Комментарии

11

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Отличная книга. Когда купил Ланс в 2008 году, очень выручала. Сейчас лежит такая книга, почти новая,

Спасибо! Удачи в делах и на дороге!

Спасибо, бро! Чтоб дороги у тебя всегда были ровные и баки полные!

От души! И тебе того же 😉

спасибо, а на гугл нет возможности залить? на укр хлопатно скачать

🙏

ох спс тебе! я как раз свою посеял.

Mitsubishi Lancer X: Руководства по эксплуатации

Материал из MMC Manuals

Перейти к навигации

Перейти к поиску

Руководства по эксплуатации Mitsubishi Lancer X. Брошюры, каталоги, спецификации, карты технического обслуживания.

↑ Mitsubishi Lancer X

| Язык/Language: | Русский • English |

|---|

Брошюры, каталоги, спецификации

Руководства по эксплуатации

- Руководство по эксплуатации Mitsubishi Lancer MY 2008 (Россия), рус., постранично || одним файлом, pdf, 58,2 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2014 (Россия), pdf, рус., 28,8 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2015 (Россия), pdf, рус., 22,5 МБ

- Руководство по эксплуатации Mitsubishi Lancer и Mitsubishi Lancer Ralliart (Россия), pdf, рус., 56,9 МБ

- Краткое руководство Mitsubishi Lancer MY 2011 (North America), pdf, eng., 1,57 МБ

- Краткое руководство Mitsubishi Lancer MY 2012 (North America), pdf, eng., 1,73 МБ

- Краткое руководство Mitsubishi Lancer MY 2014 (North America), pdf, eng., 892 кБ

- Краткое руководство Mitsubishi Lancer MY 2015 (North America), pdf, eng., 1,26 МБ

- Краткое руководство Mitsubishi Lancer MY 2016 (North America), pdf, eng., 9,76 МБ

- Краткое руководство Mitsubishi Lancer MY 2017 (North America), pdf, eng., 11,1 МБ

- Быстрое знакомство с Mitsubishi Lancer, pdf, eng., 948 кБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2011 (Europe), pdf, eng., 19,1 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2012 (Europe), pdf, eng., 22,9 МБ

- Руководство по эксплуатации Mitsubishi Lancer Sportback MY 2011 (Europe), pdf, eng., 20,4 МБ

- Руководство по эксплуатации Mitsubishi Lancer Sportback MY 2012 (Europe), pdf, eng., 21,8 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2010 (North America), pdf, eng., 25,1 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2011 (North America), pdf, eng., 42,3 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2012 (North America), pdf, eng., 22,3 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2013 (North America), pdf, eng., 23,8 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2014 (North America), pdf, eng., 57,5 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2015 (North America), pdf, eng., 16,6 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2016 (North America), pdf, eng., 13,1 МБ

- Руководство по эксплуатации Mitsubishi Lancer MY 2017 (North America), pdf, eng., 14,3 МБ

- Руководство по эксплуатации Mitsubishi Lancer Sportback MY 2010 (North America), pdf, eng., 20,6 МБ

- Руководство по эксплуатации Mitsubishi Lancer Sportback MY 2011 (North America), pdf, eng., 22,2 МБ

- Руководство по эксплуатации Mitsubishi Lancer Sportback MY 2012 (North America), pdf, eng., 22,1 МБ

- Руководство по эксплуатации Mitsubishi Lancer Sportback MY 2013 (North America), pdf, eng., 22,0 МБ

- Руководство по эксплуатации Mitsubishi Lancer Sportback MY 2014 (North America), pdf, eng., 55,1 МБ

Руководства по эксплуатации аудио-системы

- См. раздел Аудиооборудование: Руководства по эксплуатации

Карты технического обслуживания

- Периодическое техническое обслуживание (карта ТО), pdf, 301 кБ

- Периодическое техническое обслуживание при тяжелых условиях эксплуатации, pdf, 392 кБ

- Перечень запчастей и расходников для технического обслуживания Lancer X

Разное

- Активация противотуманных фар без специального оборудования

Руководство на английском языке по кузовному ремонту автомобилей Mitsubishi Lancer/Lancer Station Wagon 1993 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 1992

- Страниц: —

- Формат: PDF

- Размер: 25,2 Mb

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 1993-2000

- Страниц: —

- Формат: PDF

- Размер: 33,9 Mb

Сборник схем на английском языке электрооборудования автомобиля Mitsubishi Lancer 1997-2000 годов выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 1996-1999

- Страниц: —

- Формат: PDF

- Размер: 5,3 Mb

Сборник схем на английском языке электрооборудования автомобиля Mitsubishi Lancer 2007 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 99,3 Mb

Мультимедийное руководство на английском языке по техническому обслуживанию и ремонту автомобилей Mitsubishi Lancer/Lancer SportBack/Lancer Evolution 2004 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors

- Год издания: 2003

- Страниц: —

- Формат: —

- Размер: 191,5 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1992-1996 годов выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 41,2 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1996-2001 годов выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 1995-2000

- Страниц: —

- Формат: PDF

- Размер: 26,5 Mb

Руководство на английском языке по техническому обслуживанию и ремонту автомобилей Mitsubishi Lancer/Lancer Wagon 2005 года выпуска. .

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 2004

- Страниц: —

- Формат: PDF

- Размер: 46,3 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобиля Mitsubishi Lancer 2006 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 66,2 Mb

Сборник мультимедийных руководств на английском языке по техническому обслуживанию и ремонту автомобилей Mitsubishi Lancer/Lancer Sportback 2009-2011 годов выпуска

- Автор: —

- Издательство: Mitsubishi Motors

- Год издания: —

- Страниц: —

- Формат: —

- Размер: 4,0 Gb

уководство на английском языке по техническому обслуживанию и ремонту автомобиля Mitsubishi Lancer 2012 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: —

- Страниц: 1253

- Формат: PDF

- Размер: 40,6 Mb

Руководство на английском языке по техническому обслуживанию и ремонту автомобиля Mitsubishi Lancer серий CE/CG. .

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 2001-2002

- Страниц: —

- Формат: PDF

- Размер: 61,5 Mb

Руководство на английском и испанском языках по техническому обслуживанию и ремонту (включая руководство по кузовному ремонту) автомобиля Mitsubishi Lancer 2004 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 2003

- Страниц: —

- Формат: PDF

- Размер: 418,6 Mb

Руководство по ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1991-1995 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: СверчокЪ

- Год издания: 2005

- Страниц: 279

- Формат: PDF

- Размер: 38,2 Mb

Руководство по ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1991-2004 годов выпуска с бензиновыми и дизельными двигателями

- Автор: В. Покрышкин

- Издательство: СверчокЪ

- Год издания: 2005

- Страниц: 279

- Формат: DjVu

- Размер: 19,9 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Mitsubishi Lancer 2001-2007 годов выпуска с бензиновыми двигателями объемом 1,3/1,6/2,0 л.

- Автор: —

- Издательство: Третий Рим

- Год издания: —

- Страниц: 304

- Формат: PDF

- Размер: 165,2 Mb

Мультимедийное руководство по эксплуатации и ремонту автомобилей Mitsubishi Colt/Lancer/Mirage/Cordia/Tredia/Precis 1983-1993 годов выпуска.

- Автор: —

- Издательство: —

- Год издания: —

- Страниц: —

- Формат: ISO

- Размер: 196,8 Mb

Сборник руководств по техническому обслуживанию и ремонту автомобиля Mitsubishi Lancer 2008 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 2007

- Страниц: —

- Формат: PDF

- Размер: 186,7 Mb

Сборник руководств по техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1996-2001 годов выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 1995-2000

- Страниц: —

- Формат: PDF

- Размер: 54,0 Mb

Руководство по техническому обслуживанию и ремонту автомобилей Mitsubishi Lancer/Lancer Wagon 2005 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 2004

- Страниц: —

- Формат: PDF

- Размер: 159,7 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобилей Mitsubishi Colt/Lancer/Mirage 1991-1996 и Mitsubishi Libero 1992-2002 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 448

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Mitsubishi Lancer X 2006-2016 годов выпуска с бензиновыми двигателями.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 500

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобиля Mitsubishi Lancer Cedia 2000-2003 года выпуска.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 567

- Формат: PDF

- Размер: 47,0 Mb

уководство по эксплуатации и ремонту автомобилей Mitsubishi Lancer X и Mitsubishi Galant Fortis с 2006 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 384

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer/Lancer Wagon с 1992 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 326

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобилей Mitsubishi Colt/Lancer/Mirage/Cordia/Tredia/Precis/Galant/Sigma/Eterna/Magna/Sapporo 1983-1993 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Техно-BOOK

- Год издания: 2005

- Страниц: 273

- Формат: PDF

- Размер: 34,7 Mb

Руководство по эксплуатации и техническому обслуживанию автомобиля Mitsubishi Lancer 2008 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 2007

- Страниц: 487

- Формат: PDF

- Размер: 48,9 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобилей Mitsubishi Lancer/Lancer Wagon с 2003 года выпуска с бензиновыми двигателями объемом 1,3/1,6/2,0 л

- Автор: —

- Издательство: Арго-Авто

- Год издания: —

- Страниц: 406

- Формат: —

- Размер: —

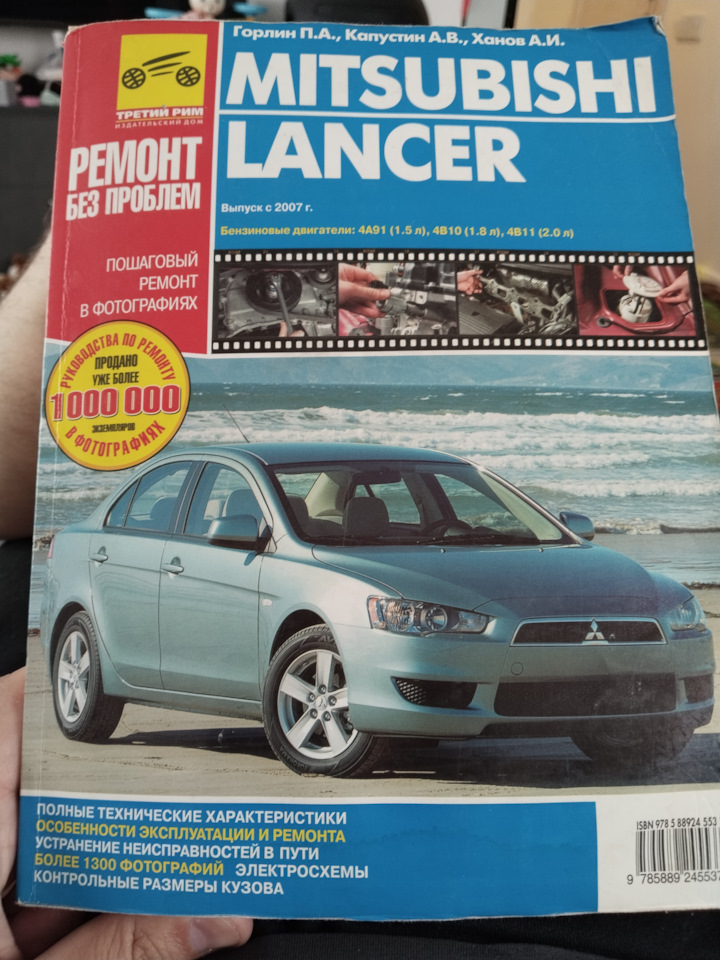

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Mitsubishi Lancer с 2007 года выпуска с бензиновыми двигателями объемом 1,5/1,8/2,0 л.

- Автор: —

- Издательство: Арго-Авто

- Год издания: —

- Страниц: 600

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1993-2003 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Автомастер

- Год издания: 2003

- Страниц: 281

- Формат: PDF

- Размер: 16,4 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Mitsubishi Lancer 2003-2010 годов выпуска с бензиновыми двигателями объемом 1,3/1,6 л.

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 304

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобилей Mitsubishi Mirage/Lancer/Colt/Galant/Eterna/Sapporo/Sigma/Cordia/Tredia/Precis 1983-1993 годов выпуска.

- Автор: —

- Издательство: MoToR

- Год издания: 1996

- Страниц: 183

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1984-1992 годов выпуска.

- Автор: Г.Р. Этцольд

- Издательство: Arinas

- Год издания: 1994

- Страниц: 339

- Формат: DjVu

- Размер: 10,4 Mb

Руководство по техническому обслуживанию и ремонту автомобиля Mitsubishi Lancer с правым рулем 2003-2007 годов выпуска с бензиновыми двигателями объемом 1,5/1,8 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 544

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобиля Mitsubishi Lancer Cedia 2000-2003 годов выпуска с бензиновыми двигателями объемом 1,5/1,8 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 584

- Формат: —

- Размер: —

-

ysh

- Любопытный Лансеровод

- Сообщения: 108

- Зарегистрирован: Вс май 04, 2008 8:21 am

- Город: Надым

- Зодиак:

#2

Непрочитанное сообщение

ysh » Вт май 20, 2008 11:56 am

Руководство по эксплуатации Mitsubishi Lancer X одним файлом.

http://kingly.ifolder.ru/6639933

Мой авто: LancerX (2008) CVT 2.0 (150л.с.) Invite+ (S25) «Серый мика» (Р) А39

-

soudakov

- Начинающий Лансеровод

- Сообщения: 11

- Зарегистрирован: Вт окт 21, 2008 1:18 pm

-

Alexey56

- Вероятный Лансеровод

- Сообщения: 3

- Зарегистрирован: Пн май 28, 2012 8:42 pm

- Зодиак:

#7

Непрочитанное сообщение

Alexey56 » Сб июн 02, 2012 9:13 am

Подскажите где можно скачать руководство по ремонту двигатель 4А91 1.5?

GROUP INDEX

LANCER /

LANCER WAGON

WORKSHOP MANUAL

FOREWORD

This Workshop manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and installation.

Use the following manuals in combination with this

manual as required.

General . . . . . . . . . . . . . . . . . . . . . . . .

Engine. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Lubrication . . . . . . . . . . . . . .

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Cooling . . . . . . . . . . . . . . . . .

Intake and Exhaust . . . . . . . . . . . . . .

Engine Electrical . . . . . . . . . . . . . . . .

Engine and Emission Control . . . . .

Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Transmission . . . . . . . . . . . .

Automatic Transmission. . . . . . . . . .

Front Axle. . . . . . . . . . . . . . . . . . . . . .

00

11

12

13

14

15

16

17

21

22

23

26

TECHNICAL INFORMATION MANUAL

PYME0302

PYME0302-A

WORKSHOP MANUAL

CHASSIS GROUP PWME0302

BODY REPAIR MANUAL

PBME0302

PBME0302-A

PARTS CATALOGUE

B606K005A_

All information, illustrations and product descriptions

contained in this manual are current as at the time of

publication. We, however, reserve the right to make

changes at any time without prior notice or obligation.

Rear Axle . . . . . . . . . . . . . . . . . . . . . .

Wheel and Tyre . . . . . . . . . . . . . . . . .

Power Plant Mount . . . . . . . . . . . . . .

Front Suspension . . . . . . . . . . . . . . .

Rear Suspension . . . . . . . . . . . . . . . .

Service Brakes. . . . . . . . . . . . . . . . . .

Parking Brakes . . . . . . . . . . . . . . . . .

Power Steering . . . . . . . . . . . . . . . . .

Body . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior . . . . . . . . . . . . . . . . . . . . . . . .

Interior and Supplemental

. . . . . . . . . .

Restraint System (SRS)

Chassis Electrical . . . . . . . . . . . . . . .

Heater, Air Conditioner and

. . . . . . .

Ventilation

Component Locations. . . . . . . . . . . .

27

31

32

33

34

35

36

37

42

51

52

54

55

70

Mitsubishi Motors Corporation May 2004

Configration Diagrams . . . . . . . . . . .

Circuit Diagrams . . . . . . . . . . . . . . . .

80

90

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL

RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

(1) Improper service or maintenance of any component of the SRS or any SRS-related component,

can lead to personal injury or death to service personnel (from inadvertent firing of the air bag)

or to the driver and passenger (from rendering the SRS inoperative).

(2) The SRS components and seat belt with pretensioner should not be subjected to heat, so

remove the SRS-ECU, driverís and front passengerís air bag modules, clock spring, side air bag

modules, and seat belt -pre-tensioner before drying or baking the vehicle after painting.

ï SRS-ECU, air bag module and clock spring 93°C or more

ï Seat belt with pre-tensioner: 90°C or more

(3) Service or maintenance of any SRS component or SRS-related component must be performed

only at an authorized MITSUBISHI dealer.

(4) MITSUBISHI dealer personnel must thoroughly review this Manual, and especially its GROUP

52B — Supplemental Restraint System (SRS), before beginning any service or maintenance of

any component of the SRS or any SRS-related component.

NOTE

Section titles with asterisks (*) in the table of contents in each group indicate operations requiring warnings.

GROUP 17

ENGINE AND

EMISSION

CONTROL

CONTENTS

17-1

ENGINE CONTROL. . . . . . . . . .

GENERAL INFORMATION . . . . . . 17-2

SERVICE SPECIFICATIONS. . . . . 17-2

ON-VEHICLE SERVICE. . . . . . . . . 17-2

ACCEL CABLE CHECK AND

ADJUSTMENT. . . . . . . . . . . . . . . . . . . . 17-2

ACCELERATOR CABLE AND

PEDAL . . . . . . . . . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . 17-3

17-2

17-3

EMISSION CONTROL MPI . . . . 17-5

GENERAL INFORMATION . . . . . .

EMISSION CONTROL DEVICE

REFERENCE TABLE . . . . . . . . . .

SERVICE SPECIFICATION(S) . . . 17-5

VACUUM HOSE. . . . . . . . . . . . . . . 17-6

VACUUM HOSE PIPING DIAGRAM . . . 17-6

VACUUM CIRCUIT DIAGRAM . . . . . . . 17-7

VACUUM HOSE CHECK. . . . . . . . . . . . 17-8

VACUUM HOSE INSTALLATION . . . . . 17-8

CRANKCASE EMISSION CONTROL

SYSTEM. . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-8

17-5

17-5

17-8

COMPONENT LOCATION (CRANKCASE

EMISSION CONTROL SYSTEM) . . . . . 17-9

POSITIVE CRANKCASE VENTILATION

SYSTEM CHECK . . . . . . . . . . . . . . . . . . 17-9

POSITIVE CRANKCASE VENTILATION

(PCV) VALVE CHECK . . . . . . . . . . . . . . 17-9

EVAPORATIVE EMISSION CONTROL

SYSTEM . . . . . . . . . . . . . . . . . . . . . 17-9

GENERAL INFORMATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-9

COMPONENT LOCATION (EVAPORATIVE

EMISSION CONTROL SYSTEM) . . . . . 17-10

PURGE CONTROL SYSTEM CHECK. . 17-10

PURGE PORT VACUUM CHECK . . . . . 17-11

PURGE CONTROL SOLENOID VALVE

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . 17-11

FUEL VAPOUR CANISTER REMOVAL

AND INSTALLATION . . . . . . . . . . . . . . . 17-12

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM . . . . . . . . . . . . . . .

GENERAL INFORMATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-13

COMPONENT LOCATION

(EGR SYSTEM) . . . . . . . . . . . . . . . . . . . 17-14

EGR SYSTEM CHECK . . . . . . . . . . . . . 17-15

EGR VALVE CHECK . . . . . . . . . . . . . . . 17-15

EGR PORT VACUUM CHECK <4G1>. . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G1> . . . . . . . . . . . . . . . . . . . . 17-16

EGR CONTROL SOLENOID VALVE

CHECK <4G6> . . . . . . . . . . . . . . . . . . . . 17-17

EXHAUST GAS RECIRCULATION (EGR)

VALVE REMOVAL AND

INSTALLATION . . . . . . . . . . . . . . . . . . . 17-18

CATALYTIC CONVERTER . . . . . . 17-18

REMOVAL AND INSTALLATION . . . . . . 17-18

17-13

17-2

ENGINE AND EMISSION CONTROL

ENGINE CONTROL

ENGINE CONTROL

GENERAL INFORMATION

M1171000100277

A cable-type accelerator mechanical

suspended-type pedal has been adopted.

SERVICE SPECIFICATIONS

M1171000300088

Item Standard value

Accel cable play mm 1.0 − 2.0

Engine idle speed r/min 4G1 750 ± 50

4G6 750 ± 100

ON-VEHICLE SERVICE

ACCEL CABLE CHECK AND

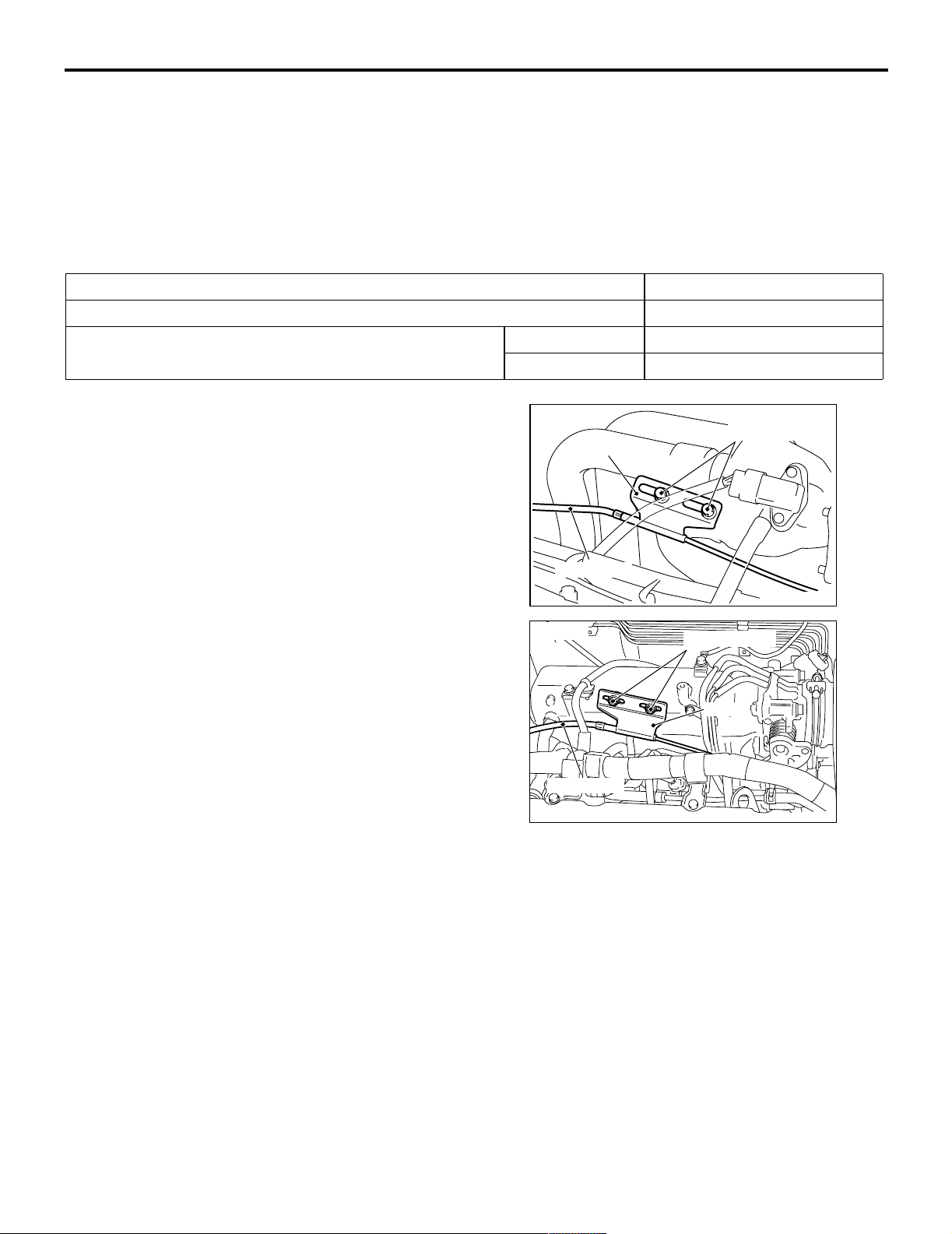

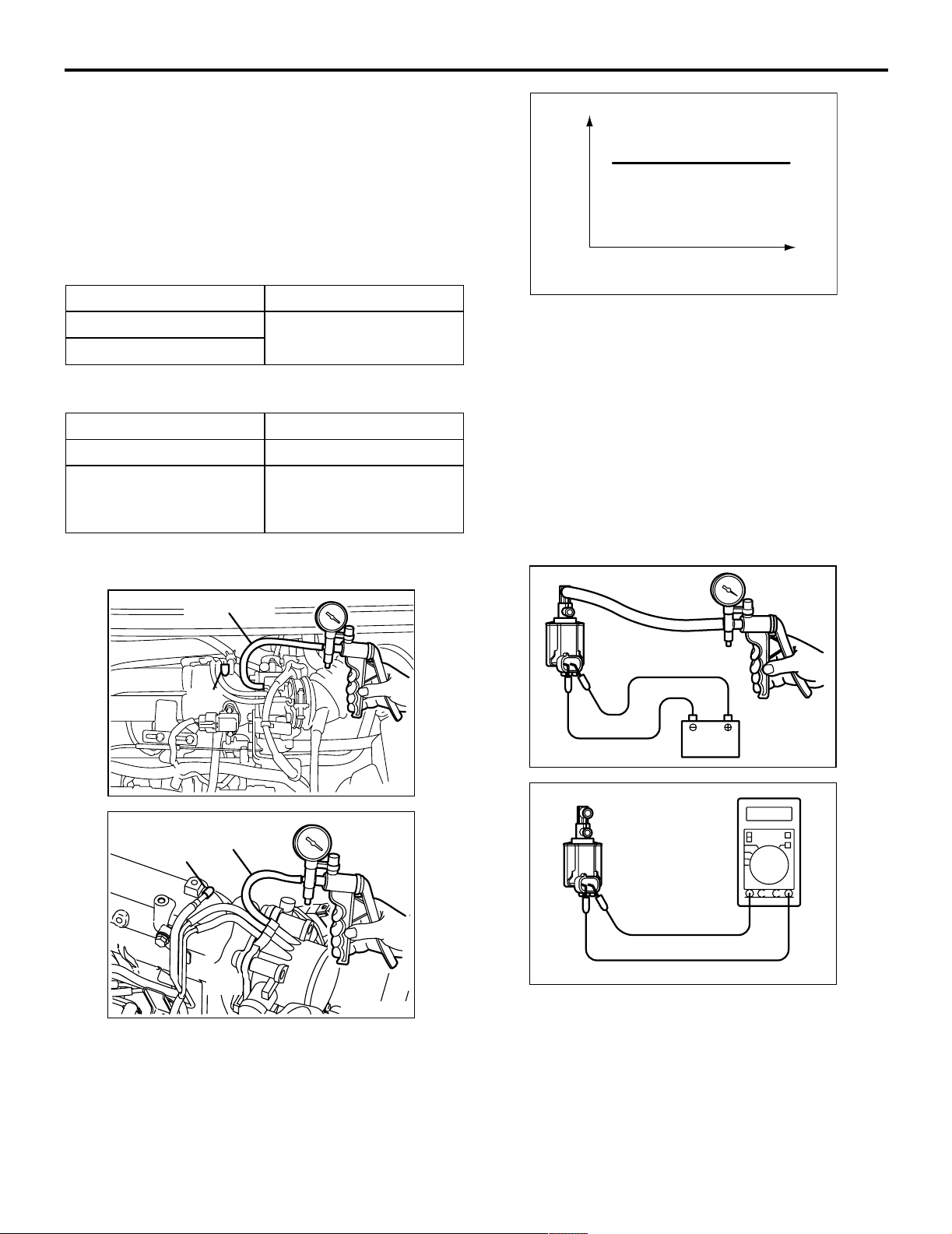

<4G1>

Adjusting bolts

Plate

ADJUSTMENT

M1171000900314

1. Turn A/C and lights OFF. Inspect and adjust at no

load.

2. Warm engine until stabilized at idle.

3. Confirm idle speed is at standard value.

Standard value:

750 ± 50 r/min <4G1>

750 ± 100 r/min <4G6>

Accel cable

<4G6>

Adjusting bolts

AC207966

AC

4. Stop engine. [ignition switch: LOCK (OFF)

position].

5. Confirm there are no sharp bends in the

accelerator cable.

6. Check the inner cable for correct slack.

Standard value: 1.0 − 2.0 mm

7. If there is too much slack or no slack, adjust play

by the following procedures.

Plate

Accel cable

AC301055

AC

(1) Loosen the adjusting bolts to release the

cable.

(2) Move the plate until the inner cable play is at

the standard value, and then tighten the

adjusting bolts.

(3) After adjusting, check that the throttle lever is

touching the stopper.

ENGINE AND EMISSION CONTROL

ENGINE CONTROL

ACCELERATOR CABLE AND PEDAL

17-3

REMOVAL AND INSTALLATION

Post-installation Operation

Adjusting the Accelerator Cable (Refer to P.17-2).

<L.H. drive vehicles>

3

M1171001200341

2

5.0 ± 1.0 N·m

12 ± 2 N·m

10

1

7

9

7

N

5

4

<R.H. drive vehicles>

5.0 ± 1.0 N·m

2

Accelerator cable assembly

removal steps

1. Inner cable connection (Accelerator

pedal side)

2. Inner cable connection (Throttle body

side)

3. Accelerator cable assembly

8

13

N

12

6

Y1060AU

11

3

1

12 ± 2 N·m

9

7

13

11

12

6

N

Y1059AU

AC304070

AB

10

N

5

4

7

8

Accelerator pedal assembly

removal steps

1. Inner cable connection (Accelerator

pedal side)

4. Accelerator pedal assembly

5. Accelerator control equip nut

6. Accelerator pedal arm and

accelerator pedal pad assembly

17-4

ENGINE AND EMISSION CONTROL

ENGINE CONTROL

Accelerator pedal assembly

removal steps (Continued)

7. Accelerator control equip bushing

8. Accelerator pedal arm return spring

9. Accelerator pedal arm stopper

INSTALLATION SERVICE POINT

>>A<< ACCEL PEDAL PAD

INSTALLATION

CAUTION

To p reve nt damag es to the ac c eler ator pe dal pad,

warm the thumb area of the accelerator pedal

pad with a dryer, etc. prior to assembling it.

NOTE: If it is difficult to assemble, apply soapy water

to the thumb area to enhance the assembling

process.

>>A<<

Accelerator pedal assembly

removal steps (Continued)

10. Accelerator pedal arm bracket

11. Ac c e l erator p edal a rm

12. Accelerator pedal pad

13. Accelerator pedal arm stopper

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

EMISSION CONTROL <MPI>

17-5

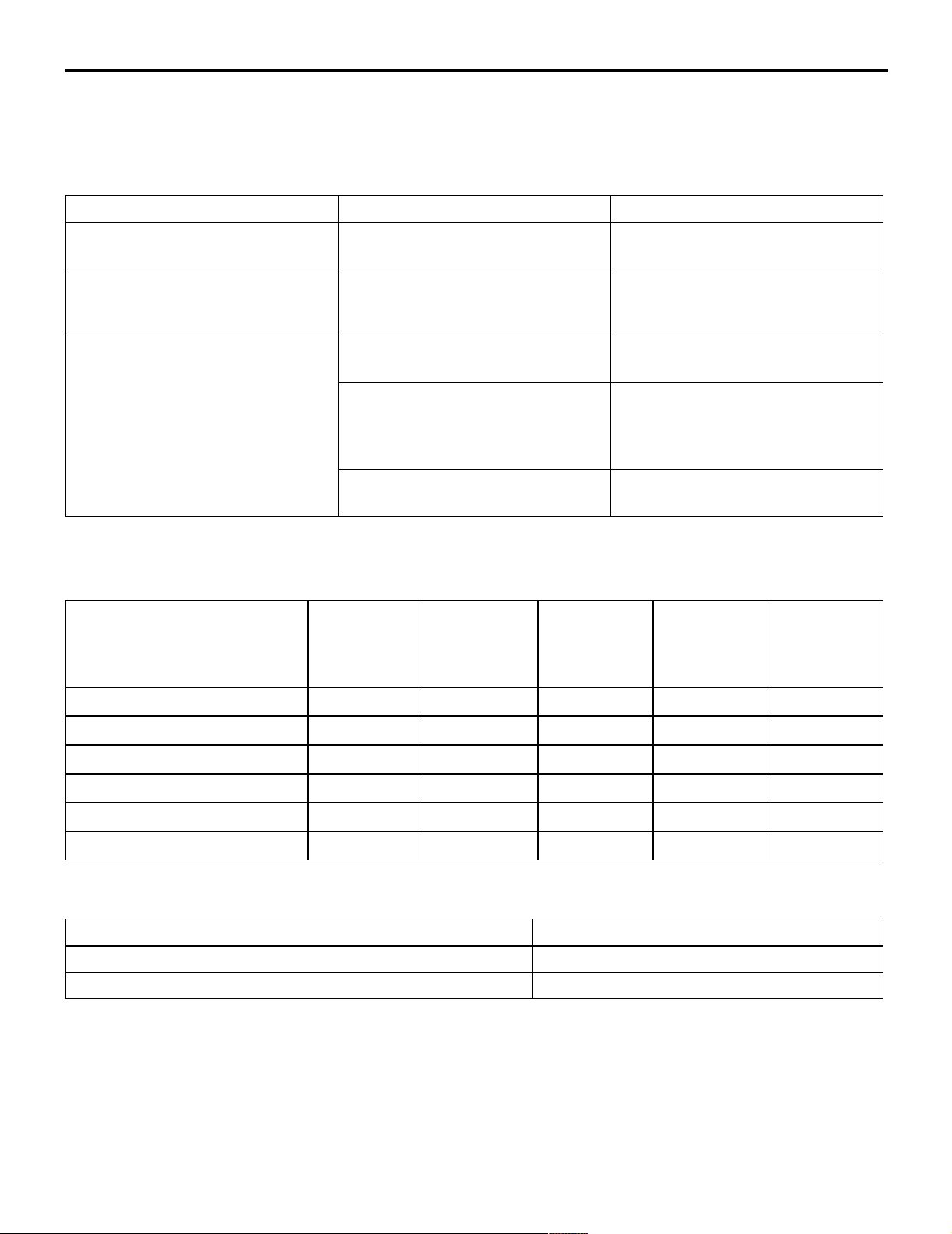

GENERAL INFORMATION

M1173000100370

The emission control system consists of the following

subsystems:

Items Name Specification

Crankcase emission control

system

Evaporative emission control

system

Exhaust emission control system Air-fuel ratio control device — MPI

Positive crankcase ventilation

(PCV) valve

Canister

Purge control solenoid valve

system

Exhaust gas recirculation system

• EGR valve

• EGR control solenoid valve

Catalytic converter Monolith type

• Crankcase emission control system

• Evaporative emission control system

• Exhaust emission control system

Varia b le flo w t yp e

(Purpose: HC reduction)

Equipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Oxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Equipped

Single type

Duty cycle type solenoid valve

(Purpose: NOx reduction)

(Purpose: CO, HC, NOx reduction)

EMISSION CONTROL DEVICE

REFERENCE TABLE

M1173006600135

Related parts Crankcase

emission

control

system

Evaporative

emission

control

system

Air/fuel ratio

control

system

Catalytic

converter

Exhaust gas

recirculation

system

PCV valve

Purge control solenoid valve

MPI system component

Catalytic converter

EGR valve

EGR control solenoid valve

×

×

××

SERVICE SPECIFICATION(S)

M1173000300288

Items Standard value

Purge control solenoid valve coil resistance (at 20°C) Ω 30 − 34

EGR control solenoid valve coil resistance (at 20°C) Ω 29 − 35

×

×

×

17-6

VACUUM HOSE

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

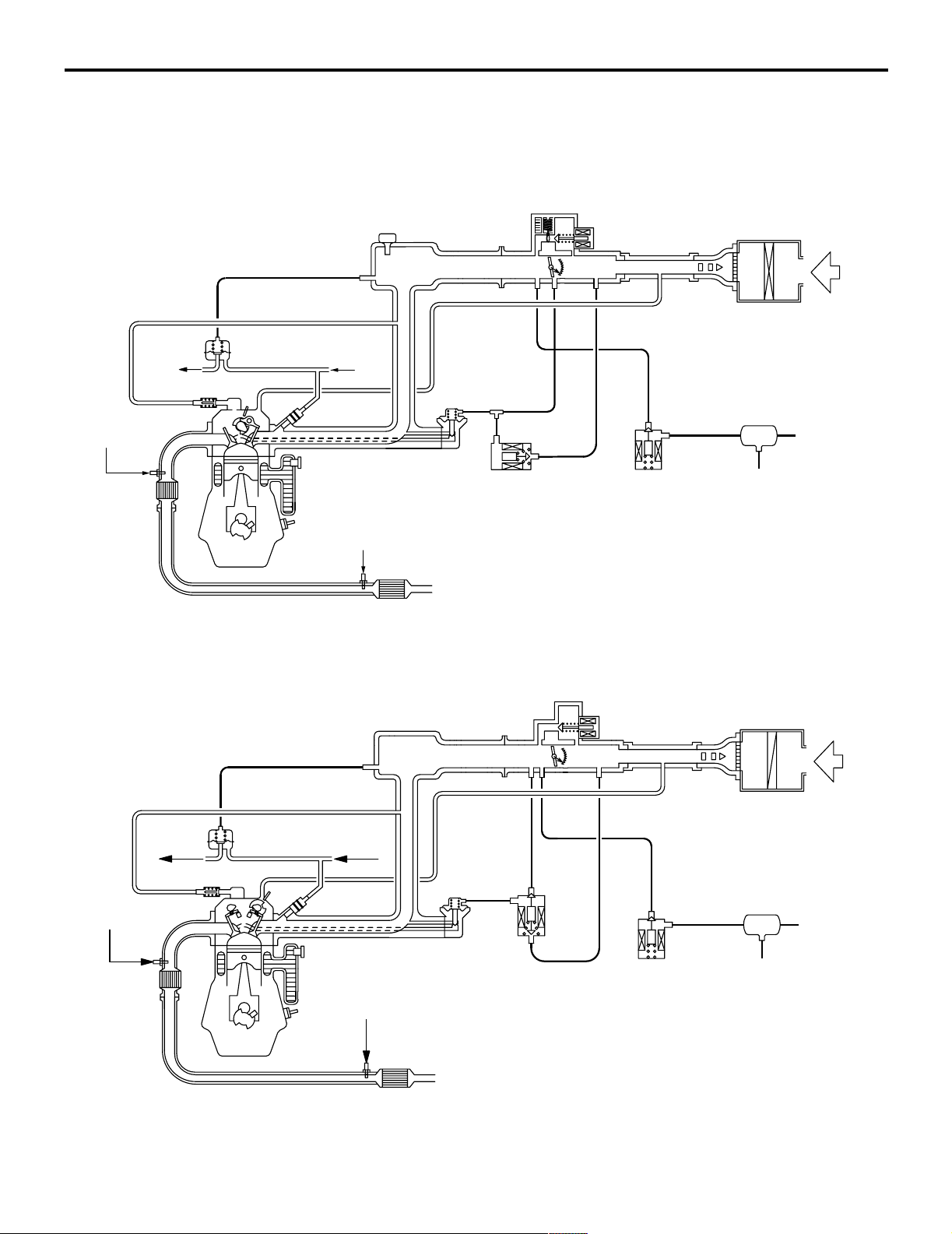

VACUUM HOSE PIPING DIAGRAM

M1173000900417

<4G1>

To

fuel tank

Oxygen sensor

(front)

Catalytic

converter

Fuel pressure

regulator

Oxygen sensor (rear)

From

fuel pump

EGR valve

EGR control

solenoid valve

Air cleaner

Air

Canister

Purge control

solenoid valve

<4G6>

To

fuel tank

Oxygen sensor

(front)

Catalytic

converter

PCV valve

Fuel pressure

regulator

Catalytic

converter

From

fuel pump

EGR valve

Oxygen sensor (rear)

Catalytic

converter

EGR control

solenoid valve

Purge control

solenoid valve

Air cleaner

Canister

AK300964

AB

Air

AK204364

AC

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

17-7

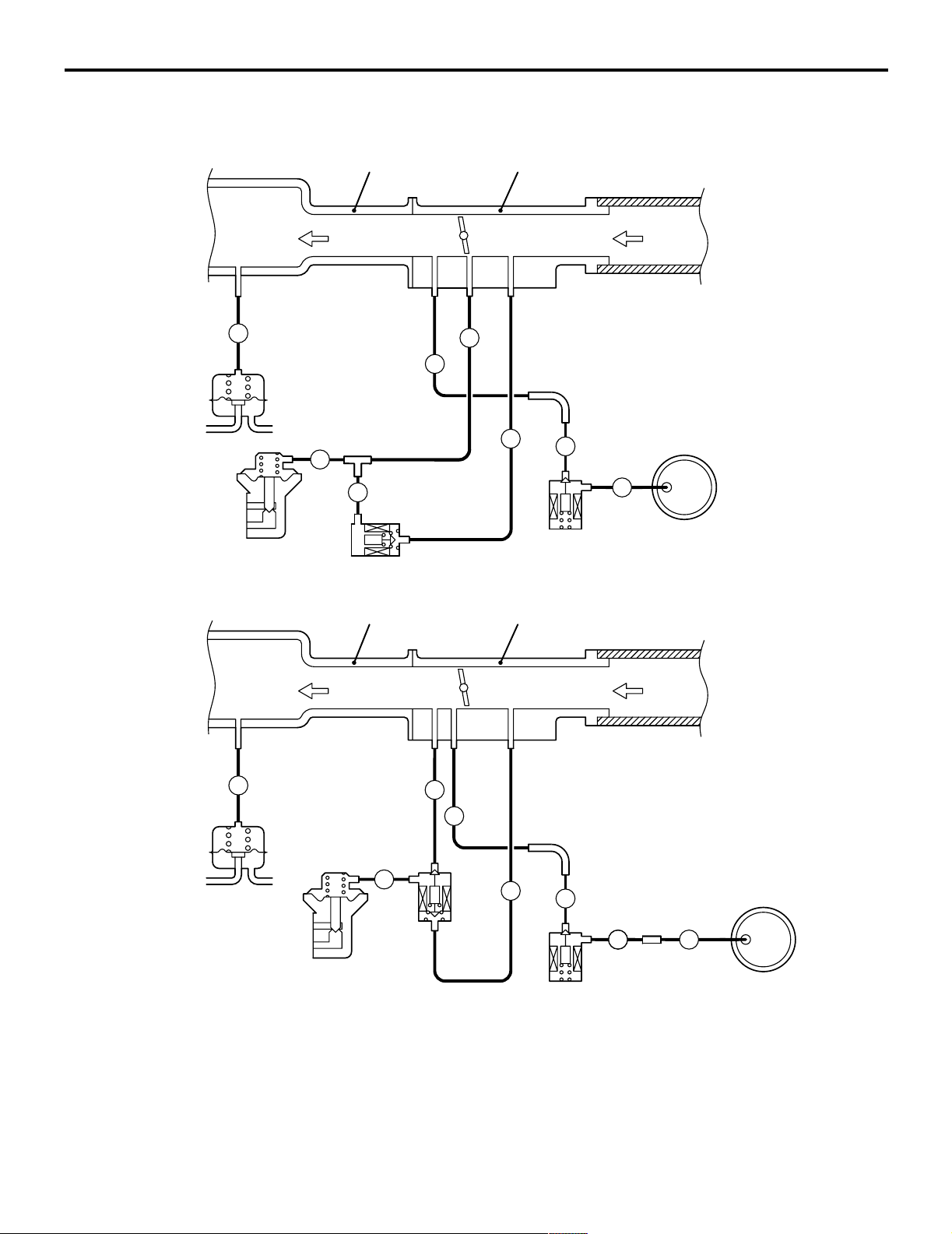

VACUUM CIRC UIT DIA GRAM

<4G1>

To

combustion

chamber

L

Fuel

pressure

regulator

Vacuum hose colour

B: Black

G: Green

R: Red

Y: Yellow

L: Blue

EGR

valve

G

M1173007100263

Intake manifold

G

EGR

control

solenoid

valve

Throttle body

From

air

cleaner

G

R

Y

R

Purge

control

solenoid

valve

Canister

B

AK300765

AB

<4G6>

To

combustion

chamber

Fuel

pressure

regulator

Vacuum hose colour

B: Black

G: Green

R: Red

W: White

Y: Yellow

L: Blue

Intake manifold

L

G

EGR

control

solenoid

EGR

valve

valve

W

R

Throttle body

Y

B

B

Purge

control

solenoid

valve

From

air

cleaner

Canister

B

AK300766

AB

17-8

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

VACUUM HOSE CHECK

M1173007300159

1. Using the piping diagram as a guide, check to be

sure that the vacuum hoses are correctly

connected.

2. Check the connection condition of the vacuum

hoses, (removed, loose, etc.) and check to be

sure that there are no bends or damage.

VACUUM HOSE INSTALLATION

M1173007200107

1. When connecting the vacuum hoses, they should

be securely inserted onto the nipples.

2. Connect the hoses correctly, using the vacuum

hose piping diagram as a guide.

CRANKCASE EMISSION CONTROL

SYSTEM

GENERAL INFORMATION (CRANKCASE

EMISSION CONTROL SYSTEM)

M1173005000237

The crankcase emission control system prevents

blow-by gases from escaping inside the crankcase

into the atmosphere.

Fresh air is sent from the air cleaner into the

crankcase through the breather hose.

The air becomes mixed with the blow-by gases

inside the crankcase.

The blow-by gas inside the crankcase is drawn into

the intake manifold through the positive crankcase

ventilation (PCV) valve.

The PCV valve lifts the plunger according to the

intake manifold vacuum so as to regulate the flow of

blow-by gas properly.

In other words, the blow-by gas flow is regulated

during low load engine operation to maintain engine

stability, while the flow is increased during high load

operation to improve the ventilation performance.

SYSTEM DIAGRAM

Ventilation hose

PCV valve

Breather hose

Air cleaner

AK204365

Air

AB

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

17-9

COMPONENT LOCATION (CRANKCASE

EMISSION CONTROL SYSTEM)

M1173007400208

<4G1>

PCV valve

AK300767

<4G6>

PCV valve

AK204366

AB

AC

POSITIVE CRANKCASE VENTILATION

(PCV) VALVE CHECK

M1173001200187

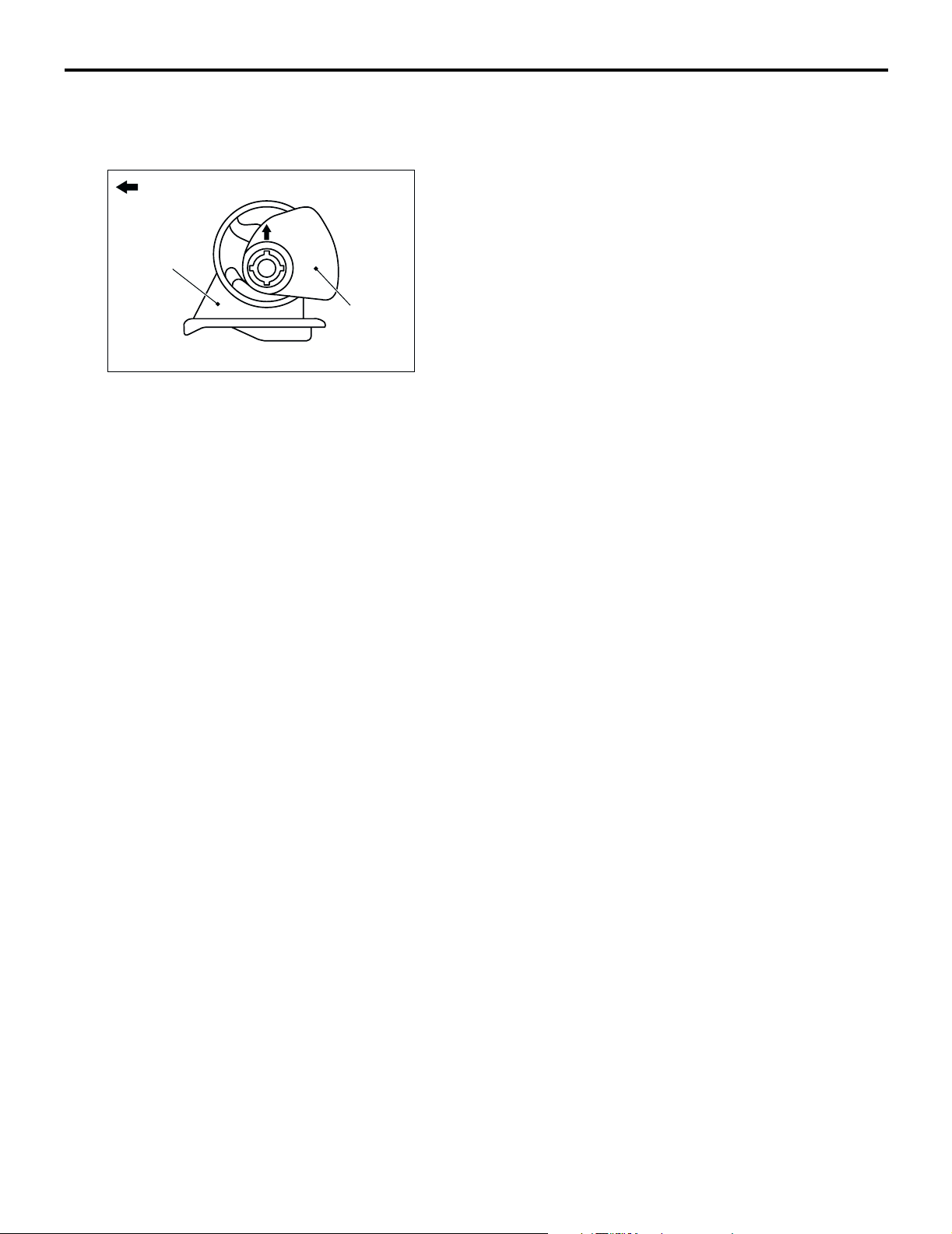

PCV valve

AK100010

AC

1. Insert a thin rod into the PCV valve from the side

shown in the illustration (rocker cover installation

side), and move the rod back and forth to check

that the plunger moves.

2. If the plunger does not move, there is a clogging

in the PCV valve. In this case, clean or replace

the PCV valve.

EVAPORATIVE EMISSION CONTROL

SYSTEM

POSITIVE CRANKCASE VENTILATION

SYSTEM CHECK

M1173001100179

1. Remove the ventilation hose from the PCV valve.

2. Remove the PCV valve from the rocker cover.

3. Reinstall the PCV valve at the ventilation hose.

4. Start the engine and run at idle.

PCV valve

AKX00336

5. Place a finger at the opening of the PCV valve

and check that vacuum of the intake manifold is

felt.

NOTE: At this moment, the plunger in the PCV

valve moves back and forth.

6. If vacuum is not felt, clean the PCV valve or

replace it.

AD

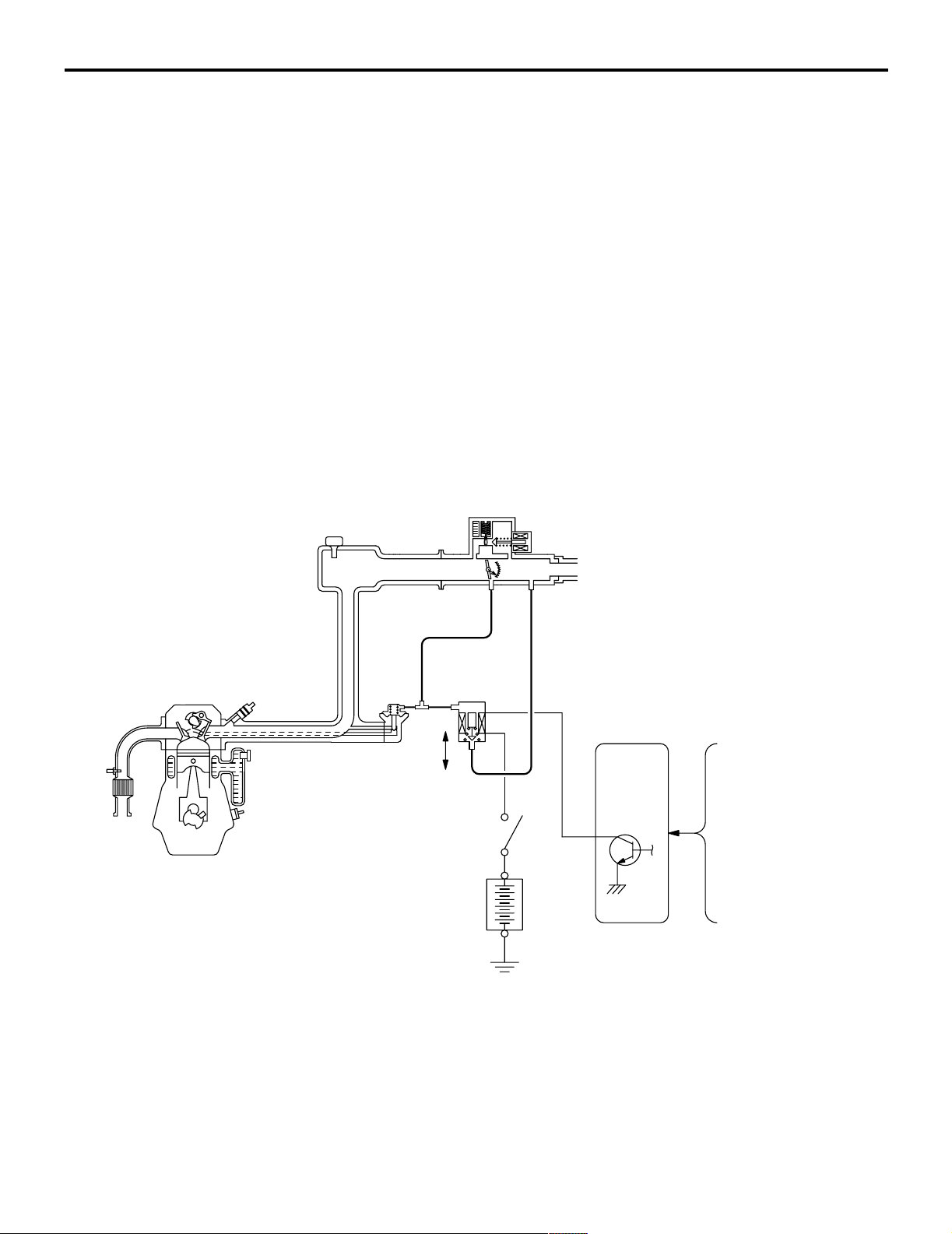

GENERAL INFORMATION (EVAPORATIVE

EMISSION CONTROL SYSTEM)

M1173005100405

The evaporative emission control system prevents

fuel vapours generated in the fuel tank from escaping

into the atmosphere.

Fuel vapours from the fuel tank flow through the fuel

tank pressure control valve and vapour pipe/hose to

be stored temporarily in the canister.

When driving the vehicle, fuel vapours stored in the

canister flow through the purge solenoid and purge

port and go into the intake manifold to be sent to the

combustion chamber.

When the engine coolant temperature is low or when

the intake air quantity is small (when the engine is at

idle, for example), the engine control unit turns the

purge solenoid off to shut off the fuel vapour flow to

the intake manifold.

This does not only insure the driveability when the

engine is cold or running under low load but also

stabilize the emission level.

17-10

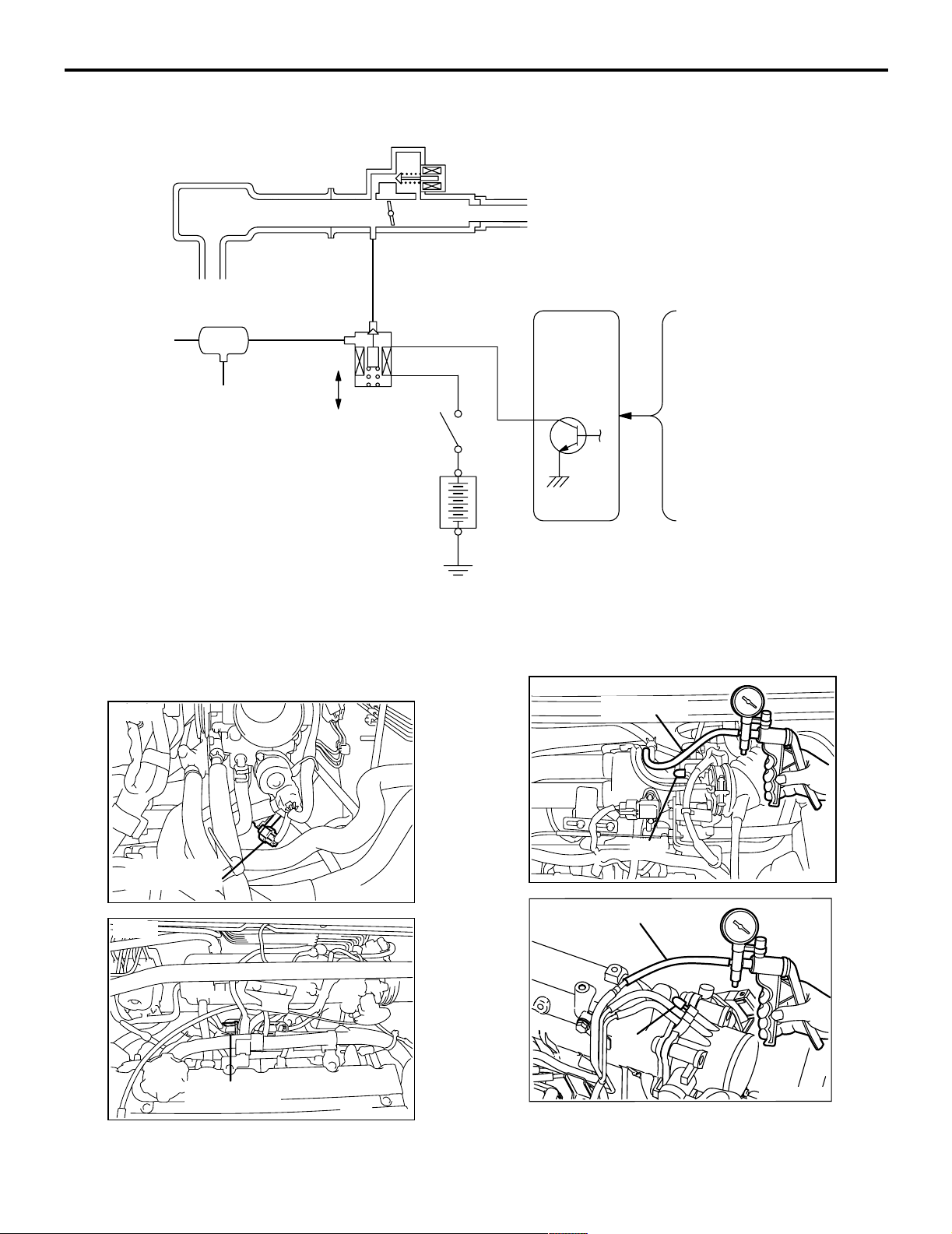

SYSTEM DIAGRAM

From

fuel

tank

Canister

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

Throttle body

Engine-ECU <4G1-M/T, 4G6>,

Engine-A/T-ECU <4G1-A/T>

OFF

Purge

control

ON

solenoid

valve

Battery

Control

relay

Manifold absolute pressure

(MAP) sensor <4G1>

Air flow sensor <4G6>

Engine coolant

temperature sensor

Intake air

temperature sensor

Barometric pressure

sensor <4G6>

COMPONENT LOCATION (EVAPORATIVE

EMISSION CONTROL SYSTEM)

M1173007500216

<4G1>

Purge control

solenoid valve

<4G6>

AK300769

AB

AK204367

PURGE CONTROL SYSTEM CHECK

M1173001400299

<4G1>

Vacuum hose

Plug

<4G6>

AK300771

Vacuum hose

Plug

AB

AC

Purge control

solenoid valve

AK300770

AB

AK300772

AB

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

1. Disconnect the vacuum hose (red stripe) from

throttle body and connect it to a hand vacuum

pump.

2. Plug the nipple from which the vacuum hose was

removed.

3. When the engine is cold or hot, apply a vacuum of

53 kPa, and check the condition of the vacuum.

17-11

Vacuum

When engine is cold

(Engine coolant temperature: 40°C or less)

Engine condition Normal condition

At idle Vacuum is maintained.

3,000 r/min

When engine is hot

(Engine coolant temperature: 80°C or higher)

Engine condition Normal condition

At idle Vacuum is maintained.

3,000 r/min (within 3

Vacuum will leak.

minutes after engine

starts)

PURGE PORT VACUUM CHECK

M1173001500177

<4G1>

Vacuum hose

Plug

Engine speed (r/min)

AK100011

AC

3. Start the engine.

4. Check that a fairly constant negative pressure is

generated regardless of the engine speed.

5. If no negative pressure is generated, the port is

probably blocked and should be cleaned.

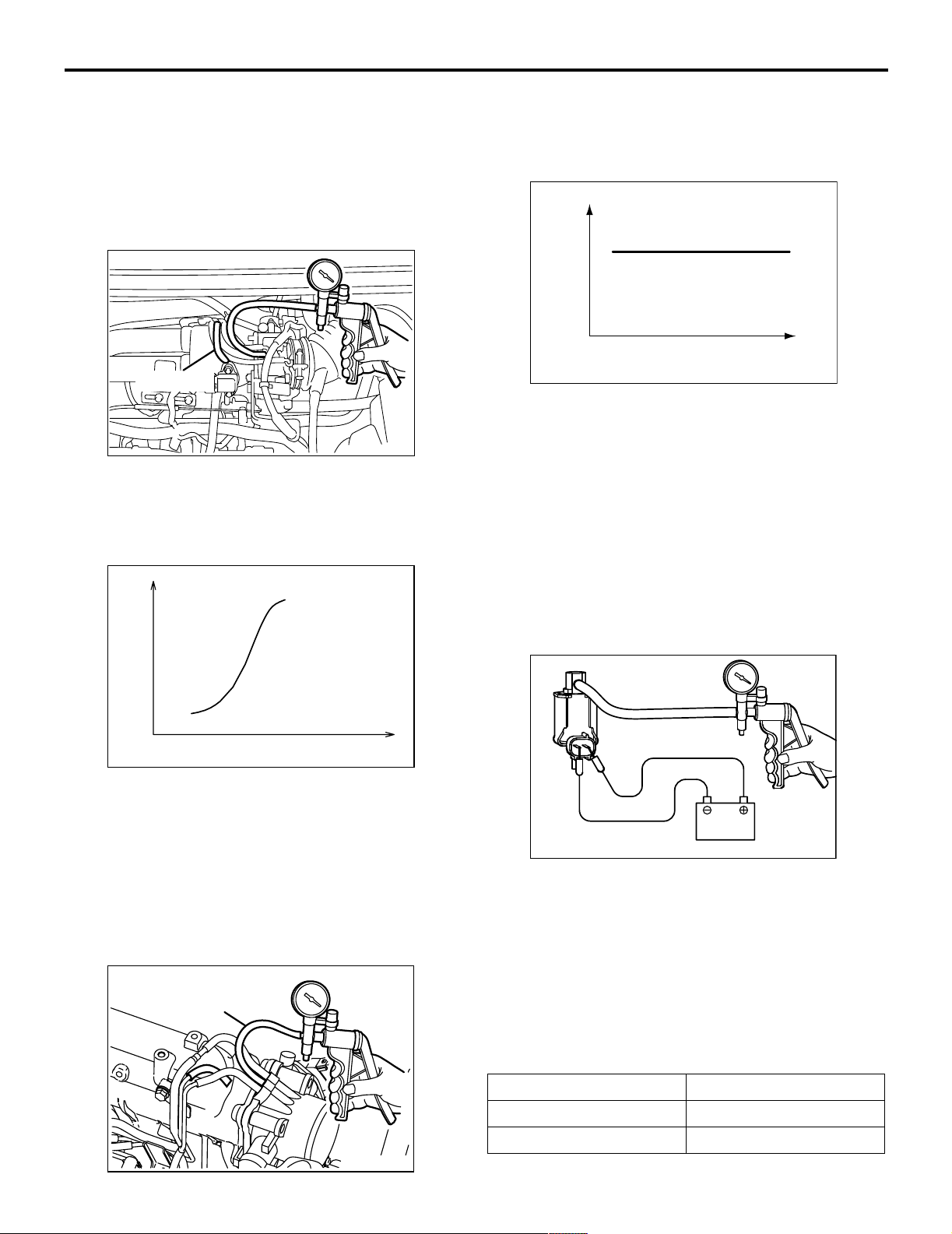

PURGE CONTROL SOLENOID VALVE

CHECK

M1173001700193

NOTE: When disconnecting the vacuum hose,

always make a mark so that it can be reconnected at

original position.

A

AK300773

<4G6>

Vacuum hose

Plug

AK300774

AB

AB

1. Disconnect the vacuum hose (red stripe) from the

throttle body and connect a hand vacuum pump to

the nipple.

2. Plug the vacuum hose (red stripe).

Battery

AK100012

AC

AK100013

1. Disconnect the vacuum hose from the solenoid

valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the

solenoid valve (refer to the illustration at left).

17-12

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

4. Check airtightness by applying a vacuum with

voltage applied directly from the battery to the

purge control solenoid valve and without applying

voltage.

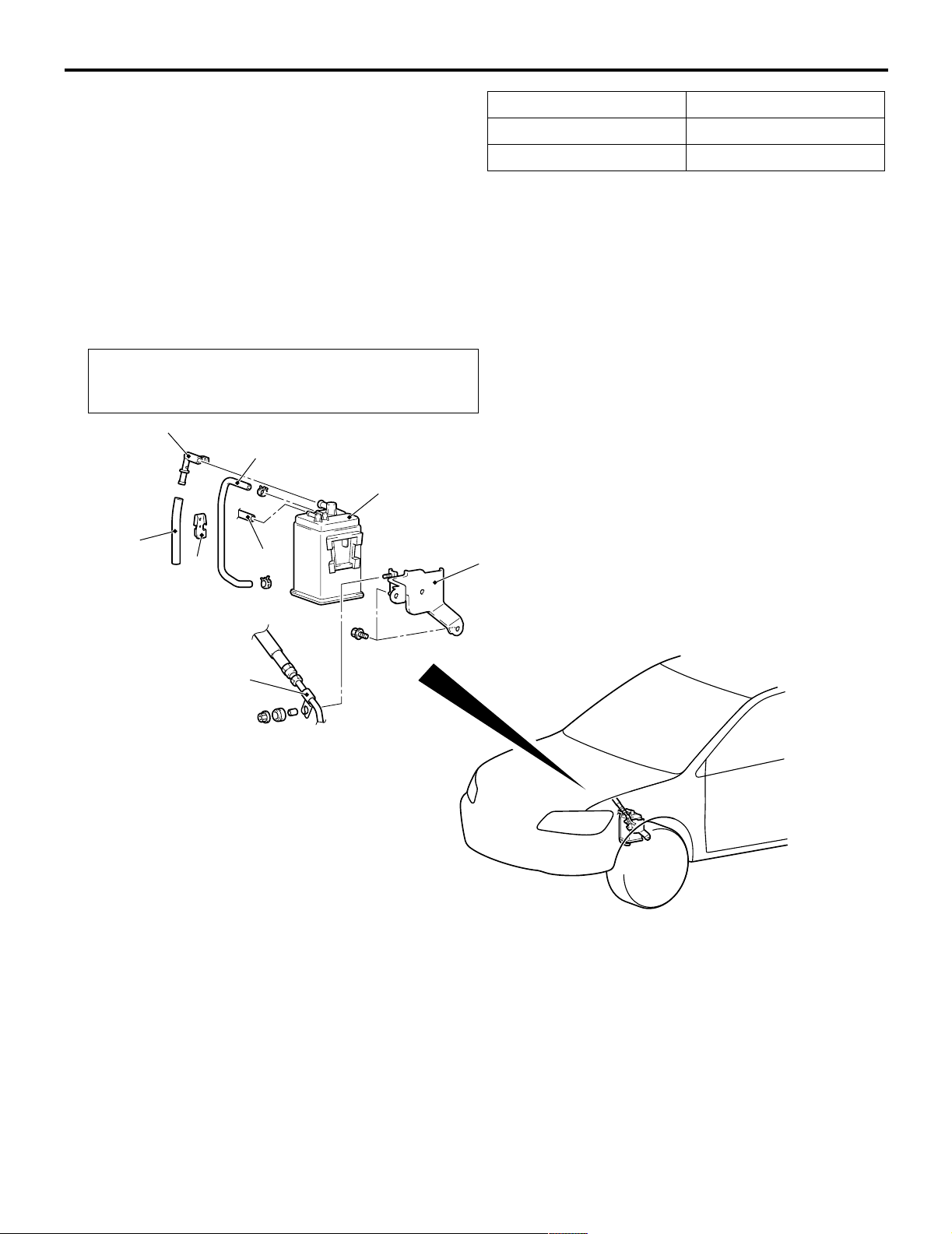

FUEL VAPOUR CANISTER REMOVAL

AND INSTALLATION

M1173004200153

Pre-removal and Post-installation Operation

Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

3

2

6

4

5

1

Battery voltage Normal condition

Applied Vacuum leaks

Not applied Vacuum maintained

5. Measure the resistance between the terminals of

the solenoid valve.

Standard value: 30 − 34 Ω (at 20°C)

8

7

Removal steps

1. Emission vacuum hose connection

2. Fuel vapour control line hose

3. Fuel vapour control check valve

4. Fuel vapour control line hose

AC208253

Removal steps (Continued)

5. Fuel vapour control line clamp

6. Fuel vapour canister

7. Fuel high-pressure hose clamp

8. Fuel vapour canister bracket

AD

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

17-13

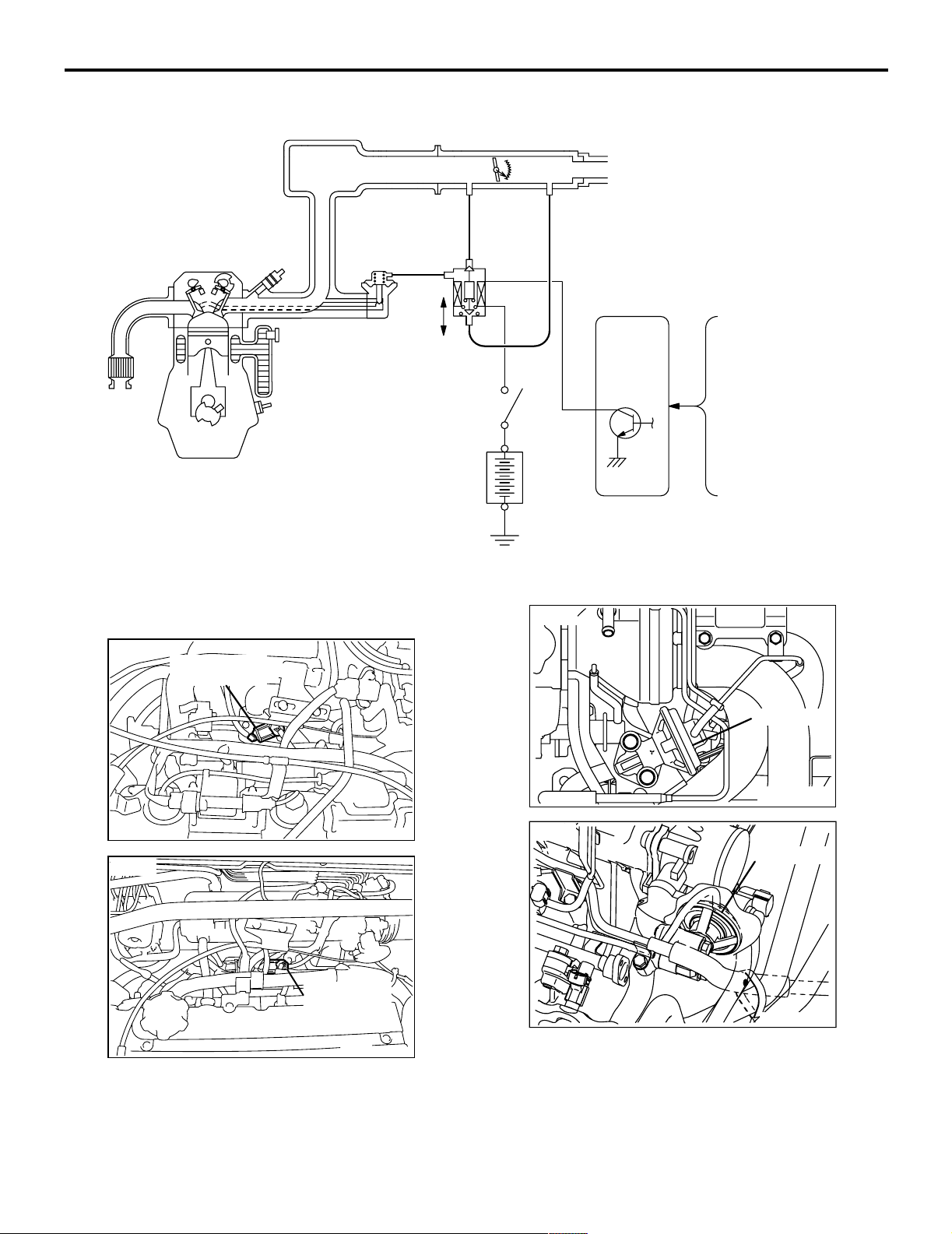

EXHAUST GAS RECIRCULATION

(EGR) SYSTEM

GENERAL INFORMATION (EGR SYSTEM)

M1173005200327

The exhaust gas recirculation (EGR) system lowers

the nitrogen oxide (NOx) emission level.

When the air/fuel mixture combustion temperature is

high, a large quantity of nitrogen oxides (NOx) is

generated in the combustion chamber.

Therefore, this system recirculates part of emission

gas from the exhaust port of the cylinder head to the

combustion chamber through the intake manifold to

decrease the air/fuel mixture combustion

temperature, resulting in reduction of NOx.

SYSTEM DIAGRAM

<4G1>

The EGR flow rate is controlled by the EGR valve so

as not to decrease the driveability.

OPERATION

The EGR valve is being closed and does not

recirculate exhaust gases under one of the following

conditions.

Otherwise, the EGR valve is opened and recirculates

exhaust gases.

• The engine coolant temperature is low.

• The engine is at idle.

• The throttle valve is widely opened.

EGR valve

OFF

ON

Battery

EGR

control

solenoid

valve

Control

relay

Engine-ECU <M/T>,

Engine-A/T-ECU <A/T>

Manifold absolute

pressure (MAP) sensor

Engine coolant

temperature sensor

Crank angle sensor

AK300775

AB

17-14

<4G6>

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

EGR

control

Solenoid

valve

OFF

EGR valve

ON

Battery

COMPONENT LOCATION (EGR SYSTEM)

M1173007600224

<4G1>

EGR control

solenoid valve

Control

relay

<4G1>

Engine-ECU

Barometric pressure

sensor

Air flow sensor

Engine coolant

temperature sensor

Crank angle sensor

AK302349

EGR valve

AB

<4G6>

AK300776

EGR control

solenoid valve

AK300778

AB

AB

<4G6>

AK300777

EGR valve

AK300779

AB

AB

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

17-15

EGR SYSTEM CHECK

M1173002600348

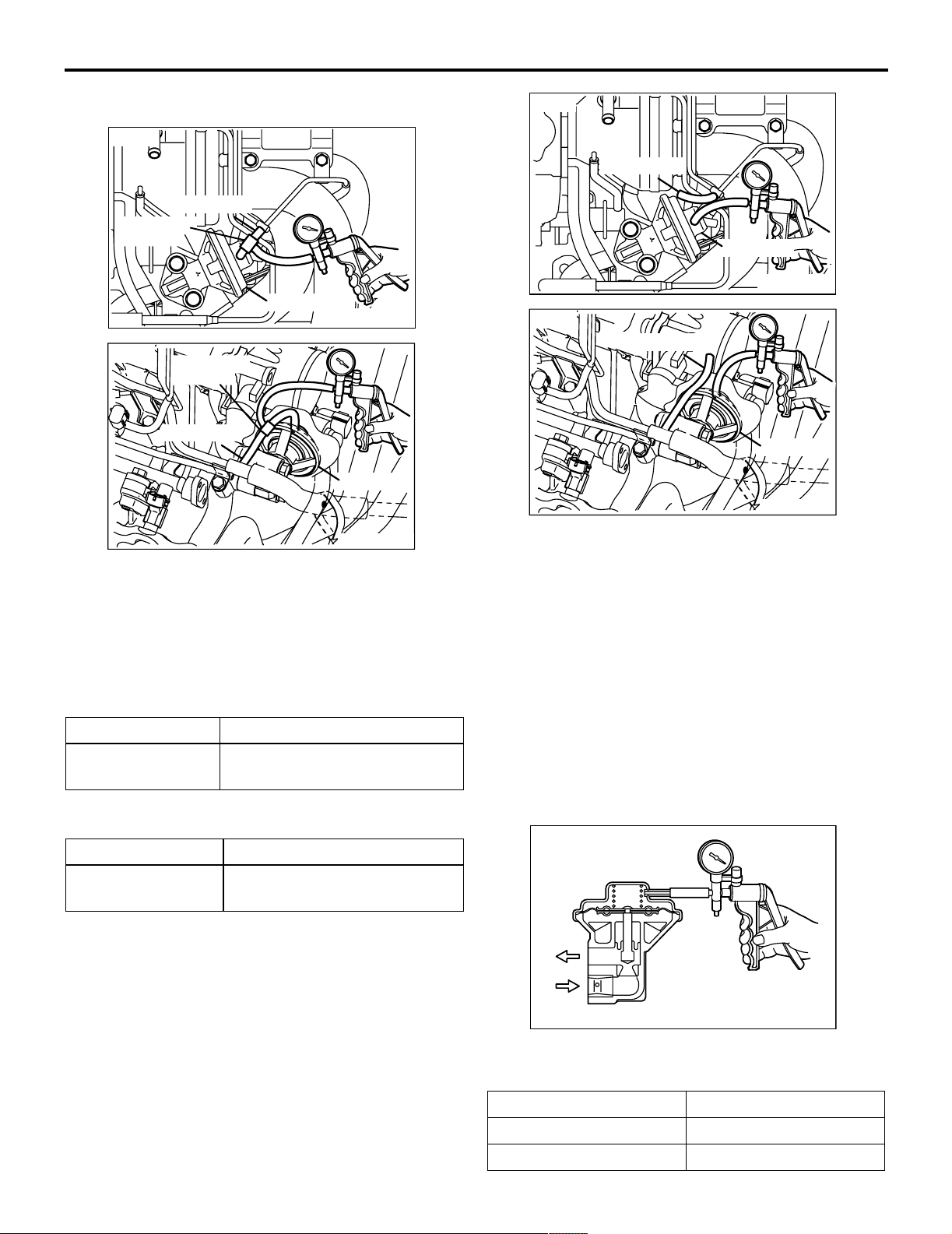

<4G1>

Green stripe

Three-way

terminal

<4G6>

EGR valve

Three-way

terminal

Green stripe

AK300780

EGR valve

AK300781

1. Disconnect the vacuum hose (Green stripe) from

the EGR valve, and then connect a hand vacuum

pump via the three-way terminal.

2. When the engine is hot or cold, check the

condition of vacuum by racing the engine.

When engine is cold

(Engine coolant temperature: 20°C or less)

Throttle valve Normal vacuum condition

Open quickly No vacuum will generate (the

same as barometric pressure.)

When engine is hot

(Engine coolant temperature: 80°C or higher)

Throttle valve Normal vacuum condition

AB

AB

<4G1>

Green stripe

EGR valve

AK300782

<4G6>

Green stripe

EGR valve

AK300783

AB

AB

4. Connect the hand vacuum pump to the EGR

valve nipple.

5. Check whether the engine stalls or the idling is

unstable when a vacuum of 30 kPa or higher is

applied during idling.

EGR VALVE CHECK

M1173002800223

1. Remove the EGR valve and inspect for sticking,

carbon deposits, etc. If found, clean with a

suitable solvent so that the valve seats correctly.

2. Connect a hand vacuum pump to the EGR valve.

3. Apply 67 kPa of vacuum, and check that the

vacuum is maintained.

Open quickly It will momentarily rise over 13

kPa

3. Disconnect the three-way terminal.

AKX00348

4. Apply a vacuum and check the passage of air by

blowing through one side of the EGR passage.

Vacuum Passage of air

5.3 kPa or less Air is not blown out

27 kPa or more Air is blown out

17-16

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

5. Replace the gasket, and tighten to the specified

torque.

Tightening torque:

<4G1> 21 ± 4 N⋅m

<4G6> 20 ± 2 N⋅m

EGR PORT VACUUM CHECK <4G1>

M1173002900167

Green strip

AK300784

1. Disconnect the vacuum hose (Green stripe) from

the throttle body EGR vacuum nipple and connect

a hand vacuum pump to the nipple.

2. Plug the vacuum hose (Green stripe).

Vacuum

AB

1. Disconnect the vacuum hose (White stripe) from

the throttle body EGR vacuum nipple and connect

a hand vacuum pump to the nipple.

2. Plug the vacuum hose (White stripe).

Vacuum

Engine speed (r/min)

AK100011

AC

3. Start the engine.

4. Check that a fairly constant negative is generated

regardless of the engine speed.

5. If no negative pressure is generated, the port is

probably blocked and should be cleaned.

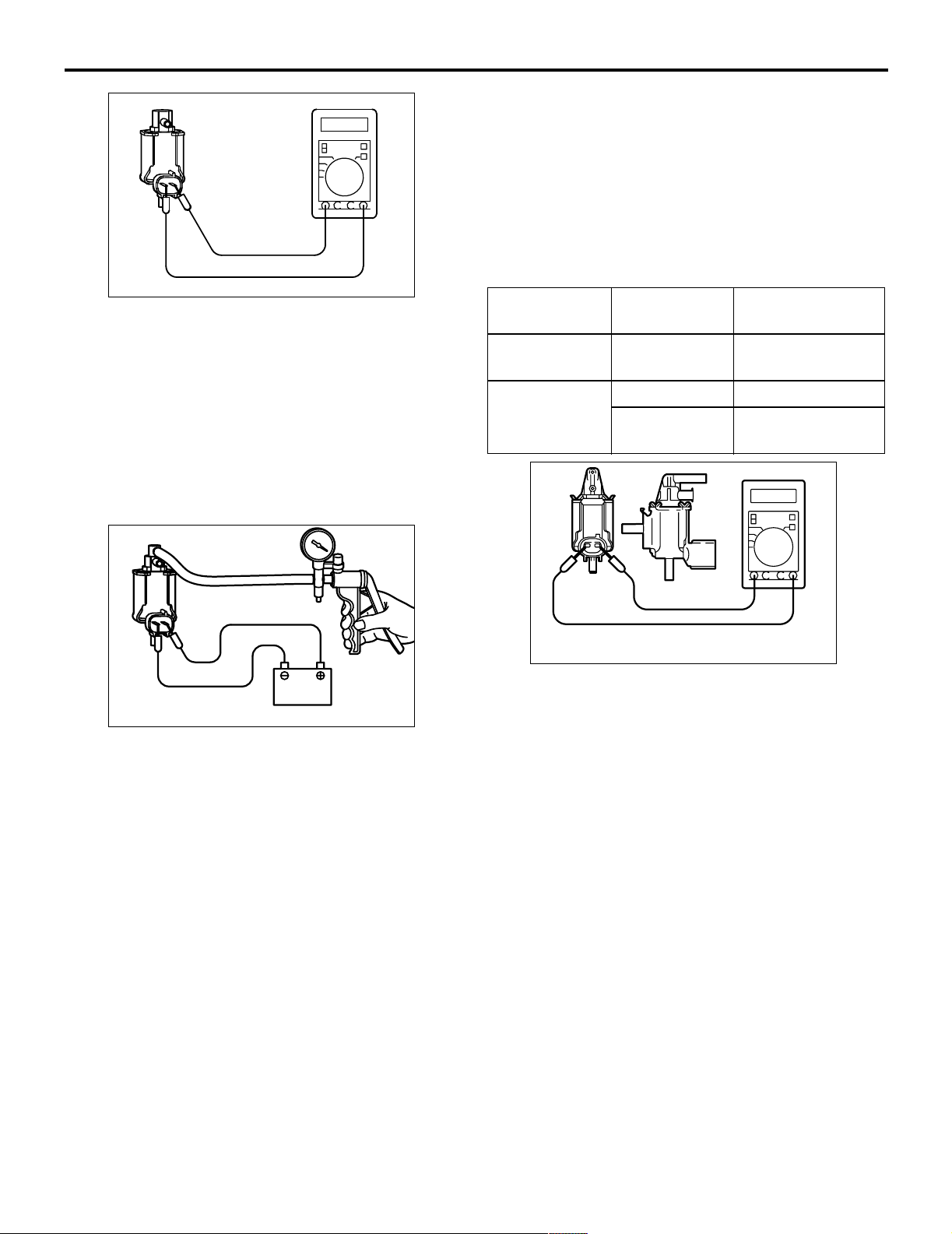

EGR CONTROL SOLENOID VALVE

CHECK <4G1>

M1173003100238

NOTE: When disconnecting the vacuum hose,

always make a mark so that it can be reconnected at

original position.

A

Engine speed (r/min)

AK201224AB

3. Start the engine and check that, after raising the

engine speed by racing the engine, purge vacuum

raises according to engine speed.

NOTE: If there is a problem with change in

vacuum, the throttle body purge port may be

clogged and require cleaning.

EGR PORT VACUUM CHECK <4G6>

M1173002900156

White stripe

AK300786

AB

B

Battery

AKX00351

AE

1. Disconnect the vacuum hose from the solenoid

valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the

solenoid valve (refer to the illustration at left).

4. Check air tightness by applying a vacuum with

voltage applied directly from the battery to the

EGR control solenoid valve and without applying

voltage.

Battery voltage Normal condition

Applied Vacuum leaks

Not applied Vacuum maintained

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

AKX00352

5. Measure the resistance between the terminals of

the solenoid valve.

Standard value: 29 − 35 Ω (at 20°C)

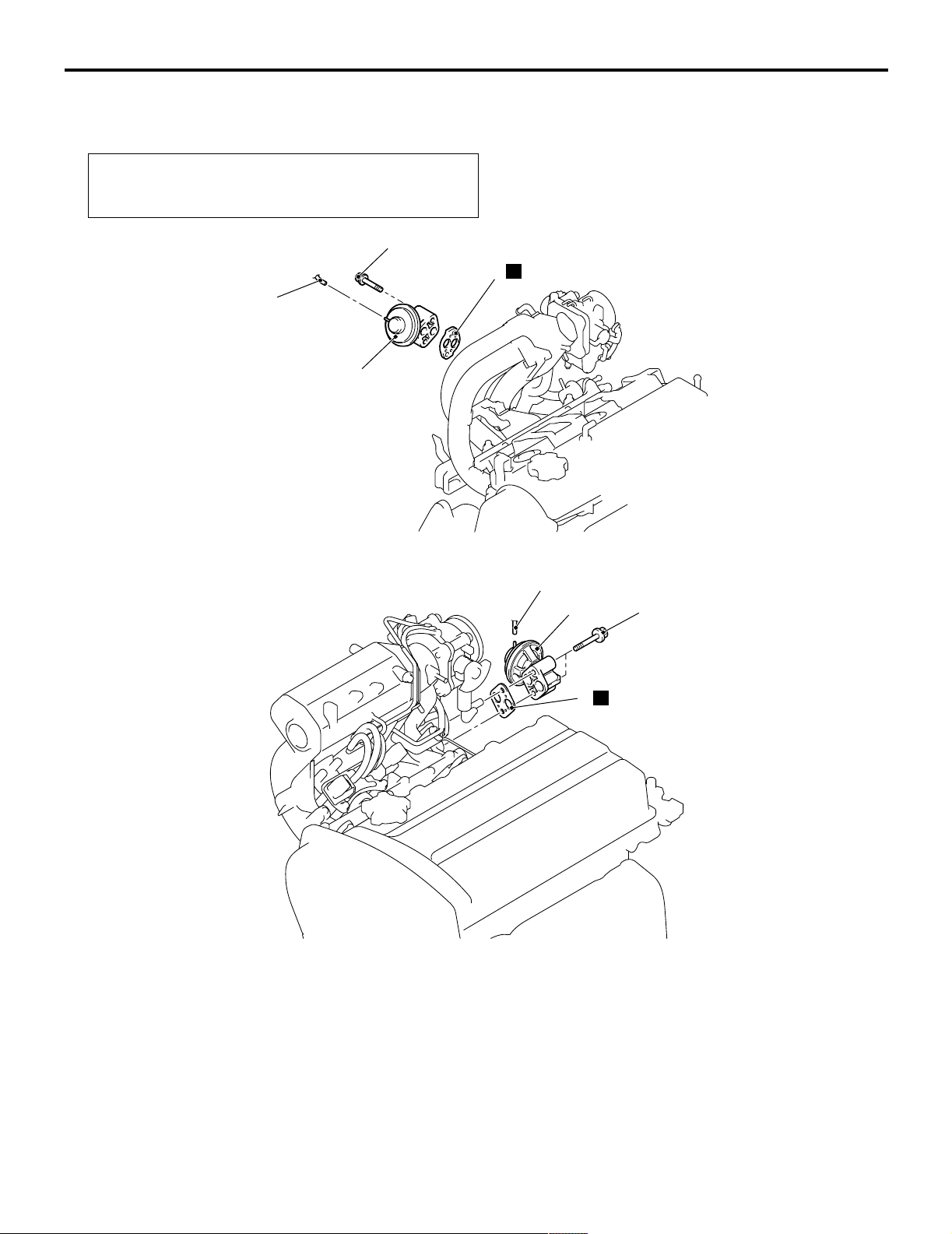

EGR CONTROL SOLENOID VALVE

CHECK <4G6>

M1173003100249

NOTE: When disconnecting the vacuum hose,

always make a mark so that it can be reconnected at

original position.

17-17

1. Disconnect the vacuum hose from the solenoid

valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the

solenoid valve (refer to the illustration at left).

4. Check air tightness by applying a vacuum with

voltage applied directly from the battery to the

EGR control solenoid valve and without applying

voltage.

Battery

voltage

Not applied Open Vacuum

Applied Open Vacuum leaks

B nipple

Normal condition

condition

maintained

Closed Vacuum

maintained

A

B

C

Battery

AK201251AB

5. Measure the resistance between the terminals of

the solenoid valve.

AK100016

Standard value: 29 − 35 Ω (at 20°C)

17-18

ENGINE AND EMISSION CONTROL

EMISSION CONTROL <MPI>

EXHAUST GAS RECIRCULATION (EGR)

VALVE REMOVAL AND INSTALLATION

M1173010500175

Pre-removal and Post-installation Operation

Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

<4G1>

<4G6>

21 ± 4 N·m

N

3

1

2

AC208130

AC

1

2

19 ± 3 N·m

Removal steps

1. Emission vacuum hose connection

CATALYTIC CONVERTER

REMOVAL AND INSTALLATION

M1173003900386

Refer to GROUP 15 — Exhaust Pipe and Main Muffler P.15-11.

N

3

Removal steps (Continued)

2. EGR valve

3. EGR valve gasket

AC301219

AC

GROUP 13

FUEL

CONTENTS

MULTIPORT FUEL INJECTION (MPI) <4G1> . . . . . . . . . . . . . . 13A

MULTIPORT FUEL INJECTION (MPI) <4G6> . . . . . . . . . . . . . . 13B

13-1

FUEL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13C

NOTES

GROUP 32

POWER PLANT

MOUNT

CONTENTS

32-1

GENERAL INFORMATION . . . . . . . . 32-2

SERVICE SPECIFICATION . . . . . . . . 32-3

SPECIAL TOOL . . . . . . . . . . . . . . . . . 32-3

ENGINE MOUNTING . . . . . . . . . . . . . 32-4

REMOVAL AND INSTALLATION . . . . . . . . 32-4

TRANSMISSION MOUNTING . . . . . . 32-5

REMOVAL AND INSTALLATION . . . . . . . . 32-5

ENGINE ROLL STOPPER,

CENTERMEMBER . . . . . . . . . . . . . . . 32-7

REMOVAL AND INSTALLATION . . . . . . . . 32-7

CROSSMEMBER . . . . . . . . . . . . . . . . 32-8

REMOVAL AND INSTALLATION . . . . . . . . 32-8

32-2

POWER PLANT MOUNT

GENERAL INFORMATION

GENERAL INFORMATION

The engine mounting system employs the inertial

axis four-point suspension method, which is field

proven.

• The optimised locations of the front and rear roll

mounts well distribute their loads thereby

reducing engine idling vibrations.

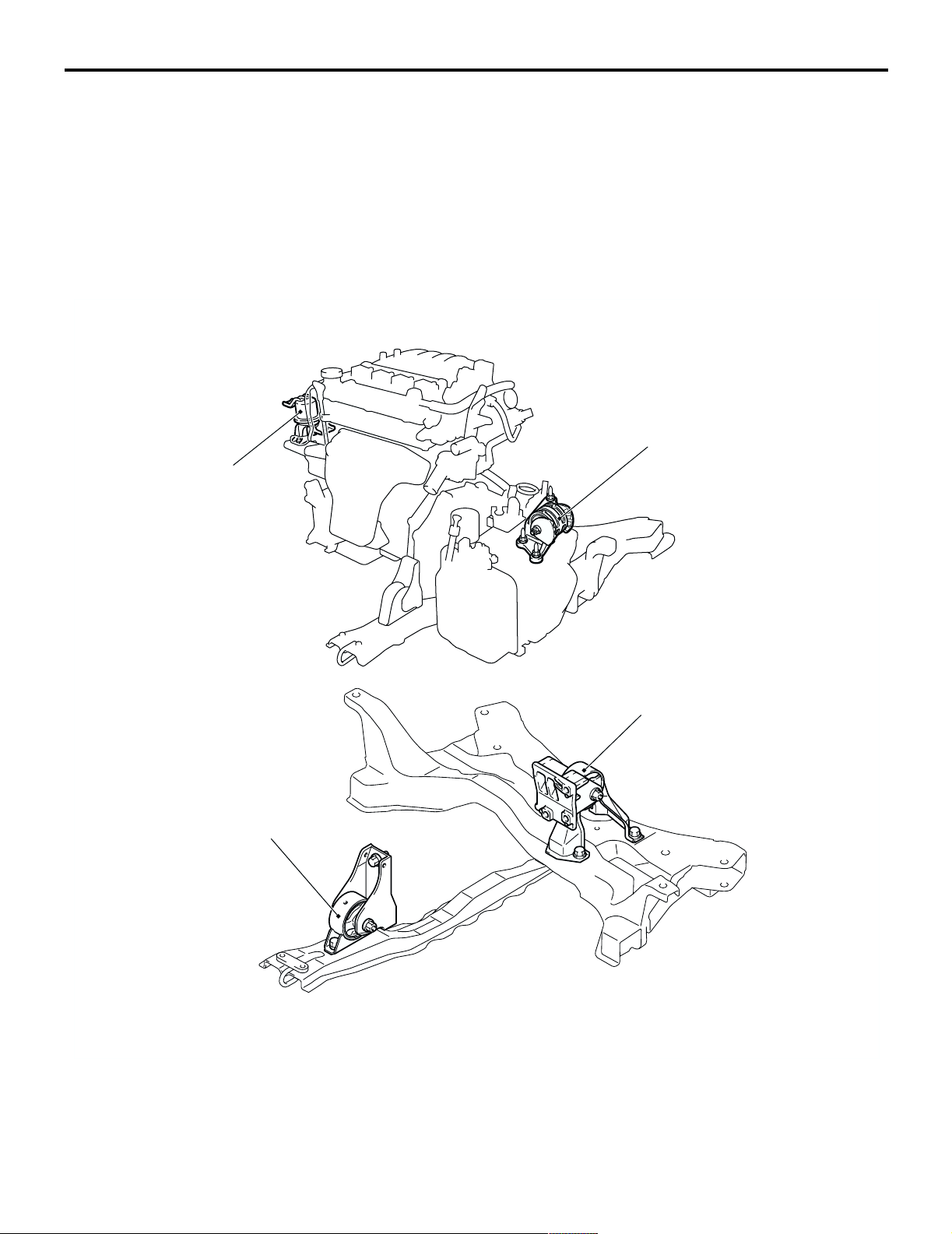

CONSTRUCTION DIAGRAM

Engine front

mounting bracket

• The fore-and-aft, liquid-filled engine mount of

M1321000100340

cylinder type is adopted to reduce engine shake

for improved riding comfort.

Transmission mounting

body side bracket

Engine front roll stopper bracket

Engine rear roll stopper bracket

Y0290AU

AC107318

AC303563

AB

POWER PLANT MOUNT

SERVICE SPECIFICATION

SERVICE SPECIFICATION

Item Standard value

Protruding length of stabilizer link thread part mm 22 ± 1.5

SPECIAL TOOL

Tool Numb er Name Use

MB991897 Ball joint remover Knuckle and tie rod end ball joint

disconnection

NOTE: Steering linkage puller

(MB990635 or MB991113) is also

AC106827

available to disconnect knuckle and

tie rod end ball joint.

32-3

M1321000300333

M1321000600378

32-4

POWER PLANT MOUNT

ENGINE MOUNTING

ENGINE MOUNTING

REMOVAL AND INSTALLATION

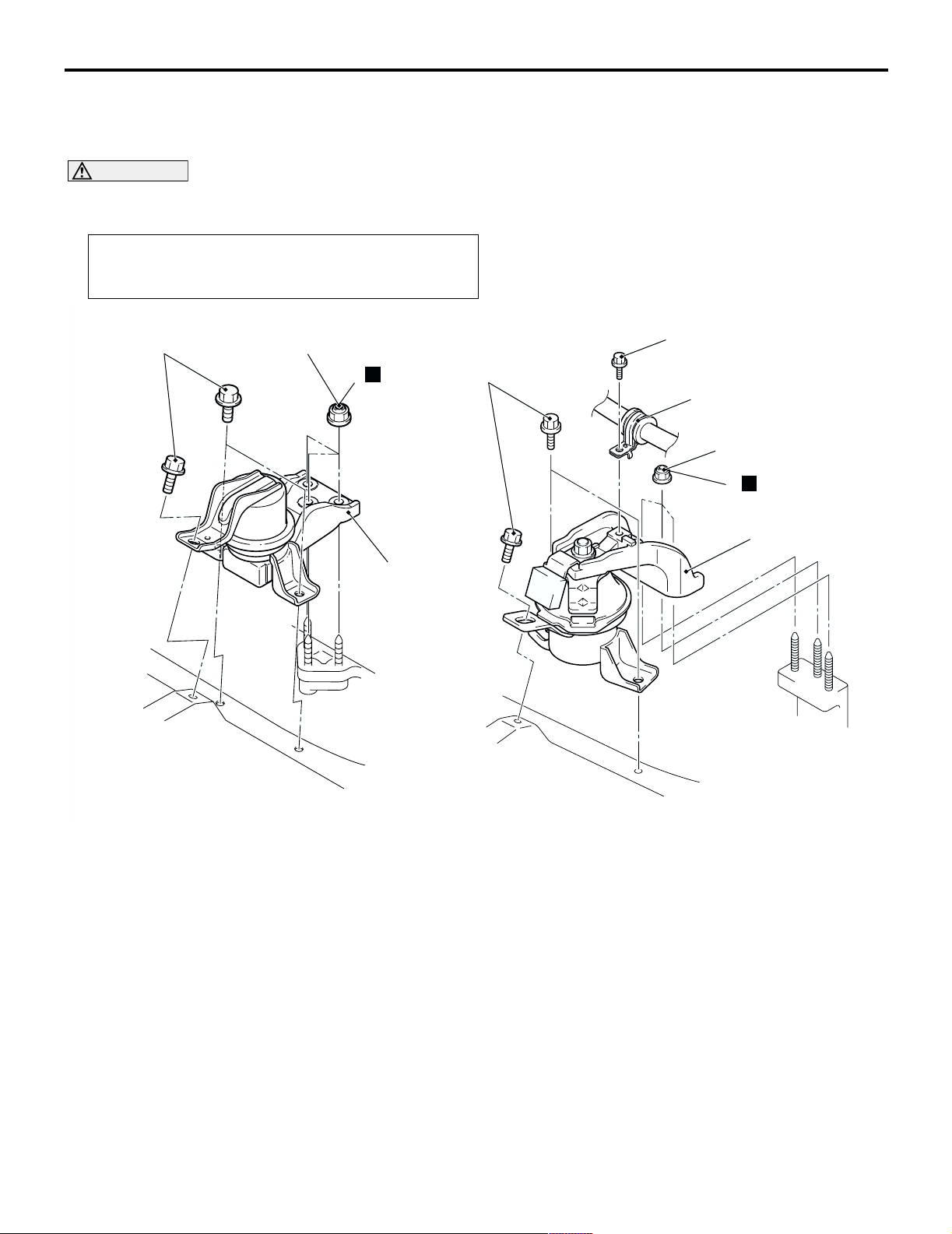

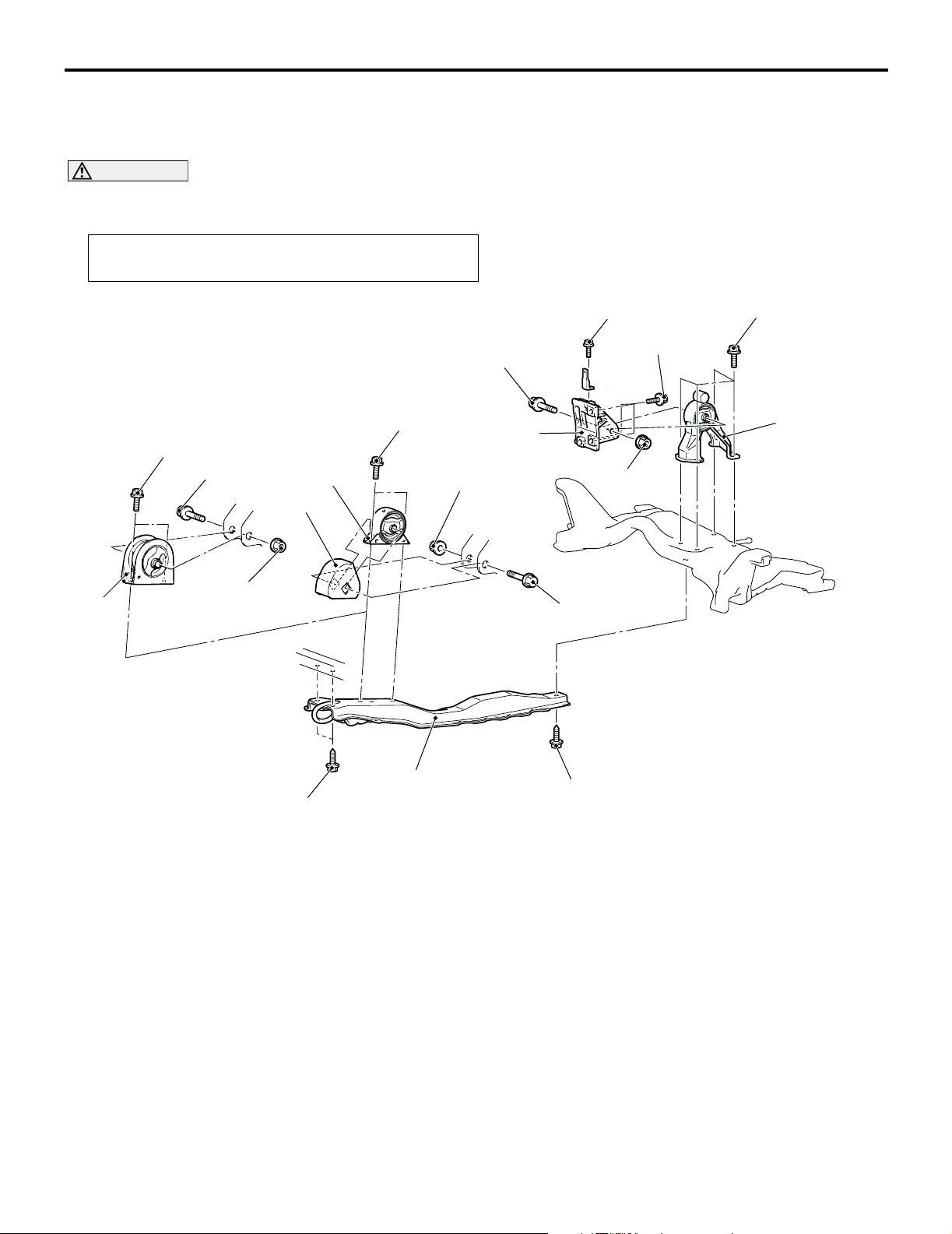

M1321001100440

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

Raise the engine and transmission assembly until its weight

is not applied to the insulator, and support it securely.

<4G1> <4G6>

44 ± 10 N·m*

67 ± 7 N·m*

N

2

44 ± 10 N·m*

3

12 ± 2 N·m

1

67 ± 7 N·m*

N

2

3

AC303999 AC303968

Removal steps

1. Pressure hose clamp <4G6>

AC304304

Removal steps (Continued)

2. Self-locking nuts

3. Engine front mounting bracket

AB

POWER PLANT MOUNT

TRANSMISSION MOUNTING

TRANSMISSION MOUNTING

32-5

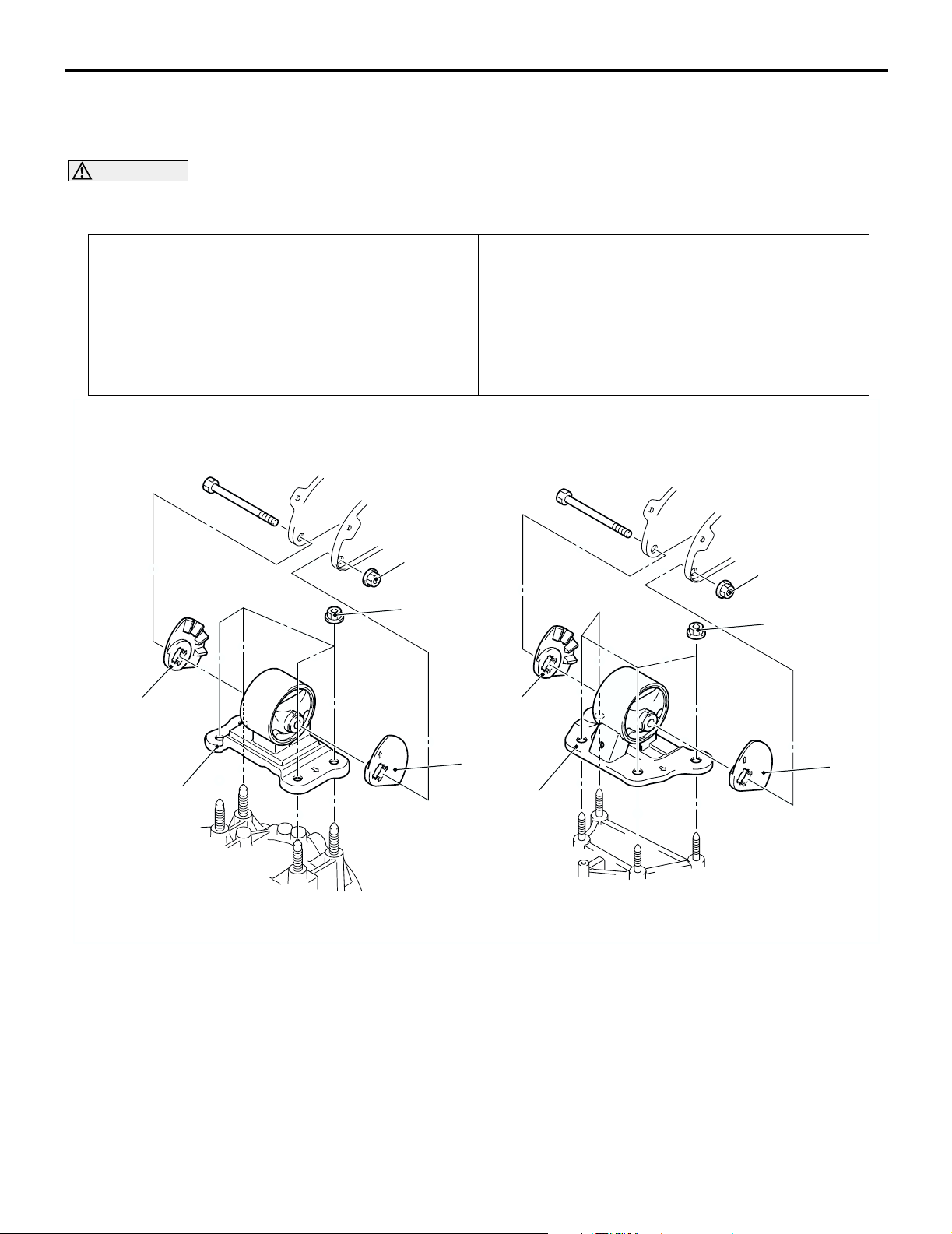

REMOVAL AND INSTALLATION

M1321001400430

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

• Raise the engine and transmission assembly until its

weight is not applied to the insulator, and support it

securely.

• Battery and Battery tray Removal

• Air Cleaner Removal (Refer to GROUP 15, Air Cleaner

P.15-3).

• Engine Rear Roll Stopper Bracket Removal (Refer to

P.32-7).

<M/T> <A/T>

80 ± 7 N·m*

Post-installation Operation

• Engine Rear Roll Stopper Bracket Installation (Refer to

P.32-7).

• Air Cleaner Installation (Refer to GROUP 15, Air Cleaner

P.15-3).

• Battery and Battery tray Installation

80 ± 7 N·m*

2

>>A<<

1

Removal steps

1. Transmission mounting body side

bracket

2. Transmission mounting stopper

47 ± 7 N·m*

2

AC303988

47 ± 7 N·m*

2

2

1

AC303989

AC304258

AB

32-6

POWER PLANT MOUNT

TRANSMISSION MOUNTING

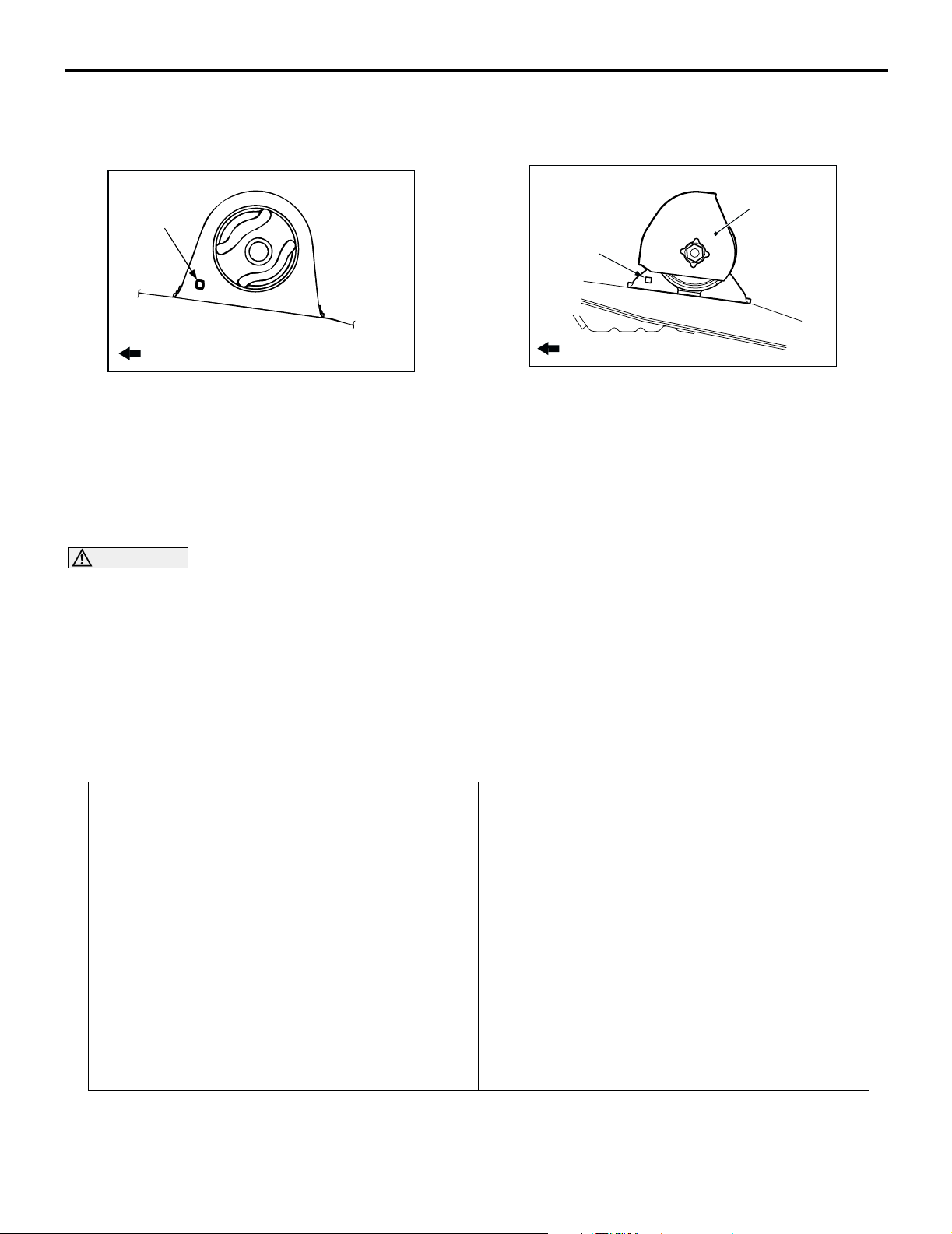

INSTALLATION SERVICE POINT

>>A<< TRANSMISSION MOUNTING

STOPPER INSTALLATION

Engine side

Transmission

mounting body

side bracket

Transmission

mounting

stopper

AC200645

AB

Install the transmission mounting stopper so that its

arrow points upward.

POWER PLANT MOUNT

ENGINE ROLL STOPPER, CENTERMEMBER

ENGINE ROLL STOPPER, CENTERMEMBER

32-7

REMOVAL AND INSTALLATION

M1321002300287

CAUTION

*: Indicates parts which should be initially tightened, and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal and Post-installation Operation

Under Cover Removal and Installation

45 ± 5 N·m*

7

<4G1> <4G6>

45 ± 5 N·m*

1

3

2

45 ± 5 N·m*

5

52 ± 7 N·m*

11 ± 1 N·m

69 ± 10 N·m

6

52 ± 7 N·m*

3

>>B<<

>>A<<

52 ± 7 N·m*

4

69 ± 10 N·m

Engine front roll stopper bracket

and centermember removal

steps

1. Engine front roll stopper bracket

connecting bolt

Centermember and engine front roll

•

stopper bracket assembly

2. Engine mounting cushion stopper

<4G6>

3. Engine front roll stopper bracket

4. Centermember

1

69 ± 10 N·m

5. Engine rear roll stopper bracket

6. Transmission case rear roll stopper

7. Engine rear roll stopper bracket

AC303978

AC304309

Engine rear roll stopper bracket

removal steps

connecting bolt

bracket

AB

32-8

POWER PLANT MOUNT

CROSSMEMBER

INSTALLATION SERVICE POINTS

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

Hole

>>B<< ENGINE MOUNTING CUSHION

STOPPER INSTALLATION <4G6>

Engine mounting

cushion stopper

Hole

Front of vehicle

AC005918

AC

Install the engine front roll stopper bracket so that its

hole points towards the front side of the vehicle.

Install the engine mounting cushion stopper as

shown.

Front of vehicle

AC304315

AB

CROSSMEMBER

REMOVAL AND INSTALLATION

CAUTION

• Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B Service Precautions P.52B-5, Air bag Module and Clock Spring P.52B-210. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

1

: Indicates parts which should be initially tightened, and then fully tightened after placing the

• *

vehicle horizontally and loading the full weight of the engine on the vehicle body.

2

: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

• *

on the earth in the unladen condition.

Pre-removal Operation

• Centermember Removal (Refer to P.32-7).

• Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

• Stee ring Wheel Air Bag Module Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

• Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).

M1321003200368

Post-installation Operation

• Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

• Centermember Installation (Refer to P.32-7).

• Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

• Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

• Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

• Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-13).

• Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

• Checking Steering Wheel Position with Wheels Straight

Ahead.

• Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-5).

Loading…