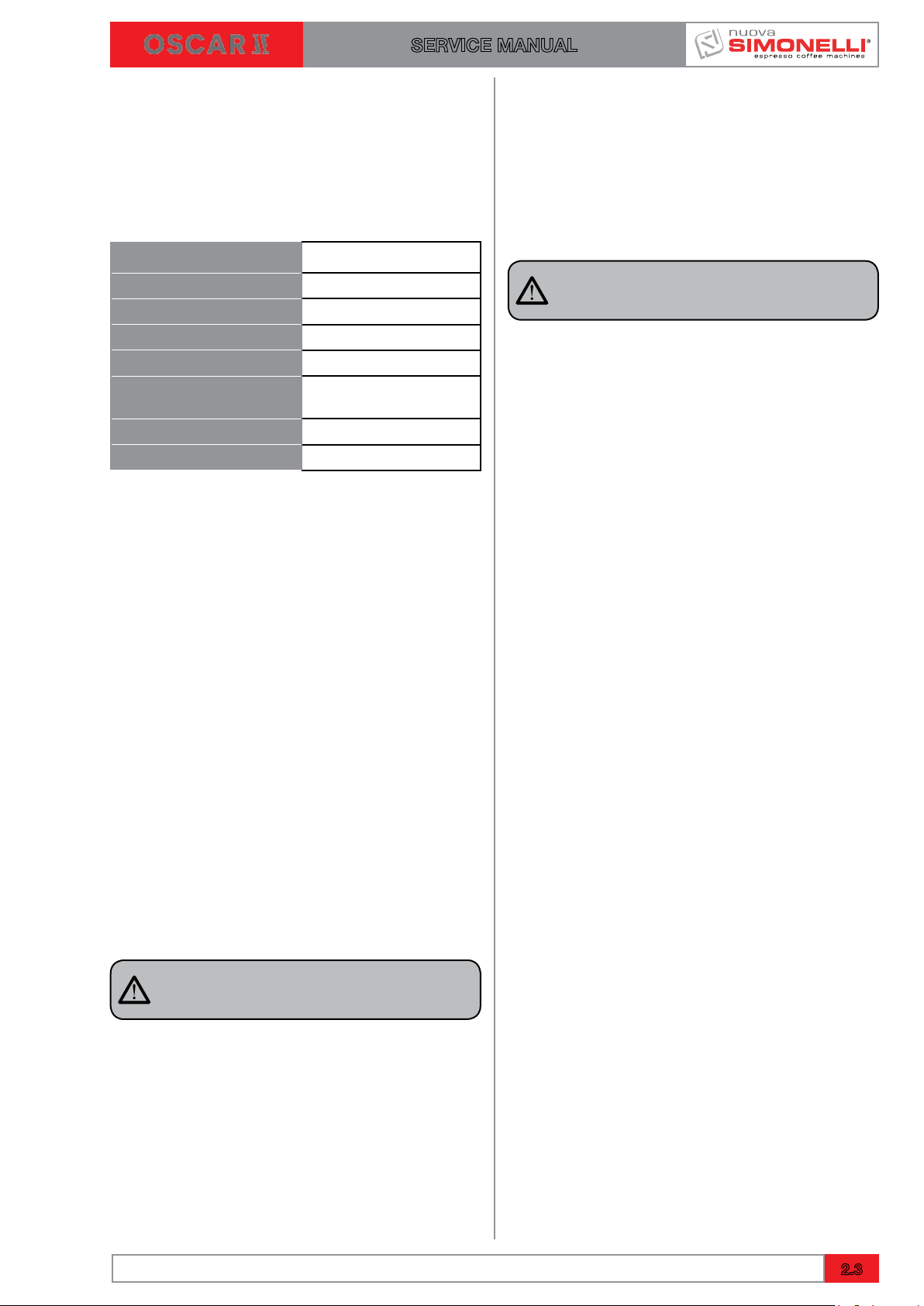

Total hardness

50 -60 ppm

Waterline pressure 2-4 bar, cold water

Minimum flow 200 l/hr

Filtration Less than 1.0 micron

Alkalinity

Total dissolved salts

10-150 ppm

50 -100 mg/L

(TDS)

Chloride < 0.5 mg/L

pH 6.5- 8.5

It is the task of a qualified technician to:

1 Adapt the water from the waterline to the

specifications required using filters and

water softeners;

2 Train the final user so that the equipment for

water treatment is constantly kept perfectly

operational.

The version with direct coupling is provided with

a loading tube 1,5 meters long with a 3/4 inch.

On one side is the fitting is straight and tapered,

the other angled at 90° with a gasket. The tube

is provided with tapered fittings therefore it is not

necessary to use Teflon tape on the fitting.

WARNING

If the water features do not comply, the warranty will automatically expire.

To connect the machine to the waterline, proceed as follows:

1 Remove the pipe from the upper door “A”

and connect one of its ends to fitting “B”

situated on machine base.

2 Connect the other end of the pipe to the

waterline using a 3/8 fitting.

NOTE

Dirty water drainage is carried out through the

drip tray both for version with connection to the

waterline and with tank.

Ed. 02 of 09/2016

2.3

SERVICE MANUAL

2.1.3 TECHNICAL SPECIFICATIONS

The machine is available in the following versions:

• single-phase 120 V 60 Hz (tank and waterline)

• single-phase 230 V 50 Hz (tank and waterline)

• single-phase 230 V 60 Hz (waterline)

The relative power absorbed is indicated on the

machine plate.

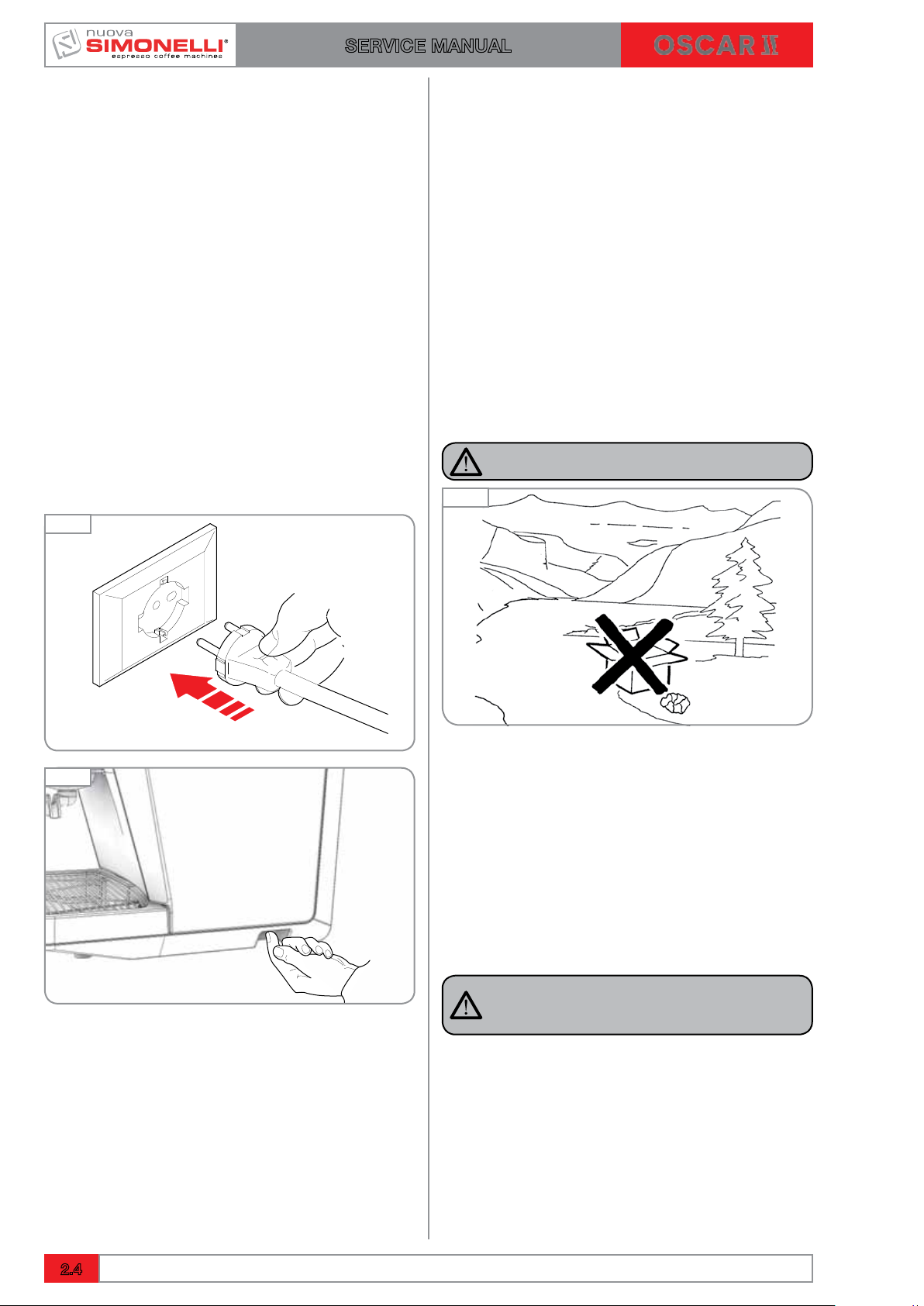

2.1.4 CONNECTION TO THE POWER LINE

Before utilising the machine, the operator must

have read and fully understood the safety instructions in this manual.

Connect the machine to the power socket.

The machine carries out the following checks.

Fig. 14

2.1.5 PROCEDURE OF FIRST

INSTALLATION

Before carrying out the installation carefully read

the safety instructions at the beginning of this

manual and particularly about how to put THE

MACHINE INTO ZERO ENERGY STATUS.

1 Once the machine has been removed from

the packaging, position it on a horizontal

surface and proceed with the installation as

illustrated in the following paragraphs.

Arrange the accessories as follows:

2 Insert the ring in its seat inside the filter

holder.

3 Insert one of the two filters.

4 Caution: danger of pollution.

DANGER OF POLLUTION

Fig. 16

Fig. 15

OK

Tank Model:

5 Open the hatch and take out the reservoir.

Especially the first time, wash the reservoir

with soap and water. Fill the reservoir with

water and make certain that the outside of

the reservoir is dry.

6 Return the reservoir to its housing and close

the hatch.

7 Make certain that the water drain tank has

been inserted.

NOTE

If the machine does not have enough water in the

tank or the pump stays on for more than 90 seconds, the machine will stop and all the buttons

flash. Getting on and off the machine: operation

of the filling boiler will run until the appropriate

level.

2.4

Ed. 02 of 09/2016

SERVICE MANUAL

NOTE

In the absence of load water at first boot:

1 Could be created air bubble between the

pump and reservoir and is preventing the

passage of water.

2 Make sure that the tank valve is working.

3 Remove and replace the tank filled with

water several times to facilitate removal of

the air bubble.

Direct attachment version:

5 Open the door of the tank and remove the

hose for direct attachment.

6 Connect the hose to the water supply and

open the tap upstream of the machine if present.

7 Make certain that the water drain tank has

been inserted.

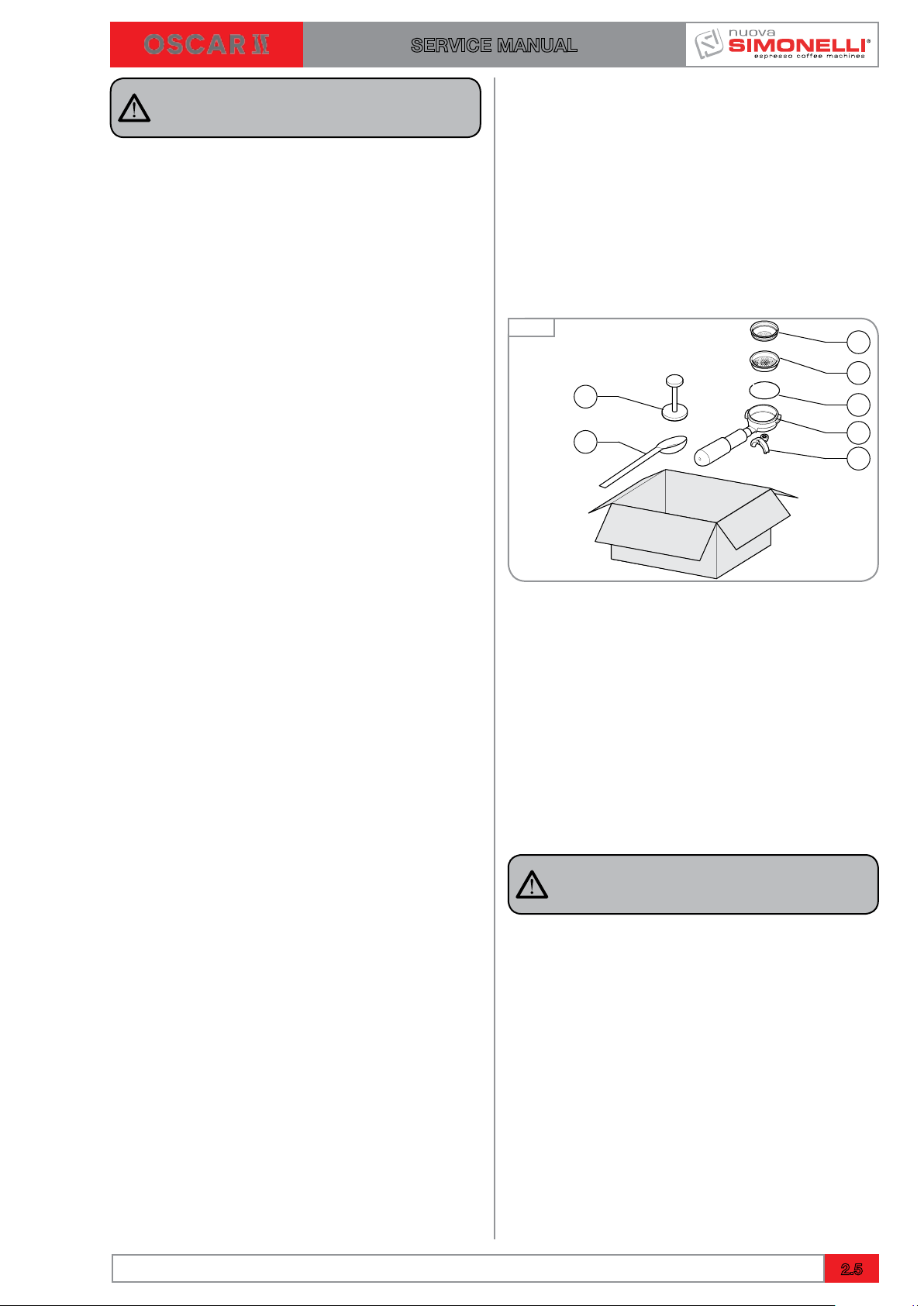

2.2 ACCESSORIES BOX

Machine is supplied with an accessories box

consisting of:

1 Single filter

2 Double filter

3 Spring

4 Filter holder

5 Dispensing nozzle

6 Coffee doser

Fig. 17

7

6

1

2

3

4

5

Make certain that the cup support grill is positioned squarely and is level:

8 Check that the steam lever is closed.

9 Make certain that the line voltage corre-

sponds to the requirements indicated on the

label.

10 The preliminary operations have been com-

pleted and the machine is ready to be set up.

2.2.1 FITTING THE FILTER HOLDER

To properly mount the filter holder:

1 Insert the spring inside the pay slot inside

the filter holder.

2 After selecting the appropriate filter (1 or 2),

insert the filter in the filter holder until you

hear the snap with spring.

3 Screw the dispensing spout up to place it

perpendicular to the handle.

NOTE

To change the filter inserted, pry up the edge with

one of the other filters.

Ed. 02 of 09/2016

2.5

SERVICE MANUAL

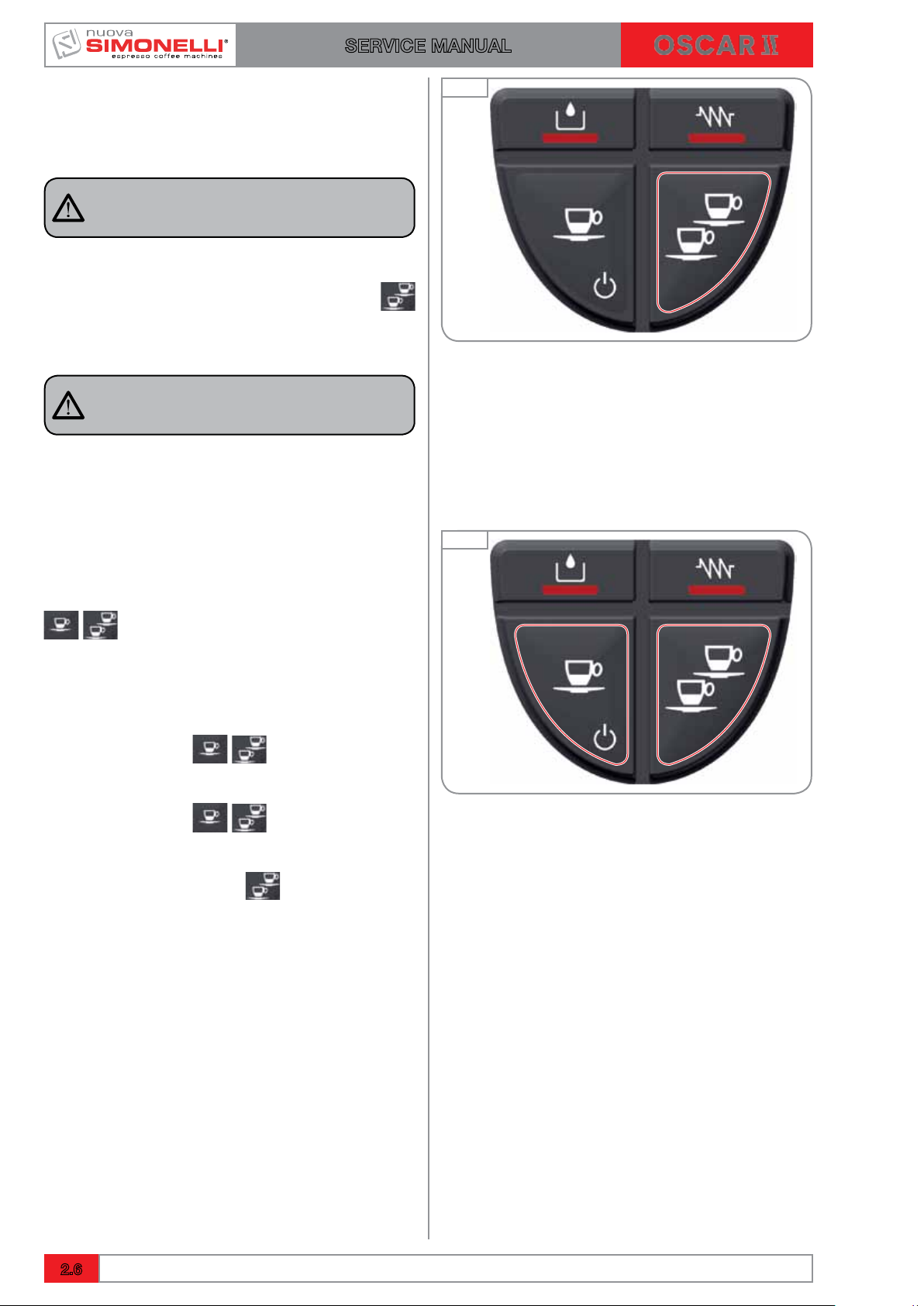

2.3 PROGRAMMING DOSES

Carry out the following operations to enter into

programming mode:

NOTE

Operation to be carried out with the machine

switched on.

To enter into programming mode, press the

two coffee dispensing button for 5 seconds.

The dispensing buttons start to flash.

NOTE

After 30 seconds of inactivity (no buttons pressed)

in programming mode, the machine returns to

normal mode and no data is memorised.

Fig. 18

PROGRAMMING COFFEE DOSES

To programme the dose of water relative to one of the

dispensing buttons, proceed as follows:

Fill the filter holder with the correct dose of coffee (the

filter holder can be single or double depending on the

button to be programmed).

Place the filter holder into the unit.

Press one of the dispensing buttons.

Dispensing starts; once the desired quantity has been

reached press the same button again.

To exit from the programming mode and memorise

the desired doses, keep the

at least 5 seconds; the buttons stop flashing.

button pressed for

Fig. 19

2.6

Ed. 02 of 09/2016

SERVICE MANUAL

3. REMOVAL OF THE EXTERNAL SURFACE

INDEX

3. REMOVAL OF THE

EXTERNAL SURFACE ………..3.1

3.1 REMOVAL OF WATER TANK …….3.2

3.2 REMOVAL OF THE CUP

HOLDER SURFACE……………3.3

3.3 REMOVAL OF THE SIDE PANELS …3.4

3.4 REMOVAL OF THE REAR PANEL …3.4

3.5 TANK TO COLLECT WATER FILED ..3.4

3.6 REMOVAL OF THE FRONT PANEL ..3.5

3.6.1 REMOVAL OF KEYBOARD …..3.6

TOOLS NEEDED:

Ed. 02 of 09/2016

3.1

SERVICE MANUAL

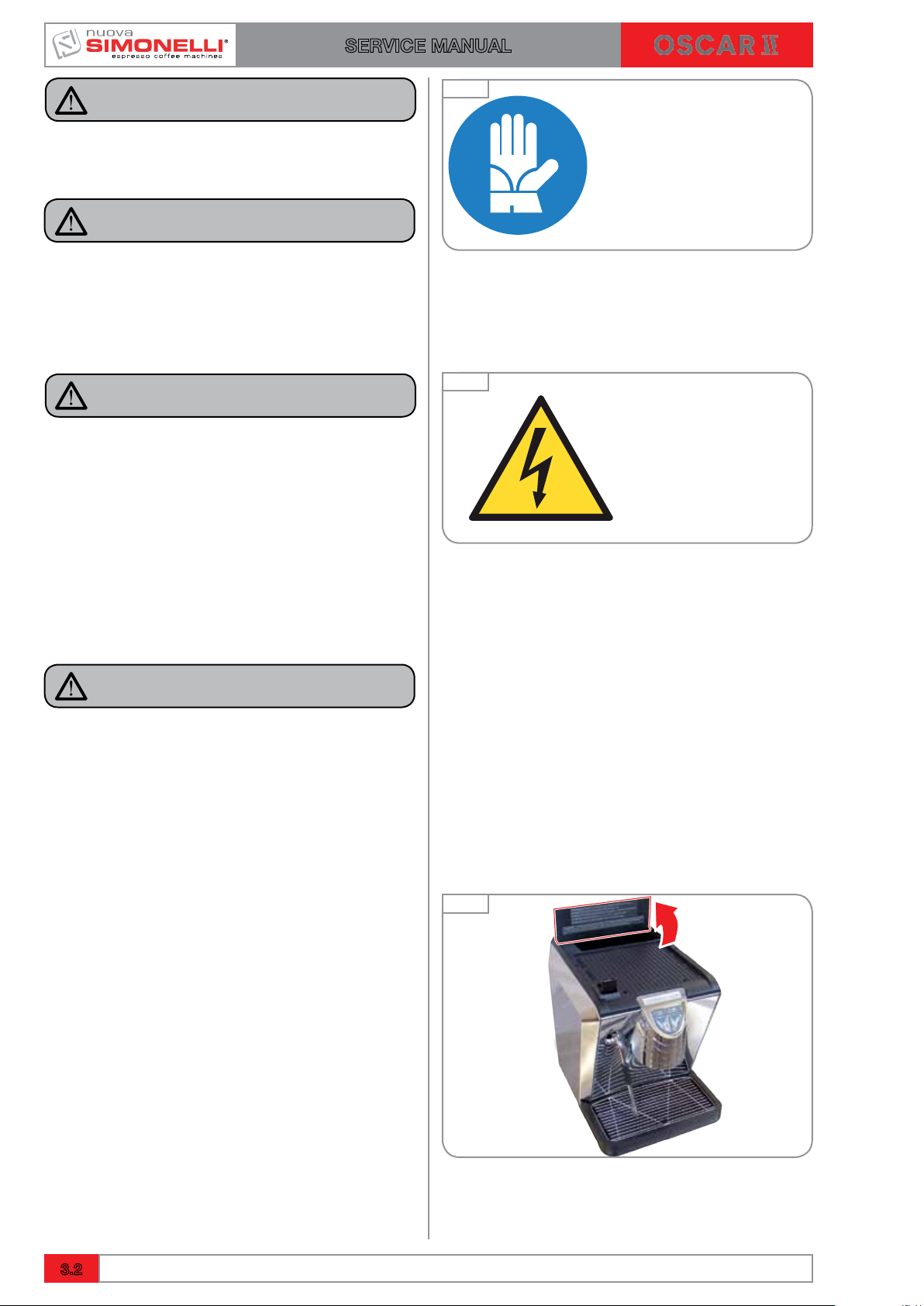

DANGER

Use gloves to protect against sharp or hot

surfaces that you can bump against involuntarily during operations.

NOTE

Before proceeding with the removal of the

panels it is advisable to clean and free up

enough space where the machine parts will

rest so that they are not be unintentionally

damaged.

DANGER

Before proceeding with the operations

described in the chapter make sure that the

machine is turned off and unplugged from the

mains. Discharge any residual pressure present in the heater.

Fig. 22

Fig. 23

DANGER

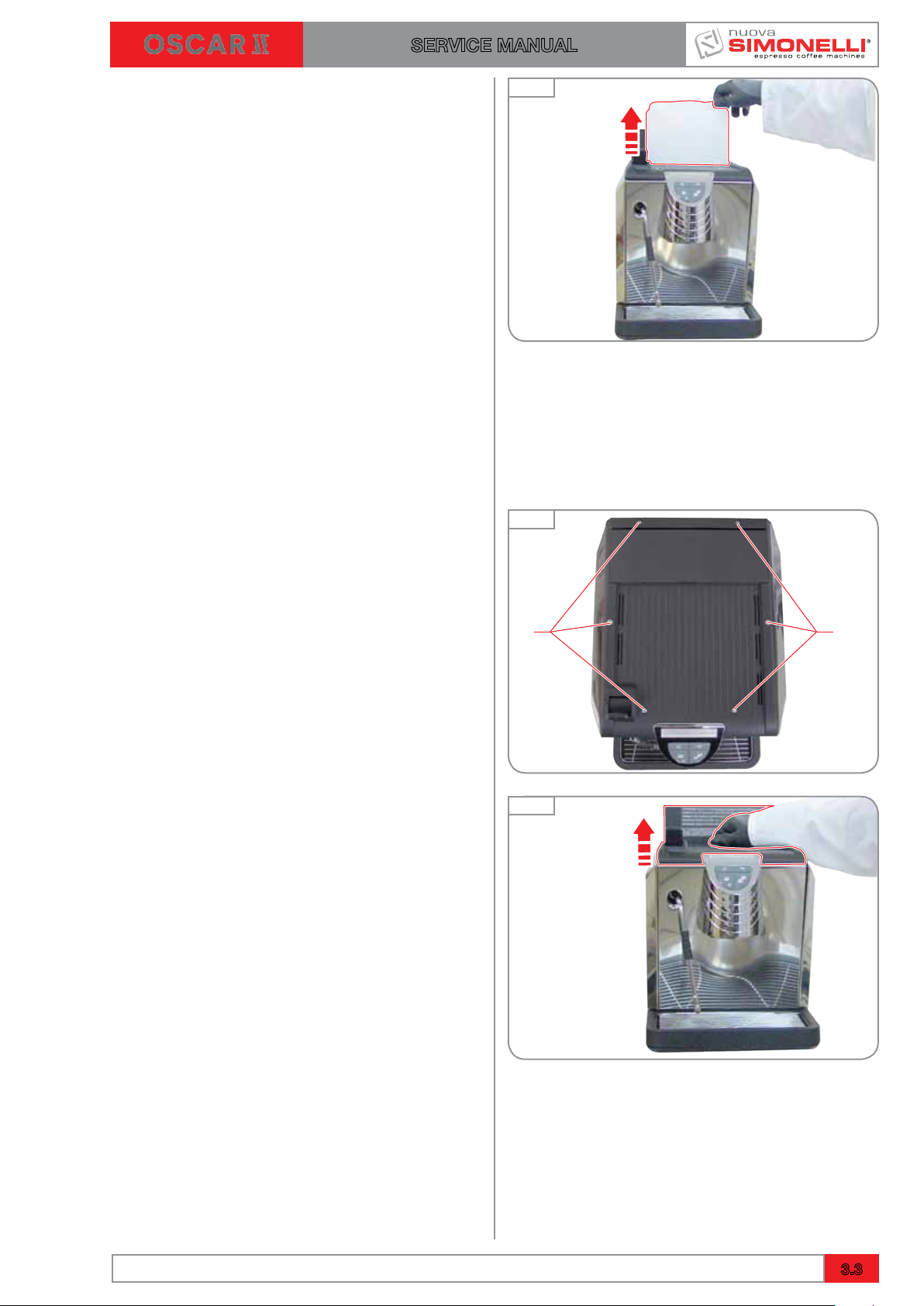

3.1 REMOVAL OF WATER TANK

To remove machine covers, take out the water

tank first:

NOTE

This operation is necessary only for the version with tank.

To remove the tank from its seat, proceed as follows:

1 Lift the water tank cap.

Fig. 22

3.2

Ed. 02 of 09/2016

SERVICE MANUAL

2 Pull the water tank upward.

3.2 REMOVAL OF THE CUP HOLDER

SURFACE

To remove the bearing surface of the cup, proceed as follows:

1 Unscrew the screws «A» with a screwdriver.

Fig. 23

Fig. 24

2 Lift the panel and pull upwards.

Fig. 25

Ed. 02 of 09/2016

3.3

SERVICE MANUAL

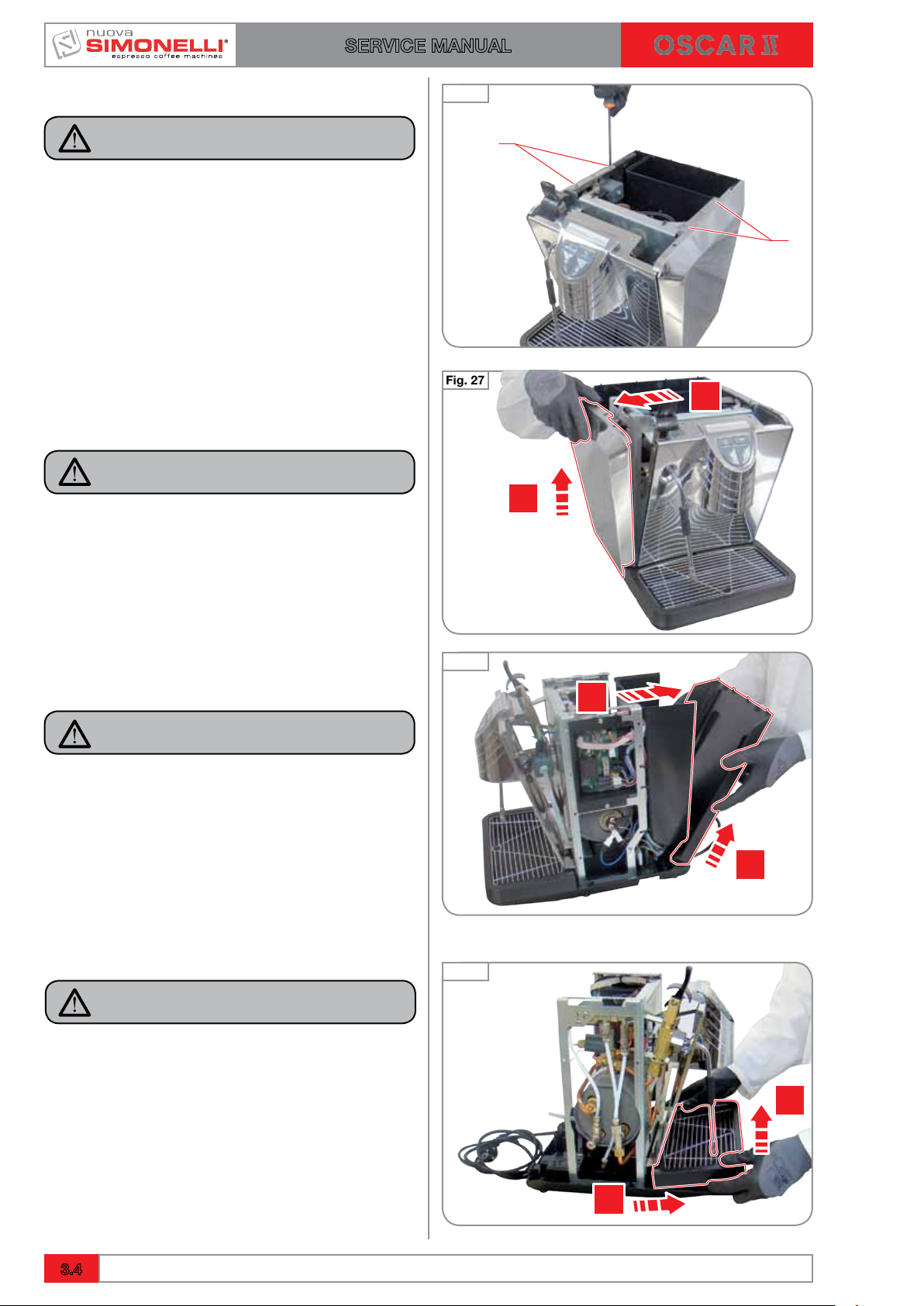

3.3 REMOVAL OF THE SIDE PANELS

NOTE

To remove the side panels, it is necessary to

remove the cup holding surface first.

1 Unscrew the «A» present on each panel

using a Phillips screwdriver.

2 Move outside the top of the panel and pull

up.

NOTE

Perform the same steps for the other side

panel.

Fig. 26

Fig. 27

3.4 REMOVAL OF THE REAR PANEL

NOTE

To remove the back panel it is necessary to

remove both side panels first.

Proceed as follows:

1 Move outside the top of the panel and pull

up.

3.5 TANK TO COLLECT WATER FILED

NOTE

To remove the tray with water you need:

1 Lift and remove the tray with water.

Fig. 28

Fig. 29

3.4

Ed. 02 of 09/2016

SERVICE MANUAL

3.6 REMOVAL OF THE FRONT PANEL

NOTE

To remove the front panel, you must remove

the top panels and water from the drain pan.

1 Disconnect the connection to the panel.

2 Unscrew the screws «A» with a Phillips

screwdriver.

Fig. 30

Fig. 31

3 Slight outside the steam nozzle, then slide

the front panel to the front of the machine.

Ed. 02 of 09/2016

Fig. 32

3.5

SERVICE MANUAL

3.6.1 REMOVAL OF KEYBOARD

NOTE

Separate the cover unit from the front panel.

1 Loosen the 4 screws “A” situated on the

back of the front panel using a Phillips

screwdriver.

2 Push in the connector located inside of the

support group to detach the panel.

Fig. 33

Fig. 34

3.6

Ed. 02 of 09/2016

Loading…

View the manual for the Nuova Simonelli Oscar II here, for free. This user manual comes under the category coffee makers and has been rated by 4 people with an average of a 9. This manual is available in the following languages: English. Do you have a question about the Nuova Simonelli Oscar II?

Ask your question here

Nuova Simonelli Oscar II specifications

Below you will find the product specifications and the manual specifications of the Nuova Simonelli Oscar II.

The Nuova Simonelli Oscar II is a coffee maker that is designed to make high-quality espresso drinks. It is made from durable materials and is built to last, ensuring that it can withstand daily use in a busy cafe or restaurant. This coffee maker features a powerful heating element that can quickly heat water to the optimal temperature for brewing espresso. It also has a large, easy-to-read display that shows the temperature of the water, the brewing time, and other important information.

The Nuova Simonelli Oscar II has a large water reservoir that can be easily refilled, reducing the need for constant maintenance and allowing for efficient operation. Additionally, it has a steam wand that can be used to froth milk perfectly, giving baristas the ability to create a wide variety of espresso-based beverages. The steam wand is made from high-quality materials and is easy to clean, ensuring that it remains in top condition for years.

Overall, the Nuova Simonelli Oscar II is a high-quality coffee maker that is designed to make premium espresso drinks. Its durable construction, powerful heating element, and easy-to-use design make it an excellent choice for baristas and coffee enthusiasts alike.

General

Frequently asked questions

Can’t find the answer to your question in the manual? You may find the answer to your question in the FAQs about the Nuova Simonelli Oscar II below.

What is the best way to descale my coffee maker?

To descale the coffee maker, it is recommended to use a liquid descaling agent which is labelled as suitable for coffee machines.

How often should I descale my coffee maker?

How often a coffee machine needs to be descaled depends on how often it is used and the hardness of the water.

If hard water is used it is recommended to descale once a month, if soft water is used once a quarter is sufficient.

What does the grind say about the taste of the coffee?

How the coffee beans are ground strongly influences the taste of the coffee. If the coffee beans are very finely ground you will have a stronger taste and if the grind is coarser you will have a milder taste.

What is espresso?

Espresso is a small amount of concentrated coffee.

How long can I keep coffee beans?

The best-before date can be found on the packaging of the coffee beans. This best-before date applies as long as the bag is closed.

What is the best way to store coffee?

It is recommended to store coffee in an airtight and clean container.

Is the manual of the Nuova Simonelli Oscar II available in English?

Yes, the manual of the Nuova Simonelli Oscar II is available in English .

Is your question not listed? Ask your question here

Рожковая автоматическая кофемашина NUOVA SIMONELLI OSCAR II AD с подключением к воде предназначена для приготовления кофе эспрессо и капучино. Оснащена одной термокомпенсированной группой и паровым краном из нержавеющей стали. Бойлер изготовлен из меди, корпус – из нержавеющей стали с вставками из ABS-пластика чёрного цвета.

Данная модель рекомендуется для профессионального применения на предприятиях общественного питания с контактной барной стойкой, например, в специализированных кофейнях, ресторанах или кафе. Компактные размеры и стильный дизайн позволяют оборудованию с лёгкостью вписаться в любой интерьер.

Для продления срока службы оборудования и достижения идеального качества готовых напитков рекомендуем приобрести водоумягчитель и фильтр-систему для смягчения и очистки воды.

Рекомендации по выбору системы фильтрации

- Возможность приготовления 2 чашек одновременно

- Удобная электронная панель управления с подсветкой и мягким нажатием кнопок

- Индикаторы нагрева и нехватки воды

- Программирование времени дозирования для обеспечения стабильного результата приготовления кофе

Особенности конструкции:

- Регулируемый паровой кран легко поворачивается на 360°

- Теплообменная система внутри бойлера обеспечивает высокую производительность пара для приготовления капучино

- Контейнер для 12 чашек в верхней части корпуса

- Профессиональный портафильтр

- Приёмный резервуар объёмом 1 л

- Профессиональный энергосберегающий бойлер

- Оснащение бойлера:

- Автоматическое наполнение водой

- Предохранительный клапан

- Обратный клапан

- Профессиональный прессостат (регулирует давление в бойлере и поддерживает температуру, необходимую для приготовления кофе)

Комплектация:

- Одинарный фильтр

- Двойной фильтр

- Портафильтр

- Пружинка

- Дозатор кофе

- Носик подачи

- Пластиковый темпер

Дополнительные аксессуары (приобретаются отдельно):

- Весы электронные

- Заглушки для портафильтра

- Коврики для темпинга

- Моющие средства

- Наборы бариста

- Наборы для темпинга

- Нок-боксы

- Питчеры

- Помпы

- Портафильтры

- Профессиональный прессостат

- Разравниватели для кофе

- Салфетки

- Смазки

- Станции для темпинга

- Темперы

- Щётки для рабочей группы

FAQ: Types of Manuals and Their Contents

Nuova Simonelli Oscar II Manuals come in various types, each serving a specific purpose to help users effectively operate and maintain their devices. Here are the common types of Nuova Simonelli Oscar II User Guides and the information they typically include:

- User Manuals: Provide comprehensive instructions on how to use the device, including setup, features, and operation. They often include troubleshooting tips, safety information, and maintenance guidelines.

- Service Instructions: Designed for technicians and repair professionals, these manuals offer detailed information on diagnosing and repairing issues with the device. They include schematics, parts lists, and step-by-step repair procedures.

- Installation Guides: Focus on the installation process of the device, providing detailed instructions and diagrams for proper setup. They are essential for ensuring the device is installed correctly and safely.

- Maintenance Manuals: Provide guidance on routine maintenance tasks to keep the device in optimal condition. They cover cleaning procedures, part replacements, and regular servicing tips.

- Quick Start Guides: Offer a concise overview of the essential steps needed to get the device up and running quickly. They are ideal for users who need immediate assistance with basic setup and operation.

Each type of Nuova Simonelli Oscar II instruction is designed to address specific needs, ensuring users have the necessary information to use, maintain, and repair their devices effectively.

Related Instructions for Nuova Simonelli Oscar II:

1

PRONTOBAR

Service manual Nuova Simonelli PRONTOBAR User Manual (Service manual), @6O345G

176

33

7

5

MYTHOS 2

User handbook manual Nuova Simonelli MYTHOS 2 Guide (User handbook manual), @4FF938

66

372

86

6

Aurelia II

Manual #83T3C3: Aurelia II Coffee Maker Manual

28

193

39

8

mac 2000

User handbook manual Nuova Simonelli mac 2000 Manual (User handbook manual), @239M35

16

309

50

9

MDU

Handbook Nuova Simonelli Coffee Grinder Handbook (File: nuova-simonelli-mdu-handbook-24, Fri 12.2024)

24

1331

213

10

Aurelia II

45

1282

218

Coffee Maker Devices by Other Brands:

|

UFESA CE7141 Operating Instructions Manual PDF User Guide (@Z861FL), UFESA CE7141 Coffee Maker (Saturday 30-11-2024) INSTRUCCIONES DE USO 30 Nov 2024 | 26 |

|

|

Wega ALE Series Use And Maintenance Manual PDF User Guide (@3I9T3D), Wega ALE Series Coffee Maker (Tuesday 25-02-2025) WEGA MACCHINE PER CAFFÈ S.r.l. 25 Feb 2025 | 68 |

|

|

better chef IM-153 Use And Care Book Manual #7G8TP1: IM-153 Coffee Maker Use and care book manual ® 19 May 2025 | 14 |

|

|

Krups Intuition Preference EA873 Manual #965RSS: Intuition Preference EA873 Coffee Maker Manual 8020005263 12 Jan 2025 | 286 |

Categories:

Coffee Maker

Coffee Grinder

Commercial Food Equipment