Have a look at the manual Yamaha F50 Service Manual online for free. It’s possible to download the document as PDF or print. UserManuals.tech offer 255 Yamaha manuals and user’s guides for free. Share the user manual or guide on Facebook, Twitter or Google+.

SERVICE MANUAL 62Y-28197-3A-11290408 F50A FT50B FT50C

NOTICE This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mechanical and electrical concepts and procedures inherent in the work, for without such knowledge attempted repairs or service to the equipment could render it unsafe or unfit for use. Because Yamaha has a policy of continuously improving its products, models may differ in detail from the descriptions and illustrations given in this publication. Use only the latest edition of this manual. Authorized Yamaha dealers are notified periodically of modifications and significant changes in specifications and procedures, and these are incorporated in successive editions of this manual. Important information1 Particularly important information is distinguished in this manual by the following notations: The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! WARNING Failure to follow WARNING instructions could result in severe injury or death to the machine operator, a bystander, or a person inspecting or repairing the outboard motor. CAUTION: A CAUTION indicates special precautions that must be taken to avoid damage to the out- board motor. NOTE: A NOTE provides key information to make procedures easier or clearer. F50A, FT50B, FT50C SERVICE MANUAL ©2000 by Yamaha Motor Co., Ltd. 1st Edition, November 2000 All rights reserved. Any reprinting or unauthorized use without the written permission of Yamaha Motor Co., Ltd. is expressly prohibited. Printed in the Netherlands

Contents General information 1GEN INFO Specifications 2SPEC Periodic checks and adjustments 3CHK ADJ Fuel system 4FUEL Power unit 5POWR Lower unit 6LOWR Bracket unit 7BRKT Electrical systems 8ELEC Index –+

62Y3A11 GEN INFO 1 2 3 4 5 6 7 8 I General information How to use this manual ................................................................................. 1-1 Manual format............................................................................................ 1-1 Symbols ..................................................................................................... 1-2 Safety while working...................................................................................... 1-3 Fire prevention........................................................................................... 1-3 Ventilation .................................................................................................. 1-3 Self-protection ........................................................................................... 1-3 Parts, lubricants, and sealants .................................................................. 1-3 Good working practices ............................................................................. 1-4 Disassembly and assembly ....................................................................... 1-4 Identification ................................................................................................... 1-5 Applicable models ..................................................................................... 1-5 Serial number ............................................................................................ 1-5 Features and benefits .................................................................................... 1-6 Newly designed four carburetors ............................................................... 1-6 CDI unit with microcomputer ..................................................................... 1-7 Lower unit .................................................................................................. 1-8 Technical tips ............................................................................................... 1-10 Carburetor ............................................................................................... 1-10 Acceleration pump ................................................................................... 1-15 Ignition system......................................................................................... 1-17 Ignition timing control............................................................................... 1-19 Power trim and tilt .................................................................................... 1-22 Propeller selection ....................................................................................... 1-32 Propeller size ........................................................................................... 1-32 Selection .................................................................................................. 1-32 Predelivery checks ...................................................................................... 1-33 Checking the fuel system ........................................................................ 1-33 Checking the gear oil ............................................................................... 1-33 Checking the engine oil ........................................................................... 1-33 Checking the battery................................................................................ 1-33 Checking the outboard motor mounting position ..................................... 1-34 Checking the remote control cables ........................................................ 1-34 Checking the steering wheel/tiller handle ................................................ 1-34 Checking the gearshift and throttle operation .......................................... 1-34 Checking the tilt system........................................................................... 1-35 Checking the engine start switch and engine stop switch/engine shut-off switch ............................................. 1-35 Checking the pilot water outlet ................................................................ 1-35 Test run ................................................................................................... 1-35 Break-in ................................................................................................... 1-36 After test run ............................................................................................ 1-36

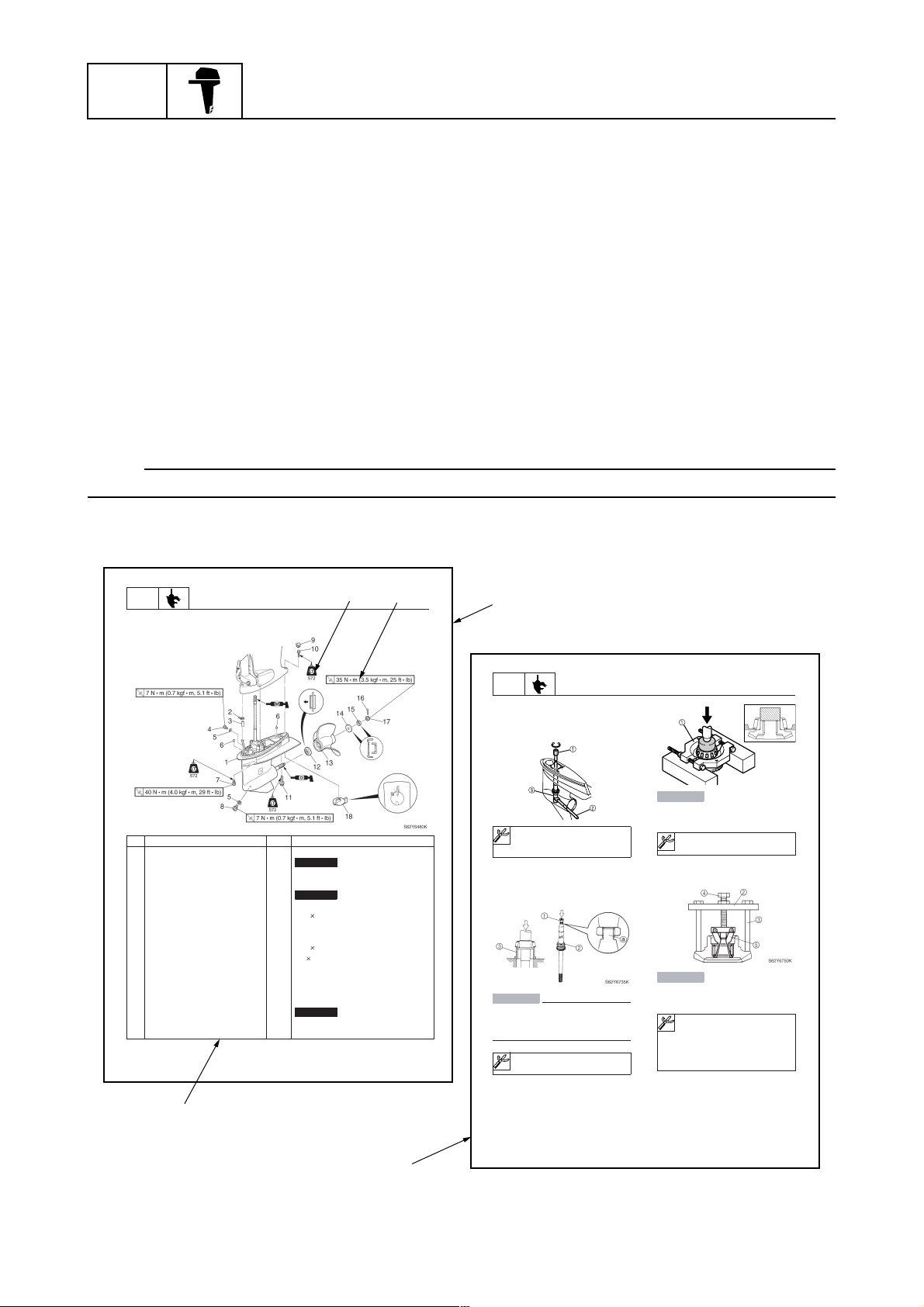

GEN INFO General information 1-162Y3A11 How to use this manual1 Manual format The format of this manual has been designed to make service procedures clear and easy to under- stand. Use the information below as a guide for effective and quality service. 1 Parts are shown and detailed in an exploded diagram and are listed in the components list. 2 Tightening torque specifications are provided in the components list at the beginning of each section and after a numbered step with tightening instructions. 3 Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant and lubrication point. 4 The components list consist of parts and part quantities, as well as bolt and screw dimensions. 5 Service points regarding removal, checking, and installation are shown in individual illustrations to explain the relevant procedure. 6 This service manual has two types of special service tools. Use part numbers that start with “J-”, “YB-”, “YM-”, “YS-”, “YU-”, “YW-”, or “YX-” for USA and Canada. Use parts numbers that start with “90890-” for all other countries. POWRPower unit 5-3562Y1A11 Cylinder head 62Y1A115-36 5 È Tightening sequence No. Part name Q’ty RemarksTightening torques Stage N·mkgf·mft·lb 1 Cylinder head 1 2Oil pum p1 3 Cylinder head cover 1 4Bolt 7 M6 × 20 mm 5 Cylinder head cover gasket1 Not reusable 6 Bolt 10 M9 × 95 mm 1st 2nd23 472.3 4.717 34 7 Spark plug 4 18 1.8 13 8Bolt 5 M6 × 25 mm 1st 2nd6 120.6 1.24.3 8.7 9 Dowel pin 2 10 Cylinder head gasket 1 Not reusable11 Grommet 4 12 Anode 4 13 Cover 4 14 Bolt 4 15 Cover 4 16 Bolt 4 17 O-ring 1 Not reusable18 O-ring 1Not reusable19 O-ring 1Not reusable20 Bolt 4 M6 × 40 mm 21 Housing 1 22 Drive shaft 1 23 Pin 1 24 Inner rotor 1 25 Outer rotor 1 26 Gasket 1 Not reusable27 Cover 1 28 Screw 2 M6 × 20 mm Cylinder head POWRPower unit 5-3162Y1A11 Removing the timing belt and sprockets 1. Set the cylinder #1 piston position to TDC of the compression stroke by align- ing the “1” mark a on the driven sprocket with the “” mark b on the cylinder head. CAUTION:Do not turn the drive sprocket counter- clockwise, otherwise the valve system may be damaged. 2. Remove the breather hose and loosen the drive sprocket nut 1 . NOTE: Use a deep socket 2 (M42) for this proce- dure. Do not turn the camshaft when loosening the drive sprocket nut.3. Remove the tensioner 4 and timing belt 5 from the driven sprocket side. 4. Loosen the driven sprocket bolt 6 and remove the driven sprocket . ÈFor USA and Canada ÉFor worldwide NOTE: Do not turn the camshaft when loosening the driven sprocket bolt. Crankshaft holder 3 : YB-06562 Crankshaft holder 18 3 : 90890-06562 Flywheel magnet holder: YB-06139 Flywheel holder: 90890-06522

62Y3A111-2 1 2 3 4 5 6 7 8 I Symbols The symbols below are designed to indicate the content of a chapter. General information Specifications Periodic checks and adjustments Fuel systemPower unit Lower unit Bracket unit Electrical systems Symbols 1 to 5 in an exploded diagram indicate the grade of lubricant and the lubrication point. 1Apply Yamaha 4-stroke motor oil 2Apply water resistant grease (Yamaha grease A, Yamaha marine grease) 3Apply molybdenum disulfide grease 4Apply anti-corrosion grease (Yamaha grease D) 5Apply low temperature resistant grease (Yamaha grease C) Symbols 6 to A in an exploded diagram indicate the type of sealant or locking agent and the appli- cation point. 6Apply Gasket Maker® 7Apply Yamabond No. 4 8Apply LOCTITE ® No. 271 (Red LOCTITE) 9Apply LOCTITE® No. 242 (Blue LOCTITE) 0Apply LOCTITE® No. 572 AApply silicon sealant GEN INFO SPEC CHK ADJ FUEL POWR LOWR BRKT ELEC –+ 12345 67890A E AMDC GM4 271 LT 242 LT 572 LTSS How to use this manual

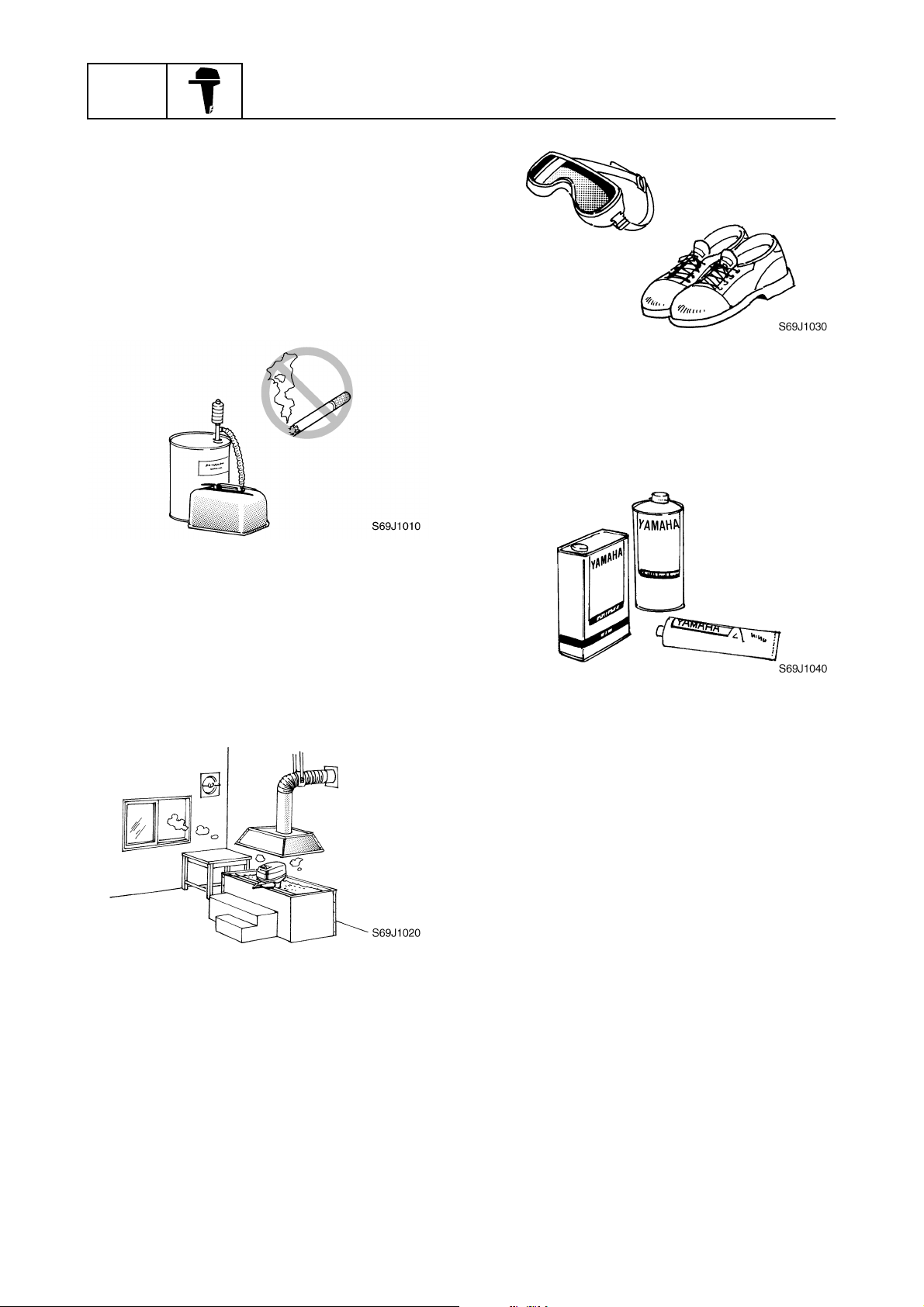

GEN INFO General information 1-362Y3A11 Safety while working1 To prevent an accident or injury and to ensure quality service, follow the safety pro- cedures provided below. Fire prevention Gasoline is highly flammable. Keep gasoline and all flammable products away from heat, sparks, and open flames. Ventilation Gasoline vapor and exhaust gas are heavier than air and extremely poisonous. If inhaled in large quantities they may cause loss of consciousness and death within a short time. When test running an engine indoors (e.g., in a water tank) be sure to do so where ade- quate ventilation can be maintained. Self-protection Protect your eyes by wearing safety glasses or safety goggles during all operations involv- ing drilling and grinding, or when using an air compressor. Protect your hands and feet by wearing pro- tective gloves and safety shoes when neces- sary. Parts, lubricants, and sealants Use only genuine Yamaha parts, lubricants, and sealants or those recommended by Yamaha, when servicing or repairing the outboard motor. Under normal conditions, the lubricants men- tioned in this manual should not harm or be hazardous to your skin. However, you should follow these precautions to minimize any risk when working with lubricants. 1. Maintain good standards of personal and industrial hygiene. 2. Change and wash clothing as soon as possible if soiled with lubricants. 3. Avoid contact with skin. Do not, for example, place a soiled rag in your pocket. 4. Wash hands and any other part of the body thoroughly with soap and hot water after contact with a lubricant or lubricant soiled clothing has been made. 5. To protect your skin, apply a protective cream to your hands before working on the outboard motor.

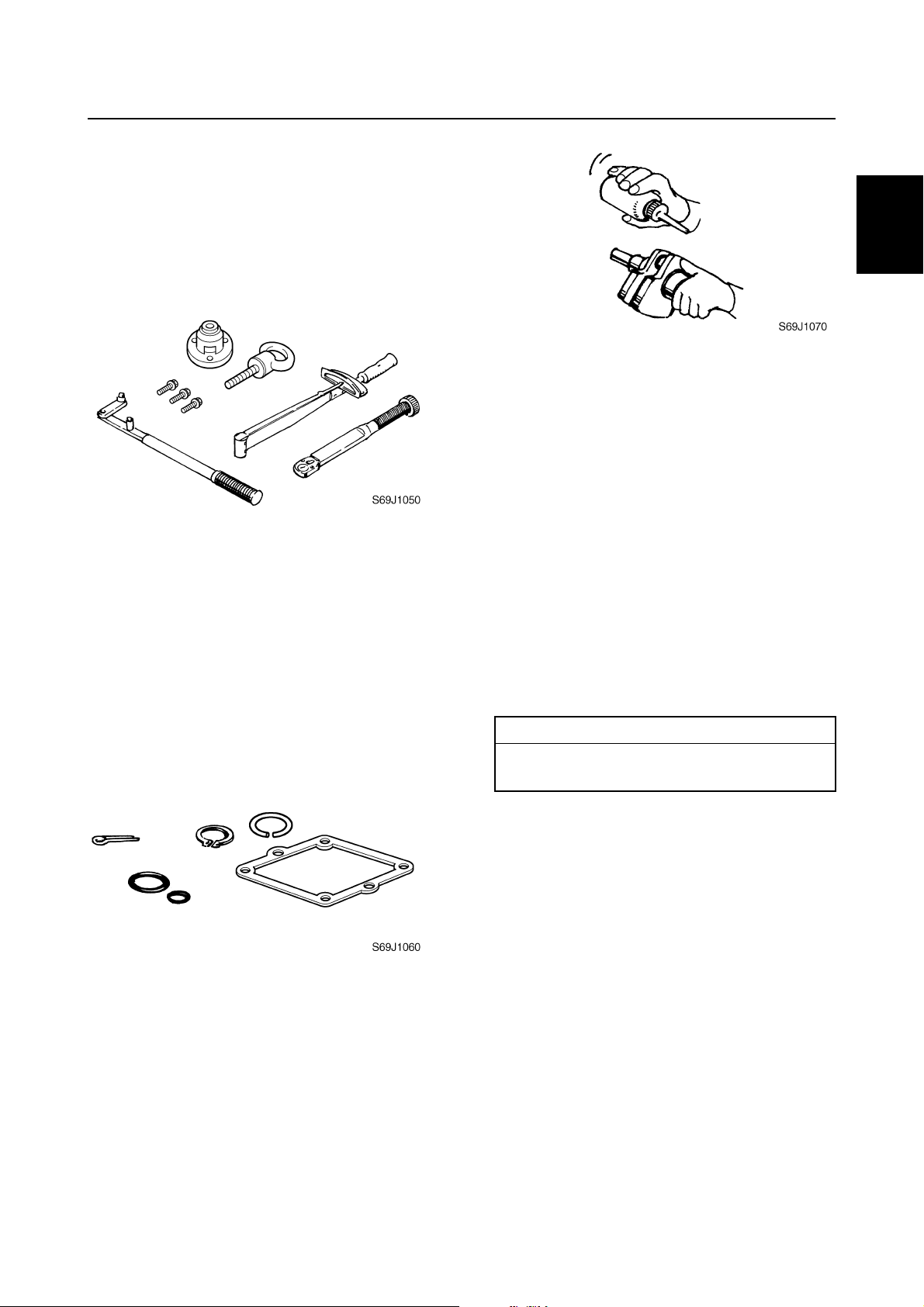

62Y3A111-4 1 2 3 4 5 6 7 8 I 6. Keep a supply of clean, lint-free cloths for wiping up spills, etc. Good working practices Special tools Use the recommended special tools to pro- tect parts from damage. Use the right tool in the right manner—do not improvise. Tightening torques Follow the tightening torque specifications provided throughout the manual. When tight- ening nuts, bolts, and screws, tighten the large sizes first, and tighten fasteners starting in the center and moving outward. Non-reusable parts Always use new gaskets, seals, O-rings, cot- ter pins, circlips, etc., when installing or assembling parts. Disassembly and assembly 1. Use compressed air to remove dust and dirt during disassembly. 2. Apply engine oil to the contact surfaces of moving parts before assembly.3. Install bearings with a manufacture iden- tification mark in the direction indicated in the installation procedure. In addition, be sure to lubricate the bearings liberally. 4. Apply a thin coat of water-resistant grease to the lip and out periphery of an oil seal before installation. 5. Check that moving parts operate nor- mally after assembly. Safety while working

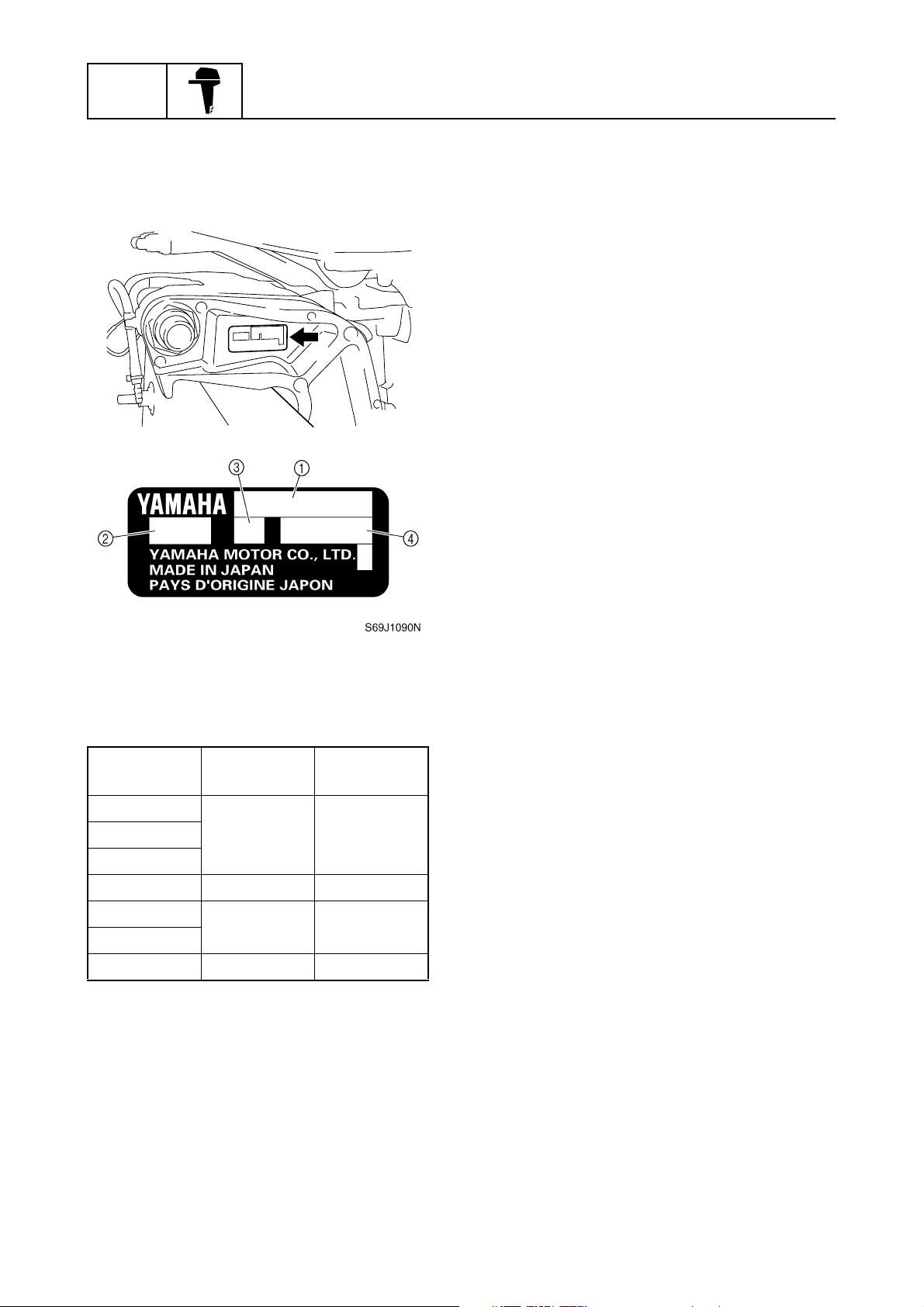

GEN INFO General information 1-562Y3A11 Identification1 Applicable models This manual covers the following models. Serial number The outboard motor serial number is stamped on a label attached to the port clamp bracket. 1Model name 2Approved model code 3Transom height 4Serial number Applicable models USA, Canada Worldwide —F50AEHD F50TH F50AEHT —F50AED F50TR F50AET T50TR FT50BET —FT50CEHD —FT50CED —FT50CET Model nameApproved model codeStarting serial No. USA, Canada F50TH 62YL: 451812– F50TR L: 421732– T50TR 64J L: 406850– Worldwide F50AEHD 62YL: 350505– F50AEHTL: 451812– X: 750469– F50AED L: 301090– F50AETL: 421626– X: 700700– FT50BET 64JL: 406850– FT50CEHD L: 650101– FT50CED L: 550101– FT50CET L: 450101–

All Yamaha manuals

Comments (0)

Related Manuals for Yamaha F50 Service Manual

F50F

FT50G

F60C

FT60D

290551

SERVICE MANUAL

6C1-28197-3G-11

NOTICE

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their trained

mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has

been written to suit the needs of persons who have a basic understanding of the mechanical and

electrical concepts and procedures inherent in the work, for without such knowledge attempted

repairs or service to the equipment could render it unsafe or unfit for use.

Because Yamaha has a policy of continuously improving its products, models may differ in detail

from the descriptions and illustrations given in this publication. Use only the latest edition of this

manual. Authorized Yamaha dealers are notified periodically of modifications and significant

changes in specifications and procedures, and these are incorporated in successive editions of this

manual.

Important information

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or death to the machine

operator, a bystander, or a person inspecting or repairing the outboard motor.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the outboard motor.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

1

F50F, FT50G, F60C, FT60D

SERVICE MANUAL

©2004 by Yamaha Motor Co., Ltd.

1st Edition, July 2004

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in the Netherlands

Contents

General information

Specifications

Periodic checks and adjustments

Fuel system

Power unit

GEN

INFO

SPEC

CHK

ADJ

FUEL

POWR

1

2

3

4

5

Lower unit

Bracket unit

Electrical systems

Troubleshooting

Index

LOWR

BRKT

–+

ELEC

TRBL

SHTG

6

7

8

9

GEN

INFO

General information

How to use this manual………………………………………………………………………1-1

Manual format………………………………………………………………………………..1-1

Symbols………………………………………………………………………………………..1-2

Safety while working…………………………………………………………………………..1-3

Fire prevention……………………………………………………………………………….1-3

Ventilation……………………………………………………………………………………..1-3

Self-protection ……………………………………………………………………………….1-3

Parts, lubricants, and sealants …………………………………………………………1-3

Good working practices …………………………………………………………………..1-4

Disassembly and assembly ……………………………………………………………..1-4

1

2

Identification………………………………………………………………………………………1-4

Applicable models ………………………………………………………………………….1-4

Serial number ………………………………………………………………………………..1-5

Outline of features ……………………………………………………………………………..1-6

Features and benefits…………………………………………………………………………1-7

Fuel system …………………………………………………………………………………..1-7

Solenoid valve ……………………………………………………………………………….1-8

Electronic control system…………………………………………………………………1-9

ECM (Electric Control Module) ……………………………………………………….1-10

Variable trolling RPM switch (optional)…………………………………………….1-11

Propeller selection……………………………………………………………………………1-12

Propeller size……………………………………………………………………………….1-12

Selection……………………………………………………………………………………..1-12

Predelivery checks …………………………………………………………………………..1-13

Checking the fuel system ………………………………………………………………1-13

Checking the engine oil level………………………………………………………….1-13

Checking the gear oil level …………………………………………………………….1-13

Checking the battery……………………………………………………………………..1-13

Checking the outboard motor mounting height………………………………….1-14

Checking the remote control cables ………………………………………………..1-14

Checking the steering system ………………………………………………………..1-14

Checking the gear shift and throttle operation…………………………………..1-15

Checking the power trim and tilt system…………………………………………..1-15

Checking the hydro tilt system………………………………………………………..1-15

Checking the engine start switch and engine stop lanyard switch ……….1-16

Checking the cooling water pilot hole ………………………………………………1-16

Test run ………………………………………………………………………………………1-17

Break-in ………………………………………………………………………………………1-17

After test run ………………………………………………………………………………..1-17

3

4

5

6

7

8

9

6C13G11

GEN

INFO

General information

How to use this manual

Manual format

The format of this manual has been designed to make service procedures clear and easy to understand. Use the information below as a guide for effective and quality service.

1

Parts are shown and detailed in an exploded diagram and are listed in the components list.

2

Tightening torque specifications are provided in the exploded diagrams and after a numbered

step with tightening instructions.

3

Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant

and lubrication point.

4

The components list consists of part names and part quantities, as well as bolt and screw dimensions.

5

Service points regarding removal, checking, and installation are shown in individual illustrations

to explain the relevant procedure.

NOTE:

For troubleshooting procedures, see Chapter 9, “Troubleshooting.”

1

40 mm

10 45 mm

60 mm

3

LOWR

Lower unit

No. Part name Q’ty Remarks

1 Lower unit 1

2 Plastic tie 1

3Hose 1

4 Check screw 1

5 Gasket 2

6 Dowel pin 2

7 Bolt 4 M10

8 Drain screw 1

9Grommet 1

10 Bolt 1 M

11 Bolt 1 M8

12 Thrust washer 1

13 Propeller 1

14 Washer 1

15 Washer 1

16 Cotter pin 1

17 Propeller nut 1

18 Trim tab 1

6-5

Lower unit

Not reusable

Not reusable

Not reusable

4

2

62Y5A11

1

LOWR

Removing the drive shaft

1. Remove the drive shaft assembly and

pinion, and then pull out the forward

gear.

Disassembling the drive shaft

1. Install the pinion nut 1, tighten it finger

tight, and then remove the drive shaft

bearing 2 using a press.

CAUTION:

• Do not press the drive shaft threads

directly.

• Do not reuse the bearing, always

replace it with a new one.

Disassembling the forward gear

1. Remove the taper roller bearing from the

forward gear using a press.

Lower unit

S62Y6850K

Drive shaft holder 4 1: 90890-06518

Pinion nut holder 2: 90890-06505

Socket adapter 2 3: 90890-06507

Bearing inner race attachment 3:

90890-06639

CAUTION:

Do not reuse the bearing, always replace

it with a new one.

Bearing separator 1: 90890-06534

2. Remove the needle bearing from the forward gear.

CAUTION:

Do not reuse the bearing, always replace

it with a new one.

a

Stopper guide plate 2: 90890-06501

Stopper guide stand 3:

90890-06538

Bearing puller 4: 90890-06535

Bearing puller claw 1 5:

90890-06536

S62Y6740K

1-1

5

6-19

62Y5A11

6C13G11

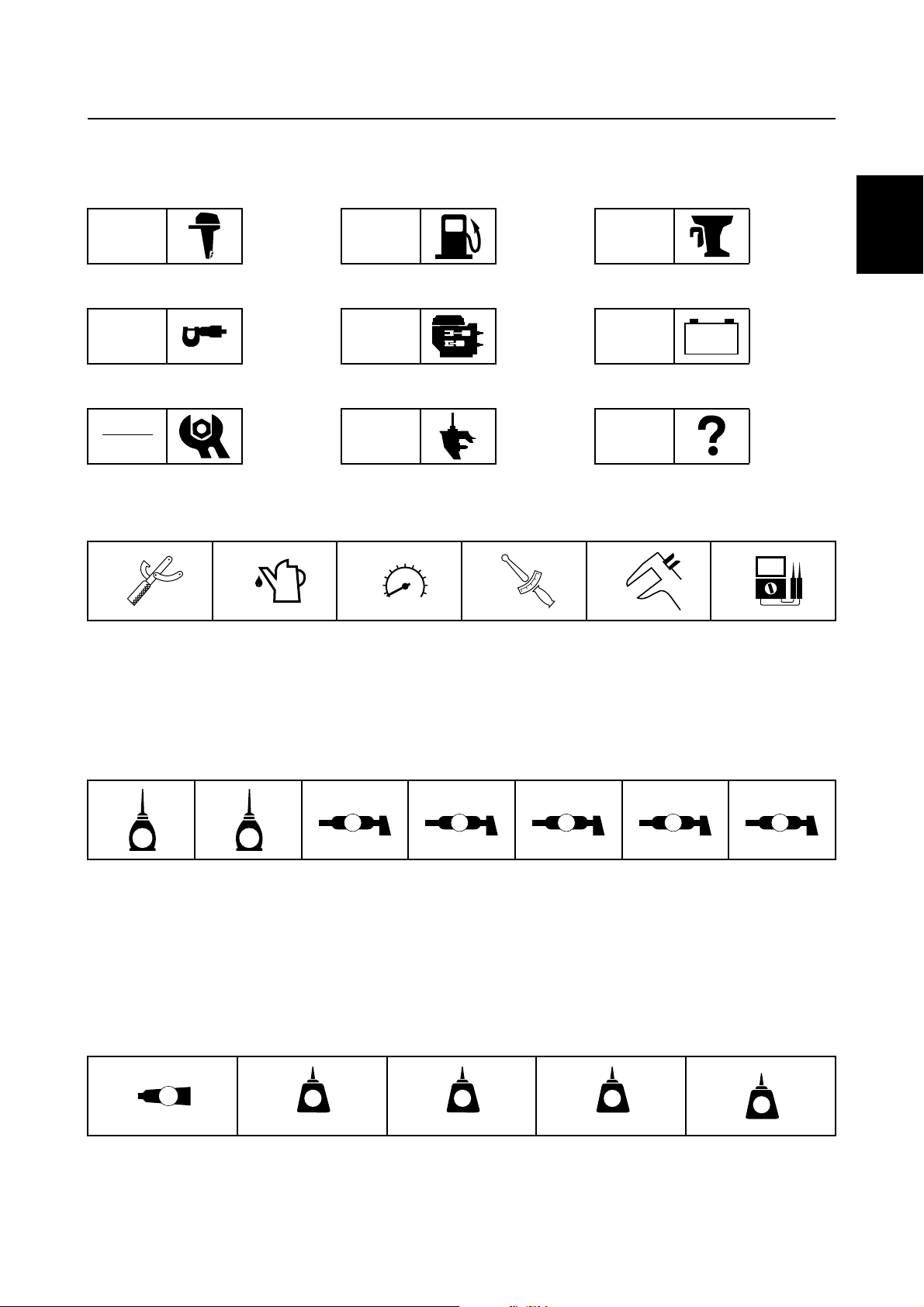

Symbols

The symbols below are designed to indicate the content of a chapter.

How to use this manual

General information

GEN

INFO

Specifications

SPEC

Periodic checks and adjustments

CHK

ADJ

Symbols 1 to 6 indicate specific data.

123456

Fuel system

FUEL

Power unit

POWR

Lower unit

LOWR

Bracket unit

BRKT

Electrical systems

ELEC

Troubleshooting

–+

TRBL

SHTG

1

2

3

4

Special tool

1

Specified oil or fluid

2

Specified engine speed

3

Specified tightening torque

4

Symbols 7 to C in an exploded diagram indicate the grade of lubricant and the lubrication point.

7890ABC

A M

E G

Apply Yamaha 4-stroke motor oil

7

Apply gear oil

8

Apply water resistant grease (Yamaha grease A)

9

Apply molybdenum disulfide grease

0

Symbols D to H in an exploded diagram indicate the type of sealant or locking agent and the application point.

DEFGH

GM

LT

271

Specified measurement

5

Specified electrical value

6

(resistance, voltage, electric current)

C I

Apply corrosion resistant grease

A

(Yamaha grease D)

Apply low temperature resistant grease

B

(Yamaha grease C)

Apply injector grease

C

LT

242

LT

572

SS

5

6

7

8

9

Apply Gasket Maker

D

Apply LOCTITE 271 (red)

E

Apply LOCTITE 242 (blue)

F

6C13G11

Apply LOCTITE 572

G

Apply silicon sealant

H

1-2

GEN

INFO

General information

Safety while working

To prevent an accident or injury and to

ensure quality service, follow the safety procedures provided below.

Fire prevention

Gasoline is highly flammable.

Keep gasoline and all flammable products

away from heat, sparks, and open flames.

Ventilation

Gasoline vapor and exhaust gas are heavier

than air and extremely poisonous. If inhaled

in large quantities they may cause loss of

consciousness and death within a short time.

When test running an engine indoors (e.g., in

a water tank) be sure to do so where adequate ventilation can be maintained.

1

Parts, lubricants, and sealants

Use only genuine Yamaha parts, lubricants,

and sealants or those recommended by

Yamaha, when servicing or repairing the outboard motor.

Under normal conditions, the lubricants mentioned in this manual should not harm or be

hazardous to your skin. However, you should

follow these precautions to minimize any risk

when working with lubricants.

Self-protection

Protect your eyes by wearing safety glasses

or safety goggles during all operations involving drilling and grinding, or when using an air

compressor.

Protect your hands and feet by wearing protective gloves and safety shoes when necessary.

1-3

1. Maintain good standards of personal and

industrial hygiene.

2. Change and wash clothing as soon as

possible if soiled with lubricants.

3. Avoid contact with skin. Do not, for

example, place a soiled rag in your

pocket.

4. Wash hands and any other part of the

body thoroughly with soap and hot water

after contact with a lubricant or lubricant

soiled clothing has been made.

5. To protect your skin, apply a protective

cream to your hands before working on

the outboard motor.

6C13G11

6. Keep a supply of clean, lint-free cloths for

wiping up spills, etc.

Good working practices

Special service tools

Use the recommended special service tools

to protect parts from damage. Use the right

tool in the right manner—do not improvise.

Tightening torques

Follow the tightening torque specifications

provided throughout the manual. When tightening nuts, bolts, and screws, tighten the

large sizes first, and tighten fasteners starting

in the center and moving outward.

Non-reusable parts

Always use new gaskets, seals, O-rings, cotter pins, circlips, etc., when installing or

assembling parts.

Safety while working / Identification

3. Install bearings with the manufacture

identification mark in the direction indicated in the installation procedure. In

addition, be sure to lubricate the bearings

liberally.

4. Apply a thin coat of water-resistant

grease to the lip and periphery of an oil

seal before installation.

5. Check that moving parts operate normally after assembly.

Identification

Applicable models

This manual covers the following models.

Applicable models

F50FED, F50FEHT, F50FET, FT50GET,

F60CEHT, F60CET, FT60DET

1

2

3

4

1

5

6

Disassembly and assembly

1. Use compressed air to remove dust and

dirt during disassembly.

2. Apply engine oil to the contact surfaces

of moving parts before assembly.

6C13G11

(*)

Hydro tilt model (For Europe)

(*)

Tiller handle model (For Oceania)

7

8

9

1-4

GEN

INFO

Serial number

The outboard motor serial number is

stamped on a label attached to the port

clamp bracket.

General information

S6C11010

Model name

1

Approved model code

2

Transom height

3

Serial number

4

Model name

Approved

model code

Starting

serial No.

F50FED

6C1 1000001–F50FEHT

F50FET

FT50GET 6C2 1000001–

F60CEHT

6C5 1000001–

F60CET

FT60DET 6C6 1000001–

(*)

Hydro tilt model (For Europe)

(*)

Tiller handle model (For Oceania)

1-5

6C13G11

Identification / Outline of features

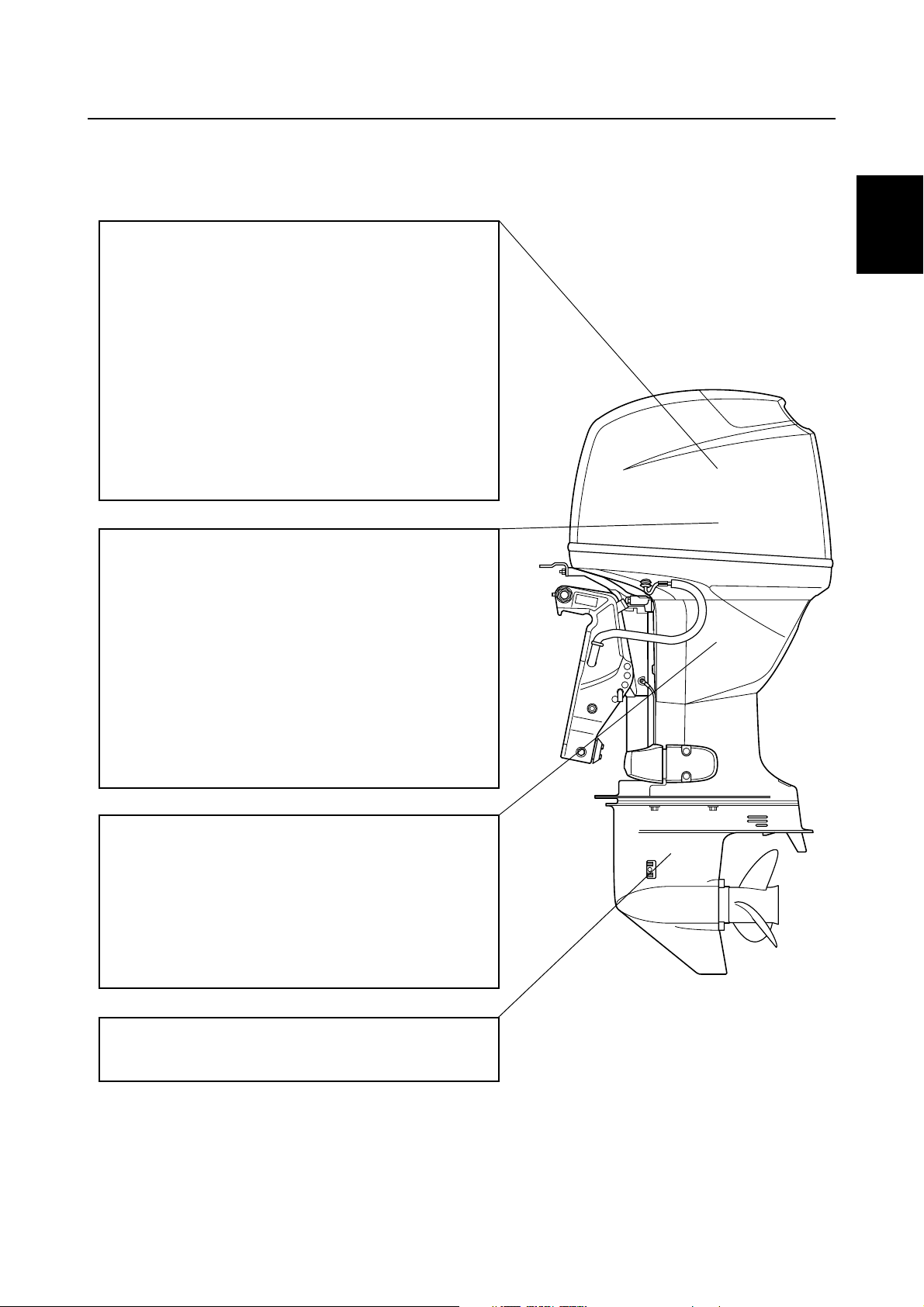

Outline of features

New electronic fuel injected F50 and F60 outboard motors have a mainly redesigned fuel and intake

system based on the carbureted F60 outboard motor.

Power unit

• Single throttle body, single throttle valve

• Multi-point injection system, group injection

(#1/#4 and #2/#3)

• Group ignition system (#1/#4 and #2/#3)

• Large plastic intake manifold

• Compact plastic fuel rail

• Modularized intake system components

• Vapor separator with built-in pressure regulator

• Solenoid valve

• Fuel cooler

• Aluminum rocker arm

Electrical

• Compact electronic fuel injection system

• Self-diagnosis system and Yamaha Diagnostic

System

• Variable trolling RPM switch (optional for tiller

handle model)

• Throttle position sensor with learning function

(adjustment free)

• Compact charging system at low rpm

• Compact fuel injectors

• Fuel filter with water separator

1

1

2

3

4

5

6

Clamp bracket/upper case

• 2-piece upper case

• Upper portion case with oil sump

• Big capacity water wall structure around muffler

• Idle exhaust labyrinth structure

• Exclusive clamp bracket for permanent mount-

ing

Lower unit

• Same lower drive unit as carbureted F60 model

6C13G11

S6C11120

1-6

7

8

9

GEN

INFO

General information

Features and benefits

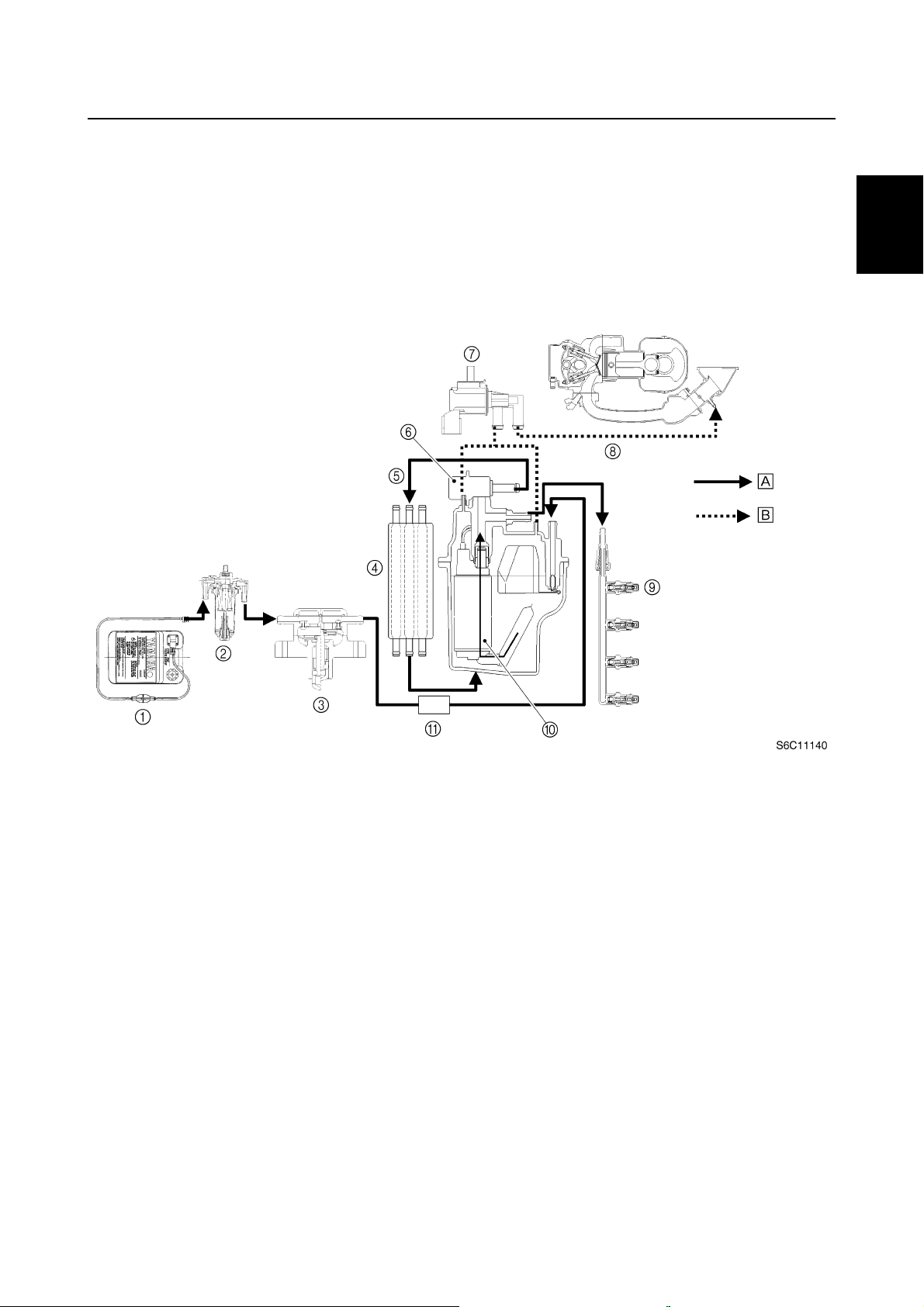

Fuel system

A pressure regulator is built into the vapor separator to obtain compact and simple fuel delivery

structure.

A plastic fuel rail is used to prevent it from corrosion and for light weight.

Fuel discharged from the pressure regulator returns to the vapor separator after cooling down

through the fuel cooler.

The fuel joint is used on the high pressure fuel hose to remove and/or install the intake unit easily.

Fuel filter (Optional) Fuel tank

Primer pump

Fuel filter with water separator

Fuel pump (Mechanical)

1

Fuel filter

Vapor separator

Electric fuel pump

Fuel cooler

Pressure regulator

injector

Fuel

#1

Fuel rail

Fuel

injector

#2 #3 #4

Fuel

injector

Fuel

injector

S6C11130

1-7

6C13G11

Features and benefits

Solenoid valve

Just after the engine is stopped, the cooling water supply is also stopped and the heat is conducted

to the vapor separator from the engine, causing birth of many fuel vapor gases.

The vapor gases are fed into the intake silencer to reburn them.

However, many vapor gases are sucked into the combustion chambers, causing a rich air and fuel

mixture, which is difficult to restart the engine.

So the solenoid valve has been used for better restarting engine while the engine is warm.

The solenoid valve stops the vapor gases not to return into the intake silencer.

1

2

3

Fuel tank

1

Fuel filter

2

Fuel pump

3

Fuel cooler

4

Return fuel hose

5

Pressure regulator

6

Solenoid valve

7

To throttle body

8

Fuel injector

9

Electric fuel pump

0

Fuel filter

A

Fuel

È

Vapor gas

É

4

5

6

7

8

6C13G11

9

1-8

GEN

INFO

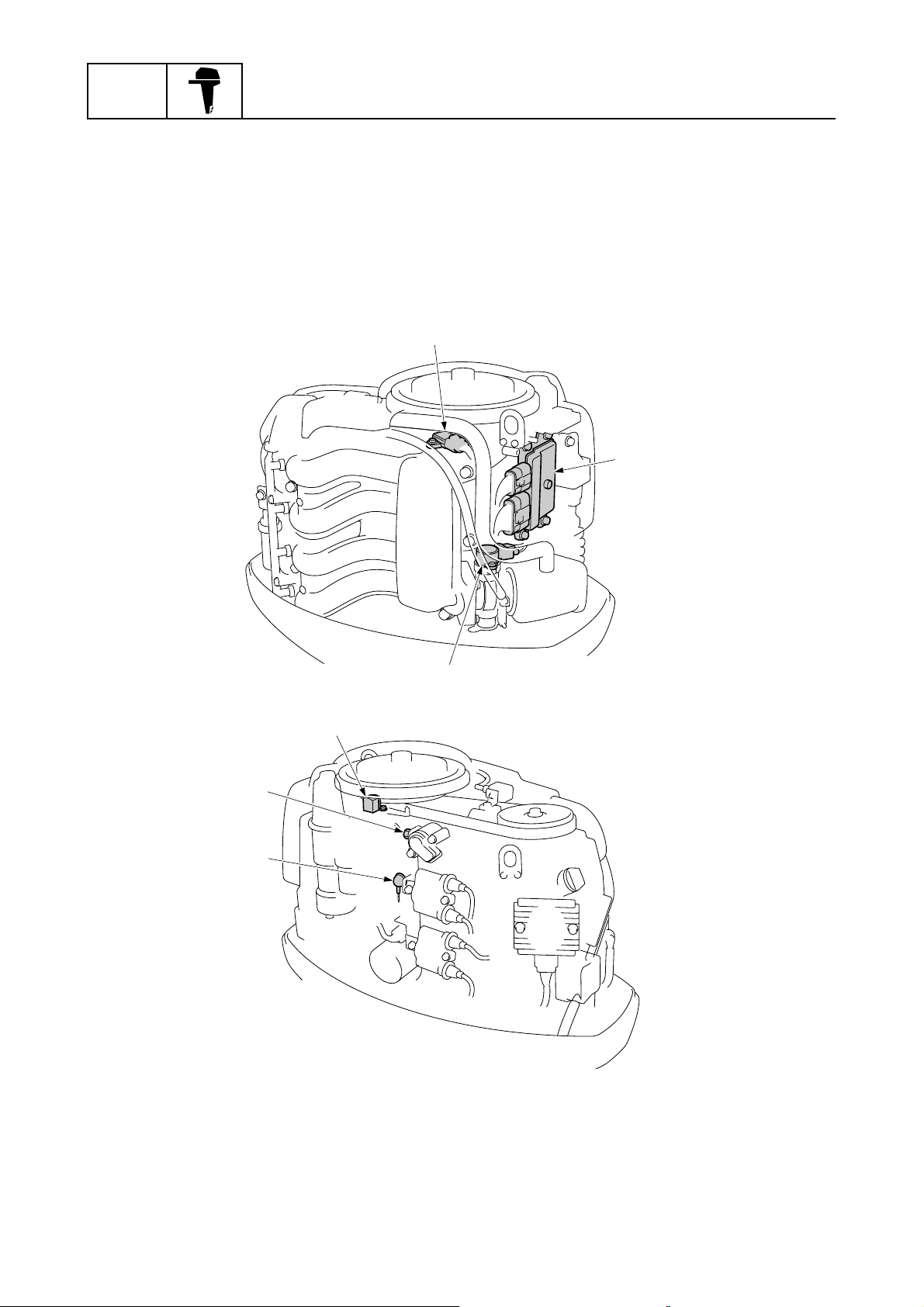

Electronic control system

The electronic control system is built up by the sensors and the ECM (Electric control Module).

The ECM receives signals from the sensors and determines the air and fuel mixture (A/F), and ignition timing.

Under various condition, the ECM gives the best-suitable engine operation.

In addition, warning control, fail-safe control, a self-diagnosis function, etc., are equipped to

increase reliability.

General information

1

2

5

4

Sensor assembly

1

(intake air temperature and intake air

pressure)

ECM

2

Throttle position sensor

3

Oil pressure switch

4

6

3

Cooling water temperature sensor

5

Pulser coil

6

S6C11150

1-9

6C13G11

Features and benefits

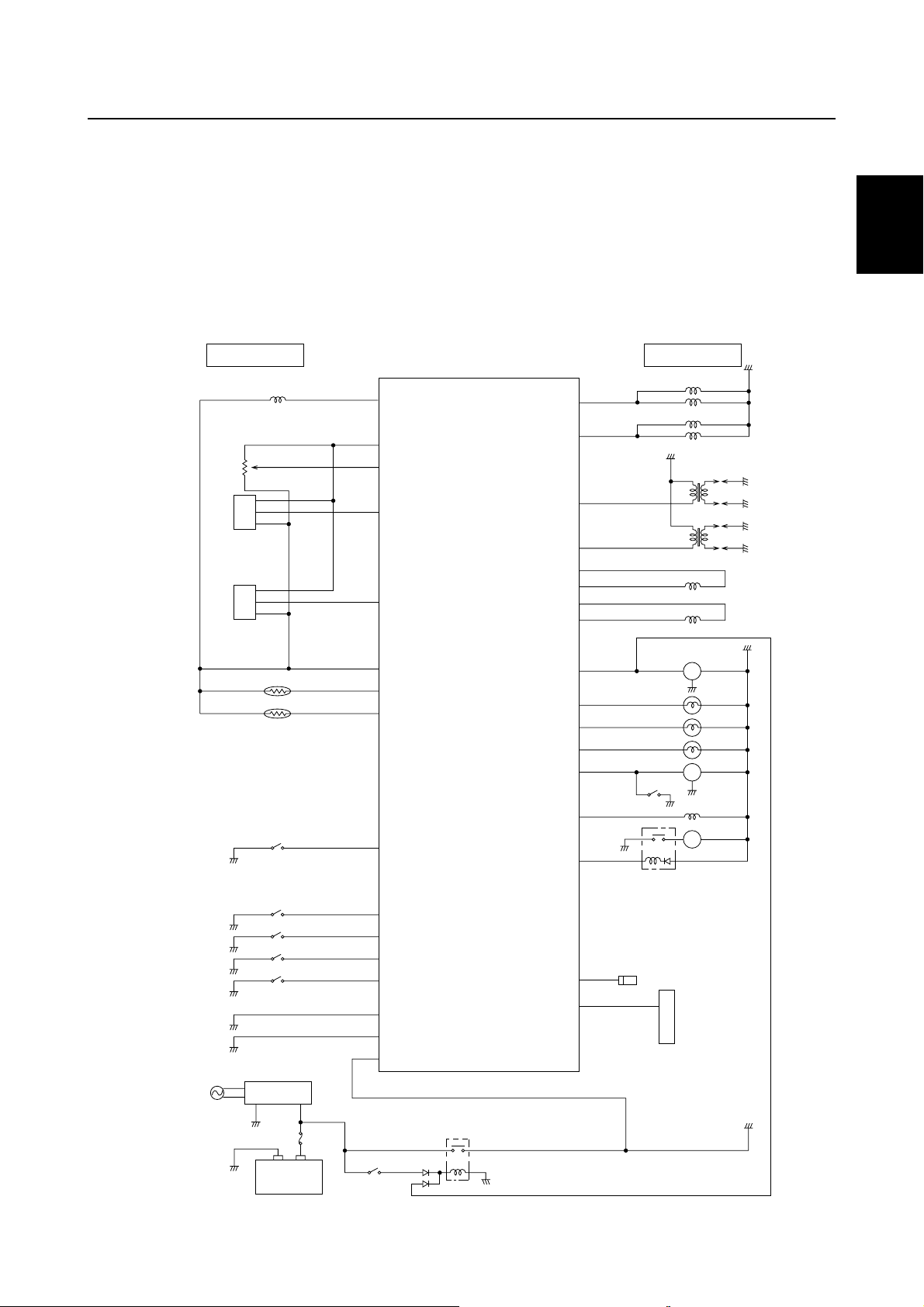

ECM (Electric Control Module)

This engine is controlled by the ECM to obtain precision combustion under various operations, and

can realize high power output, low fuel consumption, and low emission.

The ECM controls the ignition timing, fuel injection timing, and the fuel injection volume, and

ensures that the optimum ignition timing and air and fuel ratio can be achieved in all operating conditions such as engine starting, normal operation, and quick acceleration.

The self-diagnosis function is incorporated into the ECM and can be easily found a malfunction

point by a personal computer with the optional software installed.

1

40

Pulser coil

16

Power source for sensors

36

Throttle position

sensor

17

Intake air pressure

sensor

46

Cooling water pressure sensor

31

Ground for sensors

38

Intake air temperature sensor

48

Cooling water temperature sensor

34

Shift position switch

Fuel injectors #1, #4

Fuel injectors #2, #3

Ignition coil #1, #4

Ignition coil #2, #3

Idle speed control (S1)

Idle speed control (S2)

Idle speed control (S3)

Idle speed control (S4)

Tachometer

Oil pressure warning

indicator

Overheat

warning

indicator

Check engine warning

indicator

Buzzer/DES switch

Solenoid valve

Fuel pump relay

3

4

18

1

23

6

20

21

7

26

8

25

9

DES switch

11

24

OUTPUTINPUT

Main relay

Relay

2

3

4

T

BZ

P

5

6

7

6C13G11

Flywheel

magnet

Rectifier Regulator

– +

Battery

27

Engine stop lanyard switch

10

Oil pressure switch

28

Variable trolling RPM switch (UP)

29

Variable trolling RPM switch

(DOWN)

14

Ground for ECM

5

Ground

15

Battery (+)

Engine start switch

Main relay

Diagnosis

45

13

Power for diagnosis lamp

Self-diagnosis

8

9

S6C11160

1-10

GEN

INFO

Variable trolling RPM switch (optional)

This device is an optional equipment for tiller handle model.

The idling and/or trolling rpm can be controlled in the range of 620 through 900 r/min with 50 r/min

interval.

Especially for 620 through 700 r/min, the engine rpm is controlled with 40 r/min interval.

Pushing and holding the switch changes rpm continuously at 50 r/min interval.

If engine rpm reaches to the ends of specified range, the rpm is no longer changed.

CAUTION:

Do not modify the variable trolling RPM switch.

Modification such as wire extension, disassembly, etc., can malfunction for the system and/

or damage the electrical components.

NOTE:

Variable trolling RPM switch kit P/N: 6C5-W8186-00

General information

Variable trolling RPM switch (optional)

1

1

S6C11170

1-11

6C13G11

Features and benefits / Propeller selection

Propeller selection

The performance of a boat and outboard

motor will be critically affected by the size

and type of propeller you choose. Propellers

greatly affect boat speed, acceleration,

engine life, fuel economy, and even boating

and steering capabilities. An incorrect choice

could adversely affect performance and

could also seriously damage the engine.

Use the following information as a guide for

selecting a propeller that meets the operating

conditions of the boat and the outboard

motor.

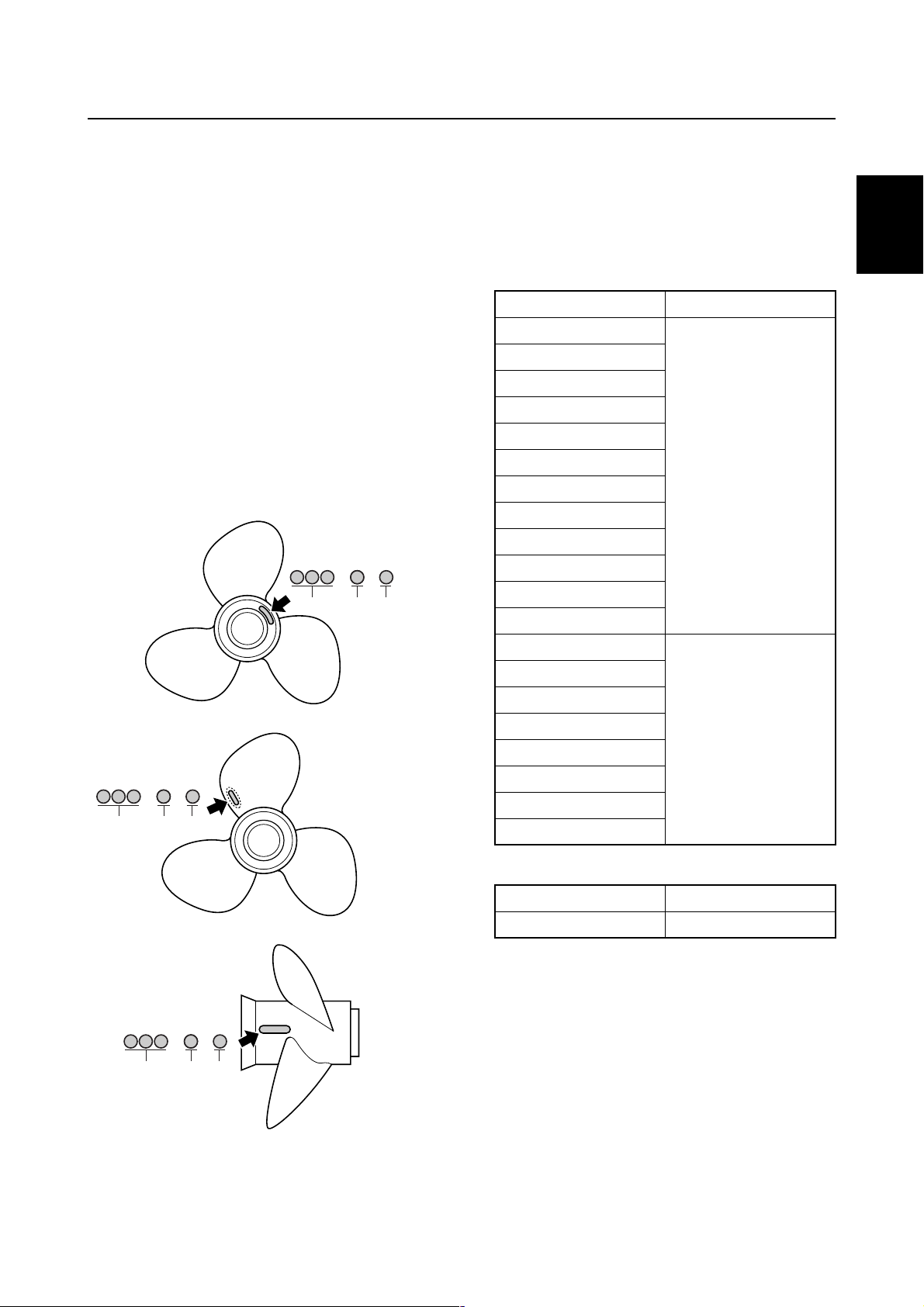

Propeller size

The size of the propeller is indicated on a

propeller blade, on the propeller boss end.

× —

a

bc

1

Selection

When the engine speed is at the full throttle

operating range (5,000–6,000 r/min), the

ideal propeller for the boat is one that provides maximum performance in relation to

boat speed and fuel consumption.

F50, F60

Propeller size (in) Material

10 × 15 — G

10 1/4 × 14 — G

10 3/8 × 13 — G

10 5/8 × 12 — G

10 3/4 × 16 — G

10 3/4 × 17 — G

Aluminum

11 × 15 — G

11 1/8 × 13 — G

11 1/4 × 14 — G

11 3/8 × 12 — G

11 5/8 × 11 — G

12 1/4 × 9 — G

1

2

3

4

× —

a

bc

× —

a

bc

S69W1030

S69W1040

10 1/4 × 14 — G

10 1/4 × 15 — G

10 1/4 × 16 — G

10 5/8 × 13 — G

Stainless

11 1/4 × 14 — G

11 1/2 × 13 — G

11 3/4 × 12 — G

12 × 11 — G

FT50, FT60

Propeller size (in) Material

14 × 11 — K Aluminum

5

6

7

8

9

Propeller diameter (in inches)

a

Propeller pitch (in inches)

b

Propeller type (propeller mark)

c

6C13G11

S69W1050

1-12

GEN

INFO

General information

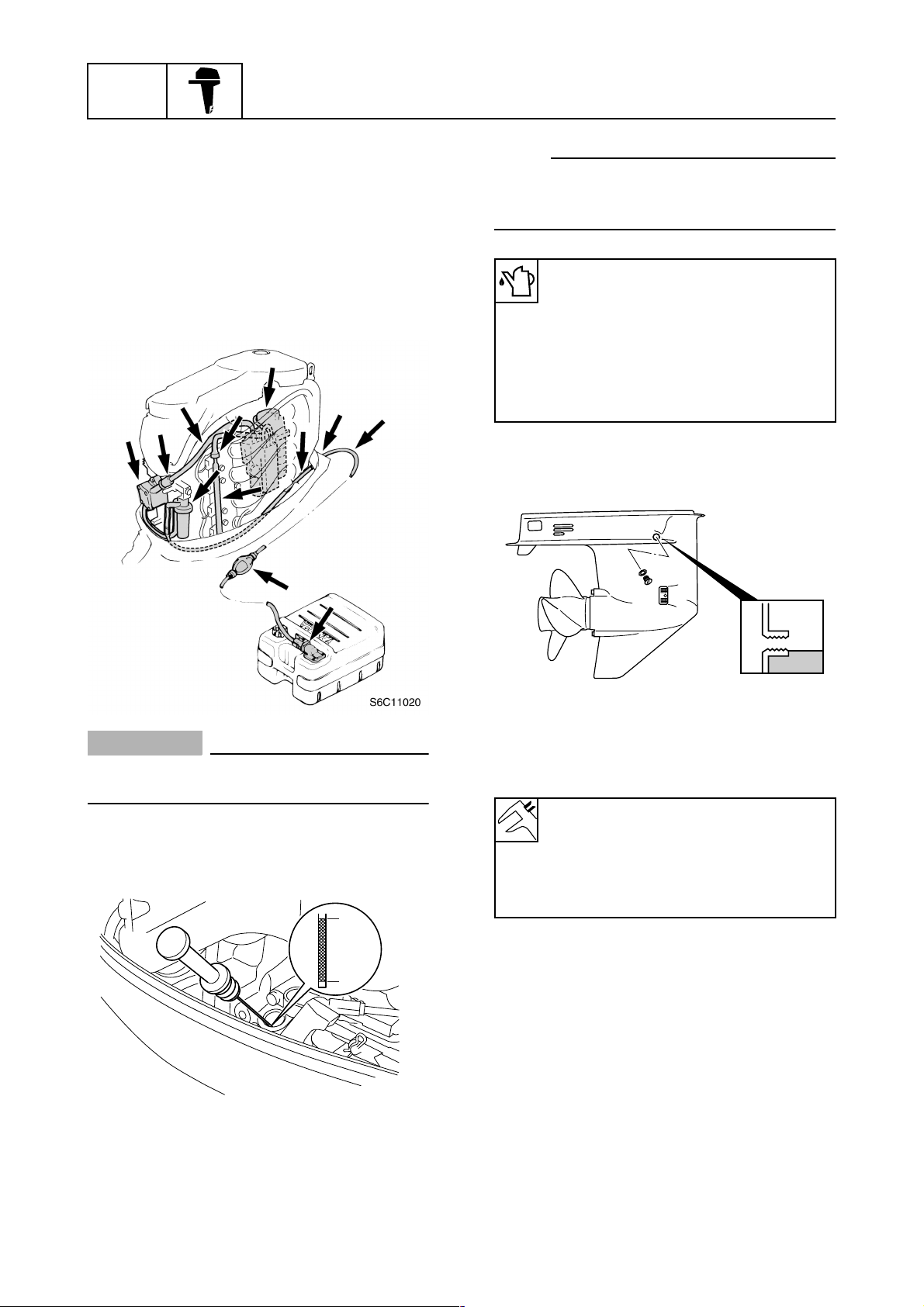

Predelivery checks

To make the delivery process smooth and

efficient, the predelivery checks should be

completed as explained below.

Checking the fuel system

1. Check that the fuel hoses are securely

connected and that the fuel tank is full

with fuel.

1

NOTE:

If the engine oil is below the minimum level

mark b, add sufficient oil until the level is

between a and b.

Recommended engine oil:

4-stroke motor oil

API: SE, SF, SG, SH, or SJ

SAE: 10W-30 or 10W-40

Engine oil quantity:

Without oil filter replacement:

2.5 L (2.64 US qt, 2.20 Imp qt)

Checking the gear oil level

1. Check the gear oil level.

CAUTION:

This is a 4-stroke engine. Never use premixed fuel.

Checking the engine oil level

1. Check the engine oil level.

a

b

S6C11030

S60V1290

Checking the battery

1. Check the capacity, electrolyte level, and

specified gravity of the battery.

Recommended battery capacity:

CCA/EN: 430 A

20HR/IEC: 70 Ah

Electrolyte specified gravity:

1.280 at 20 °C (68 °F)

2. Check that the positive and negative battery leads are securely connected.

1-13

6C13G11

Predelivery checks

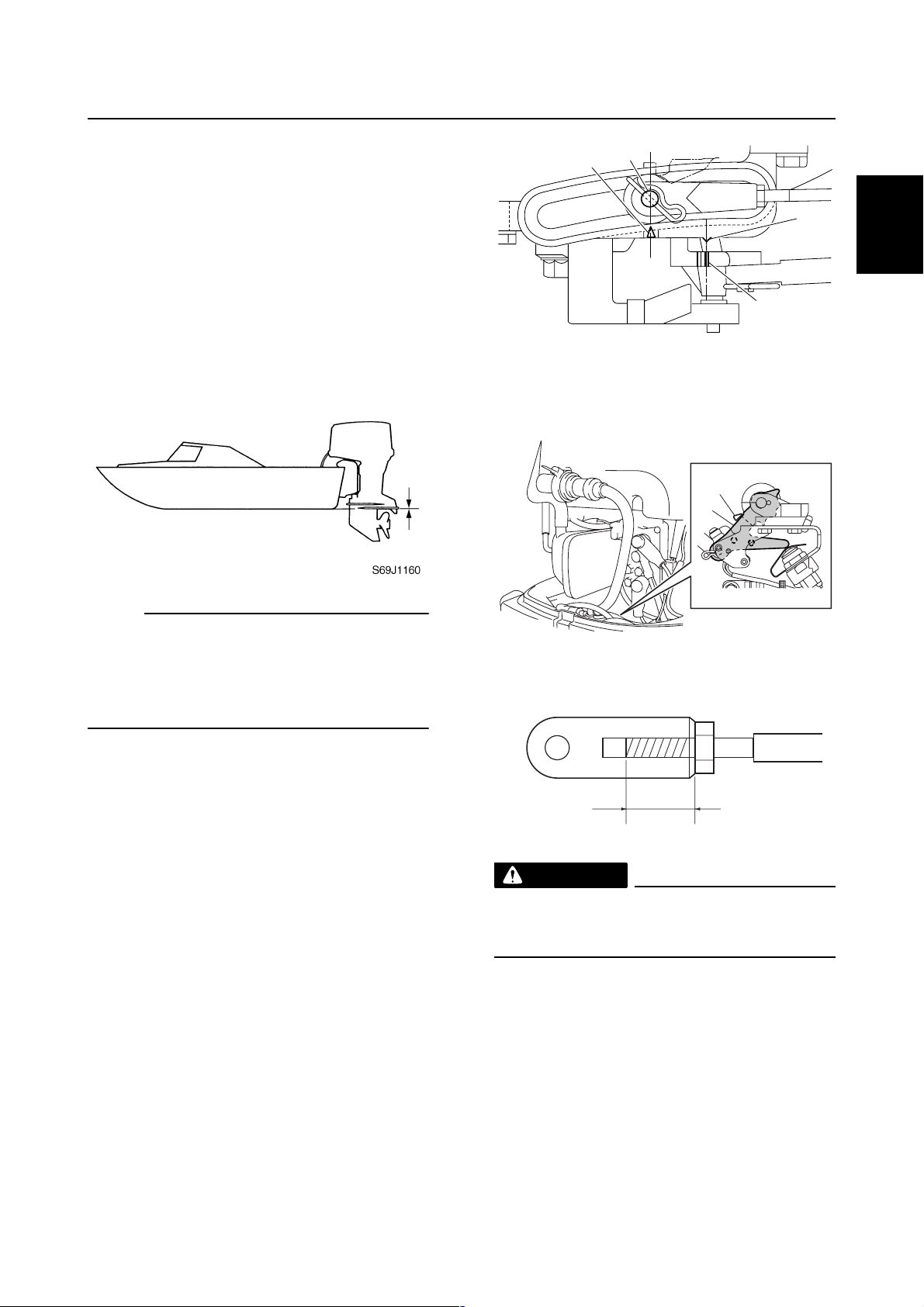

Checking the outboard motor

mounting height

1. Check that the anti-cavitation plate is

aligned with the bottom of the boat. If the

mounting height is too high, cavitation

will occur and propulsion will be reduced.

Also, the engine speed will increase

abnormally and cause the engine to

overheat. If the mounting height is too

low, water resistance will increase and

reduce engine efficiency.

a

b

d

c

S6C11080

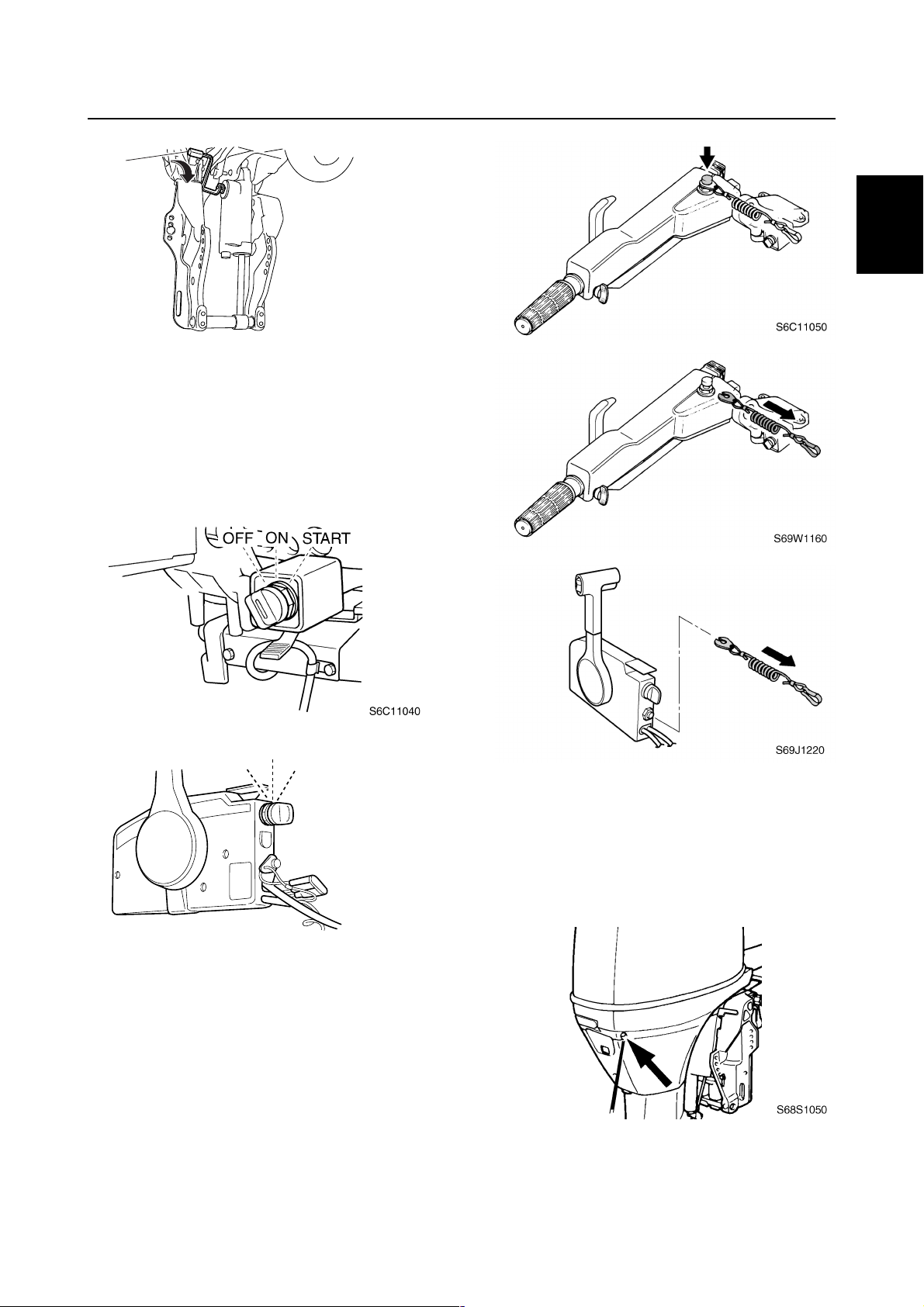

4. Check that the edge of a shift rod e is

aligned with the alignment mark f on

the bottom cowling.

f

e

1

2

3

4

NOTE:

The optimum mounting height is affected by

the combination of the boat and the outboard

motor. To determine the optimum mounting

height, test run the outboard motor at different heights.

2. Check that the clamp brackets are

secured with the clamp bolts.

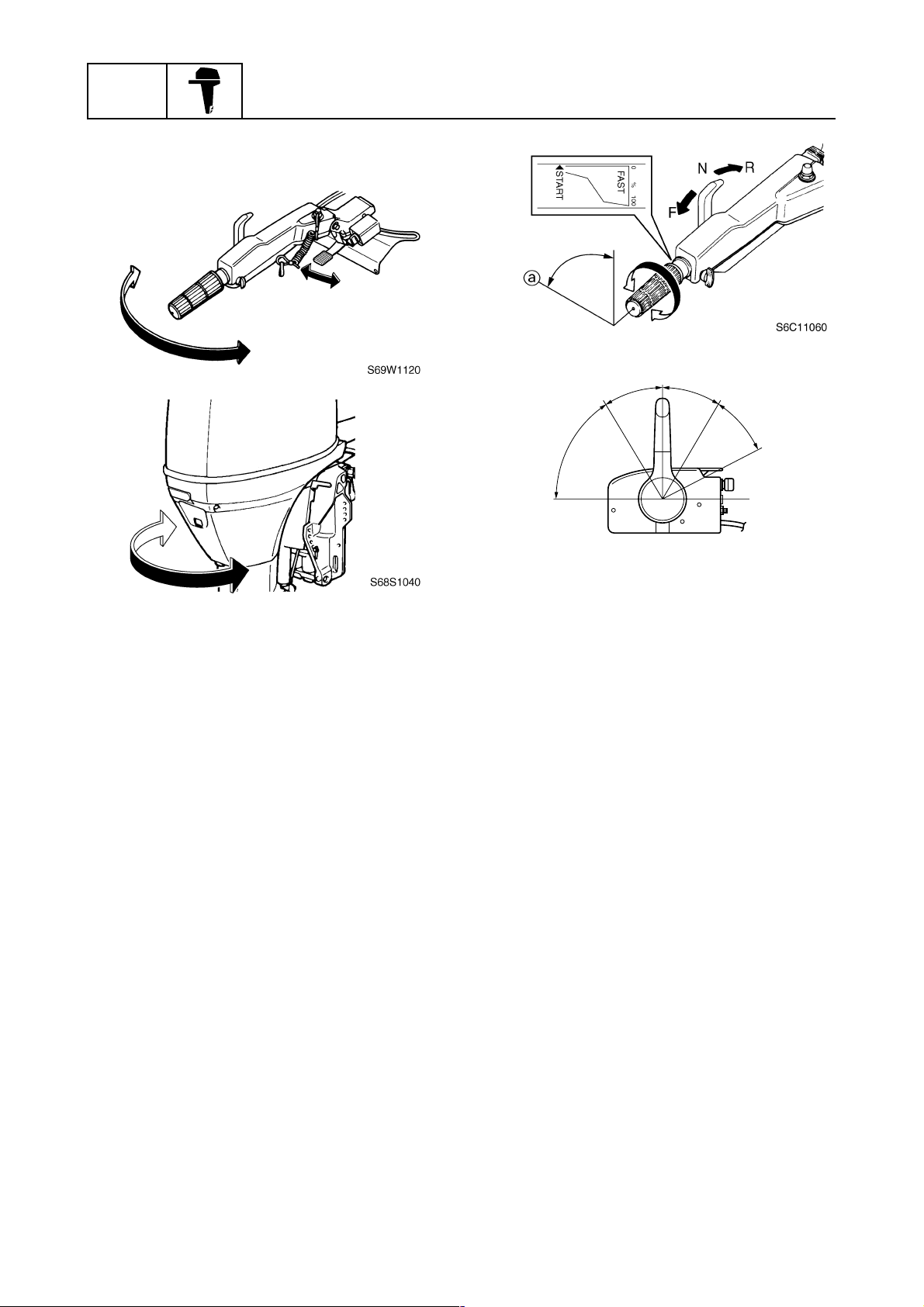

Checking the remote control cables

1. Set the remote control lever or shift lever

to the neutral position and fully close the

throttle lever or throttle grip.

2. Check that the set pin a is aligned with

the alignment mark b.

3. Check that the alignment mark c is

aligned with the mark d.

S6C11090

g

WARNING

The shift/throttle cable joint must be

screwed in a minimum of 8.0 mm (0.31 in)

.

g

Checking the steering system

1. Check the steering friction for proper

adjustment.

S6C11110

5

6

7

8

6C13G11

9

1-14

GEN

INFO

General information

2. Check that the steering operates

smoothly.

È

É

Tiller handle model

È

Remote control model

É

3. Check that there is no interference with

wires or hoses when the outboard motor

is steered.

È

É

N

F

R

a

a

S69J1210

Tiller handle model

È

Remote control model

É

Checking the power trim and tilt

system

1. Check that the outboard motor tilts up

and down smoothly when operating the

power trim and tilt unit.

Checking the gear shift and throttle

operation

1. Check that the gear shift operates

smoothly when the remote control lever

or shift lever is shifted from neutral to forward or reverse.

2. Check that the throttle operates smoothly

when the throttle grip (tiller handle

model) is turned from the fully closed

position to the fully open position a.

Check that the throttle operates smoothly

when the remote control lever (remote

control model) is shifted from forward or

reverse to the fully open position a.

2. Check that there is no abnormal noise

produced when the outboard motor is

tilted up or down.

3. Check that there is no interference with

wires or hoses when the tilted-up outboard motor is steered.

4. Check that the trim meter points down

when the outboard motor is tilted all the

way down.

Checking the hydro tilt system

1. Check that the outboard motor tilts up

and down smoothly.

2. Fully tilt the outboard motor up, and then

lock the tilt stop lever 1 to check the lock

mechanism of the hydro tilt. Replace the

hydro tilt unit if necessary.

1-15

6C13G11

Predelivery checks

1

S6C11100

Checking the engine start switch and

engine stop lanyard switch

1. Check that the engine starts when the

engine start switch is turned to START.

2. Check that the engine turns off when the

engine start switch is turned to OFF.

È

È

É

1

2

3

4

É

Tiller handle model

È

Remote control model

É

3. Check that the engine turns off when the

engine stop lanyard switch is pushed or

engine stop lanyard is pulled from the

engine stop lanyard switch.

OFF

ON

START

S60V1070

Tiller handle model

È

Remote control model

É

Checking the cooling water pilot

hole

1. Check that cooling water is discharged

from the cooling water pilot hole.

5

6

7

8

9

6C13G11

1-16

GEN

INFO

General information

Test run

1. Start the engine, and then check that the

gear shift operates smoothly.

2. Check the engine idle speed after the

engine has been warmed up.

3. Operate at trolling speed.

4. Run the outboard motor for 1 hour at

2,000 r/min or at half throttle, then for

another hour at 3,000 r/min or at 3/4

throttle.

5. Check that the outboard motor does not

tilt up when shifting into reverse and that

water does not flow in over the transom.

NOTE:

The test run is part of the break-in operation.

After test run

1. Check for water in the gear oil.

2. Check for fuel leakage in the cowling.

3. Flush the cooling water passage with

fresh water using the flushing kit and with

the engine running at idle.

Break-in

During the test run, perform the break-in

operation in the following three stages.

1. One hour a at 2,000 r/min or at approximately half throttle

2. One hour b at 3,000 r/min or 3/4 throttle

and 1 minute out of every 10 at full throttle

3. Eight hours c at any speed, however,

avoid running at full speed for more than

5 minutes

È

ab

0

1

210

c

Hour

È

1-17

S69J1240

6C13G11

SPEC

Specifications

General specifications………………………………………………………………………..2-1

Maintenance specification ………………………………………………………………….2-5

Power unit……………………………………………………………………………………..2-5

Lower unit ……………………………………………………………………………………..2-8

Electrical ……………………………………………………………………………………….2-9

Power unit……………………………………………………………………………………2-11

Lower unit ……………………………………………………………………………………2-14

Electrical ……………………………………………………………………………………..2-15

Dimensions………………………………………………………………………………….2-17

Tightening torques……………………………………………………………………………2-21

Specified torques………………………………………………………………………….2-21

General torques……………………………………………………………………………2-24

1

2

3

4

5

6

7

8

9

6C13G11

SPEC

Specifications

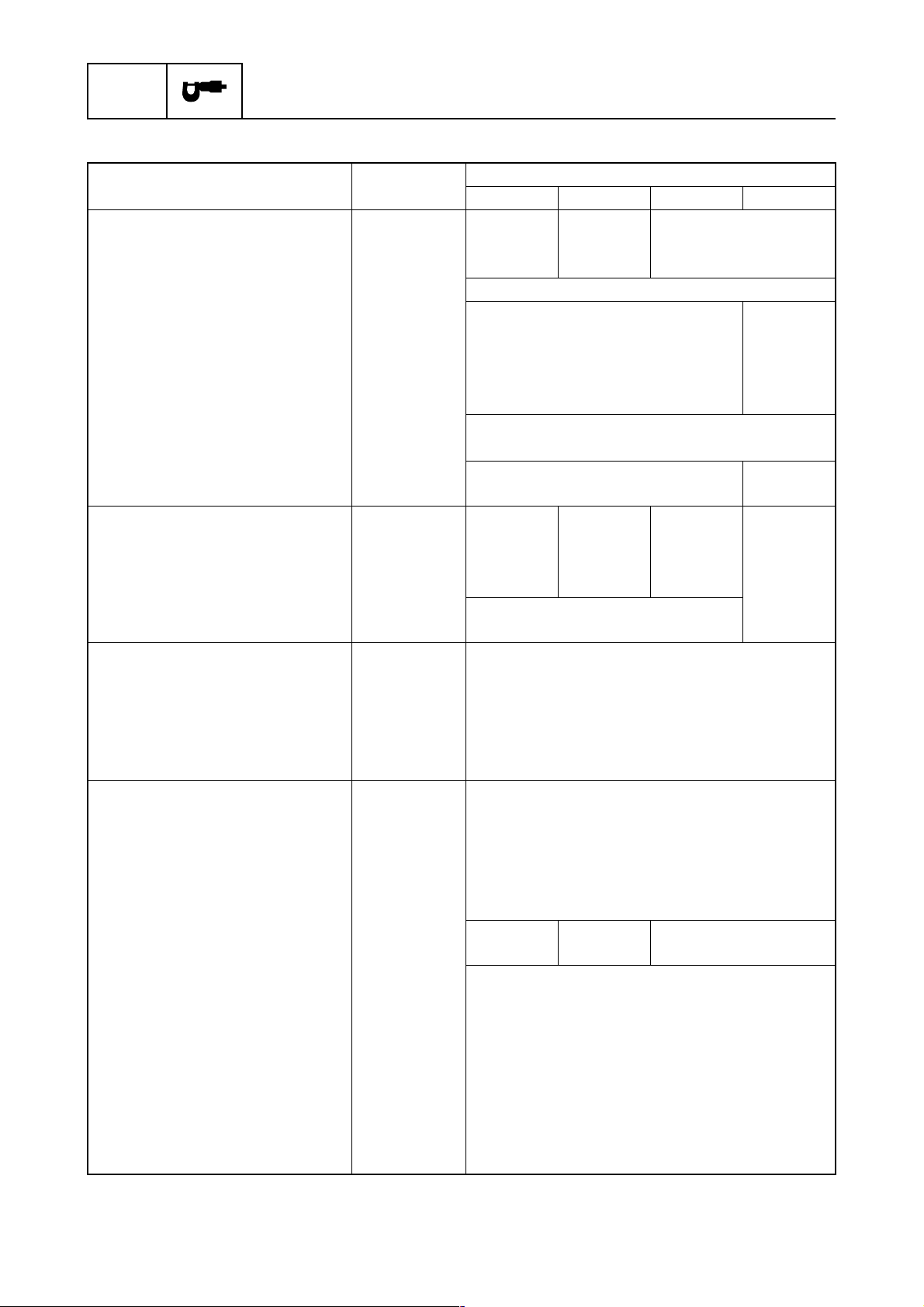

General specifications

1,339

(52.7)

114.0

(251)

Tiller

Model

706 (27.8)

110.0

(243)

Remote control

Item Unit

F50FED F50FEHT F50FET FT50GET

Dimension

Overall length mm (in) 706

(27.8)

Overall width mm (in) 384 (15.1)

Overall height

(L) mm (in) 1,415 (55.7) 1,455

(*1)

(X)

mm (in) — 1,569

Boat transom height

(L) mm (in) 508 (20.0)

(*1)

(X)

mm (in) — 635

Weight

(with aluminium propeller)

(L) kg (lb) 107.0

(236)

(*1)

(X)

kg (lb) — 119.0

Performance

Maximum output kW (hp) 36.8 (50.0) at 5,500 r/min

Full throttle operating range r/min 5,000–6,000

Maximum fuel consumption L (US gal,

18.5 (4.89, 4.07) at 6,000 r/min

lmp gal)/hr

Engine idle speed r/min 700–800

Power unit

Type In-line, 4-stroke, SOHC, 8 valves

Cylinder quantity 4

Total displacement cm

3

(cu. in) 996 (60.8)

Bore × stroke mm (in) 65.0 × 75.0 (2.56 × 2.95)

Compression ratio 9.50

Control system Remote

control

handle

Starting system Electric

Fuel system Fuel injection

Ignition system TCI

Advance system Micro computer

Maximum generator output V, A 12, 16

Spark plug DPR6EB-9 (NGK)

Cooling system Water

Exhaust system Propeller boss

Lubrication system Wet sump

(*1)

For Oceania

2

(57.3)

(61.8)

(25.0)

115.0

(254)

(262)

2-1

6C13G11

General specifications

Item Unit

Fuel and oil

Fuel type Regular unleaded gasoline

Fuel minimum rating RON

Engine oil 4-stroke motor oil

Engine oil grade

Engine oil quantity

(without oil filter replacement) L (US qt,

(with oil filter replacement) L (US qt,

Gear oil type Hypoid gear oil

Gear oil grade

Gear oil quantity cm

Bracket unit

Trim angle

(at 12° boat transom)

Tilt-up angle Degree 67 69

Steering angle Degree 40 + 40

Drive unit

Gear shift positions F-N-R

Gear ratio 1.85 (13/24) 2.31

Reduction gear type Spiral bevel gear

Clutch type Dog clutch

Propeller shaft type Spline

Propeller direction (rear view) Clockwise

Propeller identification mark G K

Electrical

Battery minimum capacity

CCA/EN A 430

20HR/IEC Ah 70

(*1)

RON: Research Octane Number

PON: Pump Octane Number = (RON + Motor Octane Number)/2

(*2)

Meeting both API and SAE requirements

(*3)

CCA: Cold Cranking Ampere

EN: European Norm (European standard)

IEC: International Electrotechnical Commission

(*2)

API GL-4

(*3)

(*1)

PON

API

SAE

lmp qt)

lmp qt)

SAE 90

3

(US oz,

lmp oz)

Degree –4 to 20

F50FED F50FEHT F50FET FT50GET

SE, SF, SG, SH, or SJ

10W-30 or 10W-40

430 (14.5, 15.2) 670

Model

90

86

2.5 (2.64, 2.20)

2.7 (2.85, 2.38)

(22.7,

23.6)

(13/30)

1

2

3

4

5

6

7

8

9

6C13G11

2-2

SPEC

Specifications

Item Unit

F60CEHT F60CET FT60DET

Model

Dimension

Overall length mm (in) 1,339 (52.7) 706 (27.8)

Overall width mm (in) 384 (15.1)

Overall height

(L) mm (in) 1,415 (55.7) 1,455 (57.3)

(*1)

(X)

mm (in) — 1,569 (61.8)

Boat transom height

(L) mm (in) 508 (20.0)

(*1)

(X)

mm (in) — 635 (25.0)

Weight

(with aluminium propeller)

(L) kg (lb) 114.0 (251) 110.0 (243) 115.0 (254)

(*1)

(X)

kg (lb) — 119.0 (262)

Performance

Maximum output kW (hp) 44.1 (60.0) at 5,500 r/min

Full throttle operating range r/min 5,000–6,000

Maximum fuel consumption L (US gal,

20.0 (5.28, 4.40) at 6,000 r/min

lmp gal)/hr

Engine idle speed r/min 700–800

Power unit

Type In-line, 4-stroke, SOHC, 8 valves

Cylinder quantity 4

Total displacement cm

3

(cu. in) 996 (60.8)

Bore × stroke mm (in) 65.0 × 75.0 (2.56 × 2.95)

Compression ratio 9.50

Control system Tiller handle Remote control

Starting system Electric

Fuel system Fuel injection

Ignition system TCI

Advance system Micro computer

Maximum generator output V, A 12, 16

Spark plug DPR6EB-9 (NGK)

Cooling system Water

Exhaust system Propeller boss

Lubrication system Wet sump

(*1)

For Oceania

2-3

6C13G11

General specifications

Item Unit

Fuel and oil

Fuel type Regular unleaded gasoline

Fuel minimum rating RON

Engine oil 4-stroke motor oil

Engine oil grade

Engine oil quantity

(without oil filter replacement) L (US qt,

(with oil filter replacement) L (US qt,

Gear oil type Hypoid gear oil

Gear oil grade

Gear oil quantity cm

Bracket unit

Trim angle

(at 12° boat transom)

Tilt-up angle Degree 69

Steering angle Degree 40 + 40

Drive unit

Gear shift positions F-N-R

Gear ratio 1.85 (13/24) 2.31 (13/30)

Reduction gear type Spiral bevel gear

Clutch type Dog clutch

Propeller shaft type Spline

Propeller direction (rear view) Clockwise

Propeller identification mark G K

Electrical

Battery minimum capacity

CCA/EN A 430

20HR/IEC Ah 70

(*1)

RON: Research Octane Number

PON: Pump Octane Number = (RON + Motor Octane Number)/2

(*2)

Meeting both API and SAE requirements

(*3)

CCA: Cold Cranking Ampere

EN: European Norm (European standard)

IEC: International Electrotechnical Commission

(*2)

API GL-4

(*3)

(*1)

PON

API

SAE

lmp qt)

lmp qt)

SAE 90

3

(US oz,

lmp oz)

Degree –4 to 20

F60CEHT F60CET FT60DET

SE, SF, SG, SH, or SJ

10W-30 or 10W-40

430 (14.5, 15.2) 670

Model

90

86

2.5 (2.64, 2.20)

2.7 (2.85, 2.38)

(22.7, 23.6)

1

2

3

4

5

6

7

8

9

6C13G11

2-4

SPEC

Specifications

Maintenance specification

Power unit

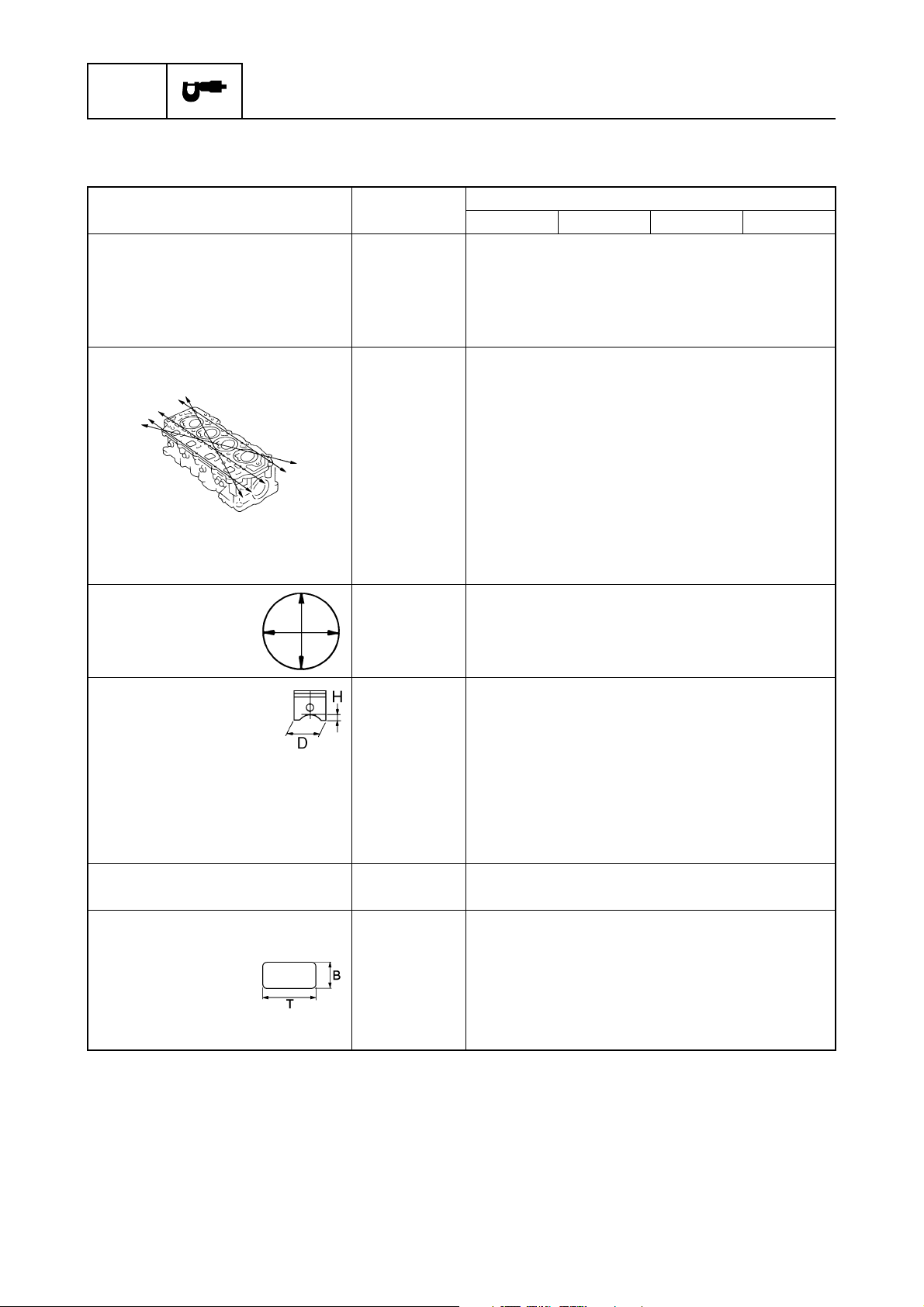

Item Unit

F50FED F50FEHT F50FET FT50GET

Power unit

Minimum compression

pressure

Oil pressure

(*1)

(*2)

kPa

kPa

(kgf/cm2, psi)

(kgf/cm

2

, psi)

125 (1.25, 18.1) at engine idle speed

Cylinder head

Warpage limit mm (in) 0.10 (0.0039)

(lines indicate straightedge

position)

Journal inside diameter mm (in) 37.000–37.025 (1.4567–1.4577)

Cylinders

Bore size mm (in) 65.000–65.015 (2.5591–2.5596)

Taper limit mm (in) 0.08 (0.0032)

Out-of-round limit mm (in) 0.05 (0.0020)

Pistons

Piston diameter (D) mm (in) 64.950–64.965 (2.5571–2.5577)

Measuring point (H) mm (in) 5.0 (0.20)

Piston clearance mm (in) 0.035–0.065 (0.0014–0.0026)

Piston pin boss bore mm (in) 15.974–15.985 (0.6289–0.6293)

Oversize piston diameter

1st mm (in) 65.200–65.215 (2.5669–2.5675)

2nd mm (in) 65.450–65.465 (2.5768–2.5774)

Piston pins

Outside diameter mm (in) 15.965–15.970 (0.6285–0.6287)

Piston rings

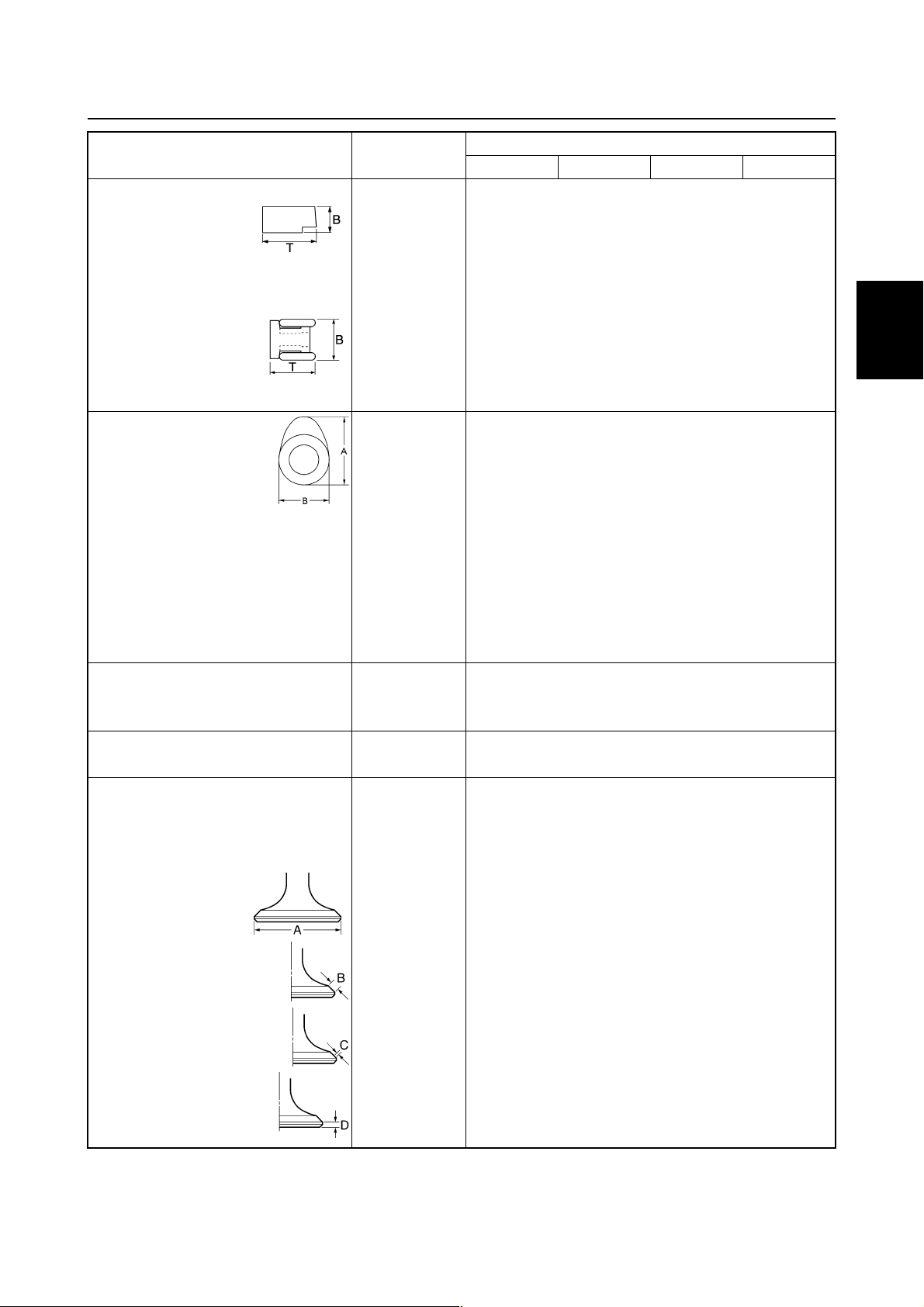

Top ring

Dimension B mm (in) 1.17–1.19 (0.0461–0.0469)

Dimension T mm (in) 2.30–2.50 (0.0905–0.0984)

End gap mm (in) 0.15–0.30 (0.0059–0.0118)

Side clearance mm (in) 0.02–0.06 (0.0008–0.0024)

(*1)

Measure conditions:

Ambient temperature 20 °C (68 °F), wide open throttle, with spark plugs removed from all cylinders.

The figures are for reference only.

(*2)

The figures are for reference only.

Model

960 (9.6, 139.2)

2

2-5

6C13G11

Maintenance specification

Item Unit

2nd piston ring

Dimension B mm (in) 1.47–1.49 (0.0579–0.0587)

Dimension T mm (in) 2.60–2.80 (0.1024–0.1102)

End gap mm (in) 0.30–0.50 (0.0118–0.0197)

Side clearance mm (in) 0.02–0.06 (0.0008–0.0024)

Oil ring

Dimension B mm (in) 2.36–2.48 (0.0929–0.0976)

Dimension T

End gap mm (in) 0.20–0.70 (0.0079–0.0276)

Side clearance mm (in) 0.04–0.18 (0.0016–0.0071)

Camshaft

Intake (A) mm (in) 30.888–30.988 (1.2161–1.2200)

Exhaust (A) mm (in) 30.824–30.924 (1.2135–1.2175)

Intake and

exhaust (B)

Camshaft journal diameter

#1

Camshaft journal diameter

#2, #3, #4

Camshaft journal oil clearance mm (in) 0.045–0.090 (0.0018–0.0035)

Camshaft runout limit mm (in) 0.03 (0.0012)

Rocker arm shaft

Rocker arm shaft outside

diameter

Rocker arms

Rocker arm inside diameter mm (in) 16.000–16.018 (0.6299–0.6306)

Valves

Valve clearance (cold)

Intake mm (in) 0.20

Exhaust mm (in) 0.30

Head diameter (A)

Intake mm (in) 31.90–32.10 (1.256–1.264)

Exhaust mm (in) 26.60–26.80 (1.047–1.055)

Face width (B)

Intake mm (in) 1.98–2.40 (0.078–0.094)

Exhaust mm (in) 2.16–2.79 (0.085–0.110)

Seat contact width (C)

Intake and exhaust mm (in) 1.3–1.5 (0.051–0.059)

Margin thickness (D)

Intake mm (in) 0.8–1.2 (0.031–0.047)

Exhaust mm (in) 1.0–1.4 (0.039–0.055)

(*1)

mm (in) 2.75 (0.1083)

mm (in) 25.950–26.050 (1.0216–1.0256)

mm (in) 36.925–36.945 (1.4537–1.4545)

mm (in) 36.935–36.955 (1.4541–1.4549)

mm (in) 15.971–15.991 (0.6288–0.6296)

F50FED F50FEHT F50FET FT50GET

Model

±

0.05 (0.008

±

0.05 (0.012

±

±

0.002)

0.002)

1

2

3

4

5

6

7

8

9

(*1)

The figures are for reference only.

6C13G11

2-6

SPEC

Specifications

Item Unit

Stem diameter

Intake mm (in) 5.475–5.490 (0.2156–0.2161)

Exhaust mm (in) 5.460–5.475 (0.2150–0.2156)

Guide inside diameter

Intake and exhaust mm (in) 5.500–5.512 (0.2165–0.2170)

Stem-to-guide clearance

Intake and exhaust mm (in) 0.025–0.052 (0.0010–0.0020)

Stem runout limit

Intake mm (in) 0.05 (0.0020)

Exhaust mm (in) 0.03 (0.0012)

Valve springs

Free length mm (in) 39.85 (1.5689)

Tilt limit mm (in) 1.7 (0.07)

Connecting rods

Small end inside diameter mm (in) 15.985–15.998 (0.6293–0.6298)

Big end inside diameter mm (in) 36.000–36.024 (1.4173–1.4183)

Connecting rod big end side

clearance

Crankpin oil clearance mm (in) 0.016–0.040 (0.0006–0.0016)

Big end bearing thickness

Yellow mm (in) 1.500–1.504 (0.0591–0.0592)

Red mm (in) 1.496–1.500 (0.0589–0.0591)

Pink mm (in) 1.492–1.496 (0.0587–0.0589)

Green mm (in) 1.488–1.492 (0.0586–0.0587)

Crankshaft

Crankshaft journal diameter mm (in) 42.984–43.000 (1.6923–1.6929)

Crankpin diameter mm (in) 32.984–33.000 (1.2986–1.2992)

Crankpin width mm (in) 21.000–21.070 (0.8268–0.8295)

Runout limit mm (in) 0.03 (0.0012)

Crankcase

Crankshaft main journal oil

clearance

Crankcase main journal

bearing thickness

Yellow mm (in) 1.502–1.506 (0.0591–0.0592)

Red mm (in) 1.498–1.502 (0.0590–0.0591)

Pink mm (in) 1.494–1.498 (0.0588–0.0590)

Green mm (in) 1.490–1.494 (0.0587–0.0588)

mm (in) 0.05–0.22 (0.0020–0.0087)

mm (in) 0.012–0.036 (0.0005–0.0014)

F50FED F50FEHT F50FET FT50GET

Model

2-7

6C13G11

Loading…

View the manual for the Yamaha F50 here, for free. This user manual comes under the category outboard motors and has been rated by 15 people with an average of a 8.2. This manual is available in the following languages: English. Do you have a question about the Yamaha F50?

Ask your question here

Yamaha F50 specifications

Below you will find the product specifications and the manual specifications of the Yamaha F50.

The Yamaha F50 is an outboard motor that is commonly used for boating. With a displacement of 996cc, it offers a reliable and efficient performance. The motor has a maximum output of 50 horsepower and a range of operating speeds. Its compact and lightweight design make it easy to handle and transport. The F50 is equipped with electronic fuel injection, which optimizes fuel efficiency and provides smooth acceleration. It also has options for propeller pitch and trolling speed, making it versatile for a variety of boating activities. The motor has a corrosion-resistant construction, with a multi-layer coating on all exposed engine surfaces. Additionally, it features an antitheft system that enhances security and protection. The F50 is designed for easy maintenance, with an oil change system that simplifies the process. Its noise reduction technology offers a quiet and comfortable ride while minimizing the impact on the environment. Overall, the Yamaha F50 is a reliable and efficient choice for boaters looking for a quality outboard motor.

General

Frequently asked questions

Can’t find the answer to your question in the manual? You may find the answer to your question in the FAQs about the Yamaha F50 below.

What is the difference between E10 and E5 petrol?

E10 petrol consists of up to ten per cent ethanol while E5 petrol will contain less than five per cent ethanol. As a result, the percentage of E10 petrol is lower than that of E5 petrol, making it less bad for the environment.

Is the manual of the Yamaha F50 available in English?

Yes, the manual of the Yamaha F50 is available in English .

Is your question not listed? Ask your question here

Yamaha F50 (2021)

Read this manual carefully before operating this

outboard motor.

OWNER’S MANUAL

F40H

F40G

F50H

FT50J

F60F

FT60G

F70A

6C1-28199-7K-E0

6C1-9-7K-1E0.book 1 ページ 2020年11月26日 木曜日 午後5時31分

View the manual for the Yamaha F50 (2021) here, for free. This manual comes under the category outboard motors and has been rated by 1 people with an average of a 7.5.

This manual is available in the following languages: English. Do you have a question about the Yamaha F50 (2021) or do you need help?

Ask your question here

Product Images (1)

Yamaha F50 (2021) specifications

Below you will find the product specifications and the manual specifications of the Yamaha F50 (2021).

The Yamaha F50 is an outboard motor released in 2021. It is designed to provide reliable and efficient performance for boats and marine vessels. The motor offers a range of features and specifications that are tailored to meet the needs of boating enthusiasts.

The Yamaha F50 is powered by a four-stroke, 50 horsepower engine, which ensures smooth and quiet operation. This motor is also equipped with Yamaha’s Variable Trolling RPM Switch (VTS) technology, allowing for precise and easy control of trolling speeds.

The F50 features a lightweight and compact design, making it suitable for a variety of boat sizes and types. It is also equipped with Yamaha’s exclusive PrimeStart system, enabling quick and easy starting in any weather conditions.

In terms of fuel efficiency, the Yamaha F50 utilizes a fuel injection system, which optimizes fuel delivery and reduces consumption. This ensures longer trips and fewer fuel stops, enhancing the overall boating experience.

The motor is designed with durability in mind, featuring a high-quality construction and corrosion-resistant materials. It is also equipped with Yamaha’s patented Shift Dampener System (SDS), which reduces noise and vibration for a smoother ride.

Overall, the Yamaha F50 is a reliable and efficient outboard motor that provides boaters with the power and performance they need on the water. Its advanced features and durable construction make it a popular choice among marine enthusiasts.

General

Frequently Asked Questions

Can’t find the answer to your question in the manual? You may find the answer to your question in the FAQs about the Yamaha F50 (2021) below.

Why does my outboard motor Yamaha F50 (2021) not start?

Ensure that the fuel tank is adequately filled with the correct fuel mixture, the ignition switch is turned on, and that the choke is properly set. Additionally, check the spark plug for any signs of damage or fouling.

How can I troubleshoot if my outboard motor Yamaha F50 (2021) overheats?

Verify that the cooling water inlet is not blocked or clogged, and that there are no obstructions in the cooling water passages. Avoid running the engine at high speeds without proper cooling, and ensure the cooling system is functioning optimally.

Why is my outboard motor Yamaha F50 (2021) vibrating excessively?

Ensure that the propeller is securely fastened and balanced. Check for any damage or deformation to the propeller, as it could be causing the vibration. Additionally, inspect the engine mounting and tighten any loose bolts or nuts.

How can I improve the fuel efficiency of my outboard motor Yamaha F50 (2021)?

Maintain proper engine trim and avoid operating the motor at unnecessarily high speeds. Regularly clean the anti-ventilation plate and propeller to reduce drag. Additionally, ensure that the fuel system is free from leaks and maintain a clean fuel filter.

What should I do if my outboard motor Yamaha F50 (2021) is emitting excessive smoke?

Verify that the fuel being used is of the correct type and quality. If the fuel is old or contaminated, drain and replace it with fresh fuel. Ensure that the oil injection system is operating correctly, and inspect the spark plugs for any signs of oil fouling.

What is the difference between E10 and E5 petrol?

E10 petrol consists of up to ten per cent ethanol while E5 petrol will contain less than five per cent ethanol. As a result, the percentage of E10 petrol is lower than that of E5 petrol, making it less bad for the environment.

Is the manual of the Yamaha F50 (2021) available in English?

Yes, the manual of the Yamaha F50 (2021) is available in English .

Is your question not listed? Ask your question here

-

Страница 1

Read this manual carefully before operating this outboard motor. O WNER’S MANU AL F50 T50 F60 T60 F70 LIT-18626-09-90 6C1-28199-3B-E0 6C1-9-3B-1E0.book 1 ページ 2012年 11月19日 月曜日 午前10時35分[…]

-

Страница 2

EMU25063 ZMU07696 Les gaz d’échappement du moteur de ce pr oduit contiennent des substances chimiques connues dans l’État de Californie pour pr o v oquer le cancer , des anomalies congénitales et des troubles de la reproduction. Read this manual carefully before oper ating this outboard motor. Keep this manual onboard in a waterproof bag whe[…]

-

Страница 3

Important manual information EMU44140 To the owner Thank you for selecting a Yamaha outboard motor. This Owner’s Manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instruct ions will help you ob- tain maximum enjoyment from your new Yamaha. If you have an y question about th[…]

-

Страница 4

Table of contents Safety information …. ……………………. 1 Outboard motor safety ………………… 1 Propeller …………….. ……………………… 1 Rotating parts ….. …………………………. 1 Hot parts ……………. ……………………… 1 Electric shock ….. …………………………. 1 Power tri[…]

-

Страница 5

Table of contents Tilt support lever for power trim and tilt model ……. ……………………. 35 Cowling lock lever(s) (turn type)…… 36 Flushing device …… ……………………. 36 Fuel filter/Water separator ………….. 36 Instruments and indicators ………… 38 Indicators …………. …………………….. 38 Low oil[…]

-

Страница 6

Table of contents Procedure for tilting up (power trim and tilt models) …. ……………………. 72 Procedure for tilting down (power trim and tilt mode ls) …………………. 73 Shallow water ……… ………………….. 74 Power trim and tilt models …………… 74 Cruising in other conditions ………… 75 Maintenance……..[…]

-

Страница 7

1 Safety information EMU33622 Outboard motor safety Observe these precautions at all times. EMU36501 Propeller People can be injured or killed if they come in contact with the propeller. The propeller can keep moving even wh en the motor is in neutral, and sharp edges of the propeller can cut even when stationary. Stop the engine when a person […]

-

Страница 8

Safety information 2 EMU33820 Gasoline exposure and spills Take care not to spill gasoline. If gasoline spills, wipe it up immediately with dry rags. Dispose of rags properly. If any gasoline spills onto your skin, immedi- ately wash with soap and water. Change clothing if gasoline spills on it. If you swallow gasoline, inhale a lot of gaso- line v[…]

-

Страница 9

Safety information 3 EMU33772 Avoid collisions Scan constantly for people, objects, and oth- er boats. Be alert for conditions that limit your visibility or block your vision of others. Operate defensively at safe speeds and keep a safe distance away from people, ob- jects, and other boats. Do not follow directly behind other boats or waterskie[…]

-

Страница 10

Safety information 4 go to boatus.org. For Canada All operators of pleasure craft must illustrate competency by means of a Pleasure Craft Operators Card with the exception of Per- sonal Water Craft used for rental purposes which require a rental checklist be complet- ed. Pleasure Craft Operators Cards can be obtained following the completion of a c[…]

-

Страница 11

Safety information 5 Suite 8 Bolton, ON L7E 1H1 http://www.nmma.org/ EMU33691 Basic boating rules (Rules of the road) Just as there are rules that apply when you are driving on streets and highways, there are waterway rules that apply when you are driving your boat. These rules are used inter- nationally. (For U.S. A.: and are also en- forced by th[…]

-

Страница 12

Safety information 6 Meeting If you are meeting another power vessel head on, and are close enough to run the risk of collision, neither of you has the right-of- way Both of you should alter course to avoid an accident. You should keep the other ves- sel on your port (left) side. This rule doesn’t apply if both of you will clear one another if yo[…]

-

Страница 13

Safety information 7 trawls are considered to be “fishing vessels” under the International Rules. Vessels with trolling lines are not considered fishing ves- sels. Fishing vessels have the right-of-way regardless of position . Fishing vessels can- not, however, impede the passage of other vessels in narrow channels. Sailing vessel right-of-way […]

-

Страница 14

Safety information 8 ZMU01708 6C1-9-3B-1E0.book 8 ページ 2012年 11月19日 月曜日 午前10時35分[…]

-

Страница 15

9 General information EMU25171 Identification numbers record EMU25184 Outboard motor serial number The outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare parts from your Yamaha dealer or for reference in […]

-

Страница 16

General information 10 EMU33523 Read manuals and labels Before operating or worki ng on this outboard motor: Read this manual. Read any manuals supplied with the boat. Read all labels on the outb oard motor and the boat. If you need any addition al information, contac t your Yamaha dealer. EMU33832 Warning labels If these labels are dam[…]

-

Страница 17

General information 11 F70 3 1 2 ZMU07691 6C1-9-3B-1E0.b ook 11 ページ 2012 年11月19日 月曜日 午前10時35分[…]

-

Страница 18

General information 12 EMU33912 Contents of labels The above warning labe ls mean as follows. 1 WA R N I N G EWM01691 Emergency starting does not have start- in-gear protection. Ensure shift control is in neutral before starting engine. 2 WA R N I N G EWM01681 Keep hands, hair, and clothing away from rotating parts while the engine is running. […]

-

Страница 19

General information 13 EMU35132 Symbols The following symbols mean as follows. Notice/Warning Read Owner’s Manual Hazard caused by continuous rotation Electrical hazard ZMU05696 ZMU05664 ZMU05665 ZMU05666 6C1-9-3B-1E0.b ook 13 ページ 2012 年11月19日 月曜日 午前10時35分[…]

-

Страница 20

14 Specifications and requirements EMU34521 Specifications TIP: “(AL)” stated in the specification data below represents the numerical value for the alumi- num propeller installed. Likewise, “(SUS)” repr esents the value for stainless steel propeller installed and “(PL)” for plastic propeller installed. EMU2821R Dimension and weight: Ov[…]

-

Страница 21

Specifications and requirements 15 Total displacement: 996 cm 3 (60.8 c.i.) Bore stroke: 65.0 75.0 mm (2.56 2.95 in) Ignition system: TCI Spark plug (NGK): F50B DPR6EB-9 F50HB DPR6EB-9 F60B DPR6EB-9 F60HB DPR6EB-9 F70A LKR7E F70HA LKR7E T50B DPR6EB-9 T60B DPR6EB-9 Spark plug gap: 0.8–0.9 mm (0.031–0.035 in) Steering system: F50B Rem[…]

-

Страница 22

Specifications and requirements 16 Recommended engine oil grade 1: SAE 10W-30/10W-40/5W-30 API SE/SF/SG/SH/SJ/SL Engine oil quantity (without oil filter re- placement): 1.9 L (2.01 US qt, 1.67 Imp.qt) Engine oil quantity (wit h oil filter replace- ment): 2.1 L (2.22 US qt, 1.85 Imp.qt) Lubrication system: Wet sump Recommended gear oil: Yamalube Mar[…]

-

Страница 23

Specifications and requirements 17 tions such as poor handling, loss of control, or fire hazards. Because the motor is very heavy, spe- cial equipment and training is required to mount it safely. Your dealer or othe r person experienced in proper rigging should mount the motor using correct equipment and complete rigging in- structions. For fur[…]

-

Страница 24

Specifications and requirements 18 pellers for every Yamaha outboard motor and every application. Your outboard motor came with a Yamaha propeller selected to perform well over a range of applications, but there may be uses where a different propeller would be more appropriate. Your Yamaha dealer can help you select the right propeller for your boa[…]

-

Страница 25

Specifications and requirements 19 If oil grades listed under Recommended en- gine oil grade 1 are not available, select an alternative oil grade listed under Recom- mended engine oil grade 2. Recommended engine oil grade 1 Recommended engine oil grade 2 EMU36360 Fuel requirements EMU41331 Gasoline Use a good quality gasoline that meets the minimum[…]

-

Страница 26

Specifications and requirements 20 without Ethanol and gasoline with Ethanol, which is typically referred to as E10 gasoline. According to federal regulations, E10 gaso- line may contain up to 10% Ethanol. A high quality gasoline without Ethanol is the preferred fuel for your Yamaha outboard mo- tor. However, if gasoline with Ethanol is the only fu[…]

-

Страница 27

Specifications and requirements 21 dition, gasoline used for boating will typically age longer between refills than gasoline used in automobiles, resulting in stale and unusable gasoline that may cause starting and running problems, fuel system damage, and internal engine damage. Yamaha recommends the use of two Ya- malube gasoline additives to red[…]

-

Страница 28

Specifications and requirements 22 plugs. Consult your Yamaha dealer for details. EMU25222 Emission control information EMU25230 North American models This engine conforms to U.S. Environmental Protection Agency (EPA) regulations for ma- rine SI engines. See the label affixed to your engine for details. EMU31561 Approval label of emission control c[…]

-

Страница 29

Specifications and requirements 23 EMU25274 Star labels Your outboard motor is labeled with a Cali- fornia Air Resources Board (CARB) star la- bel. See below for a description of your particular label. EMU40330 One Star — Low Emission The one-star label id entifies engines that meet the Air Resources Board’s Personal Watercraft and Outboard mar[…]

-

Страница 30

Specifications and requirements 24 EMU33861 Four Stars — Super Ultra Low Emission The four-star label identifies engines that meet the Air Resources Board’s Sterndrive and Inboard marine engine 2009 exhaust emission standards. Personal Watercraft and Outboard marine engines may also comply with these st andards. Engines meet- ing these standard[…]

-

Страница 31

25 Components EMU2579Y Components diagram TIP: * May not be exactly as shown; also may not be included as standard equipment on all mod- els (order from dealer). F50B, F50HB, T50B, F60B, F60HB, T60B TRIP TIME BATT Km/h knot mph km mile SPEED YAMAHA set mode 9 12 11 6 7 5 10 8 13 14 15 1 3 4 2 16 17 18 19 20 21 23 22 24 25 26 27 28 29 30 ZMU07948 1.[…]

-

Страница 32

Components 26 F70A 1 3 2 4 11 9 5 6 7 8 11 TRIP TIME BATT Km/h knot mph km mile SPEED YAMAHA set mode 14 15 16 17 18 19 13 12 10 ZMU07415 1. Top cowling 2. Water separator 3. Cowling lock lever 4. Drain screw 5. Anti-cavitation plate 6. Trim tab (anode) 7. Propeller* 8. Cooling water inlet 9. Anode(s) 10. Clamp bracket 11. Tilt support lever 12. Po[…]

-

Страница 33

Components 27 F70HA TRIP TIME BATT Km/h knot mph km mile SPEED YAMAHA set mode 24 25 26 27 12 1 3 2 19 20 21 22 23 4 11 15 13 16 9 11 5 6 7 8 18 17 28 14 10 ZMU07118 1. Top cowling 2. Water separator 3. Cowling lock lever 4. Drain screw 5. Anti-cavitation plate 6. Trim tab (anode) 7. Propeller* 8. Cooling water inlet 9. Anode(s) 10. Clamp bracket 1[…]

-

Страница 34

Components 28 EMU25803 Fuel tank If your model was equipped with a portable fuel tank, its function is as follows. WA R N I N G EWM00020 The fuel tank supplied with this engine is its dedicated fuel reservoir and must not be used as a fuel storage container. Com- mercial users should conform to relevant licensing or approval authority regula- tions[…]

-

Страница 35

Components 29 EMU25830 Fuel joint This joint is used to connect the fuel line. EMU43120 Fuel gauge This gauge shows th e approximate amount of fuel remaining in the fuel tank. EMU43150 Pressure relief tab This is attached to the filler hole of the fuel tank. EMU43130 Fuel tank cap This cap seals the fuel tank. To loosen the cap, press and hold the […]

-

Страница 36

Components 30 EMU26212 Neutral throttle lever To open the throttle wi thout shifting into ei- ther forward or revers e, put the remote con- trol lever in the neutra l position and lift the neutral throttle lever. TIP: The neutral throttle lever will operate only when the remote control lever is in neutral. The remote control lever will operate only[…]

-

Страница 37

Components 31 EMU25962 Throttle indicator The fuel consumption curve on the throttle indicator shows the relative amount of fuel consumed for each throttle position. Choose the setting that offers the best performance and fuel economy for the desired operation. EMU25976 Throttle friction adjuster A friction device prov ides adjustable resis- tance […]

-

Страница 38

Components 32 tangled, preventing it from functioning. Avoid accidentally pulling the cord dur- ing normal operation. Loss of engine power means the loss of most steering control. Also, without engine power, the boat could slow rapidly. This could cause people and objects in the boat to be thrown forward. [EWM00122] EMU26003 Engine stop button The […]

-

Страница 39

Components 33 EMU31432 Steering friction adjuster A friction device prov ides adjustable resis- tance to the steering mechanism, and can be set according to operator preference. An ad- juster lever is located on the bottom of the tiller handle bracket. To increase resistance, turn the lever to the port side “A”. To decrease resistance, turn the[…]

-

Страница 40

Components 34 EMU26155 Power trim and tilt switch on bottom cowling The power trim and tilt switch is located on the side of the bottom cowling. Pushing the switch “ ” (up) trims the outboard motor up, and then tilts it up. Pushing the switch “ ” (down) tilts the outboard motor down and trims it down. When the switch is released, the outboa[…]

-

Страница 41

Components 35 proximately 3000 r/min. For instructions on us ing the variable troll- ing RPM switches, see page 68. EMU26244 Trim tab with anode WA R N I N G EWM00840 An improperly adjusted trim tab could cause difficult steering. Always test run after the trim tab has been installed or re- placed to be sure steering is correct. Be sure you hav[…]

-

Страница 42